First-order buoyancy magnetic liquid damping vibration absorber for magnetic shielding

A magnetic liquid, magnetic shielding technology, applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problems of difficult flow of magnetic liquid, low viscous energy consumption efficiency, large mass, etc., to avoid flow Difficult problems, improved centering effect, effect of various shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described with accompanying drawing as specific embodiment:

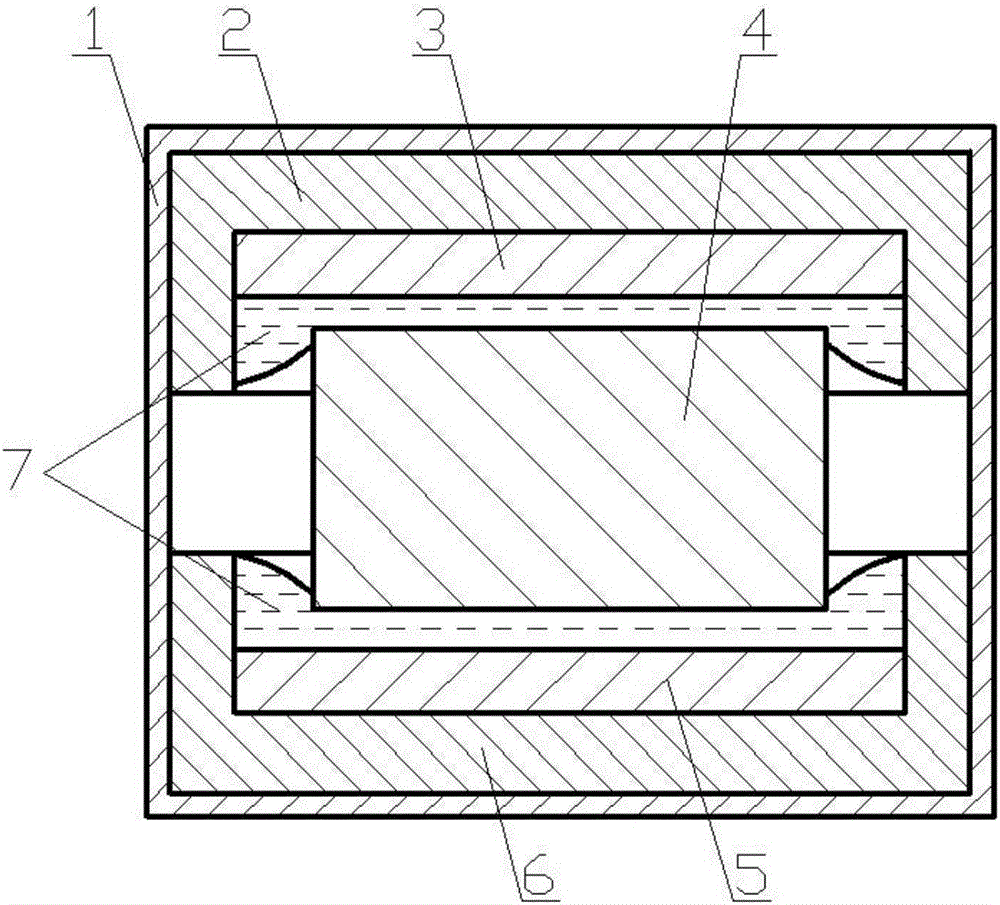

[0026] A first-order buoyancy principle magnetic liquid shock absorber with double cone angle, such as figure 1 , the vibration damping device includes: a housing 1 , an upper shield 2 , an upper permanent magnet 3 , a mass 4 , a lower permanent magnet 5 , a lower shield 6 and a magnetic liquid 7 .

[0027] Connections between the parts making up the device:

[0028] The upper shield 2 is an inverted "concave" structure, and the upper surface of the upper permanent magnet 3 is installed in the groove of the upper shield 2 and fixedly connected. The lower shield 6 is an upright "concave" shape structure, and the lower surface of the lower permanent magnet 5 is installed in the groove of the lower shield 6 and fixedly connected.

[0029] The housing 1 is a thin-walled cavity structure, and the upper surface of the upper shield 2 equipped with the upper permanent magnet 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com