Sound production device

A technology of sound-generating devices and voice coils, which is applied in the field of electroacoustics, can solve problems such as the lead wires of the voice coil hitting other components, and achieve the effects of optimized acoustic performance, good frequency response and good rigidity of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

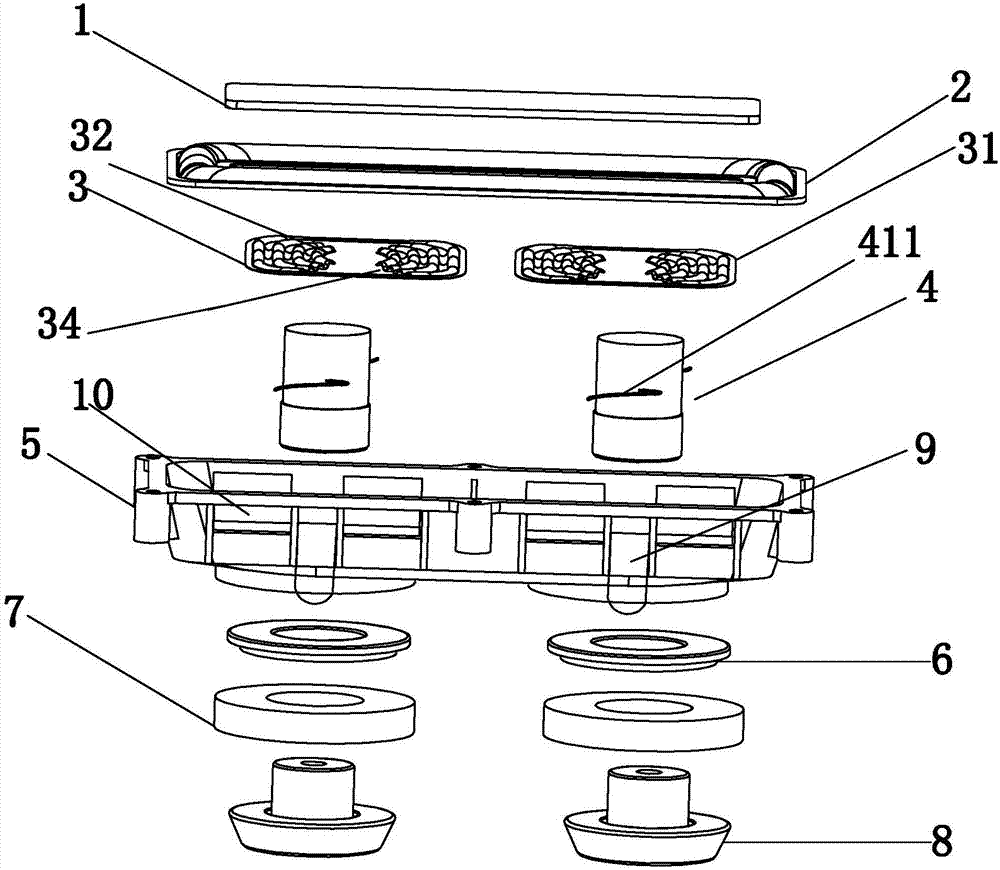

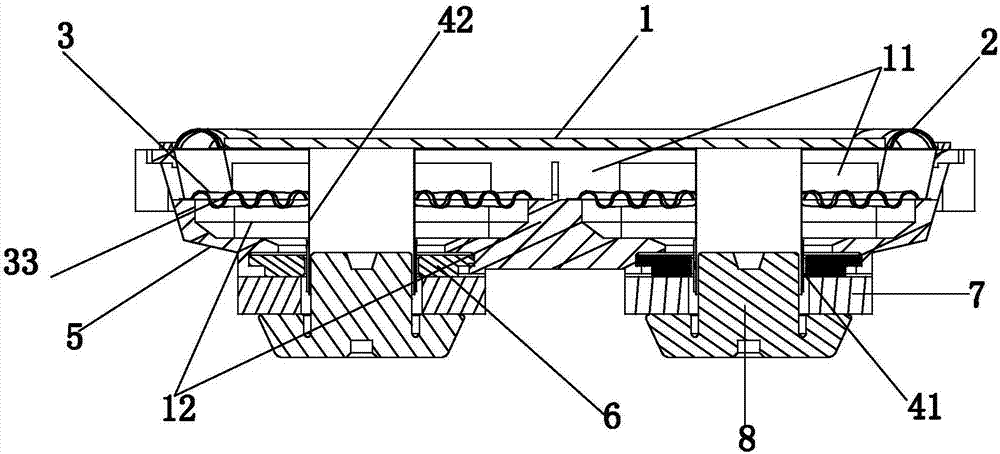

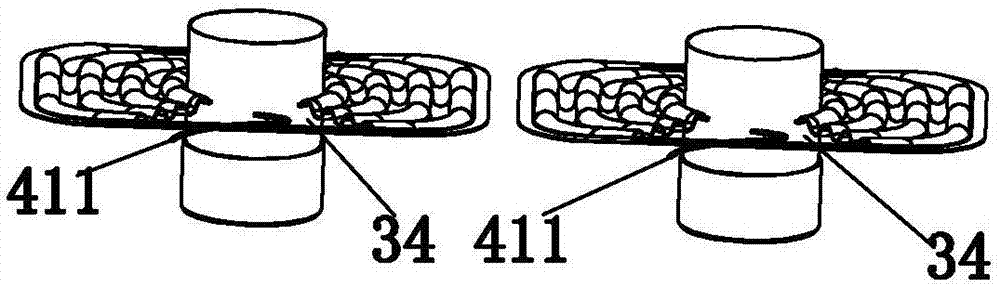

[0029] Such as Figure 1-Figure 2 Commonly shown, the long and narrow moving coil sound generator of this embodiment includes two drive units, that is, two voice coil units 4 and two corresponding magnetic circuit units, wherein the voice coil unit 4 includes a voice coil 41 and a The skeleton 42 supporting the voice coil, the voice coil 41 is connected with the vibrating component (for example connected with the dome 2 ) through the skeleton 42 . The vibrating assembly includes a rectangular diaphragm 2 and a dome 1 combined in the middle of the diaphragm 2, and the dome 1 is designed as a flat plate. It should be noted that the vibrating membrane 2 and the dome 1 here are both strip-like structures, and this structural design can maximize the use of the effective radiation area and further optimize the acoustic performance of the product. The vibrating membrane 2 includes an edge portion bonded and fixed to the housing 5 and a ring disposed inside the edge portion, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com