Diaphragm, MEMS microphone chip and manufacturing method thereof

A microphone and diaphragm technology, applied in the direction of semiconductor electrostatic transducers, electrostatic sensors, electrostatic transducer microphones, etc., can solve the problem of low-frequency response drop of MEMS microphones, and achieve low-frequency sensitivity, increase damping, and improve low-frequency response. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

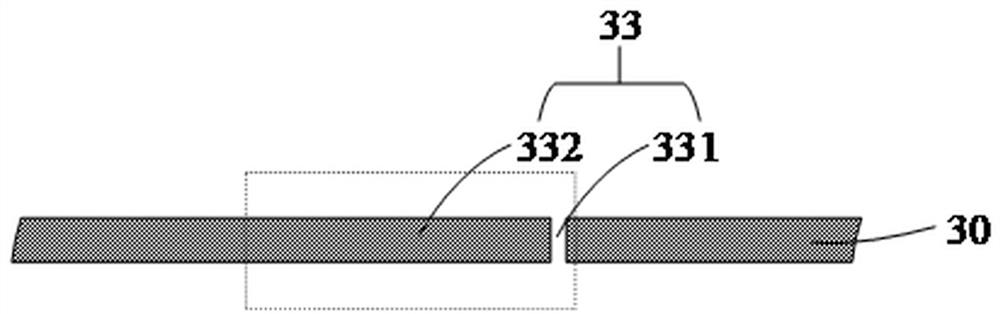

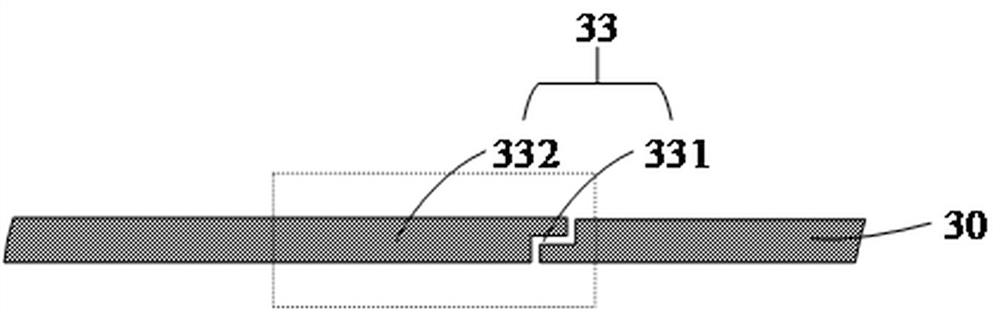

[0075] Embodiment 1: This embodiment provides a diaphragm, including a diaphragm body 30, such as image 3 As shown, the diaphragm body 30 is provided with a vent valve 33, the vent valve 33 includes a connecting end connected to the diaphragm body 30 and a movable part 332 away from the connecting end, the outer periphery of the movable part 332 and the diaphragm The main body 30 has stepped stepped edges, and the adjacent movable parts 332 or the stepped edges between the movable parts 332 and the diaphragm body 30 are staggered to form a stepped platform, and gaps 331 are formed between the staggered stepped edges. The vertical section of the pores 331 is stepped. That is, the pores 331 have a stepped cross section.

[0076] Such as image 3 As shown, in this embodiment, there is one ladder-like platform. That is, the "number of steps" of the cross-section of the pores 331 is two.

[0077] Specifically, the shape of the diaphragm body 30 is circular, or other centrally ...

Embodiment 2

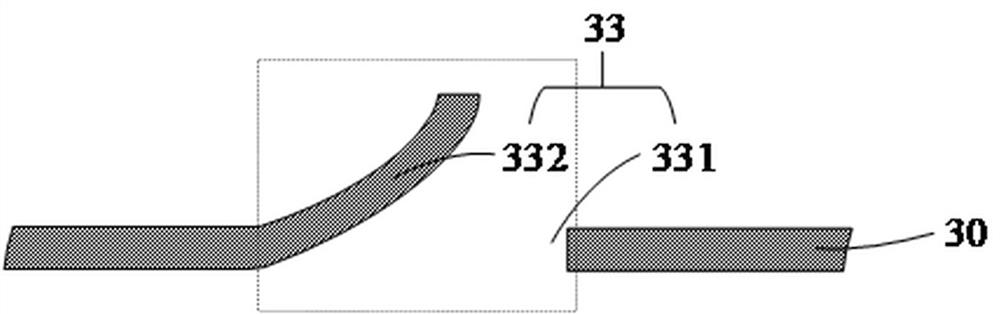

[0080] Embodiment 2: as attached Figure 4 As shown, in this embodiment, there are multiple ladder-like platforms. That is, the "number of steps" of the cross-section of the pores 331 is plural. The remaining parts are the same as in Embodiment 1 in this embodiment.

[0081] In Embodiment 1 of the present invention, as image 3 As shown, the "step number" of the section of the pores 331 is two; in Embodiment 2 of the present invention, as Figure 4 As shown, the "number of steps" of the section of the pores 331 is three.

[0082] For clarification, see Figure 1-Figure 2 , the pore 331 of the existing air release valve 33 is usually set in a rectangular shape. Although this air release valve 33 can be opened when it is subjected to a severe impact to relieve pressure, under normal circumstances, that is, when the air release valve 33 is in a non-open state , the air damping of the rectangular hole 331 is too small, which will cause the low frequency response of the MEMS m...

Embodiment 3

[0083] Embodiment 3: as Figure 5 Shown, the present invention also provides a kind of MEMS microphone chip, comprises:

[0084] The substrate 10 is provided with a back cavity 11 penetrating vertically;

[0085] The diaphragm body 30 is arranged on one side of the substrate 10 at intervals, and at least part of the diaphragm body 30 is vibrated above the back cavity 11;

[0086] The back plate 60 is arranged at intervals on the side of the diaphragm body 30 away from the substrate 10; the back plate 60 is also provided with one or more spaced through holes 61, and the through holes 61 penetrate the back plate 60 vertically;

[0087] The vibration gap 53 is set between the diaphragm body 30 and the back plate 60, and is located above the back cavity 11;

[0088] The diaphragm body 30, the back plate 60 and the vibration gap 53 together form a capacitor structure;

[0089] The sacrificial layer 52 is located between the diaphragm body 30 and the back plate 60 and outside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com