Twist drill with spiral cutting back tool

A flank and helical technology, applied in the field of twist drills, can solve problems such as stress concentration, affecting the use effect, easy wear or edge chipping, and achieve the effect of avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

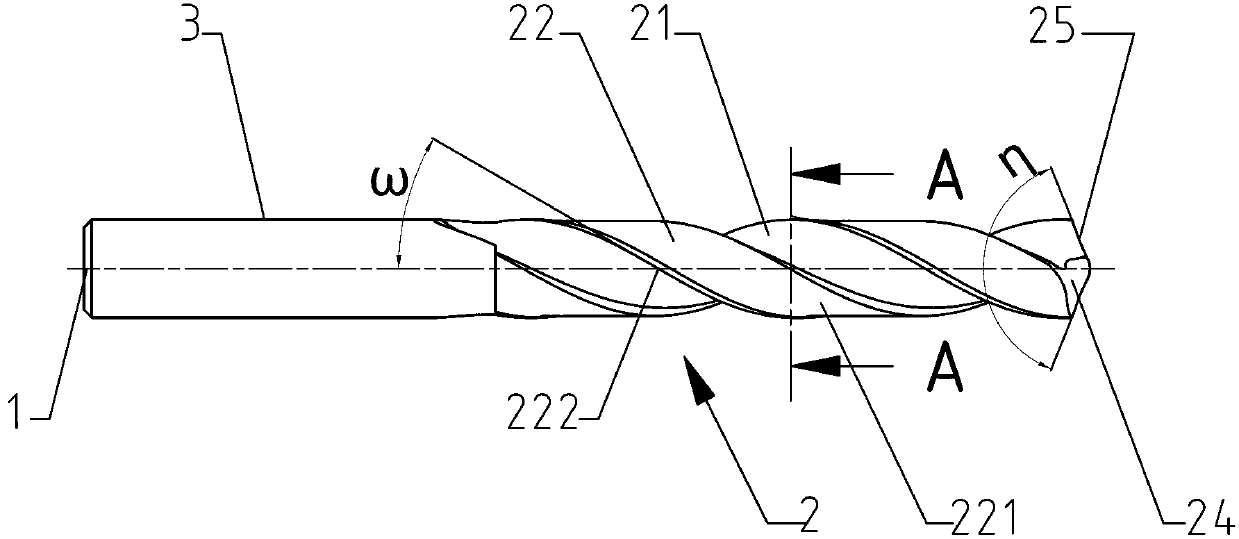

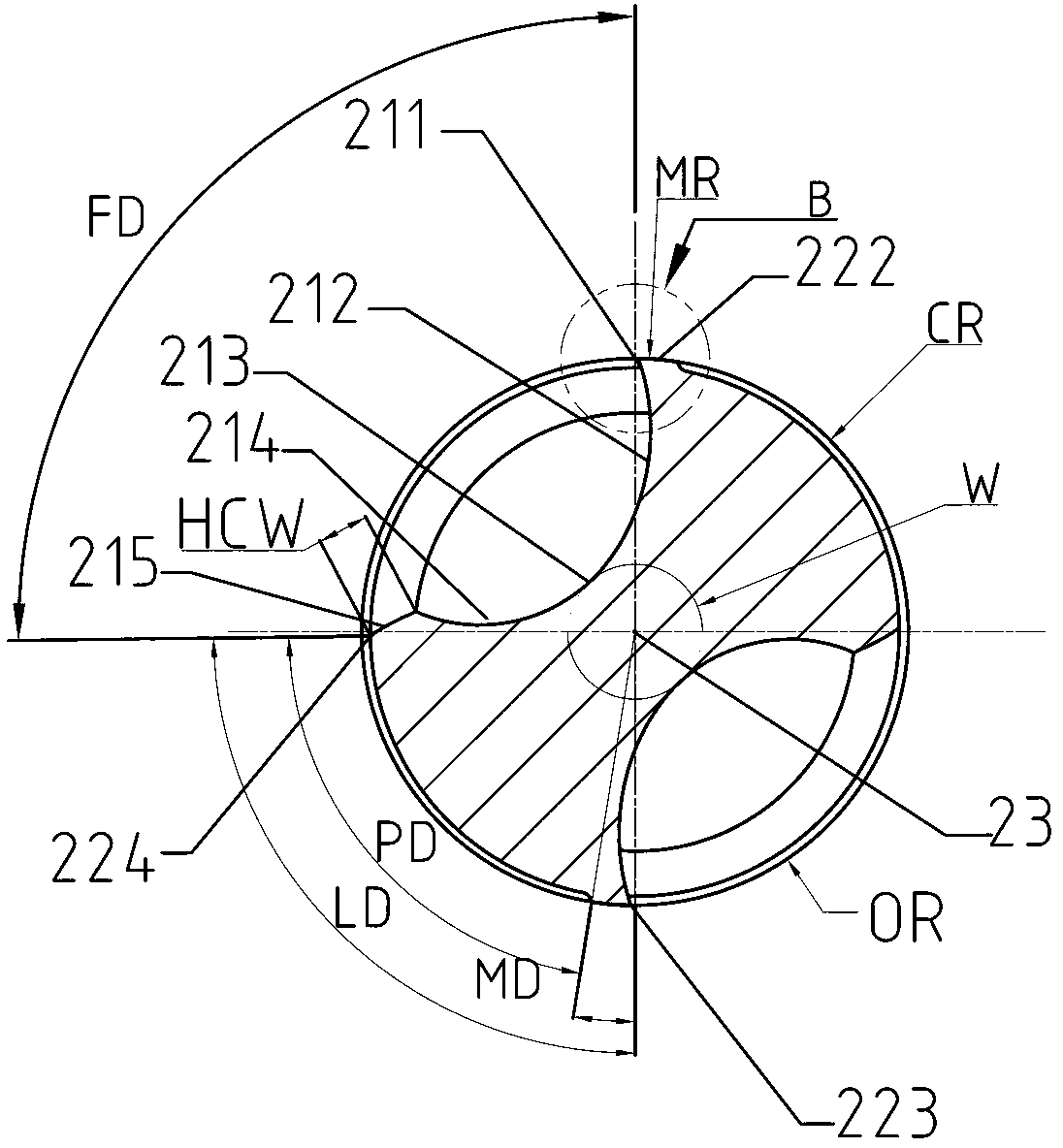

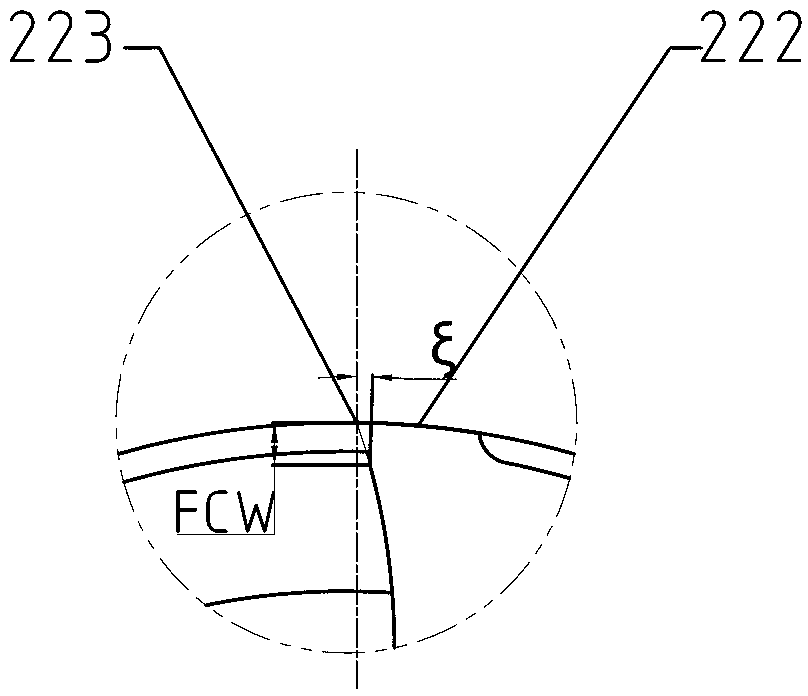

[0040] Such as figure 1 As shown, a twist drill with a helical cutting flank includes a cutting part 2 that rotates around the axis 1 and a shank 3 that matches the jacket. The cutting part 2 is provided with two The front end of the cutting part 2 spirally extends toward the shank part 3 to discharge the groove 21 for cutting chips. The cutting part 2 is also provided with a blade back 22 respectively connecting the outer peripheral edges of the two grooves 21. The groove 21 is a groove extending along the axis 1 with a helix angle of ω and a radial section corresponding to an arc length of FD (such as figure 2 shown), including the groove front end connection part 211, the groove front end 212, the groove bottom 213, the groove end 214 and the groove end connection part 215, the groove front end 212, the groove bottom 213 and the groove The groove end 214 is on the same smooth curve, wherein, ω=0°~60°; the blade back 22 includes a clearing area 221, a margin 222, a periph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com