Patents

Literature

141results about How to "Large axial force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

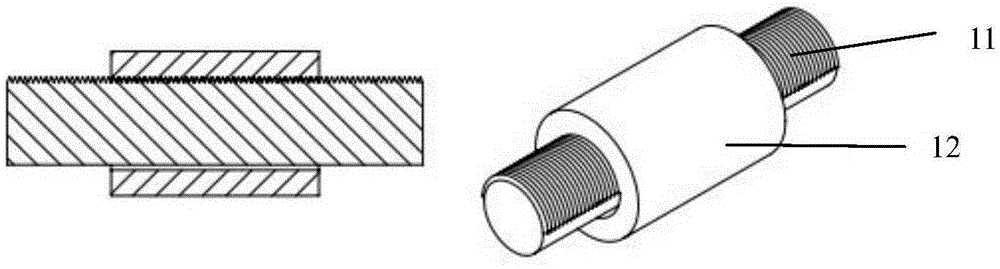

Telescopic positioning device and application thereof

The invention discloses a telescopic positioning device and application thereof and belongs to the technical field of telescopic connection. Engaging positioning or separation telescopic type connection is achieved through convex and concave engaging mechanisms which are evenly and continuously distributed; each convex and concave engaging mechanism comprises a convex tooth component and a groove component engaged with or disengaged from the convex tooth component; the engaging portion of each convex tooth component is provided with at least one partition groove in the cross section perpendicular to the relative displacement direction so that the two parts can stretch out and draw back and can be positioned; the convex and concave engaging mechanisms comprise the rotating engaging mechanism of non-complete round threads, the wedge expansion engaging mechanism and the rotating engaging mechanism of a non-circular cross section cam shaft; and the rotating engaging mechanism of the non-complete round threads can be applied to functional mechanisms of lifting and folding position restoration of bike seats or bike handlebars. The telescopic positioning device achieves the fast telescopic adjusting, locking and positioning through the threads or a pawl mechanism. Compared with a similar hydraulic or pneumatic mechanism, the telescopic positioning device is easy to manufacture, low in weight and reliable in performance, and cost is substantially reduced.

Owner:戚善鸣

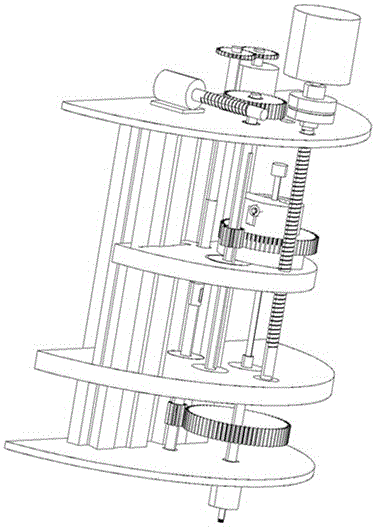

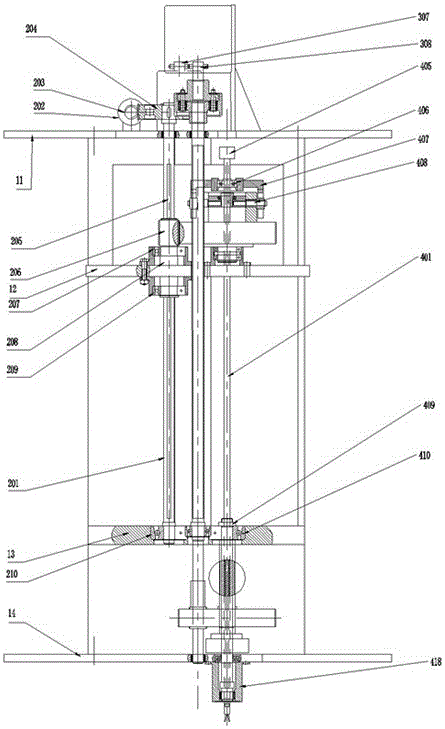

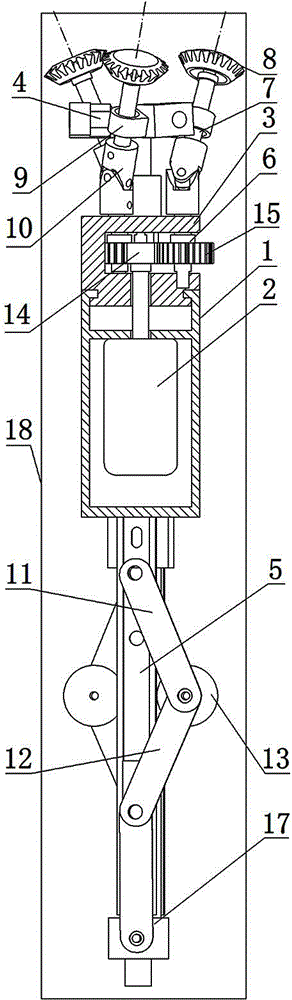

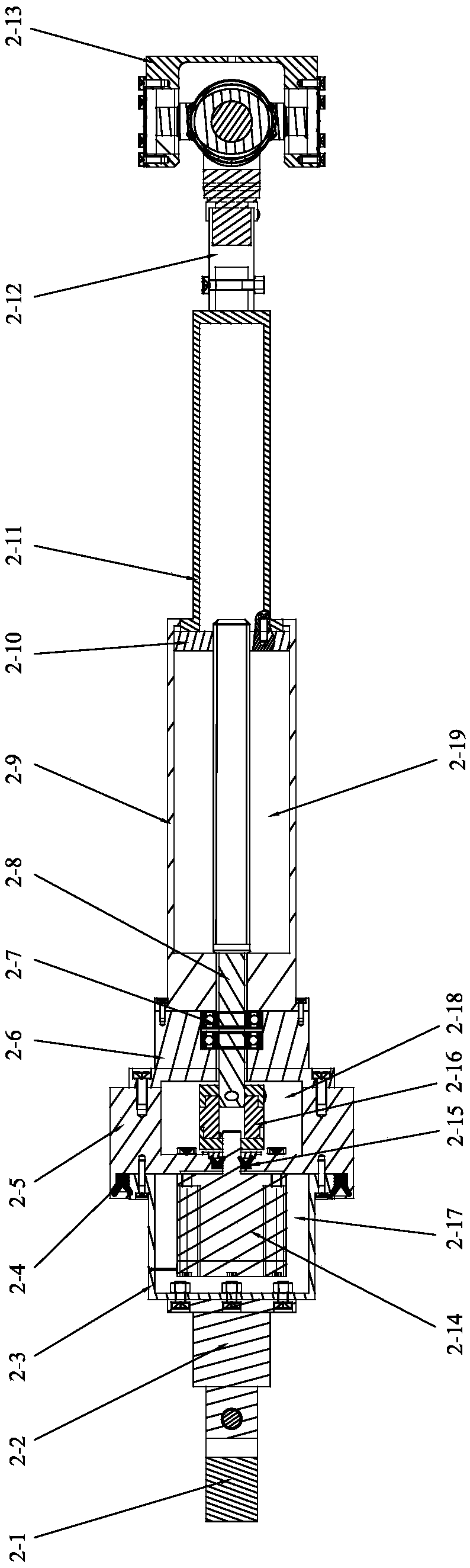

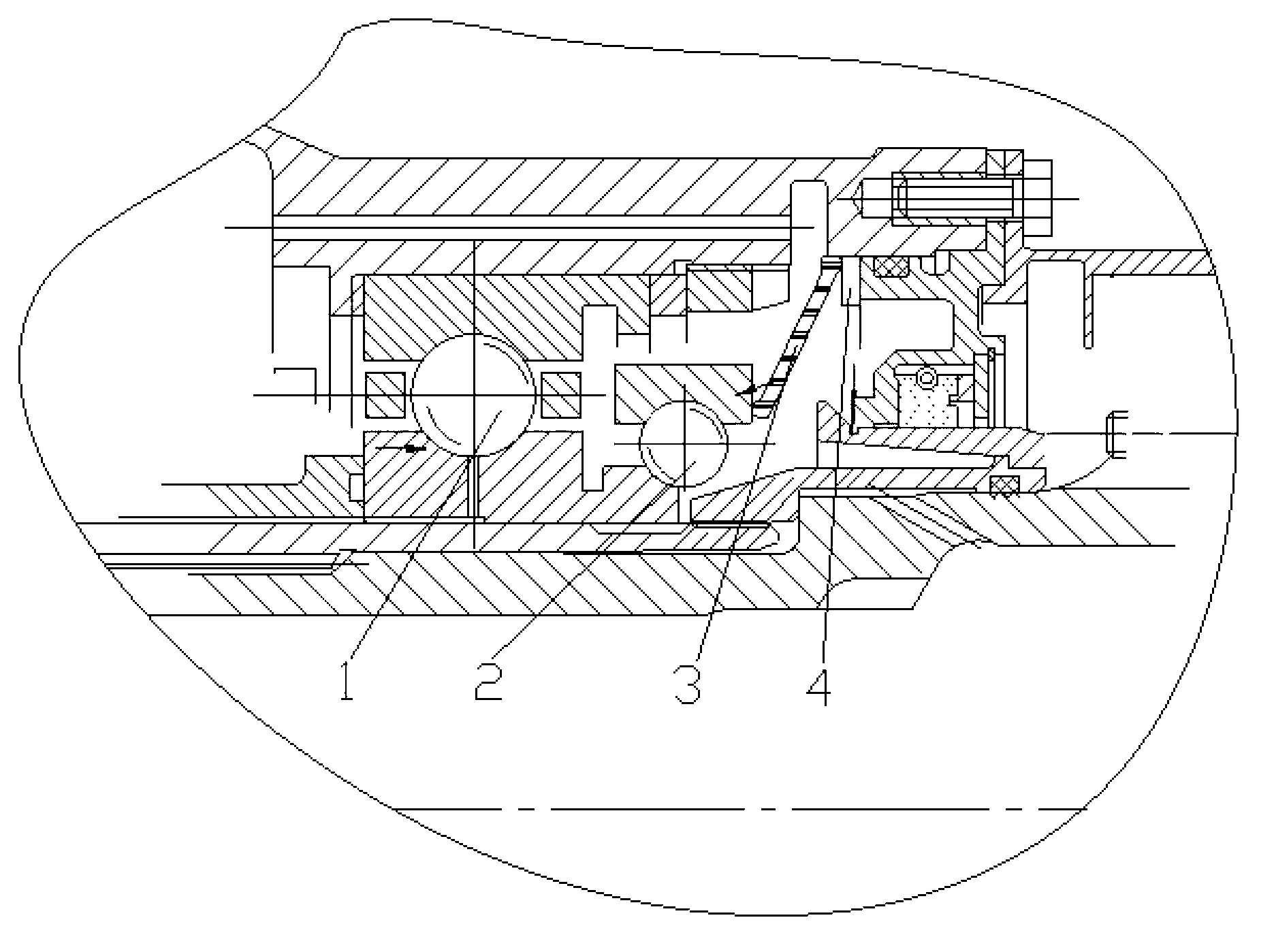

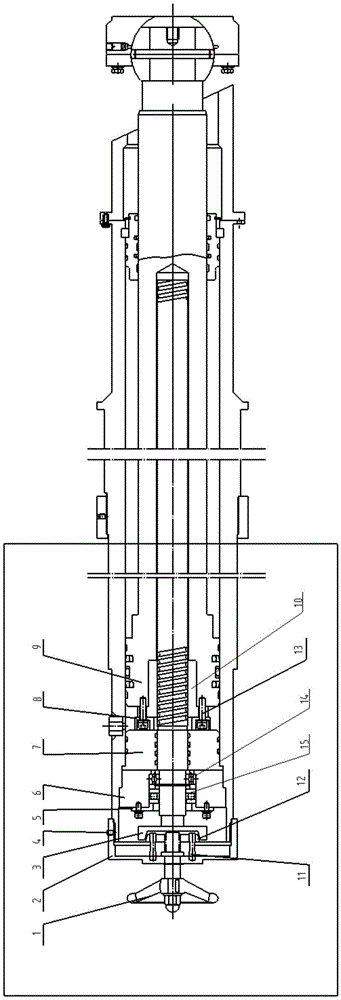

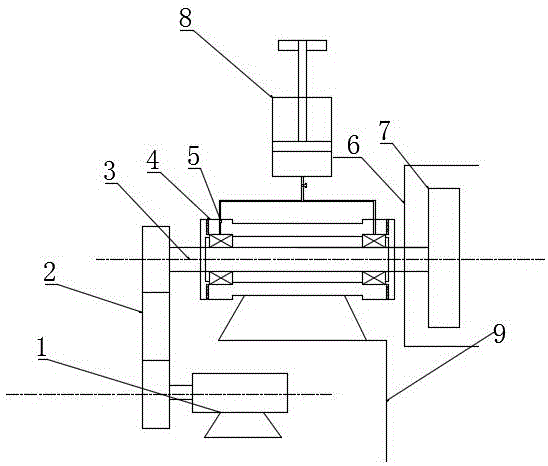

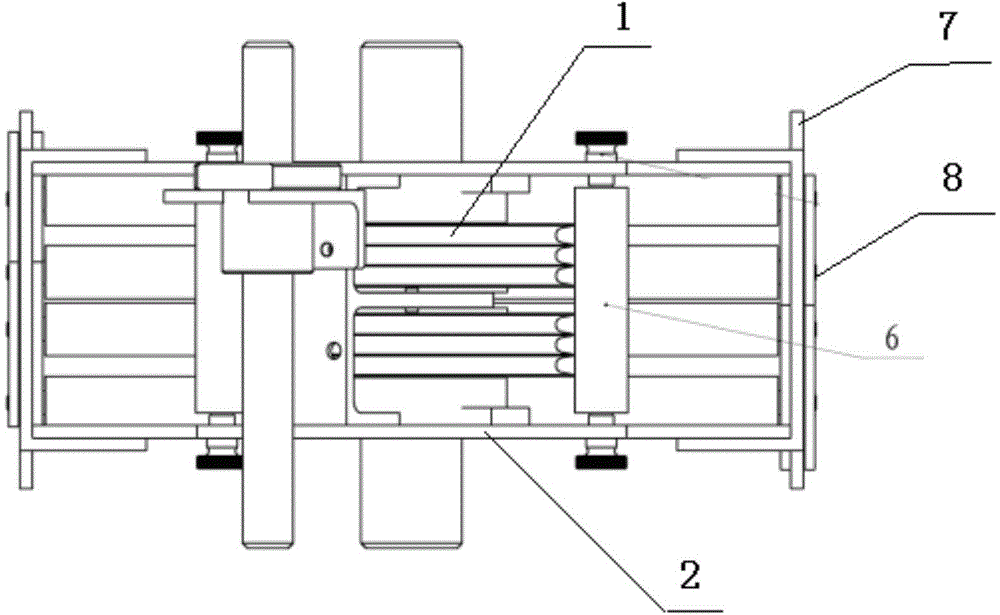

Minimally-invasive surgery assistant robot

InactiveCN105919670ACompact structureIncrease stiffnessProgramme-controlled manipulatorSurgical robotsLess invasive surgeryBall screw

The invention provides a minimally-invasive surgery assistant robot, relates to the field of surgery robots, particularly relates to a minimally-invasive surgery assistant robot and aims to solve the problem that an existing robot hardly opens high-quality and high-accuracy wounds in minimally-invasive surgery. The robot comprises a main shaft lifting mechanism, a main shaft rotating mechanism and a main shaft tail end opening and closing mechanism, wherein the main shaft lifting mechanism is used for driving a ball screw-nut pair via a coupler by using a motor, so that a movable plate exerts the lifting function on a guide rail pair; the main shaft rotating mechanism is used for transmitting torque to a long sleeve by driving two pairs of gears via the motor, then transmitting the torque to a main shaft and enabling the main shaft to rotate; the main shaft tail end opening and closing mechanism is used for transmitting the torque via a worm and gear and a pair of gears by using the motor, lifting a turntable and stretching an inner rod so as to close a tail end surgical instrument.

Owner:HARBIN UNIV OF SCI & TECH

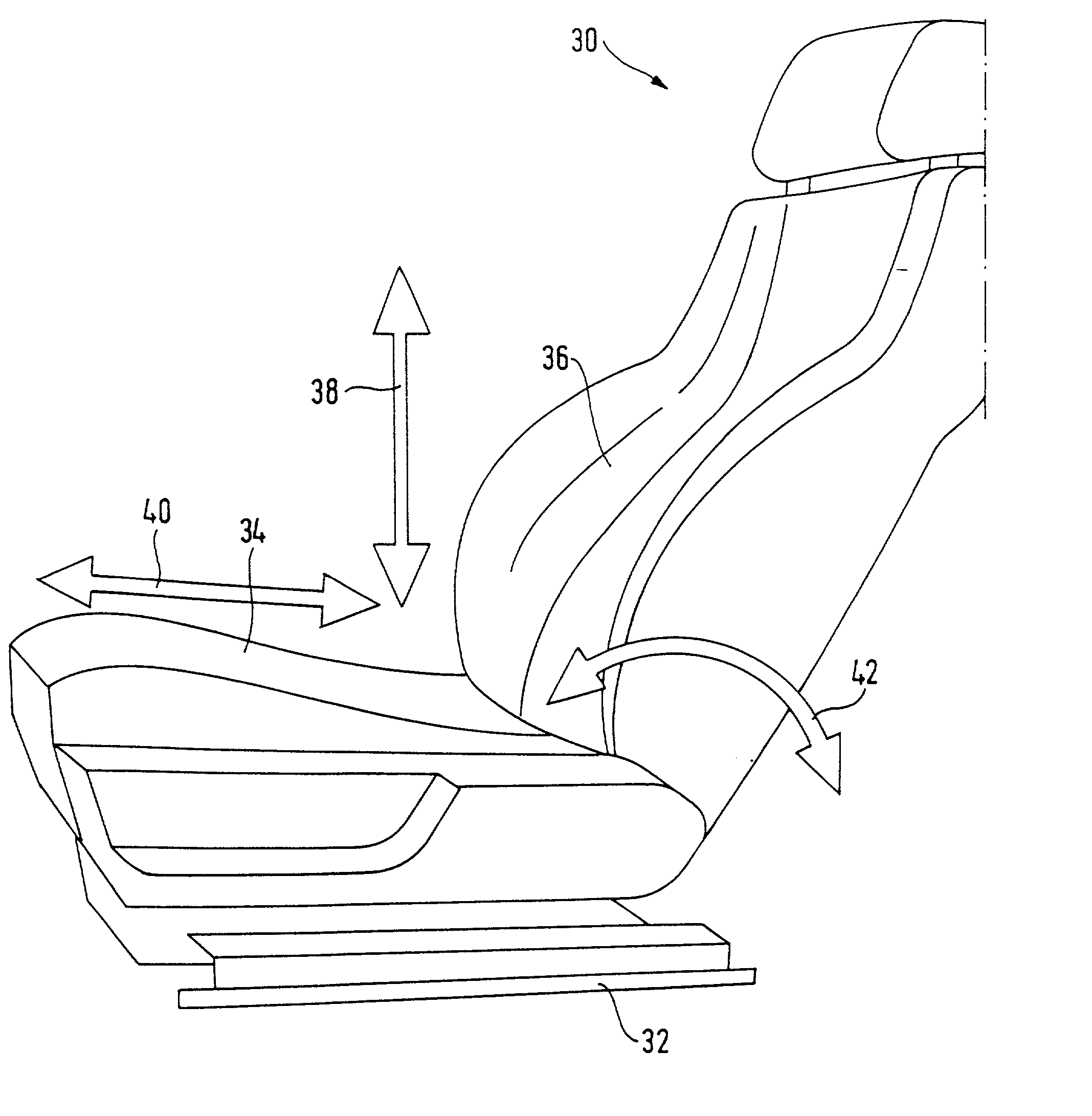

Seat

Owner:BAYERISCHE MOTOREN WERKE AG

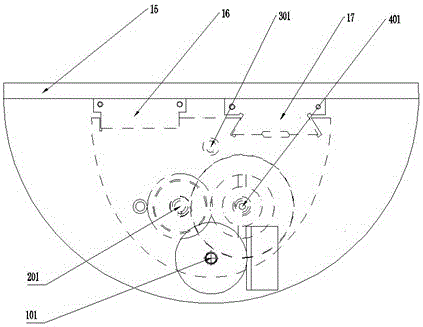

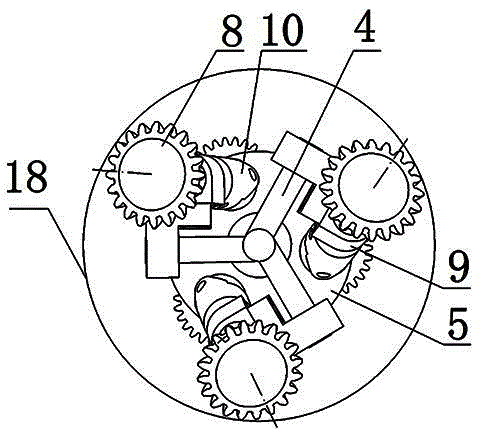

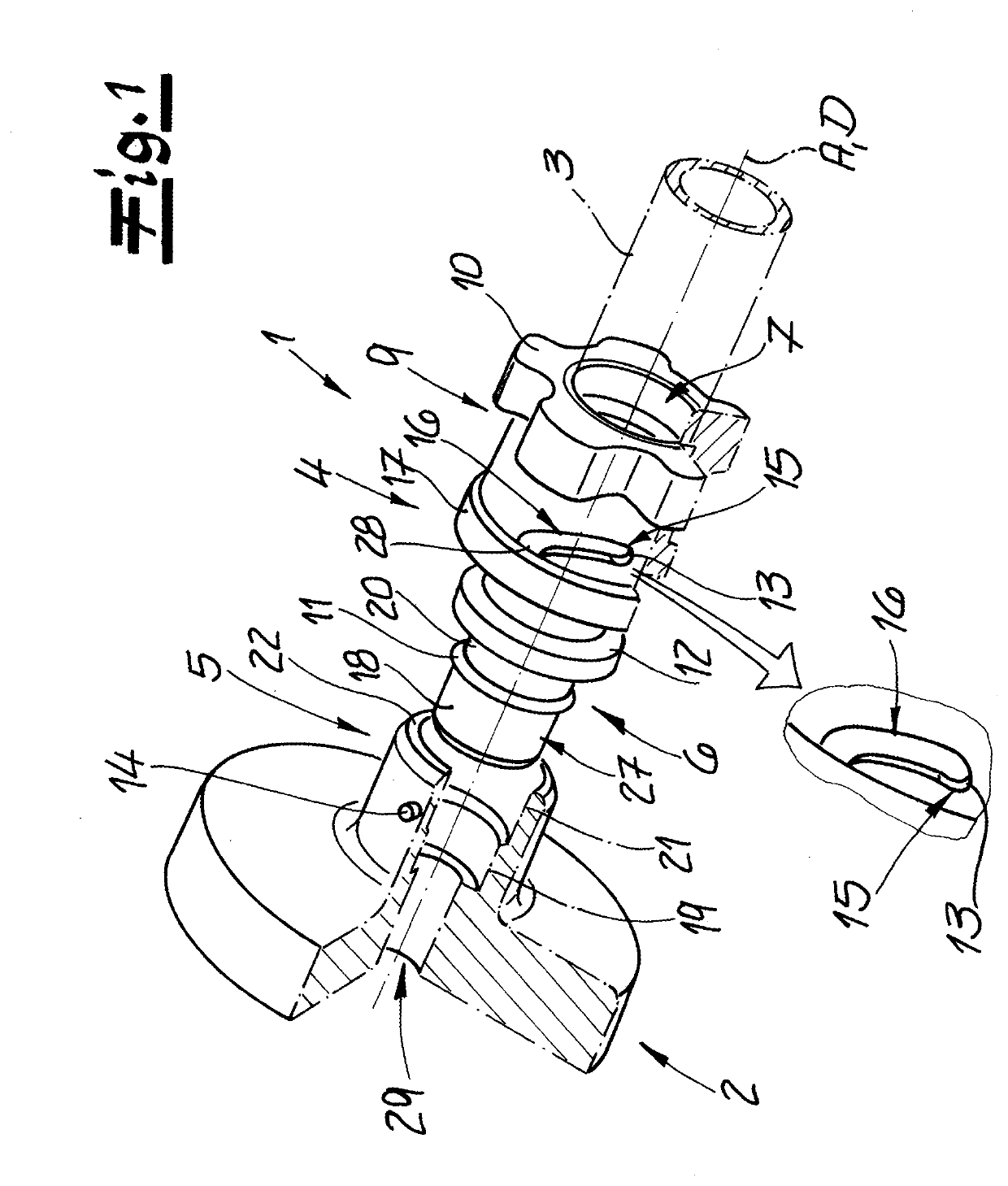

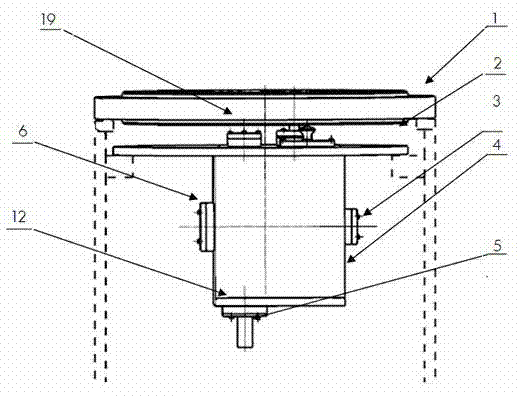

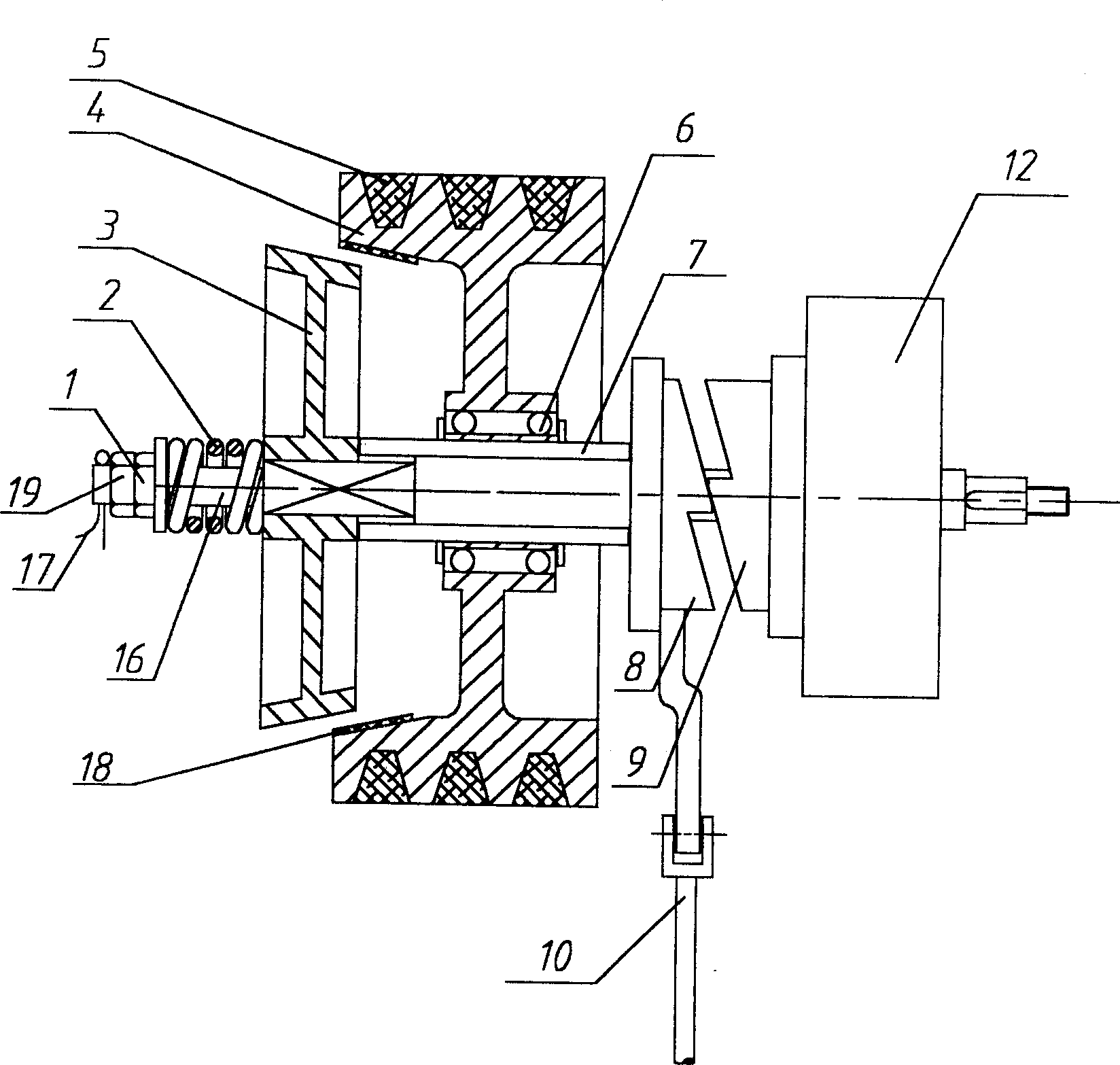

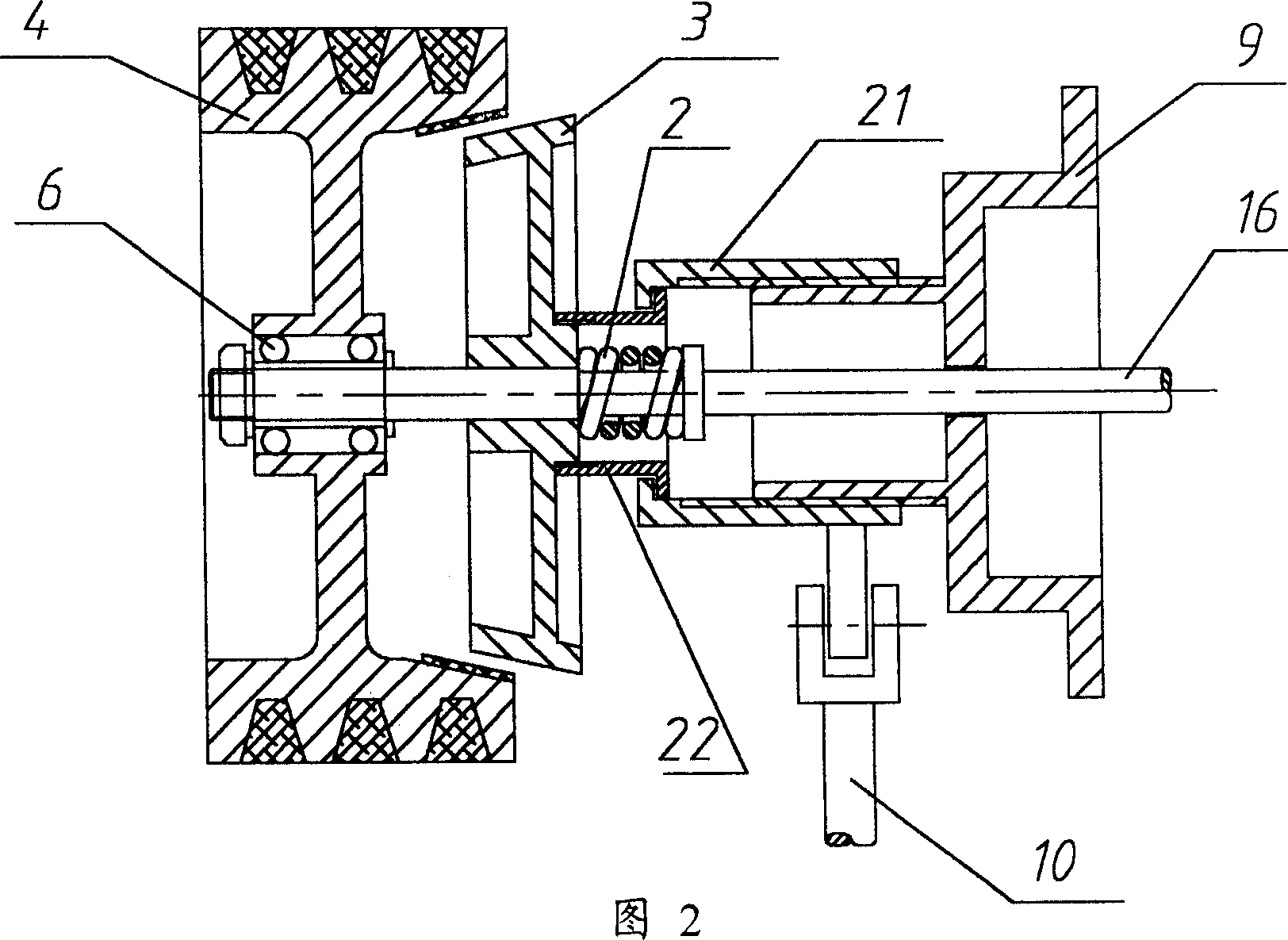

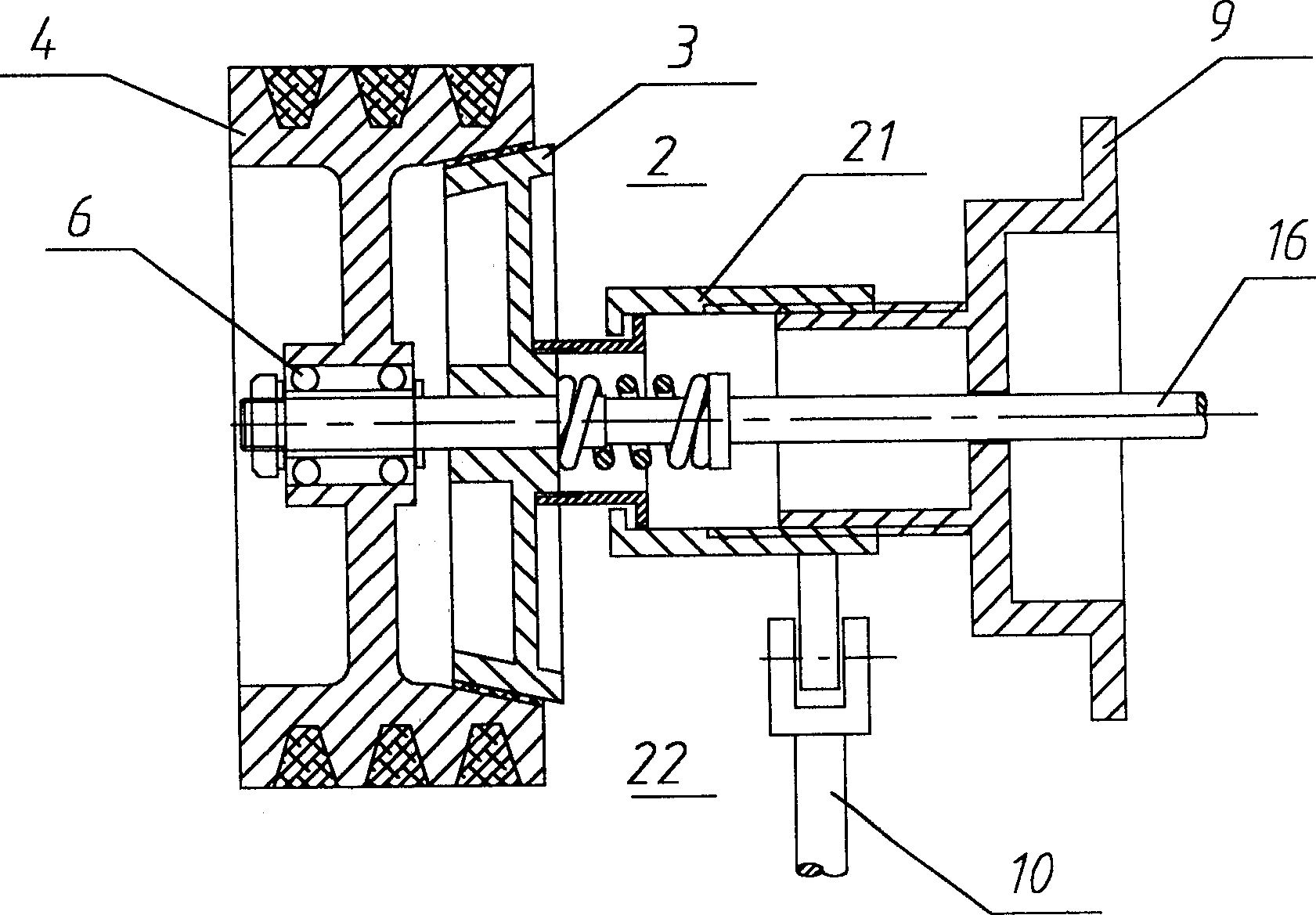

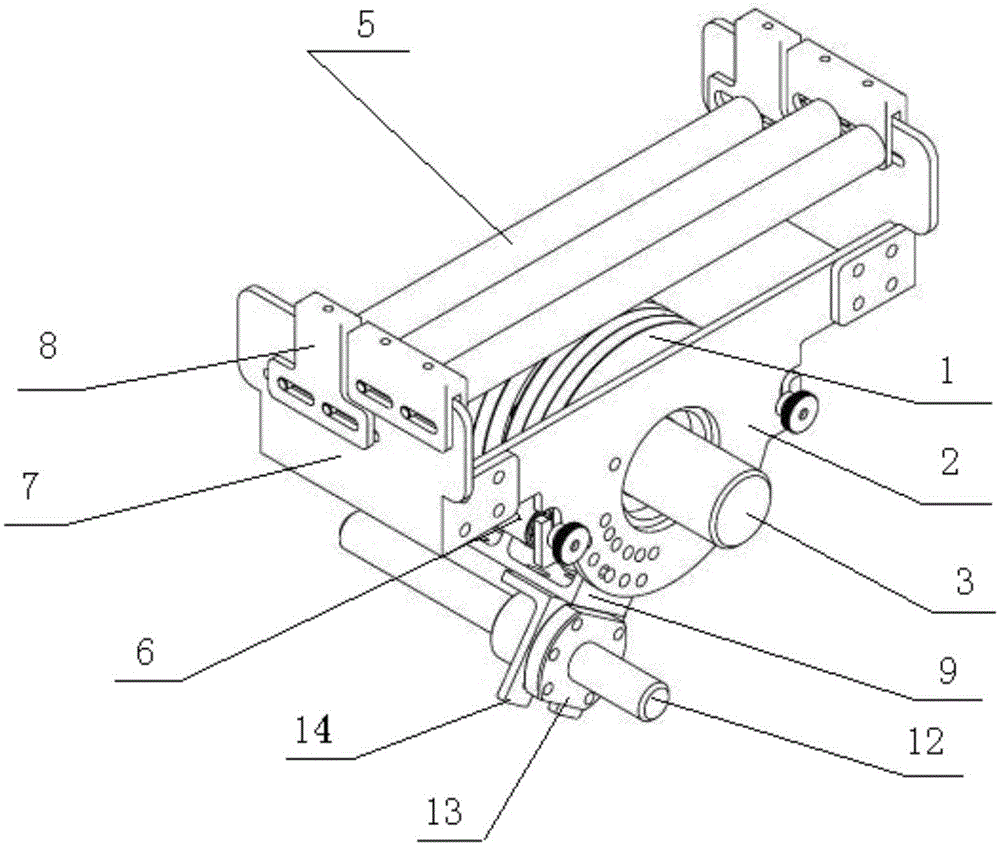

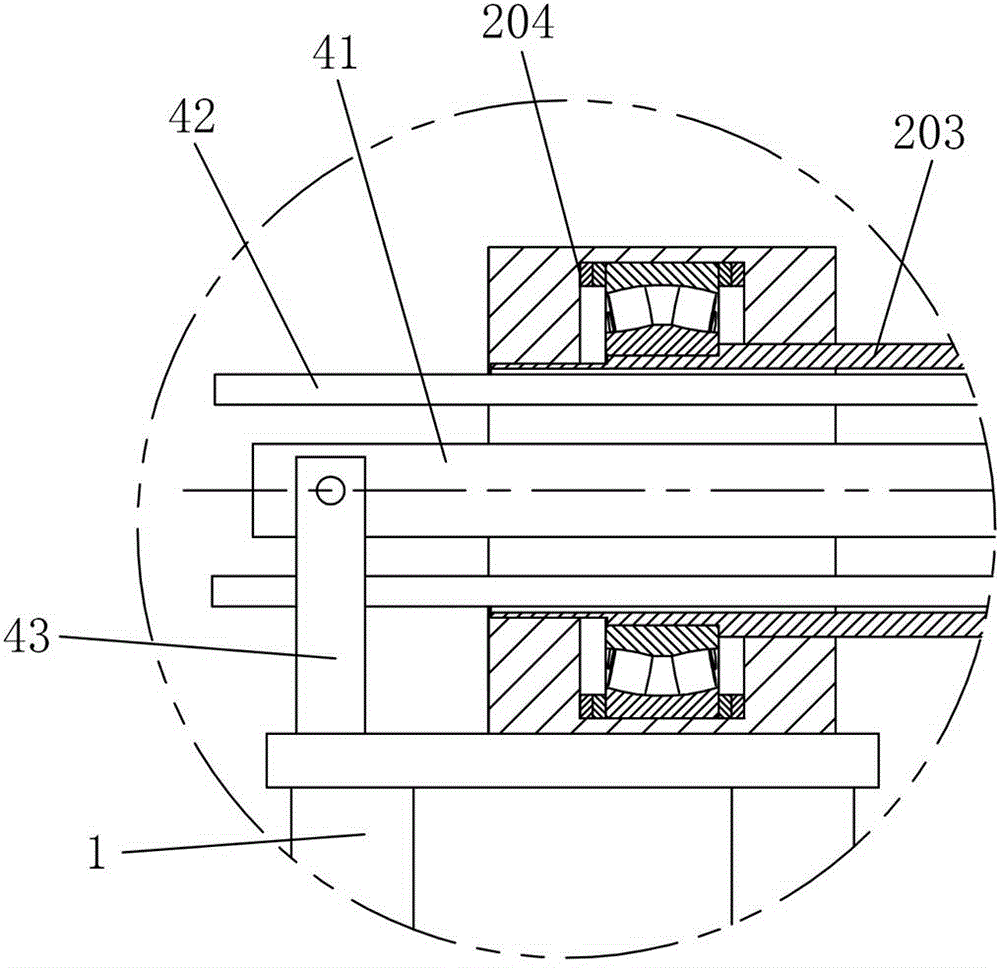

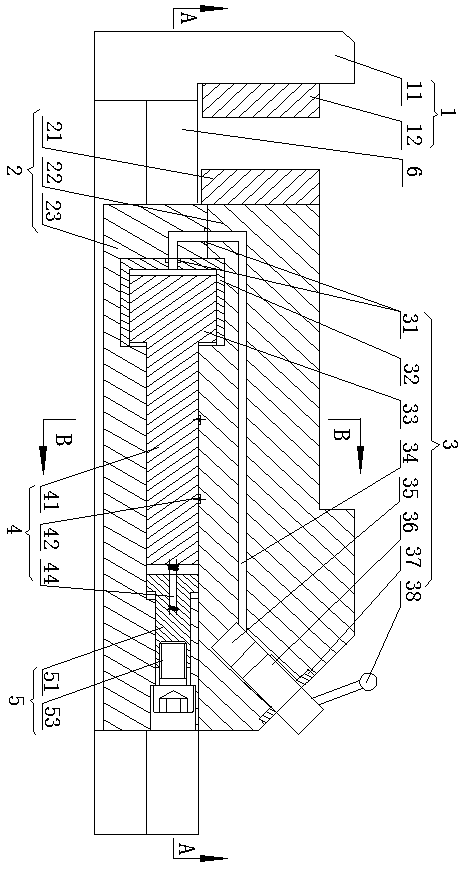

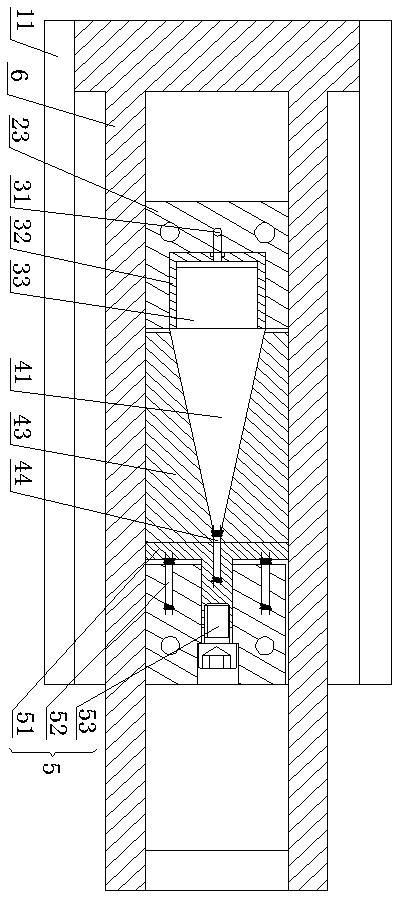

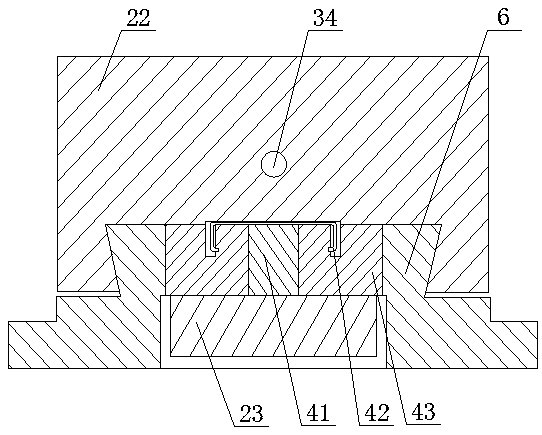

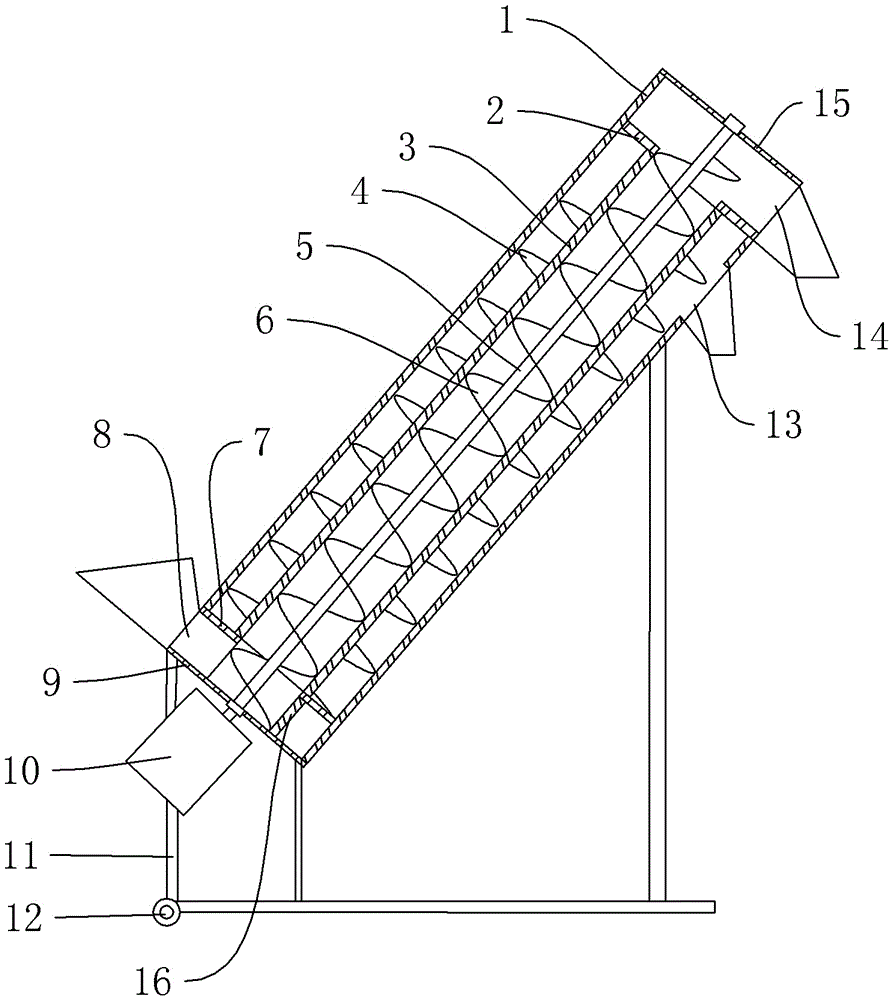

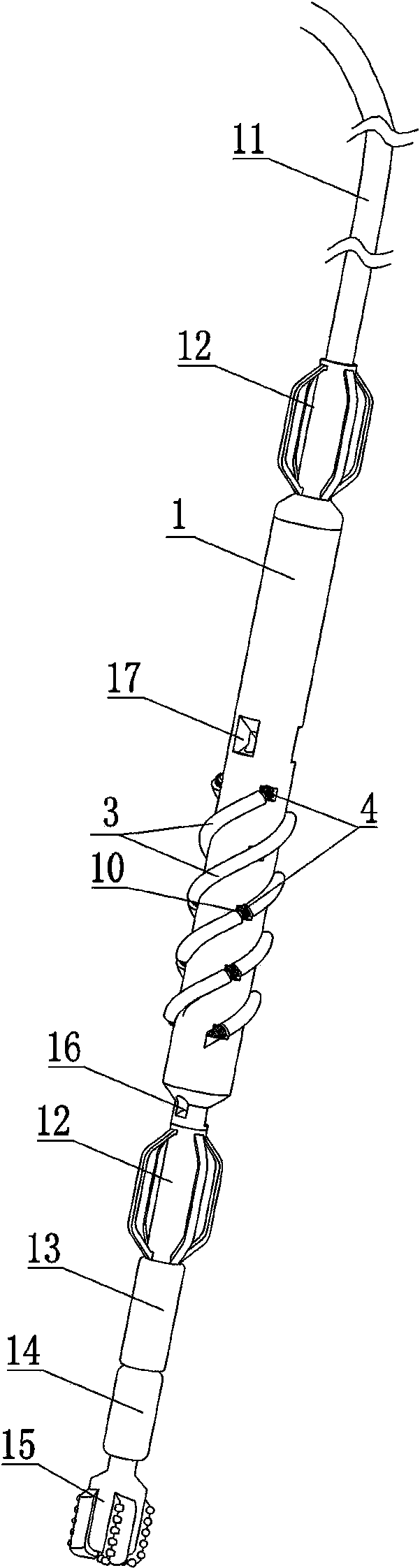

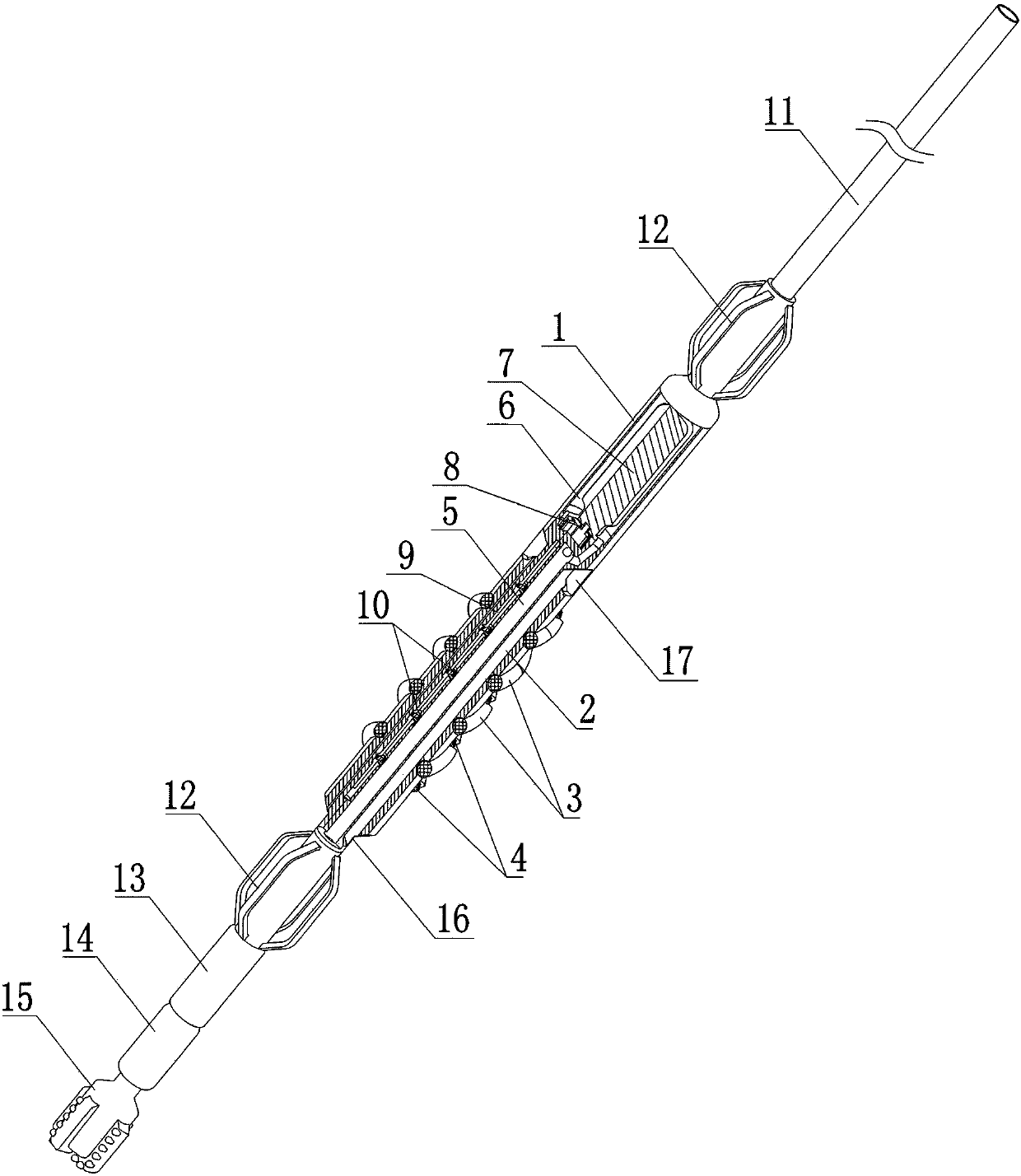

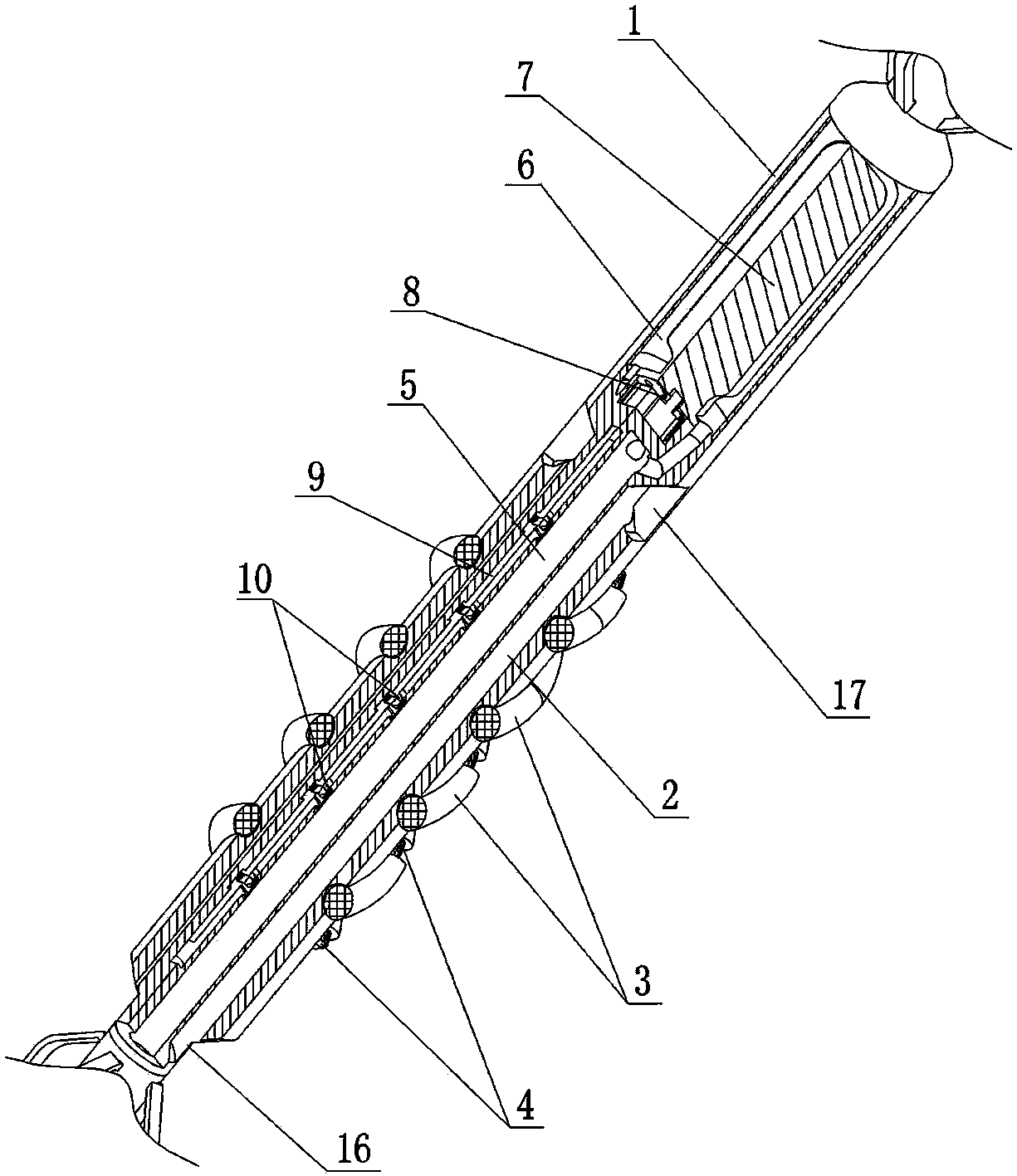

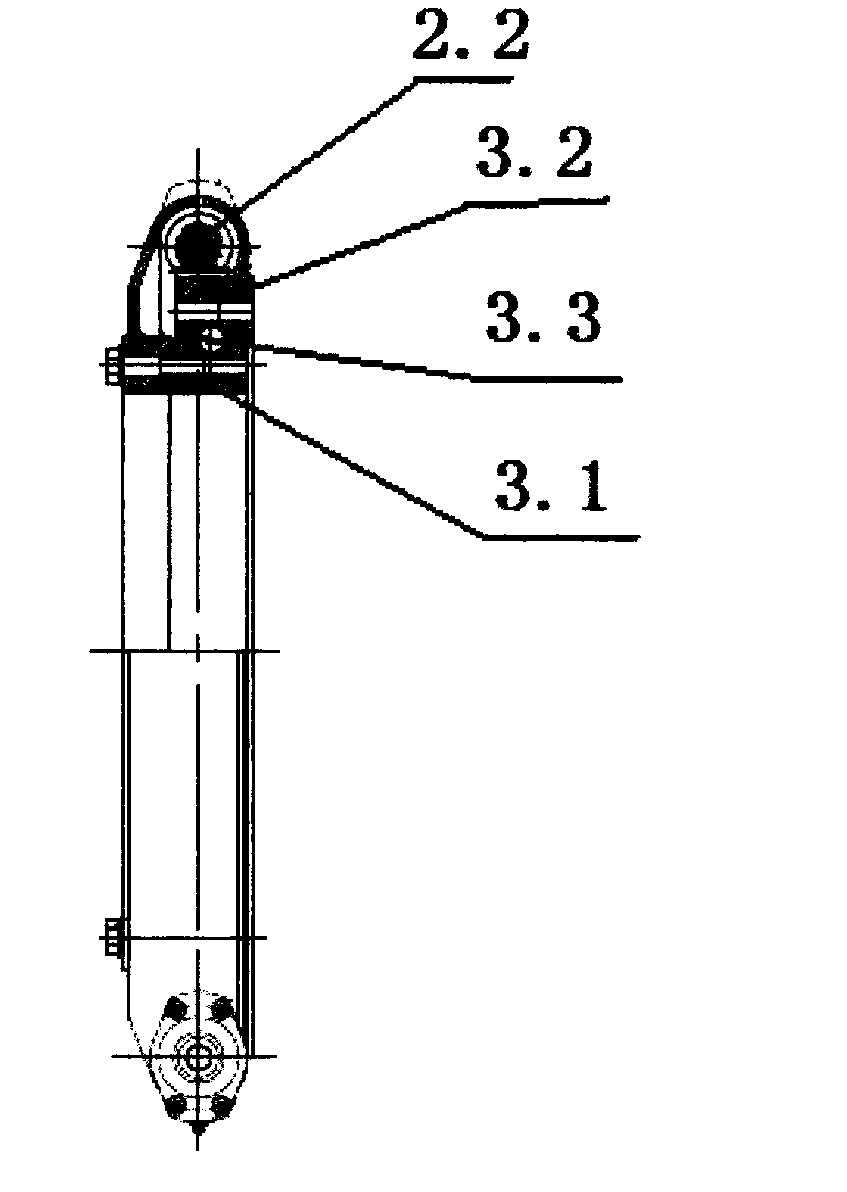

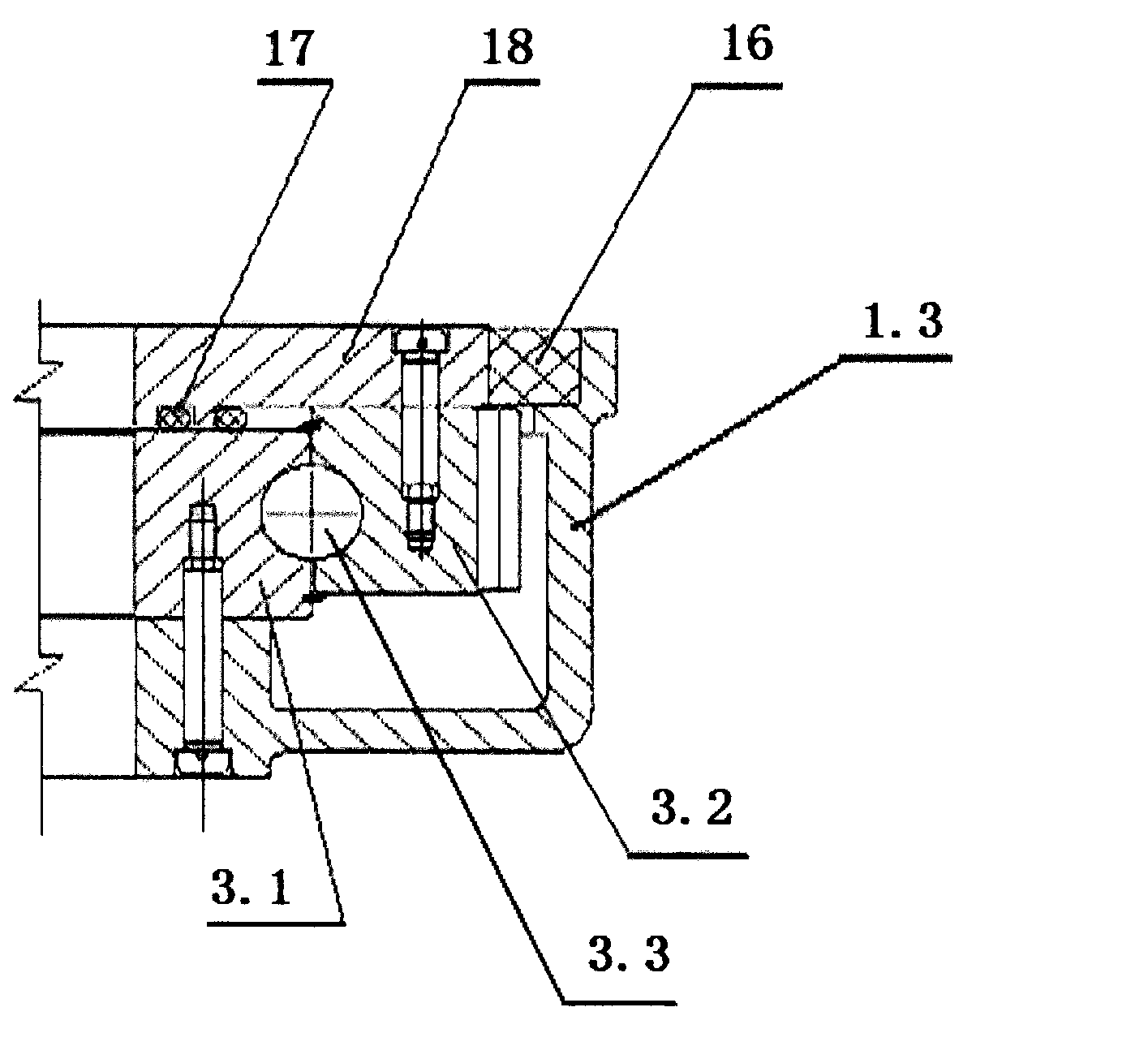

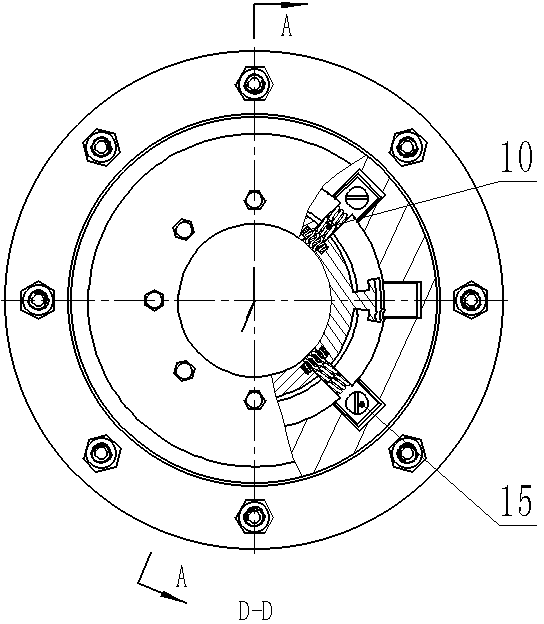

Initiative-driving spiral pipeline robot

ActiveCN102979988ALarge axial forceImprove transmission efficiencyPipe elementsDrive wheelDrive shaft

The invention discloses an initiative-driving spiral pipeline robot which comprises a machine body (1), a power unit (2), a driving shaft (6) and an axle (7); one end of the machine body (1) is provided with a driving wheel carrier (3); a reducing mechanism (4) is arranged on the driving wheel carrier (3); the axle (7) is arranged on the reducing mechanism (4); a driving wheel (8) is fixedly arranged on the axle (7); the driving shaft (6) and the axle (7) are connected through a connector (10); and the driving shaft (6) is connected with the output shaft of the power unit (2) through a transmission device. The initiative-driving spiral pipeline robot has the beneficial effects that the driving wheel is directly initiative-driving by the driving device, the scope of application of the robot is expanded, the operation is stable under the working conditions of different pipe diameters, and the axial force is large; and meanwhile, the axial position of the robot is adjusted by controlling the operation of the driving wheel, so that the adjustment precision is high, and the operation position of the robot is precisely controlled.

Owner:SOUTHWEST PETROLEUM UNIV

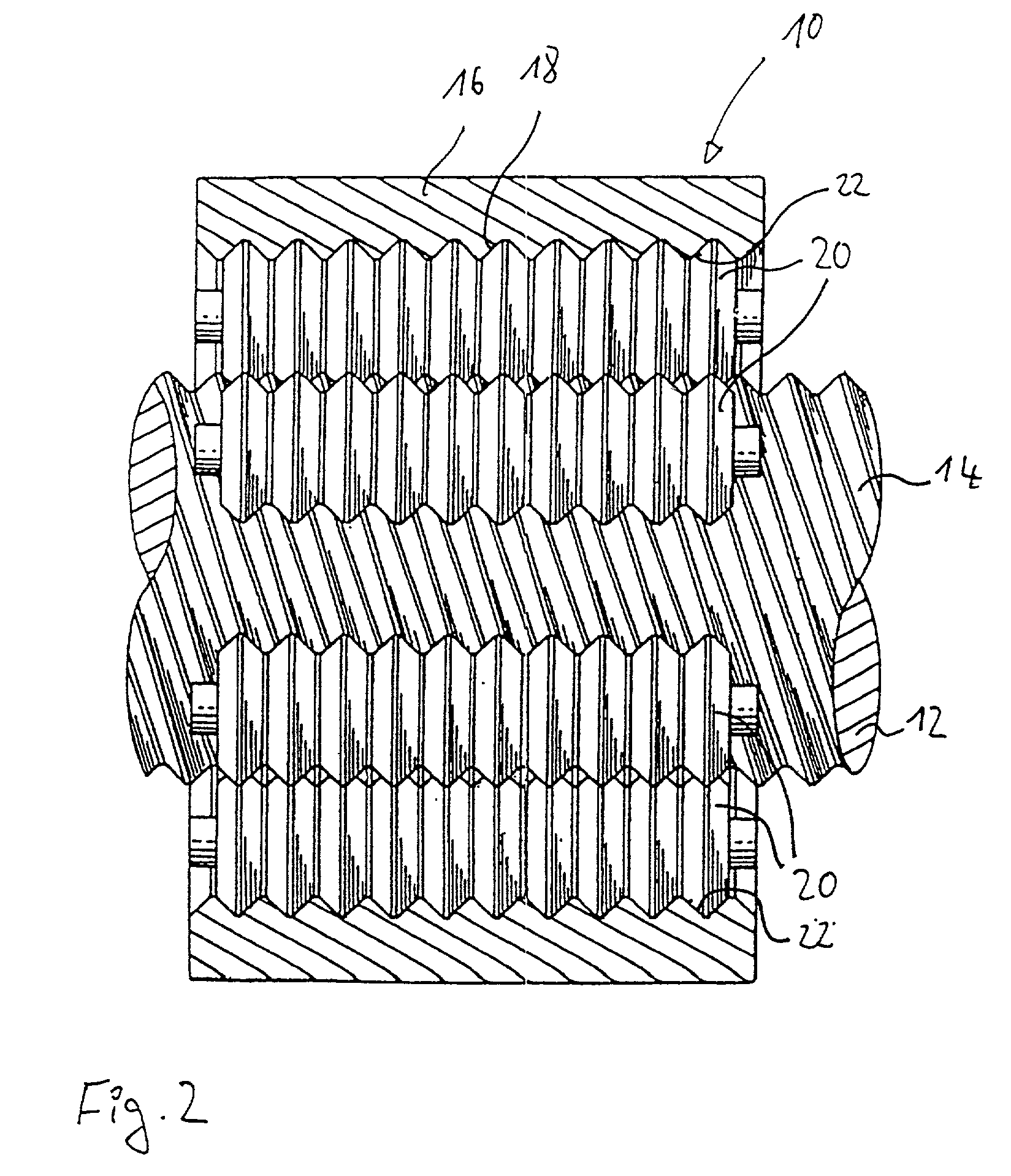

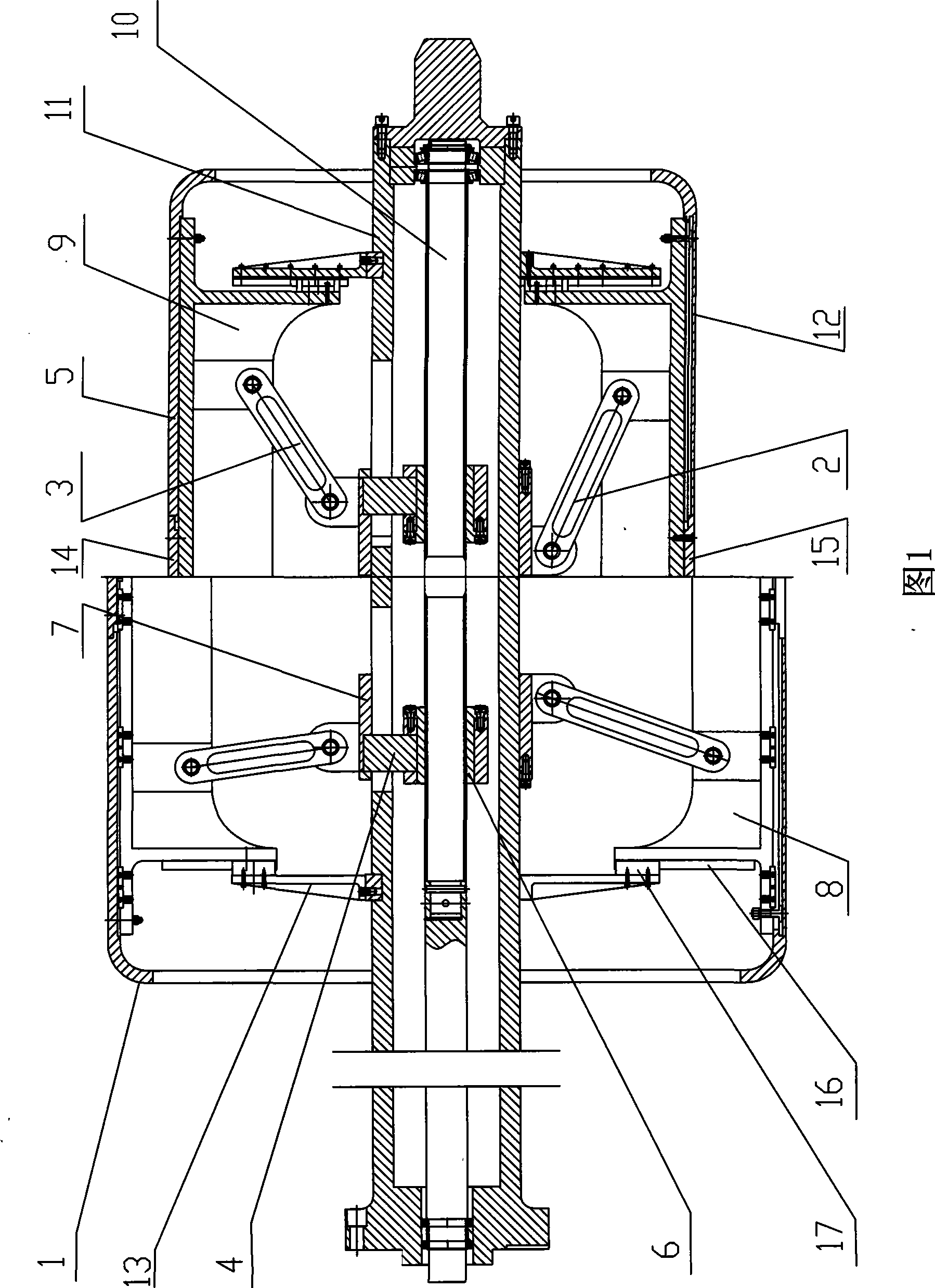

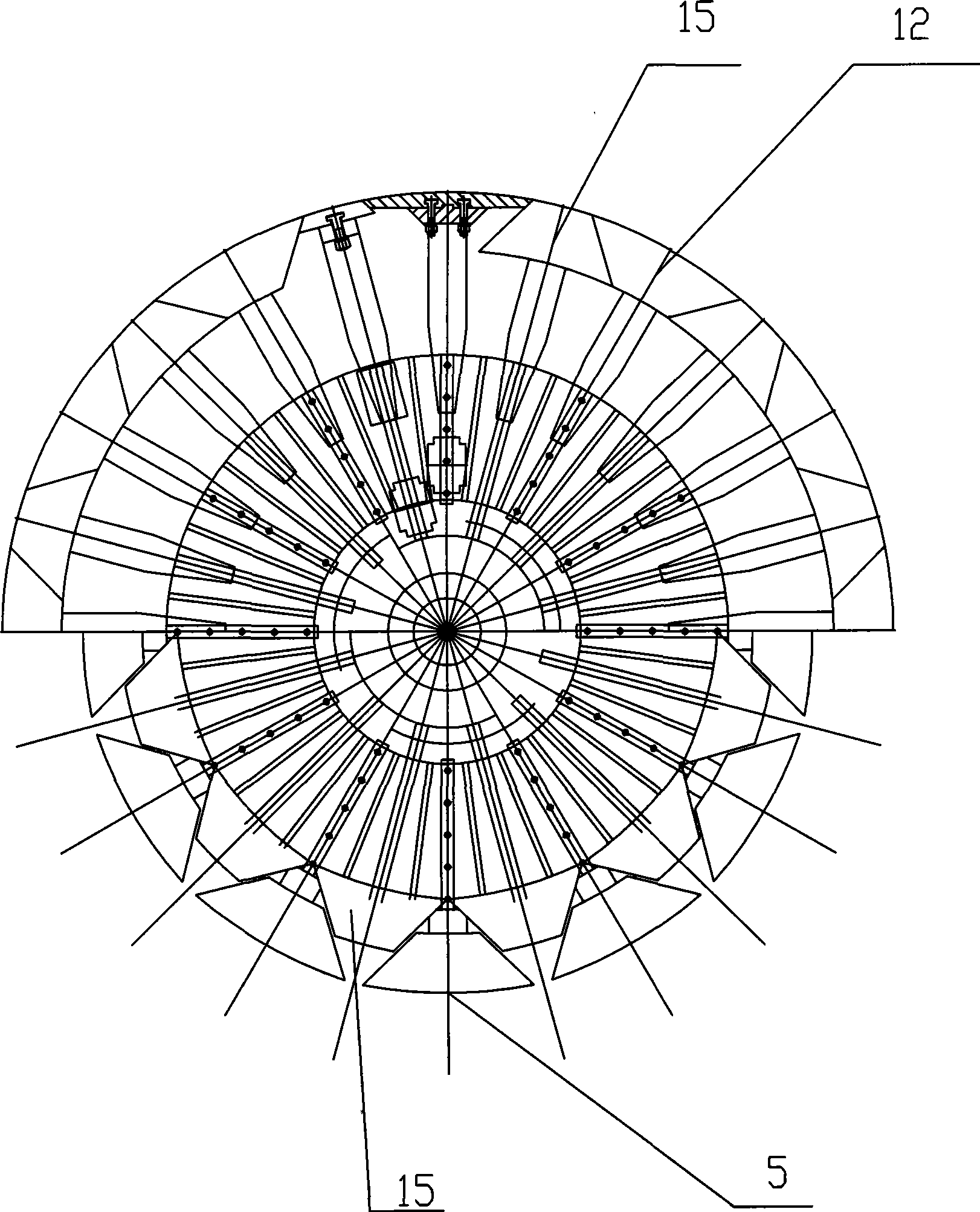

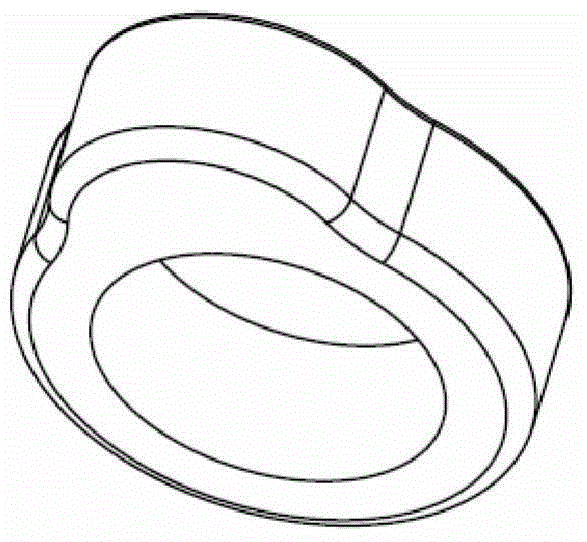

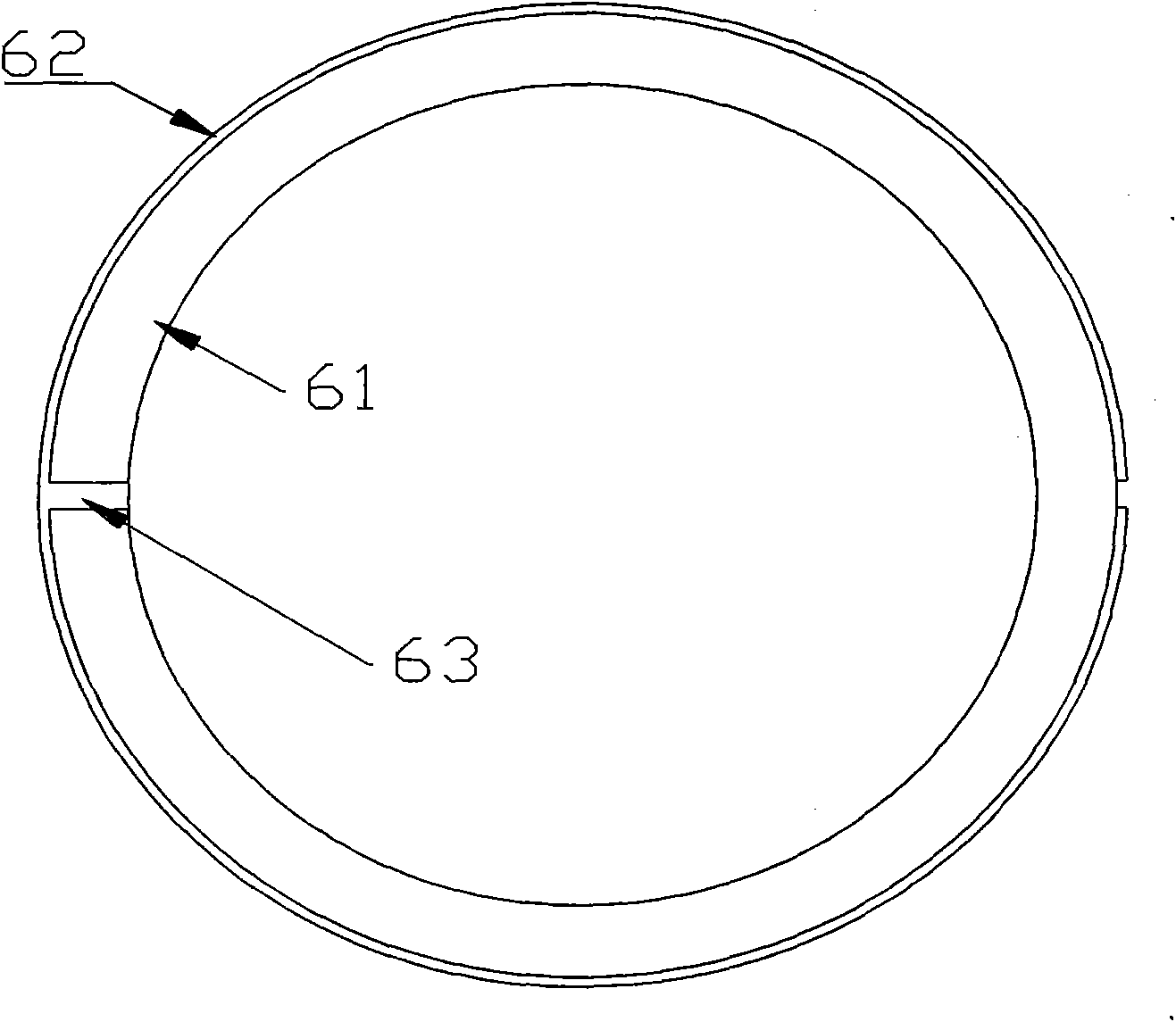

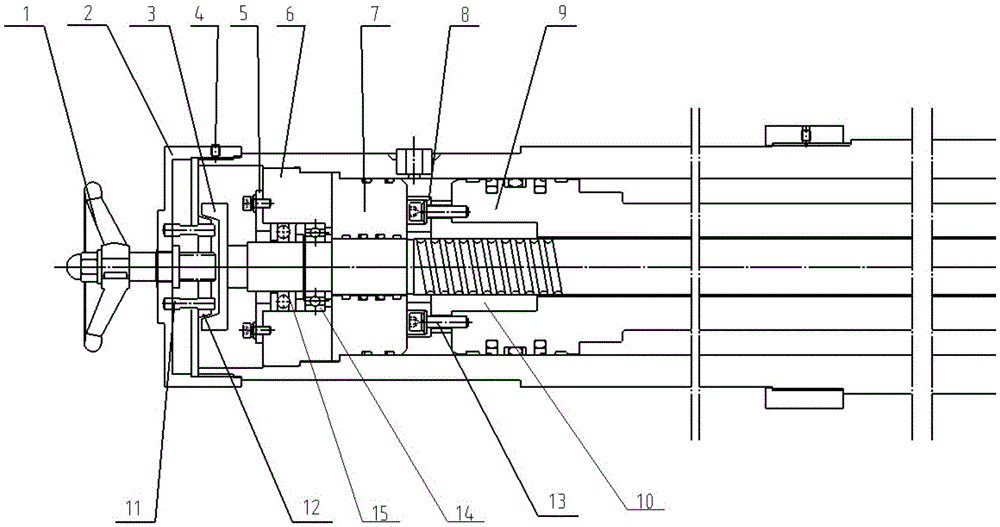

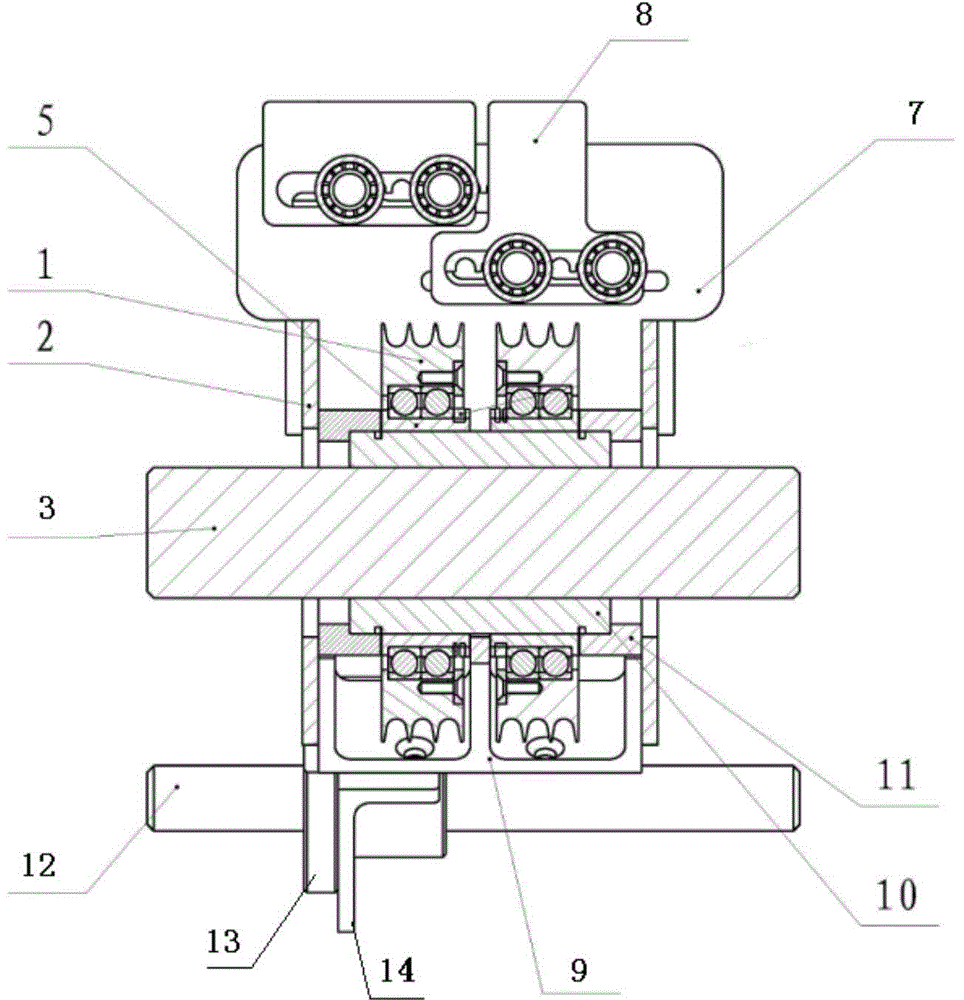

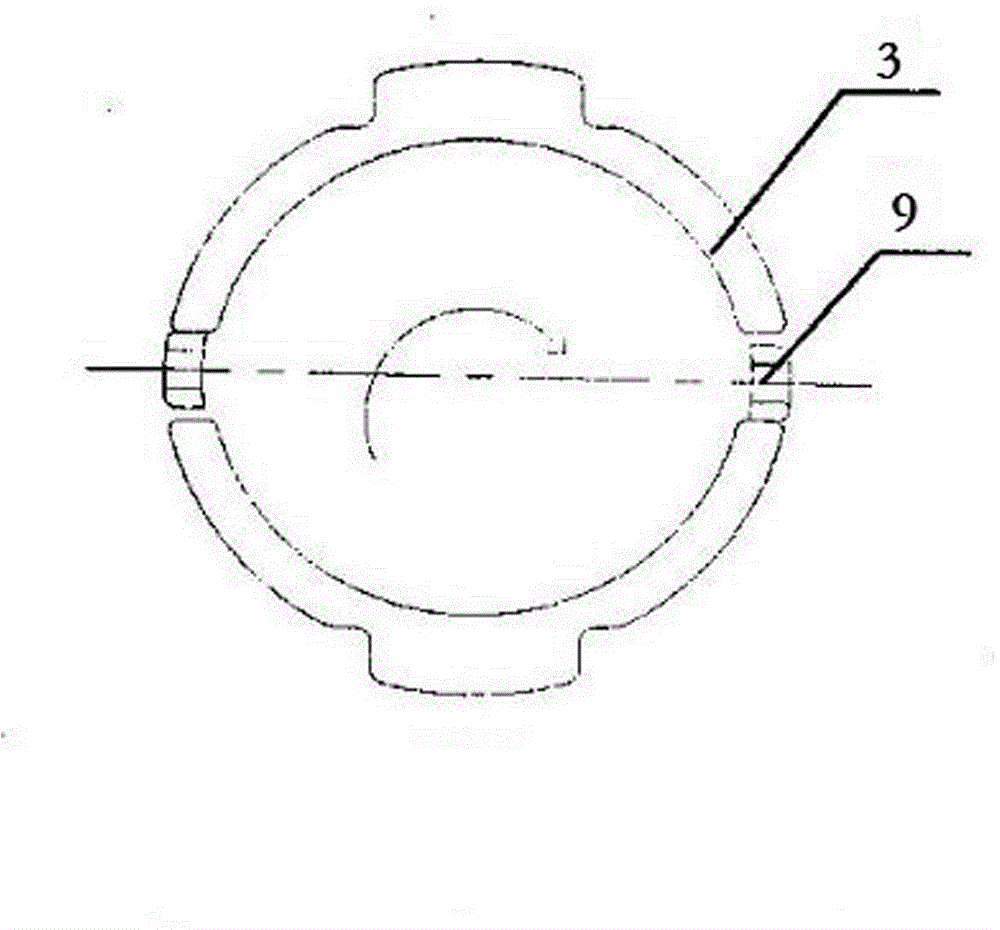

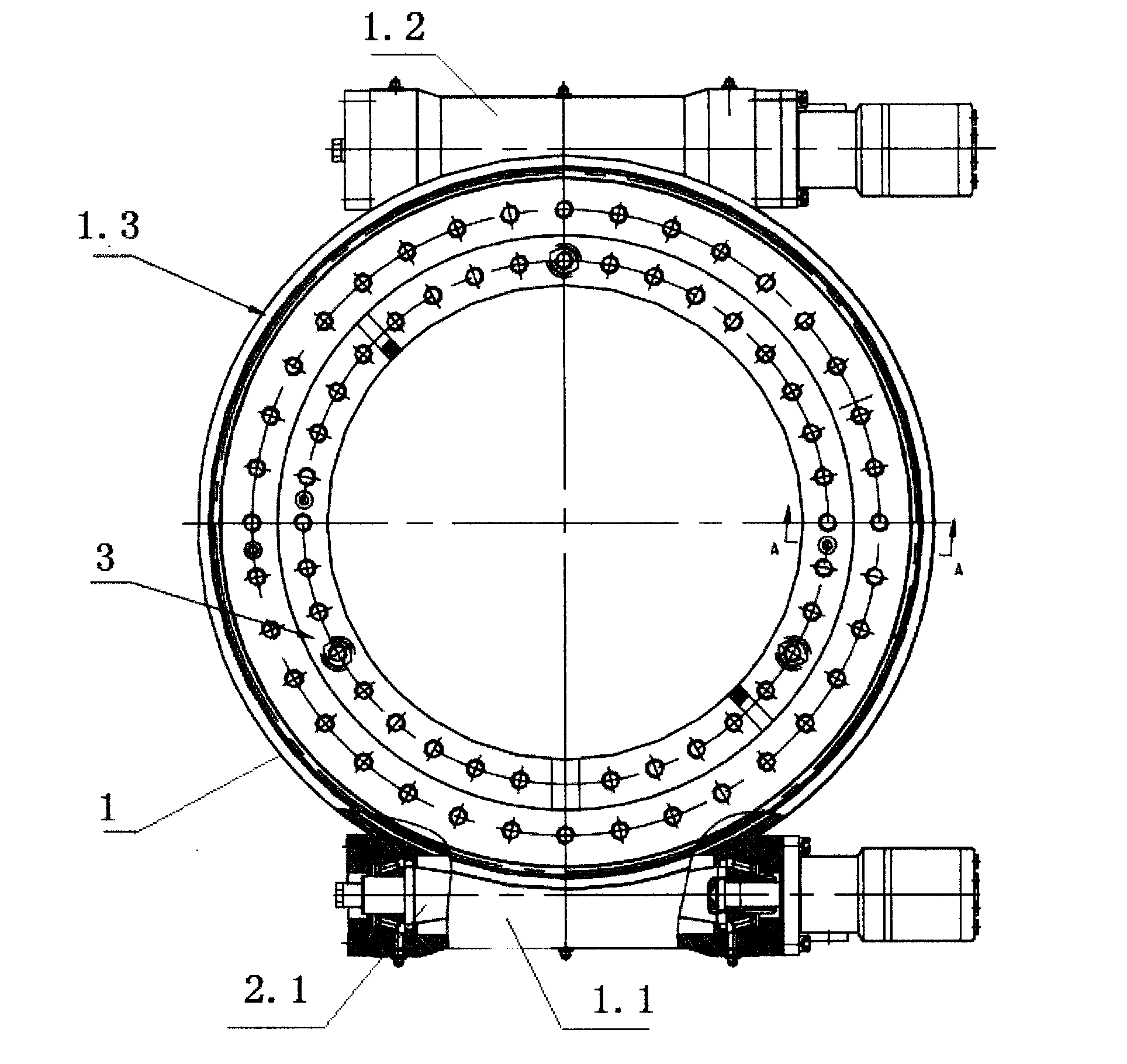

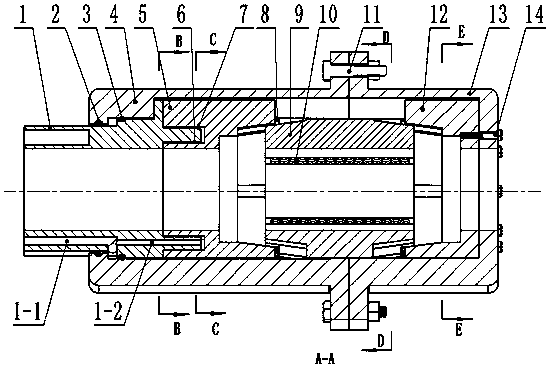

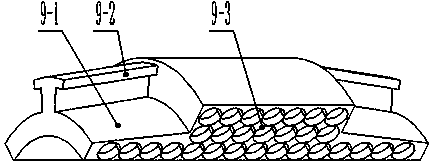

Assembly drum of all-steel meridian large tyre-forming machine

The invention discloses a building drum of an all-steel giant radial tire building machine. The drum comprises wide drum shoe collapsible mechanisms and narrow drum shoe collapsible mechanisms which are driven by a feed screw nut and embedded on a hollow main shaft, two sets of the wide drum shoe collapsible mechanisms and the narrow drum shoe collapsible mechanisms are symmetrically arranged on the right side and the left side, each set of the wide drum shoe collapsible mechanisms and the narrow drum shoe collapsible mechanisms comprises drive sleeves, a wide drum shoe connection rod, a narrow drum shoe connection rod, a left support ring and a right support ring, wherein, the left drive sleeve and the right drive sleeve are sheathed on the hollow main shaft and connected with a left nut and a right nut by a drive key, the left support ring and the right support ring are coaxially and symmetrically fixed on the two sides of the hollow main shaft; one end of the wide drum shoe connection rod and one end of the narrow drum shoe connection rod at the two sides are symmetrically articulated on corresponding drive sleeves, the other end of the wide drum shoe connection rod and the other end of the narrow drum shoe connection rod at the two sides are symmetrically articulated on a wide drum shoe seat and a narrow drum shoe seat; two ends of the wide drum shoe seat and the narrow drum shoe seat are in radial slide fit matched between a left positioning disk and a right positioning disk; drum shoulders form a whole body with the narrow drum shoe and the wide drum shoe after slide adjustment. The building drum has the advantages of good rigidity, strong stability, and fixed adjustment of the drum shoulders of the narrow drum shoe and the wide drum shoe, and the narrow drum shoe and the wide drum shoe without providing a drum shoulder telescopic mechanism.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

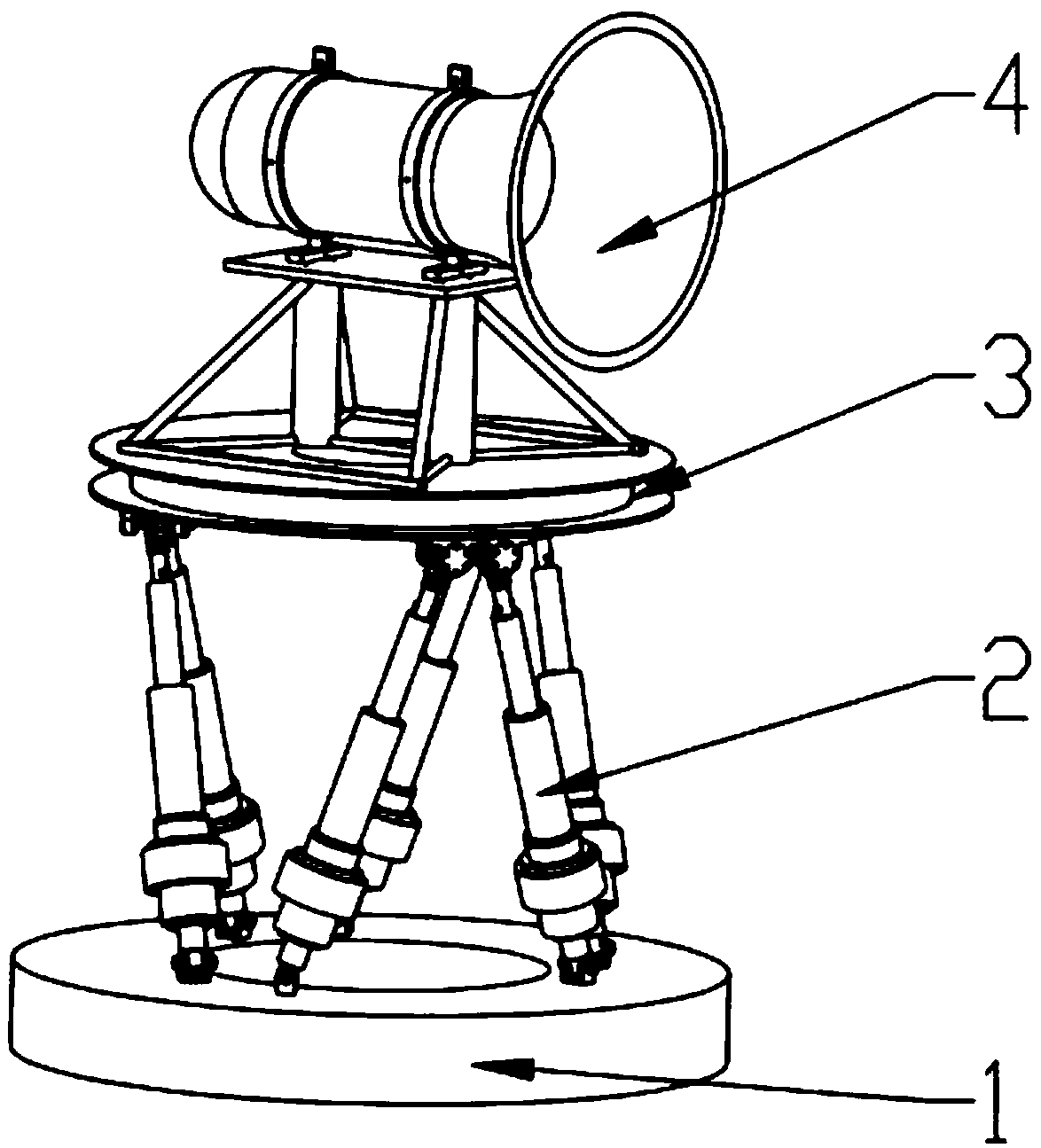

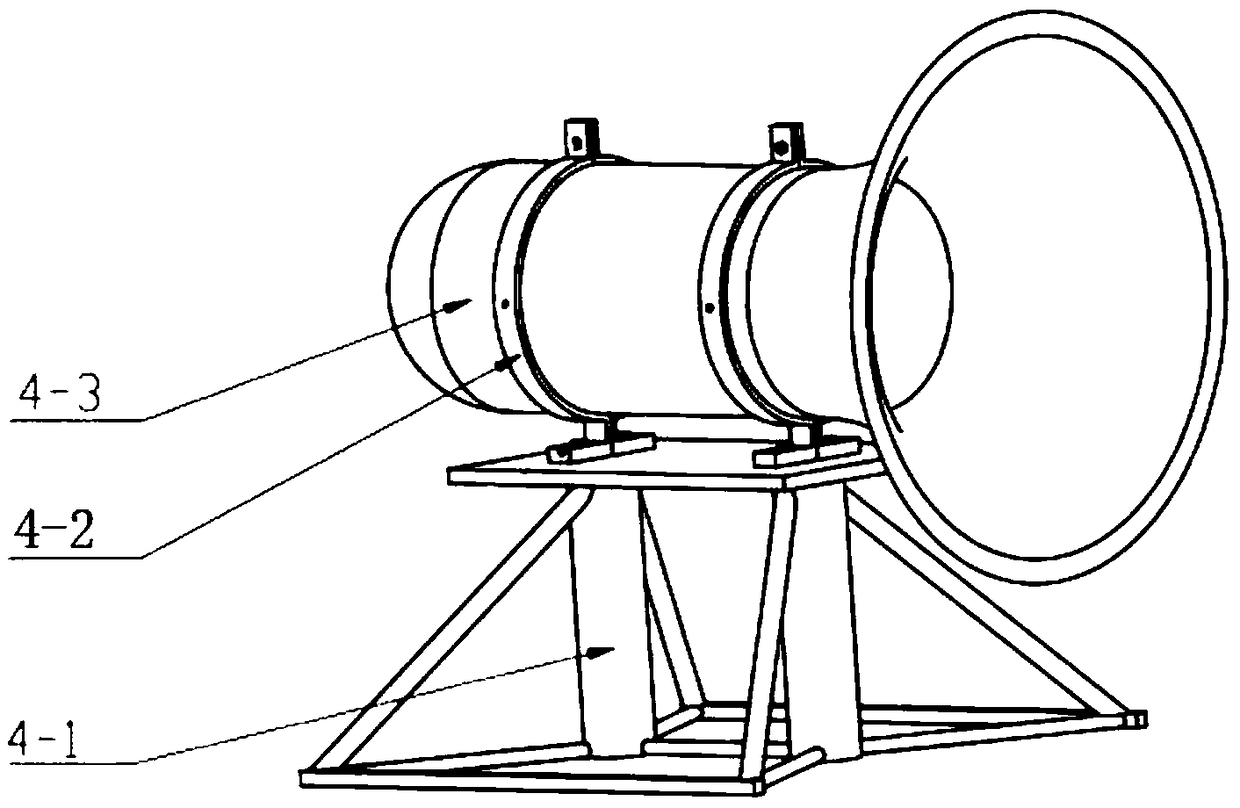

A six-degree-of-freedom underwater recovery device

InactiveCN109263838AGood self-lockingImprove stabilityVessel salvagingUnderwater equipmentMarine engineeringDegrees of freedom

The invention belongs to the field of underwater recovery devices. The purpose is to provide a six-degree-of-freedom underwater recovery device, which can automatically control the conical guide coverto achieve six-degree-of-freedom movement in space, thereby changing the position and attitude of the conical guide cover, thereby increasing the permissible angle of the AUV entering the conical guide cover in disguise. The technical scheme is as follows: a six-degree-of-freedom underwater recovery device is characterized in that the device comprises an upper platform, a lower platform, a docking device fixed on the upper platform for recovering AUV and six telescopic rods sequentially arranged in a W-shape between the upper platform and the lower platform to adjust the position of the docking device; the six telescopic rods have the same structure and the included angle between two adjacent telescopic rods is the same; the lower end of the expansion rod is rotatably connected with the lower platform through a first Hooke hinge, and the upper end of the expansion rod is rotatably connected with the upper platform through a second Hooke hinge.

Owner:ZHEJIANG SCI-TECH UNIV

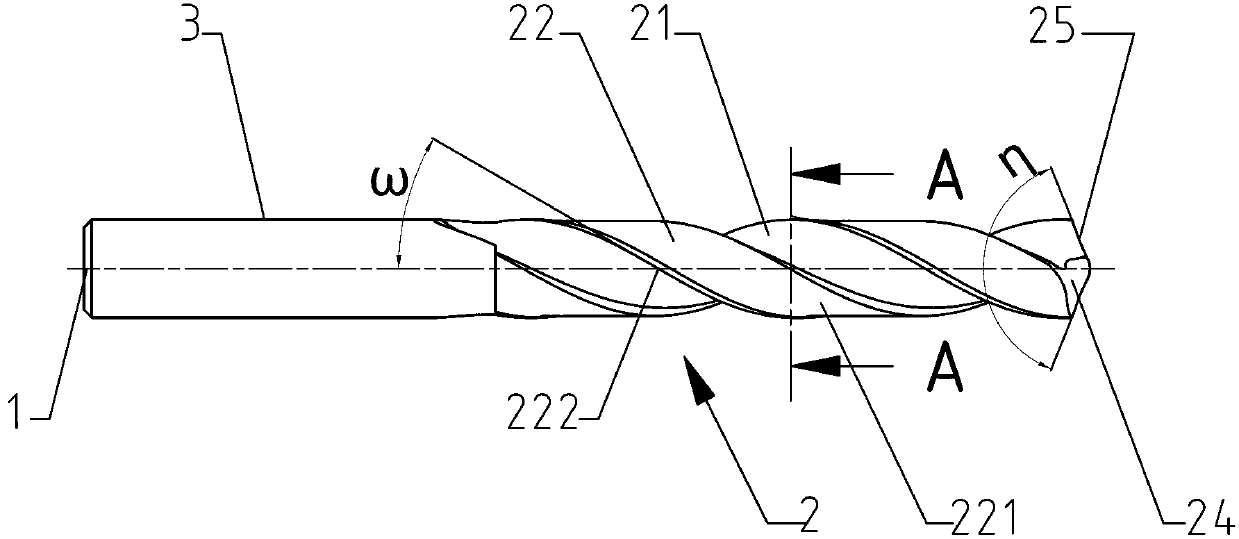

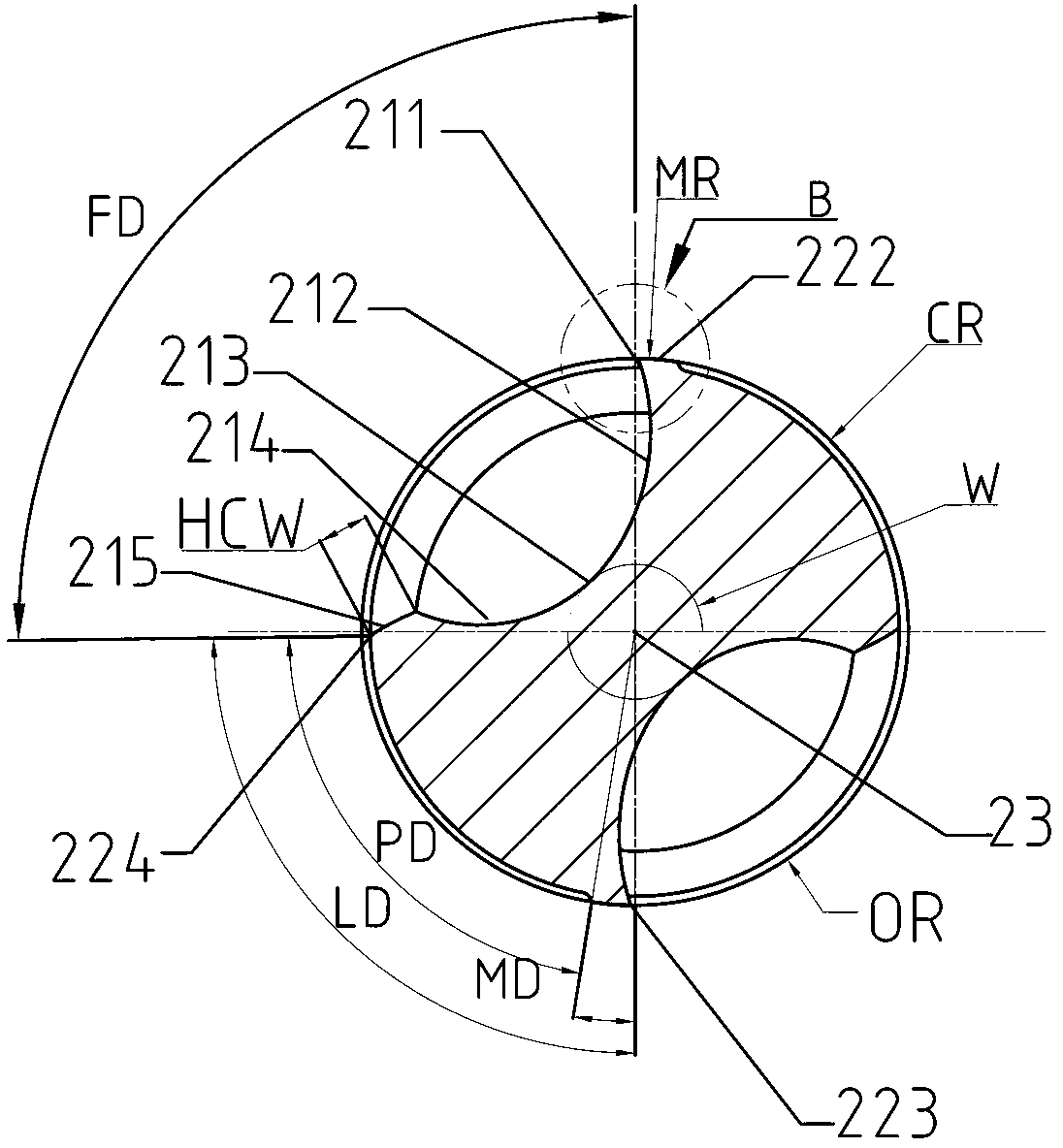

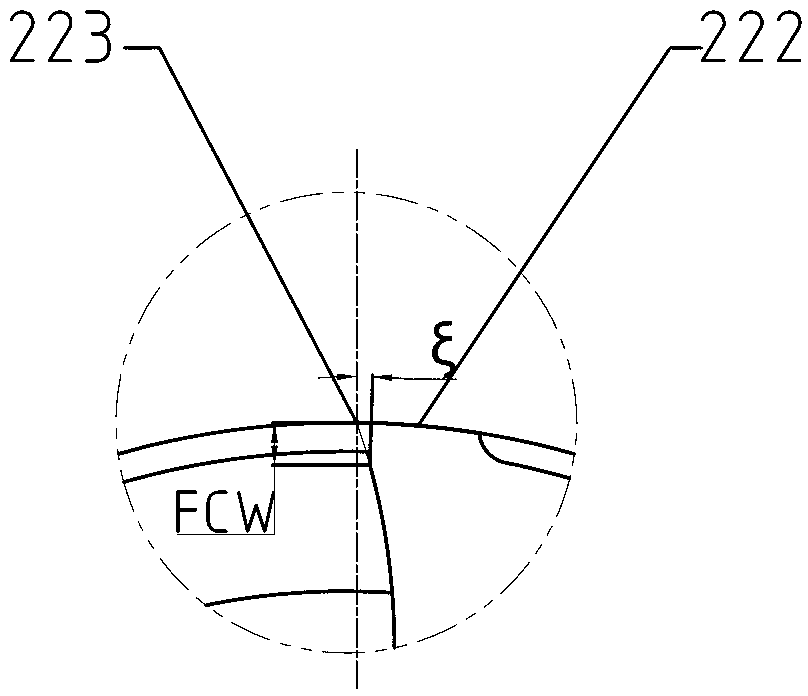

Twist drill with spiral cutting back tool

ActiveCN103128346AExcellent machinabilityGood centering effectTwist drillsStress concentrationEngineering

The invention discloses a twist drill with a spiral cutting back tool. The twist drill with the spiral cutting back tool comprises a cutting portion which rotates around an axis and a handle portion which matches with a jacket. Two grooves which extend from the front end of the cutting portion to the handle portion in a spiral mode and are sued for discharging cutting chips are formed in the cutting portion. The cutting portion is further provided with blade backs which are respectively connected with the periphery of the two grooves. The twist drill with the spiral cutting back tool is characterized in that the grooves form two spiral cutting back tool faces at the front end of the cutting portion, the two cutting back tool faces are intersected in a drill core position to form an S-shaped drill core cutting blade and two main cutting blades, the main cutting blade is connected with the S-shaped drill core cutting blade through a cutting blade connection portion in a smooth mode, each cutting back tool face begins from the main cutting blade and is formed by smoothly connecting a main back blade face, a transition face and a the cutting back tool face stop face. According to the twist drill with the spiral cutting back tool, the spiral cutting back tool faces are intersected to form the S-shaped drill core cutting blade which is connected with the main cutting blade in a smooth mode, stress concentration is greatly reduced, drilling load and centring capacity are further improved, and the twist drill with the spiral cutting back tool is easy to be widely popularized.

Owner:大连远东工具有限公司

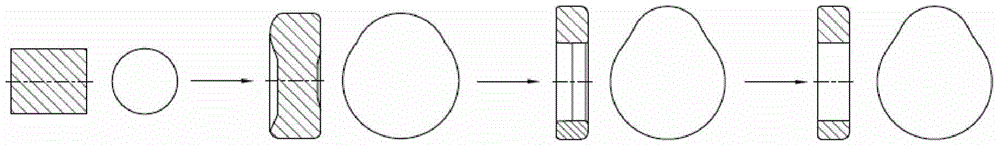

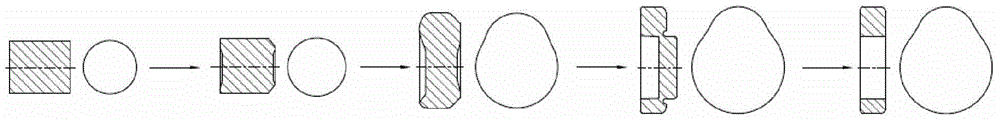

Precise cold forging formed cam sheet manufacturing method

ActiveCN104148574AReduce tensile stressReduce the expansion rateMetal-working apparatusEngine componentsWire rodBall bearing

The invention relates to a precise cold forging formed cam sheet manufacturing method. The manufacturing method includes the steps of A, pretreatment, B, cold forging forming and C, thermal treatment, wherein in the step A, a steel wire rod or a steel bar is annealed, drawn and lubricated, so that a first blank suitable for cold upsetting forming is obtained; in the step B, a cam sheet is forged through a horizontal or vertical forging machine, and the cold forging forming step includes an expansion and extrusion procedure. Due to the adoption of the expansion and extrusion technology, acquisition of a ball bearing steel cold forging cam is possible for the first time; compared with the traditional upsetting technology, forging force is greatly reduced, the cold hardening speed is low, cracks are not likely to generate, the service life of a die is greatly prolonged, a metallographic structure can not be changed in the cold forging process, and a surface structure is free of the carbon insufficiency risk; due to the fact that a finally-used outline is obtained through precise extrusion or finishing directly, the outline of the cam does not need to be ground, and equipment investment and part cost are greatly reduced.

Owner:HANGZHOU XZB TECH

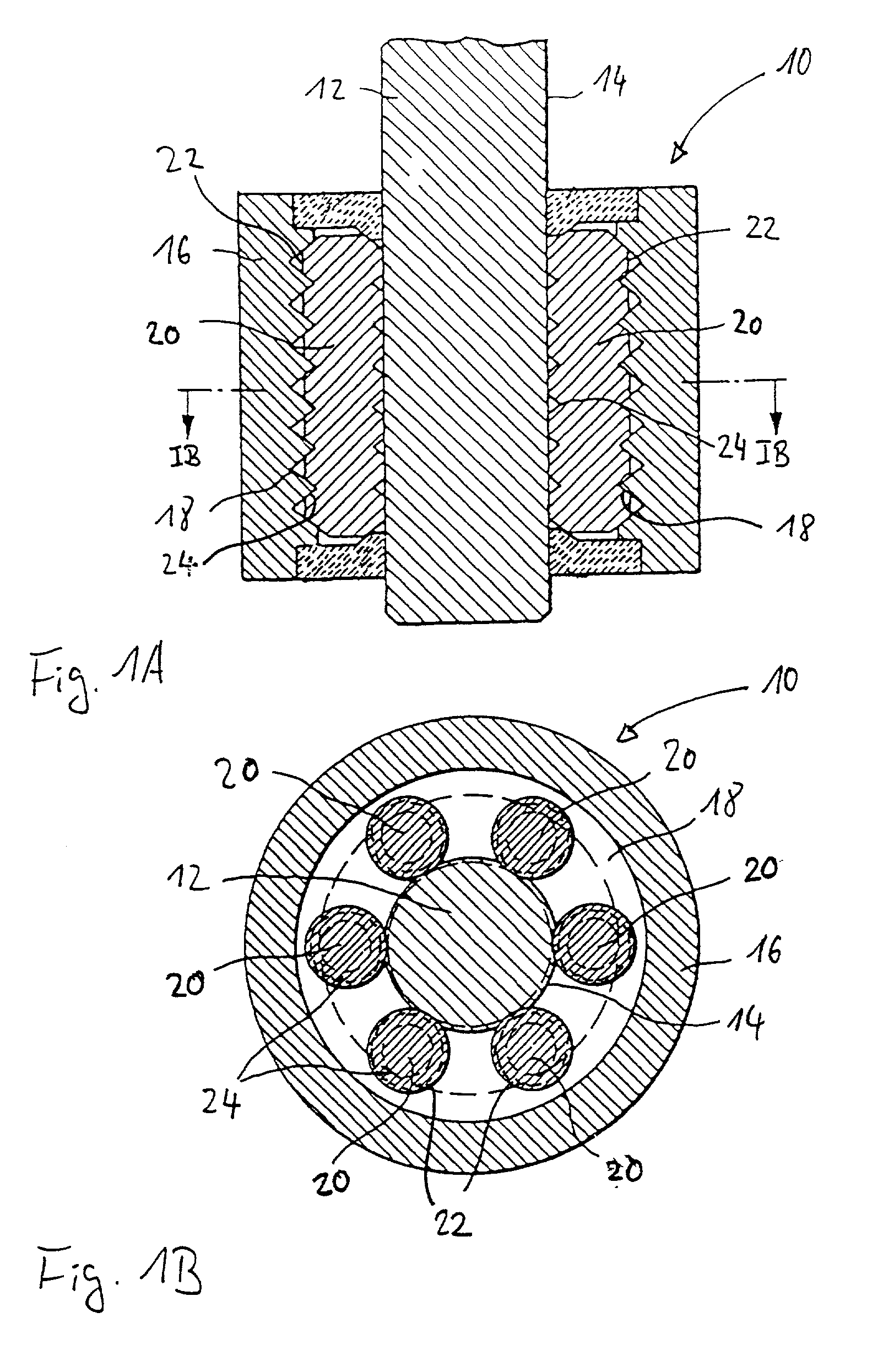

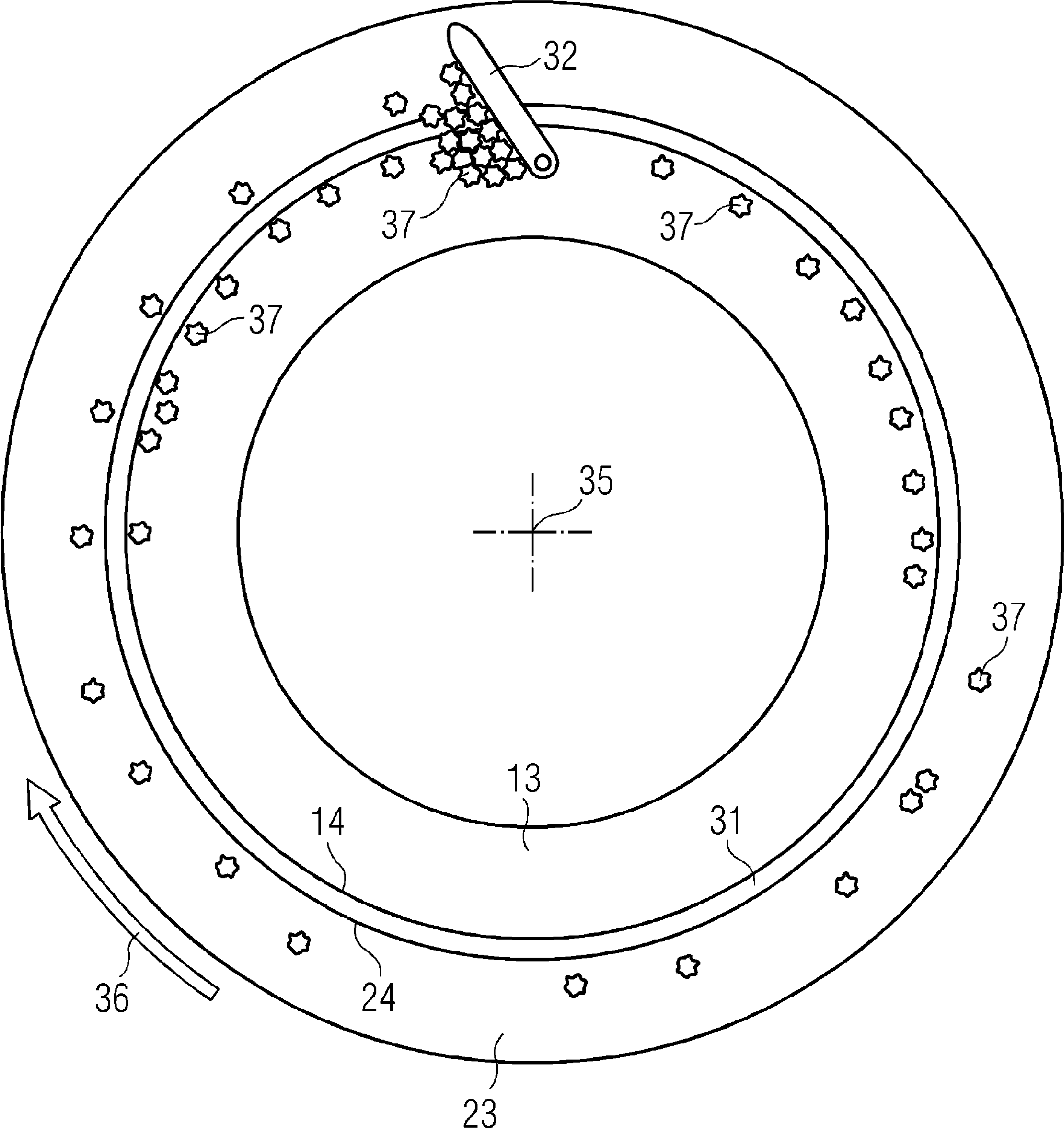

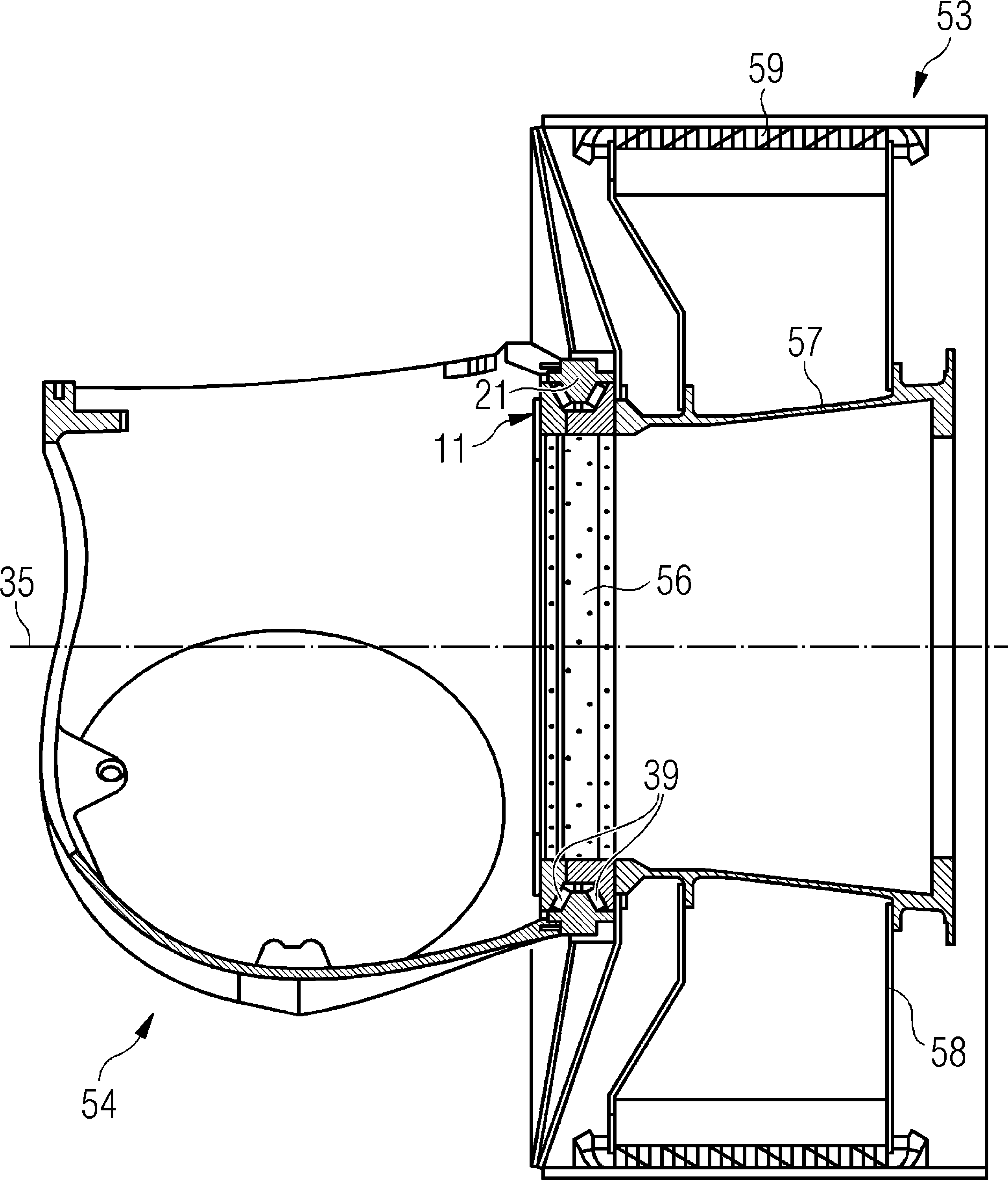

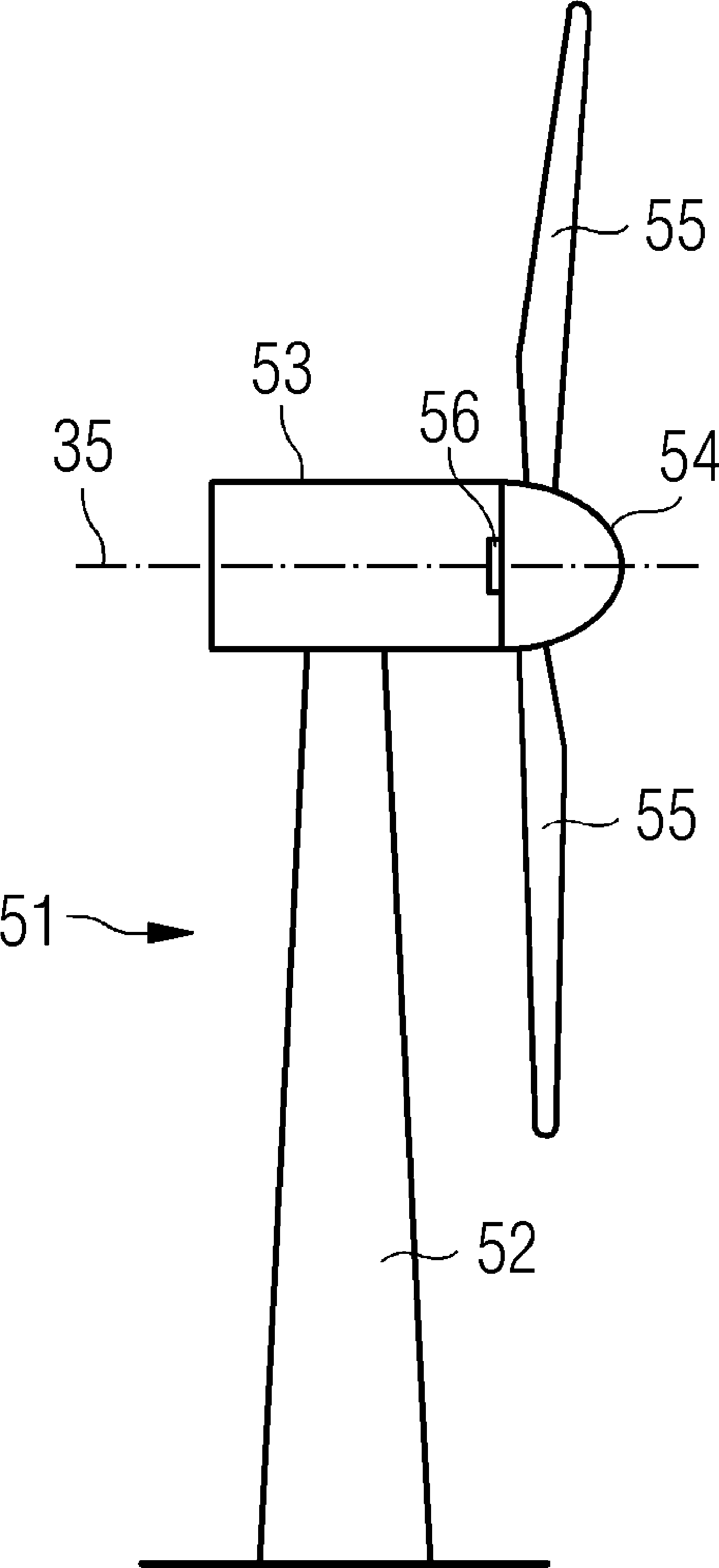

Bearing and method of collecting a lubricant leaking out of a bearing

ActiveCN103967936ALarge axial forceLarge radial forceShaftsBearing componentsCollection systemGravitational force

A bearing, which is suitable for a wind turbine, with a lubricant collection system is provided. The bearing comprises a first bearing component with a first contact face and a first front face. It furthermore comprises a second bearing component with a second contact face and a second front face. The first front face is coupled with the first contact face; the second front face is coupled with the second contact face. The first bearing component and the second bearing component are movable relative to each other. The first contact face and the second contact face are prepared and arranged in a way to accommodate a lubricant. Furthermore, the bearing comprises a scraper, which is attached to the first front face and is in contact with the second front face. Finally, the invention also relates to a method of collecting a lubricant leaking out of a bearing, wherein the bearing is suitable for a wind turbine and comprises a first step of scraping off the lubricant escaping from in-between the first contact face and the second contact face, and a second step of guiding the scraped-off lubricant to a lubricant collection device by means of gravitational force.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

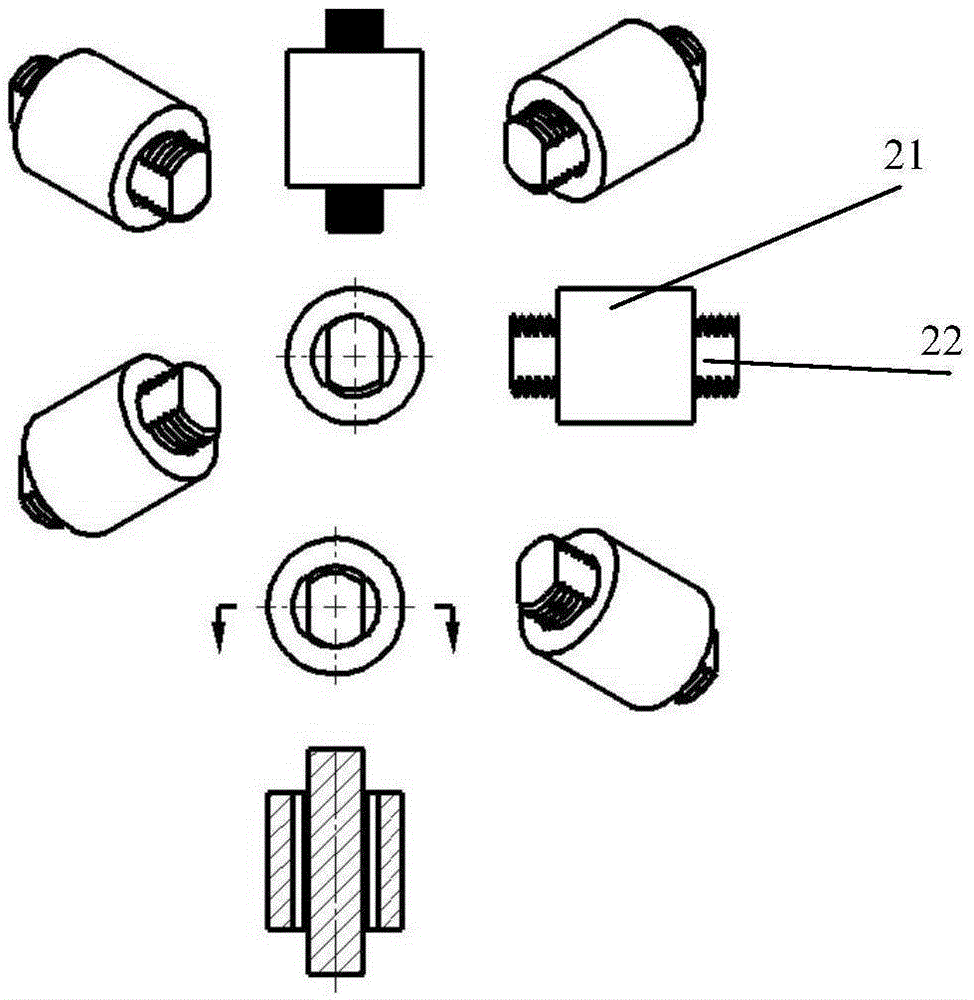

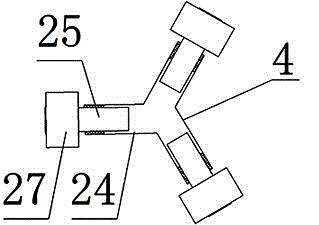

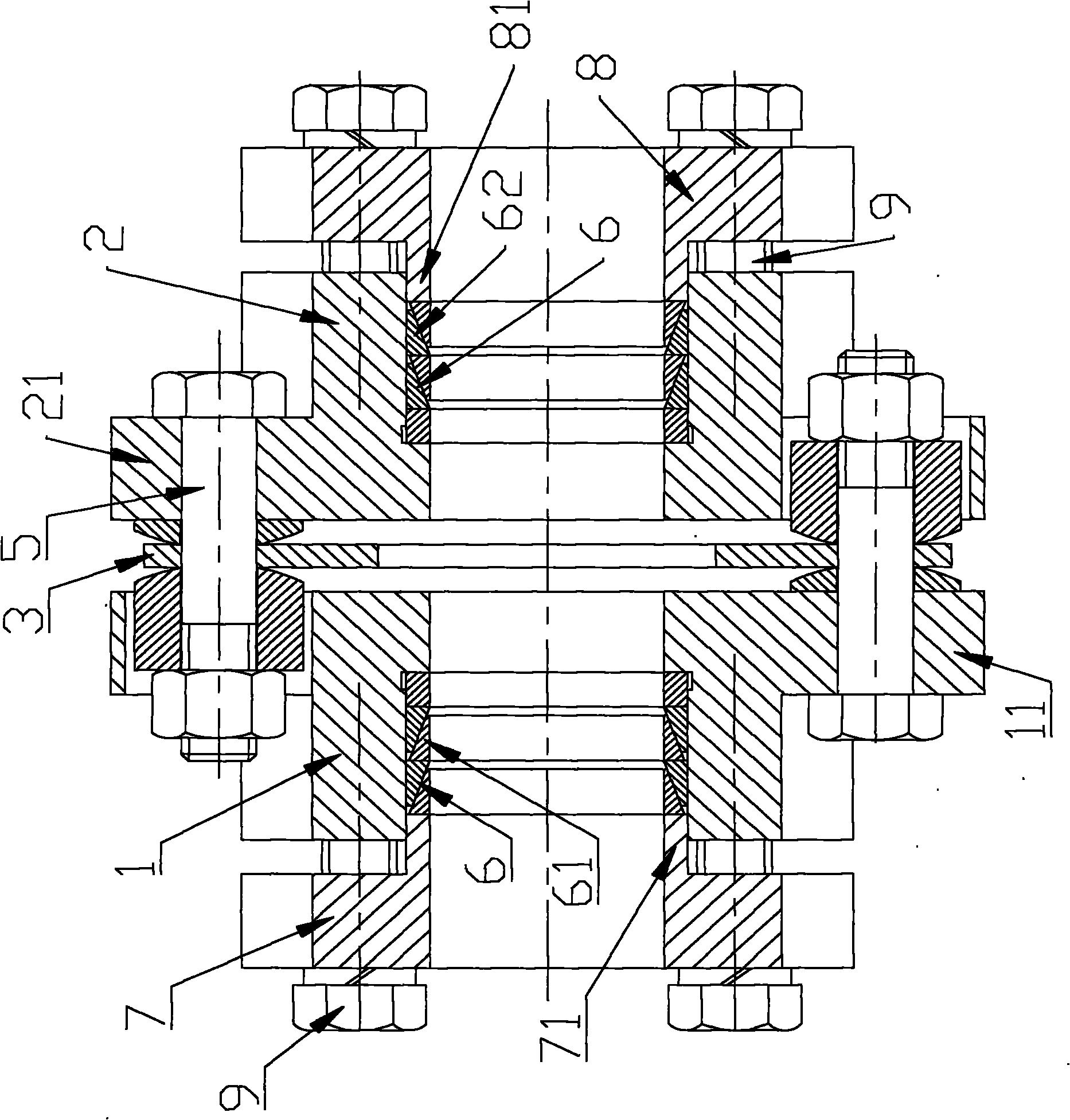

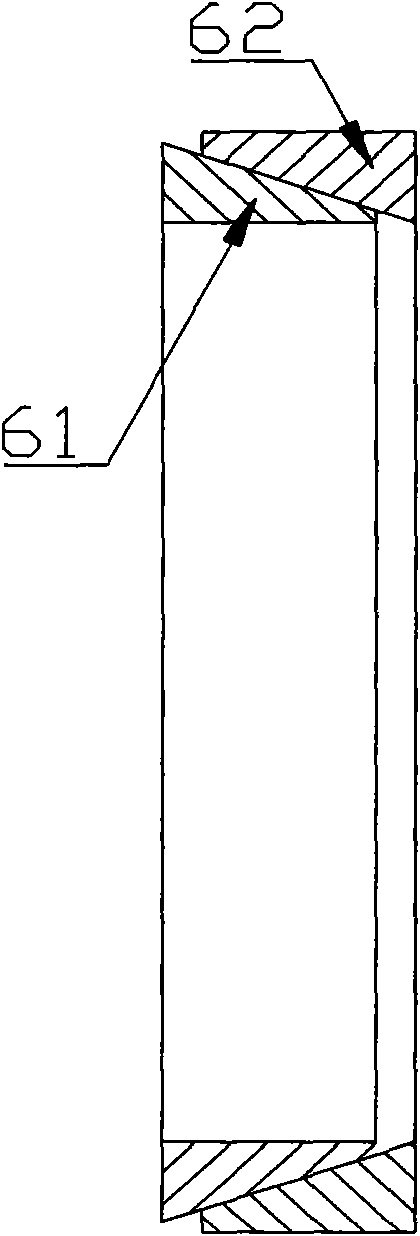

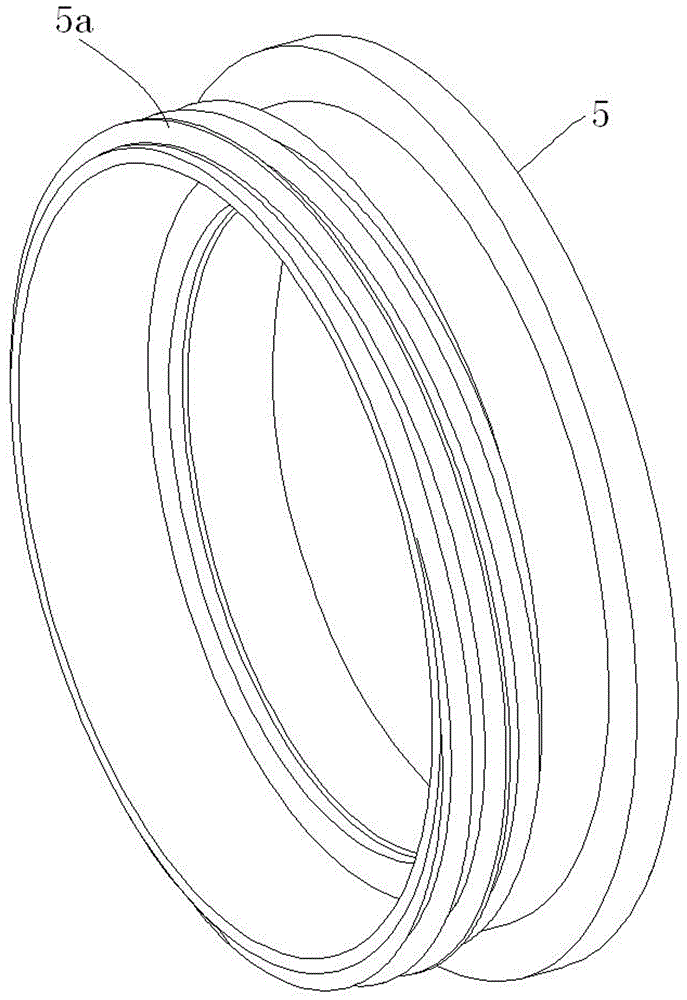

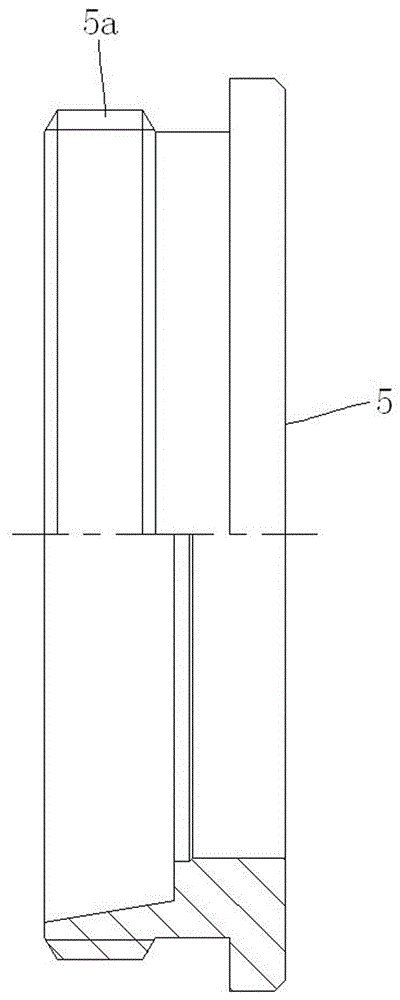

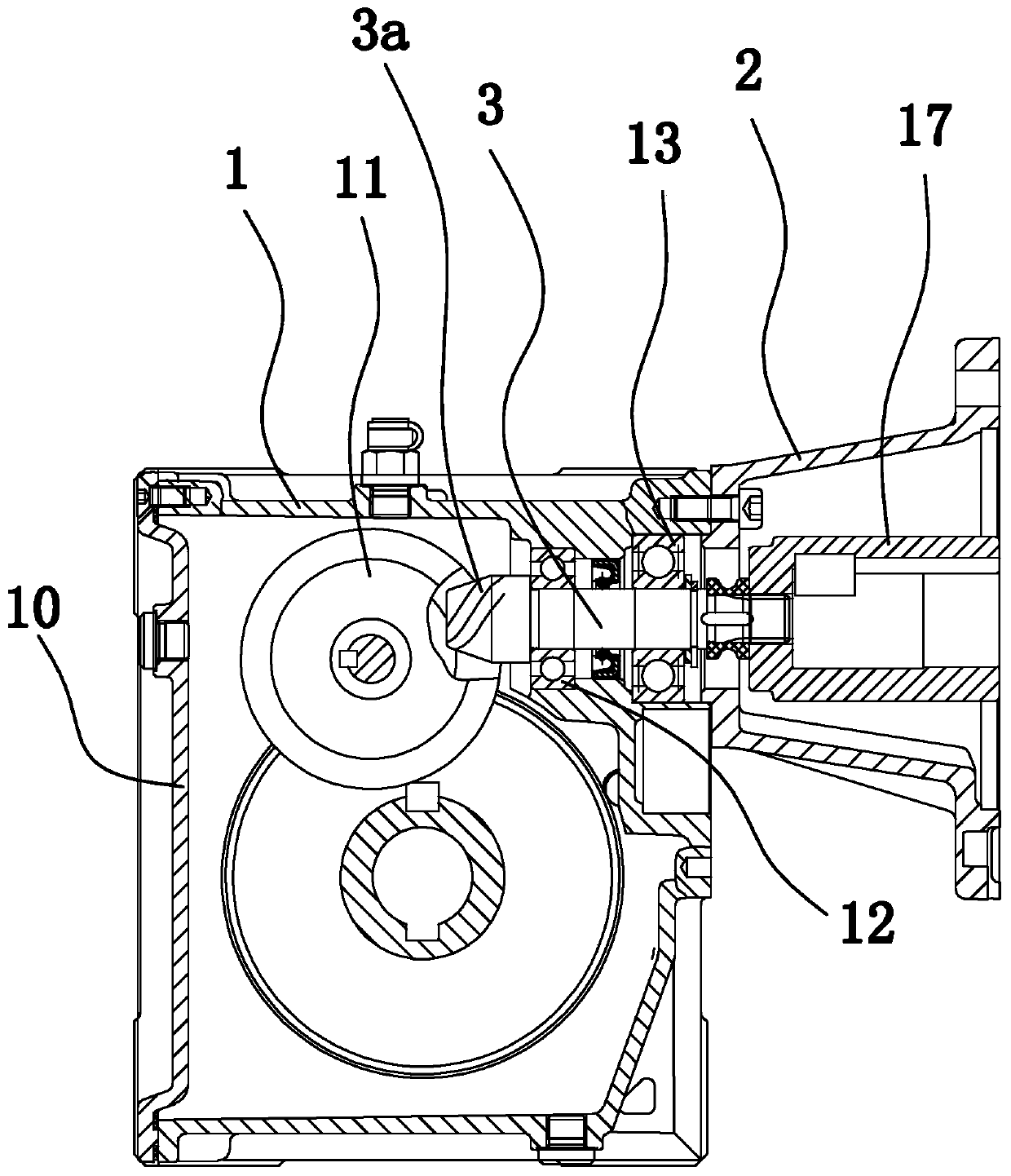

Elastic coupling of one-way precise diaphragm

The invention provides an elastic coupling of a one-way precise diaphragm, which has the advantages of simple structure, low cost and capability of supporting large repeated fluctuating loads, impact loads and bending moment. An input flange and an output flange of the elastic coupling and the diaphragm between the input flange and the output flange are connected by bolts; an expansion sleeve consisting of an outer conical ring and an inner conical ring is arranged in shaft holes of an input shaft and an output shaft; the inner conical ring and the outer conical ring are cones which have radial notches and are unclosed in a circumferential direction; the outer peripheral surface of the inner conical ring and the inner peripheral surface of the outer conical ring are conical surfaces which are matched mutually; the elastic coupling also comprises two end covers which are respectively connected with the input shaft and the output shaft through the bolts in an axial direction; and compaction parts which extend into the shaft hole of the input shaft or the output shaft and are contacted with the end face of the expansion sleeve are arranged on the end cover, and when moving along the axial direction, the compaction parts push the inner conical ring or the outer conical ring to move axially and reduce the inner peripheral diameter of the inner conical ring.

Owner:溧阳市威联传动机械有限公司

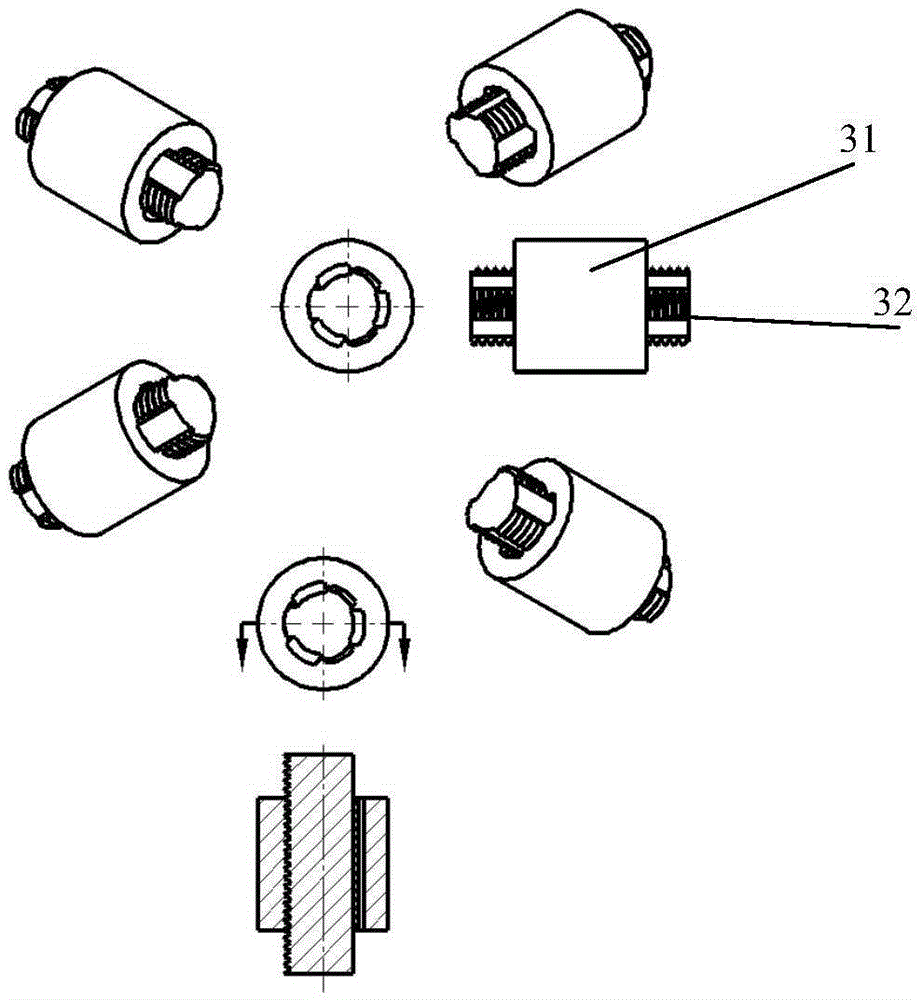

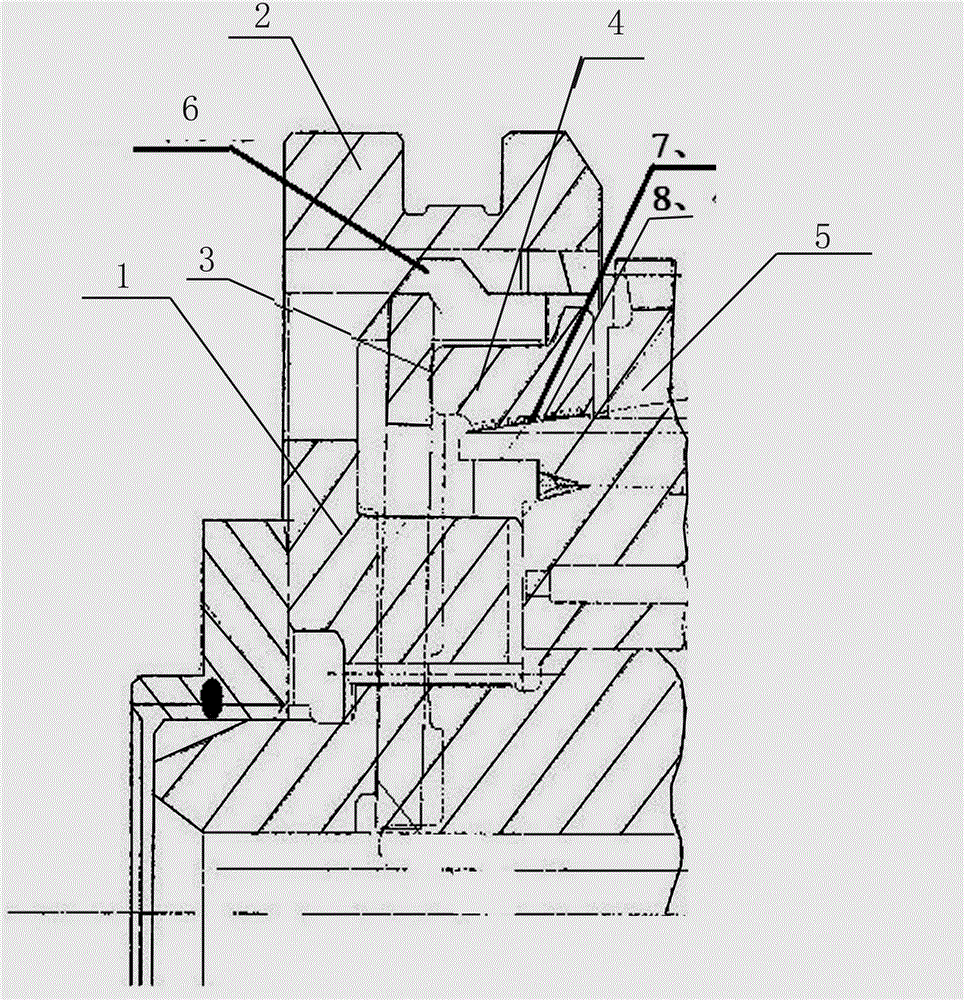

Waterproof self-locking radio-frequency coaxial connector assembly

InactiveCN106654700ASmooth transmissionImprove locking forceEngagement/disengagement of coupling partsCouplings bases/casesElectrical conductorRadio frequency signal

The invention discloses a waterproof self-locking radio-frequency coaxial connector assembly. The assembly comprises male and female radio-frequency coaxial connectors; the male connector comprises a cylindrical clamping jaw, a bush and a thread sleeve; a conical hole and a clamping jaw annular bulge are arranged at the front end of a cylindrical body of the clamping jaw; the clamping jaw annular bulge is provided with an outwards tilted radial conical surface which is tilted outwards and radially; an outer threaded section is arranged on the outer wall surface of the bush; the thread sleeve is provided with an inner threaded section and a first thread sleeve annular bulge which is bulged inwards; the thread sleeve is in threaded connection with the outer threaded section of the bush through the inner threaded section; the first thread sleeve annular bulge props against the outer conical surface when the thread sleeve is moved forwards through manual screwing; the outwards tilted radial conical surface of the clamping jaw props against a female annular bulge; the assembly further comprises a cylindrical waterproof sleeve made of an elastic waterproof material; and two ends of the waterproof sleeve tightly sleeve a female outer conductor and a cable respectively. According to the assembly, the female and male connectors are not mutually rotated and moved after being inserted and combined, so that stable dynamic intermodulation and stable radio-frequency signal transmission are achieved and the waterproof effect is good.

Owner:CHANGZHOU XINSHENG ELECTRONICS

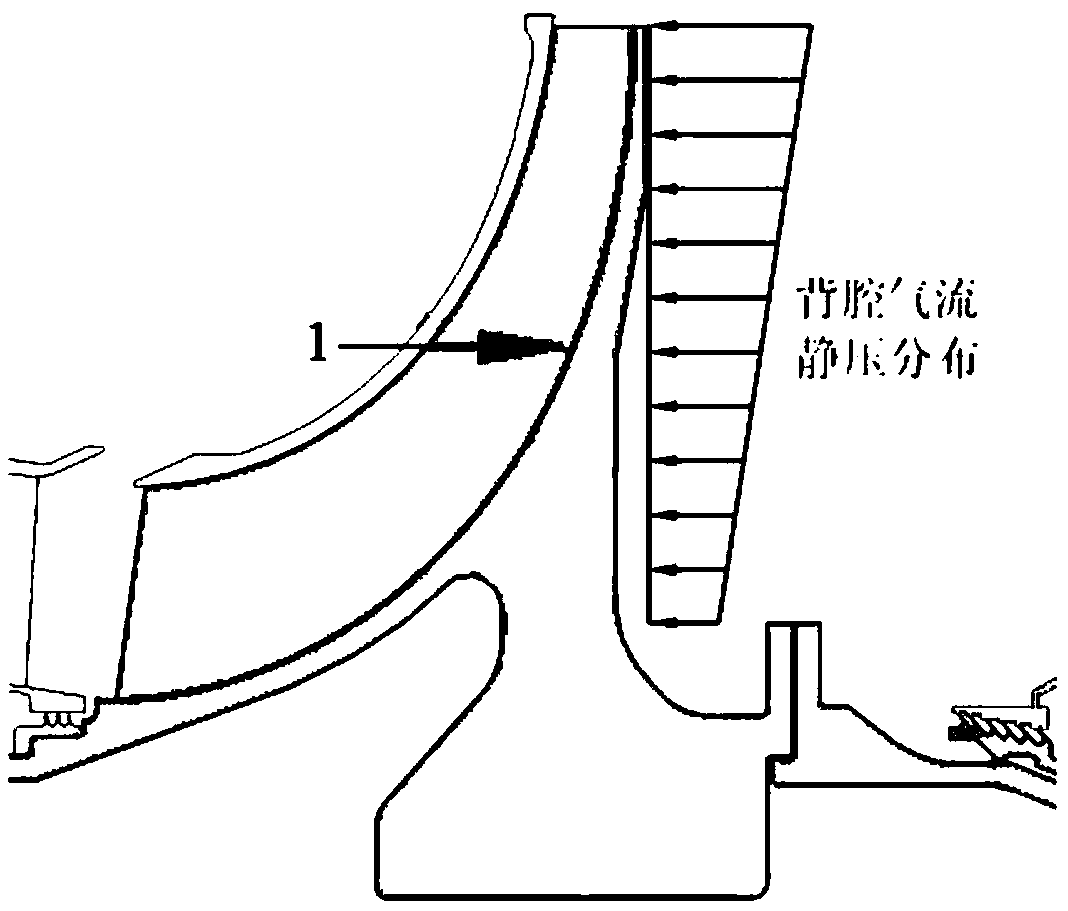

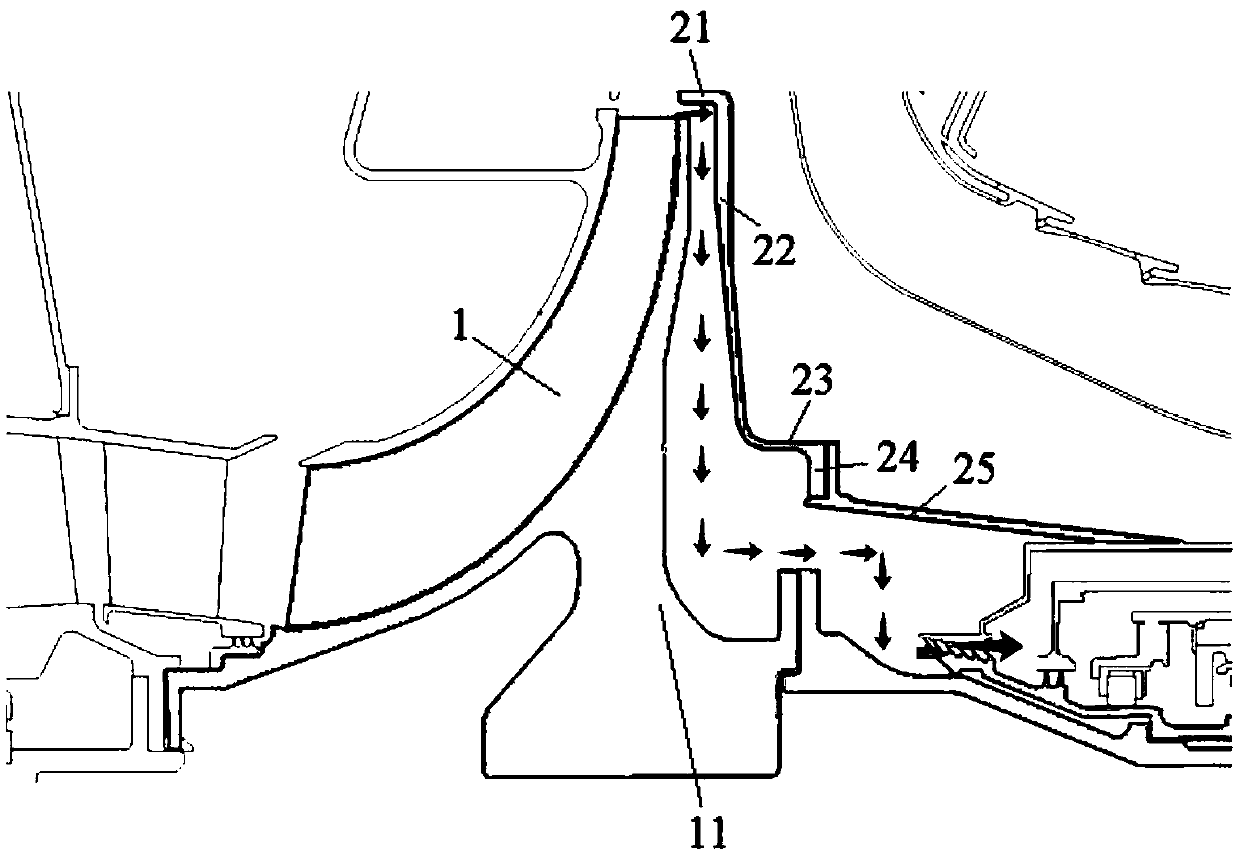

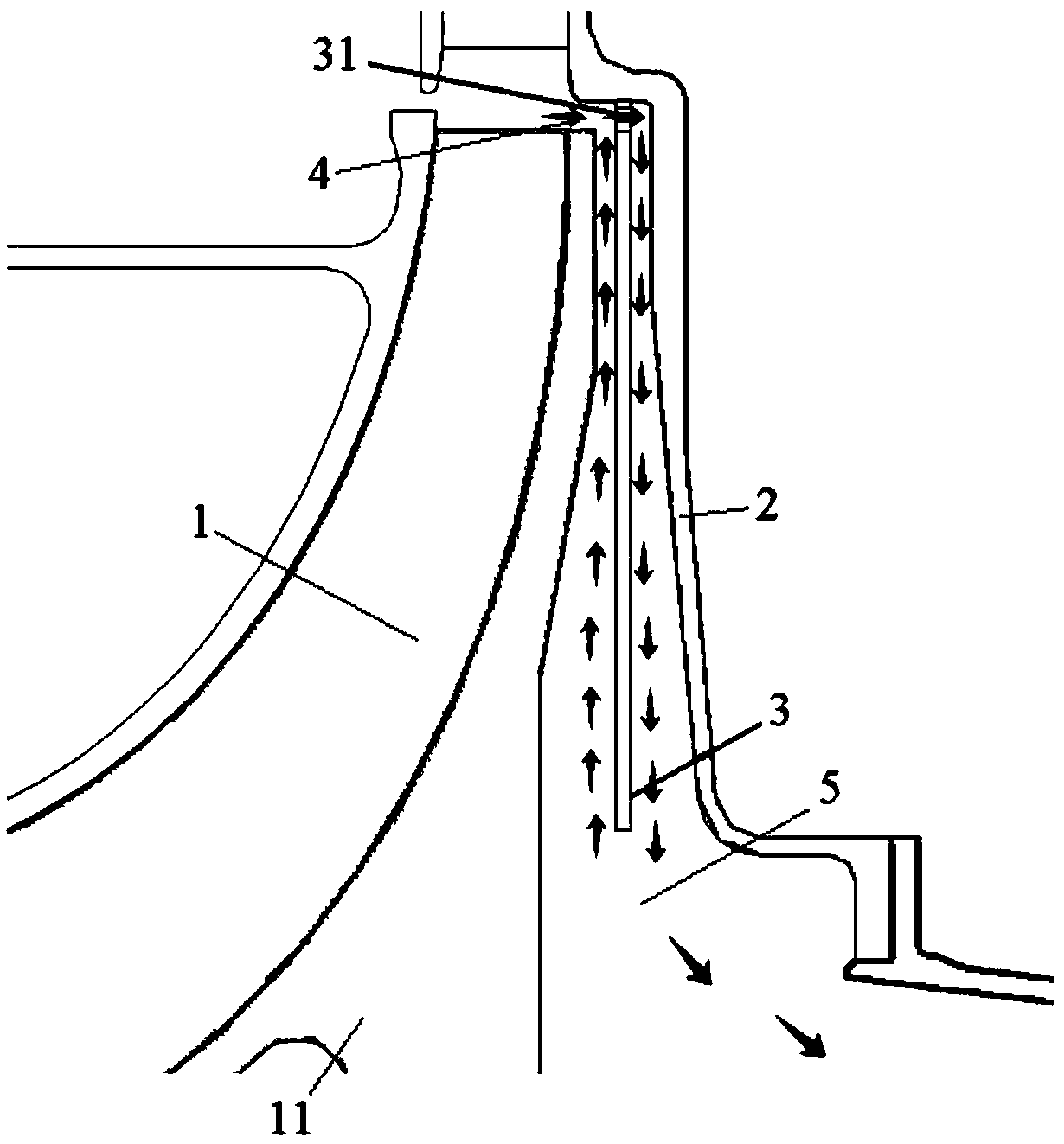

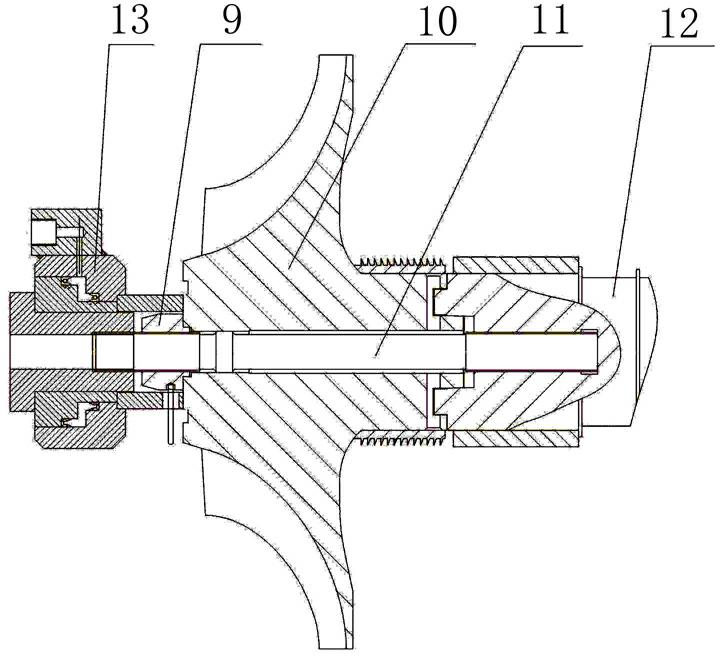

Centrifugal compressor air entraining structure and gas turbine engine

ActiveCN109578337AReduce radial pressure dropMeet cooling and sealing requirementsPump componentsPumpsAxial forceCentrifugal force

The invention relates to the technical field of turbine engines, and provides a centrifugal compressor air entraining structure and a gas turbine engine. The air entraining structure comprises a centrifugal impeller disc, a baffle and an annular partition plate, the baffle and the centrifugal impeller disc form a stator gap and a back cavity, the stator gap communicates with the back cavity, the annular partition plate is connected to the baffle and located between the centrifugal impeller disc and the baffle, the annular partition plate is provided with a through hole right opposite to the stator gap so that airflow at an outlet of a centrifugal impeller can pass through the stator gap and the through hole to flow into the space between the annular partition plate and the baffle, airflowsurrounding the annular partition plate is formed, the flow direction of the airflow between the centrifugal impeller disc and the annular partition plate is outward in the radial direction, the coriolis force direction is opposite to the airflow tangential speed direction, influences of centrifugal force produced by airflow tangential movement are weakened, radial pressure drop of airflow of theback cavity can be reduced, the average static pressure of the back cavity can be increased, and therefore forward axial force of the back cavity of the centrifugal impeller disc is increased.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

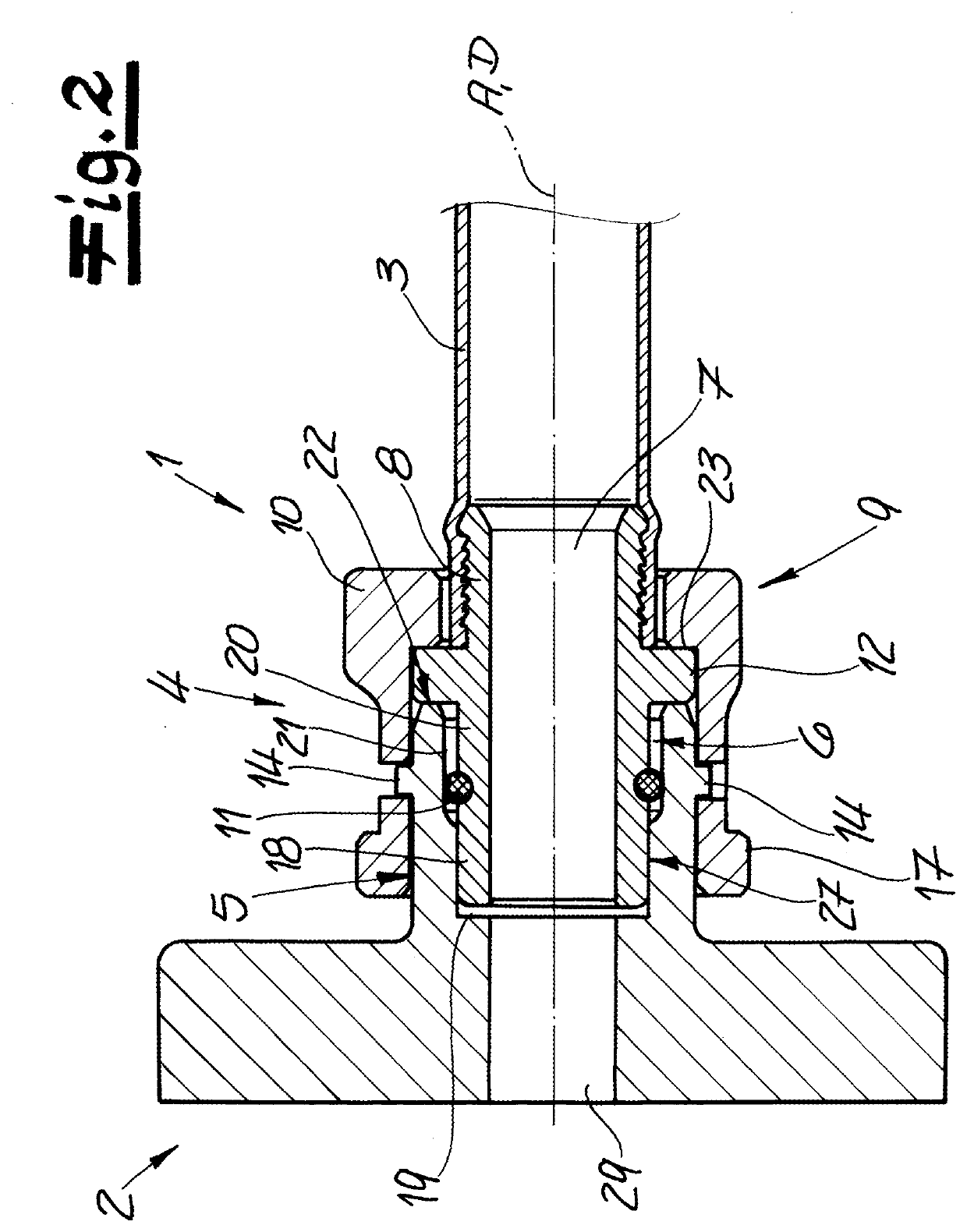

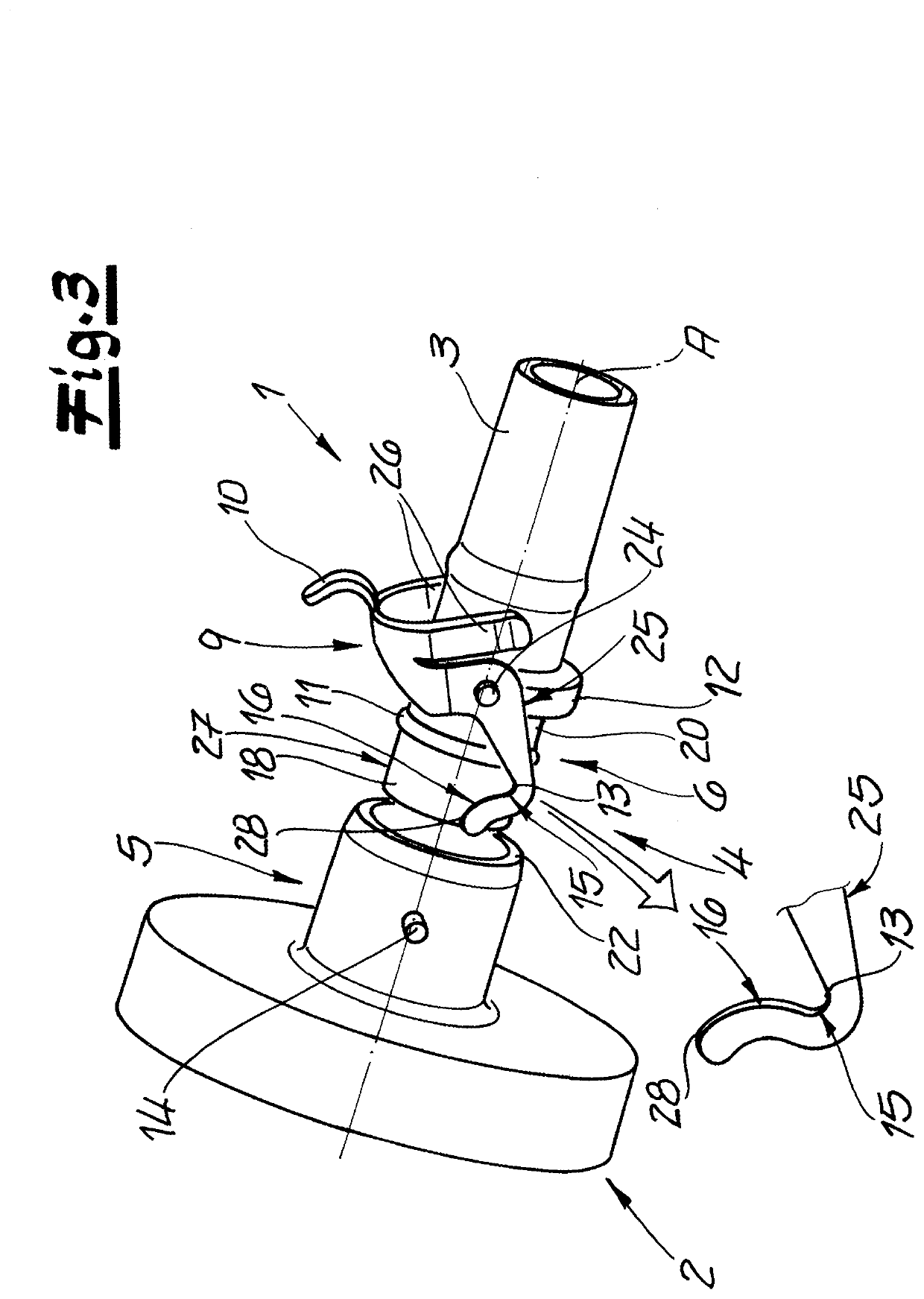

Fluid line for connection with a coupling

PendingUS20220364667A1Easy to produceEasy to set upPipe laying and repairPipe couplingsTemperingCoupling

A method for producing a tube arrangement for the transport of tempering medium, in which base body sections are provided, which have congruently configured separating surfaces, wherein at least one functional element on at least one base body section is arranged in such a way that it can be in contact with the tempering medium, whereafter the base body sections are joined along the separating surface and bonded to one another to form the tube arrangement.

Owner:TI AUTOMOTIVE FULDABRUECK

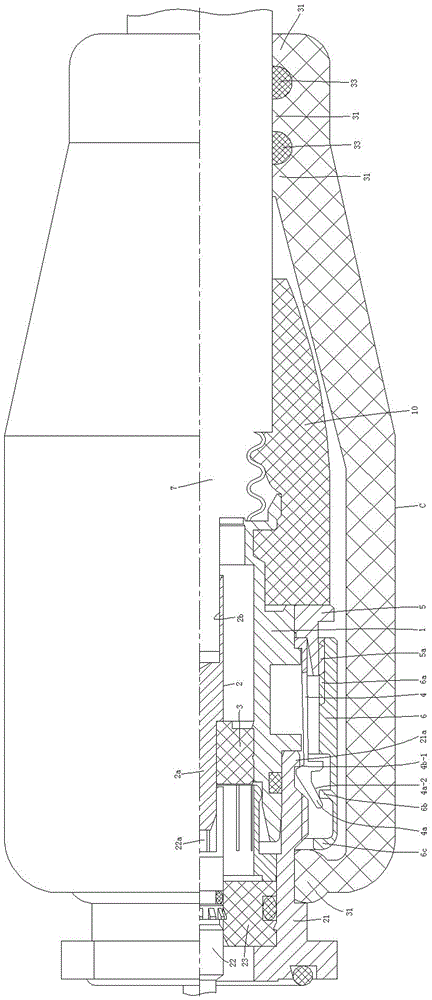

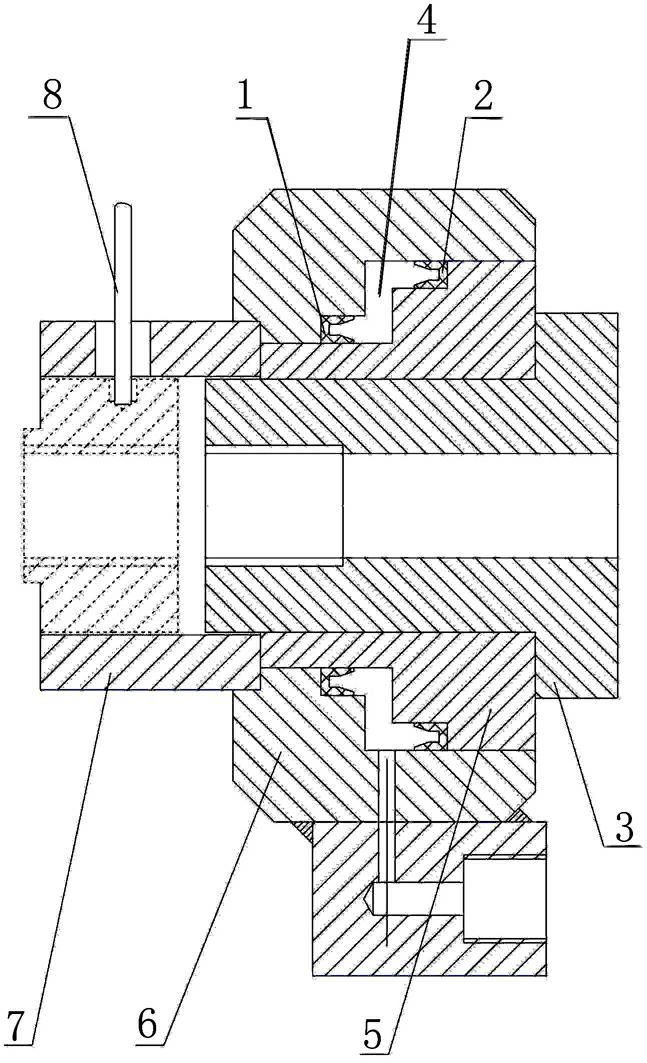

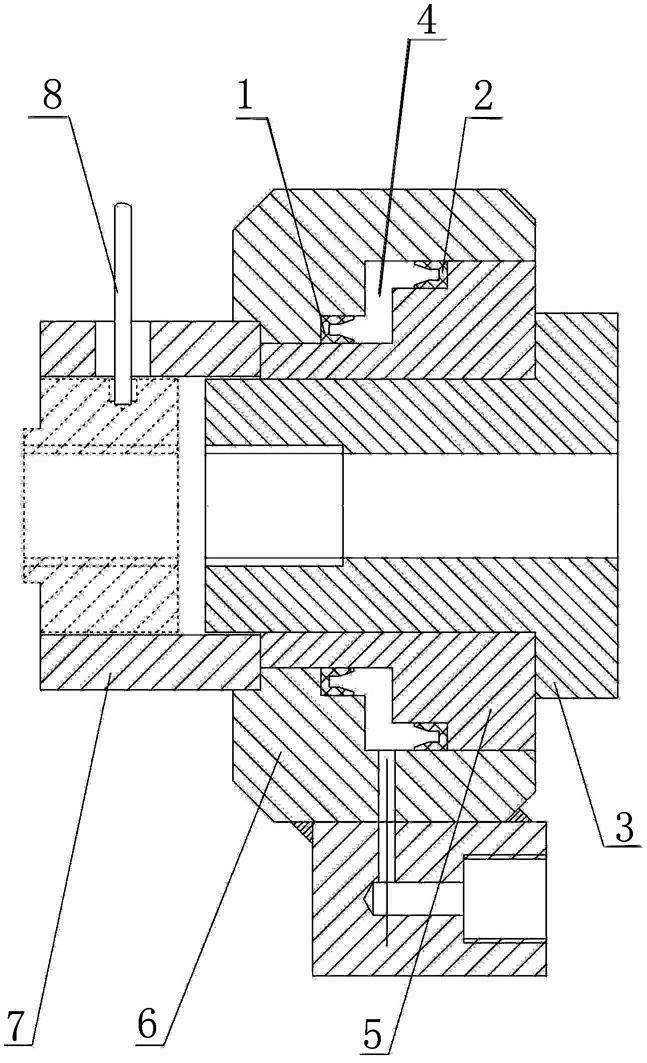

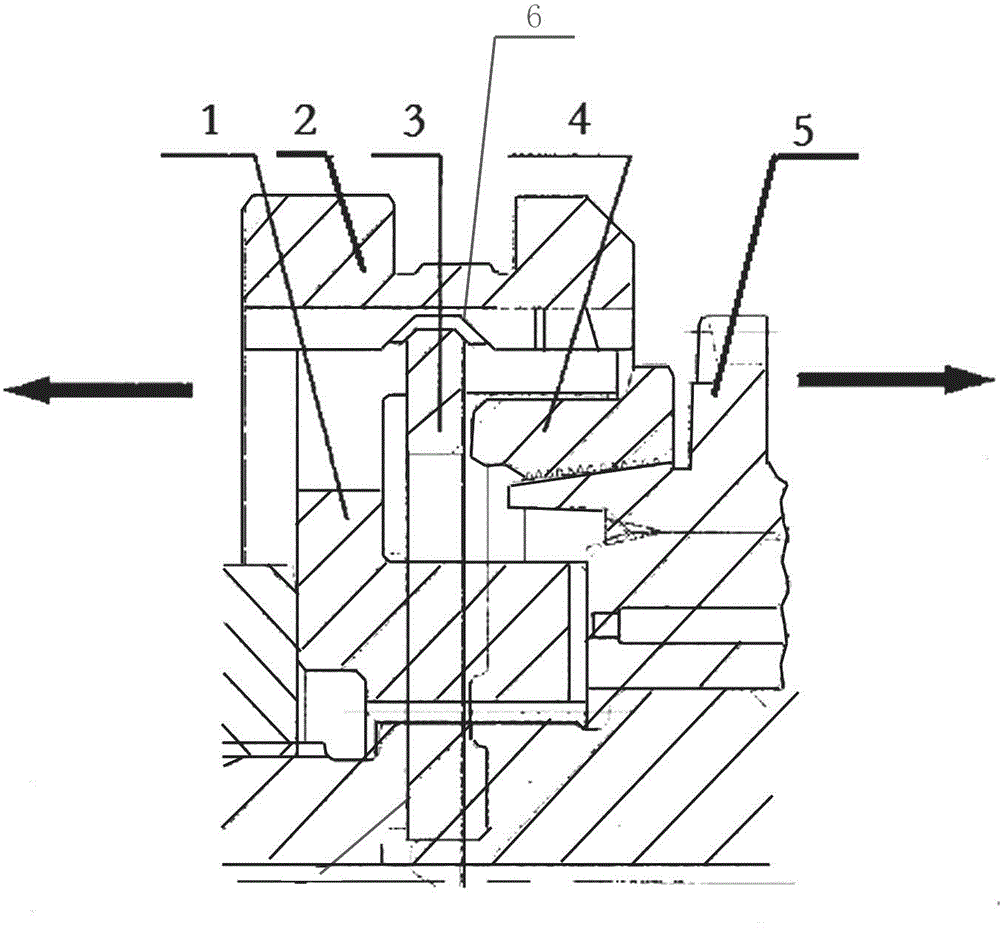

Structure for aviation gas turbine rotor supporting point ball bearing axial pre-load

InactiveCN102979625AImprove loadingImprove applicabilityTurbine/propulsion lubricationAviationBall bearing

A structure for aviation gas turbine rotor supporting point ball bearing axial pre-load includes a main bearing, an auxiliary bearing, a disc spring, and an adjustable pad, wherein the auxiliary bearing is fixed on a gas turbine rotor and shares a bearing inner ring with the main bearing, the outer ring is fixed on a stator in the manner of floating or clearance fitting, one end of the disc spring sticks tightly against the outer ring end face of the auxiliary bearing, the other end of the disc spring sticks tightly against the end face of the adjustable pad, and the adjustable pad is fixed on the stator. The structure has the advantages of being applicable to different aviation gas turbines, meeting the need of rotor supporting point ball bearing axial pre-load, improving the loading condition of the ball bearing, and improving the reliability of the ball bearing. The structure is simple in structure, easy for assembly, and high in environmental adaptability and reliability, can pre-add a large axial force, can apply different preload according to the requirements of different gas turbine axial forces; and effectively improves the applicability of the main bearing.

Owner:AECC SHENYANG ENGINE RES INST

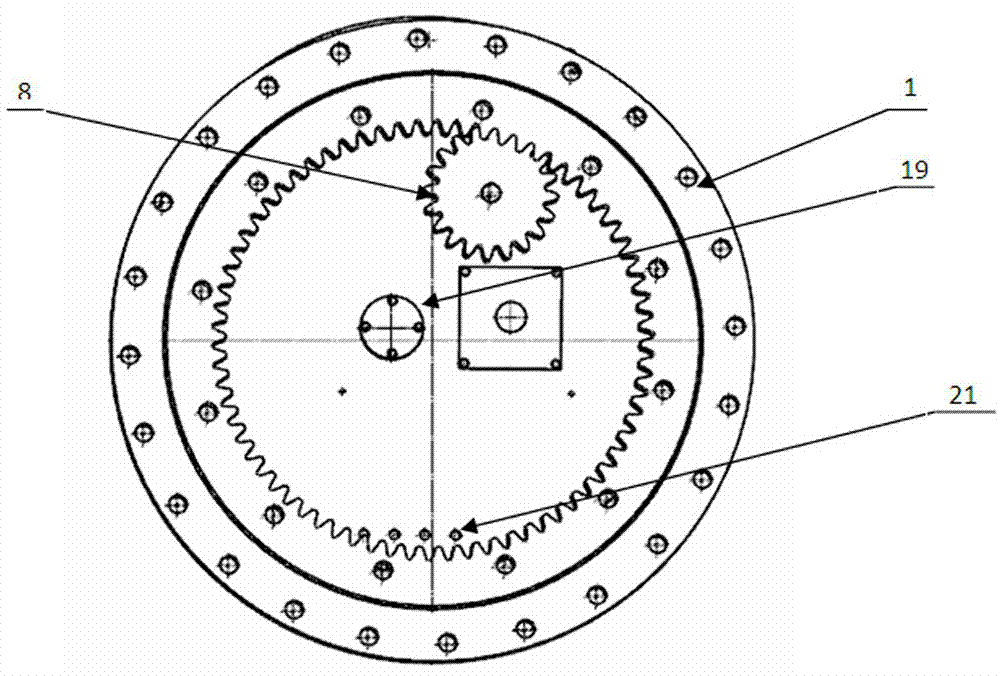

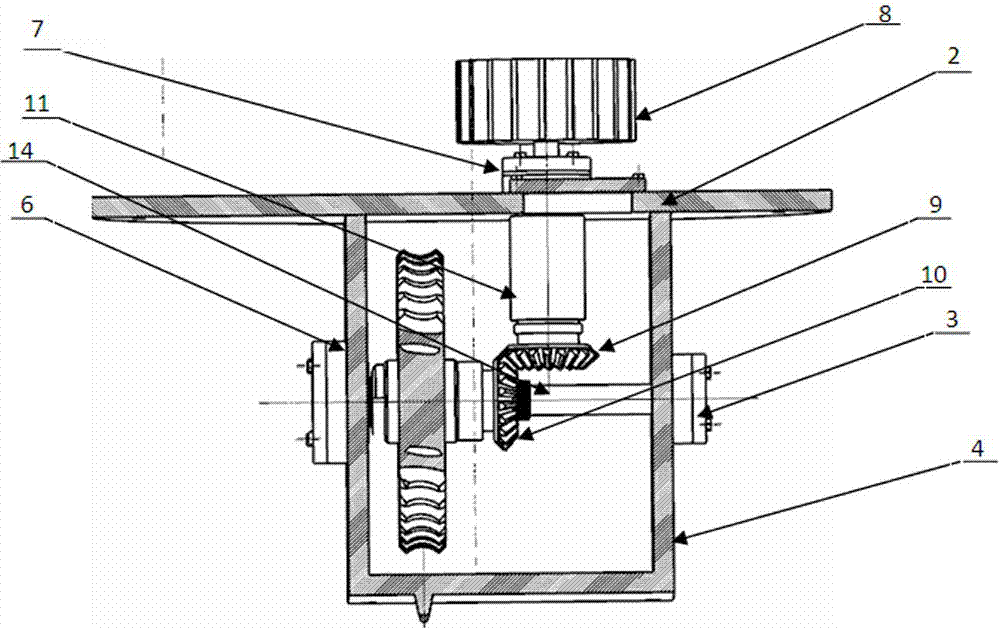

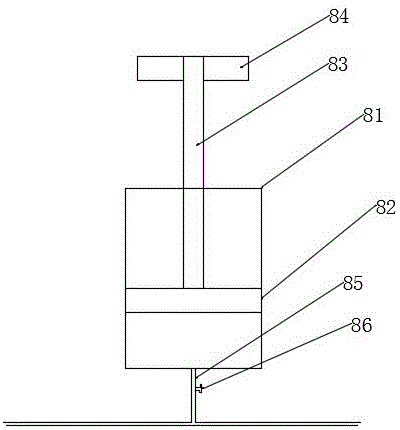

Built-in solar tracking azimuth driving device

InactiveCN104500658AAvoid interferenceSimple structureToothed gearingsGearing detailsStub axleReduction ratio

The invention discloses a built-in solar tracking azimuth driving device which comprises a circular box cover, an inner tooth type four-point contact ball turntable bearing, a worm rod, a turbine worm rod-bevel gear speed reducer component and an output short shaft, wherein the circular box cover is fixed on the position at the top end in a hollow vertical column; the speed reducer component is mounted on the lower part of the circular box cover; the output short shaft of the speed reducer component is upward; an external gear is mounted on the short shaft; the external gear is meshed with the inner tooth type four-point contact ball turntable bearing; the worm rod is arranged in the speed reducer component; an input end of the worm rod is connected with a motor; a variable parameter is set according to the requirement for the outline structure size and reduction ratio of the device. According to the invention, different reduction ratios can be easily realized through the driving pair parameter design, and meanwhile, a triple-axle bearing structure and an inside mounting mode of the vertical column can ensure that the larger wind load overturning moment, axial force and radial force can be endured by the device.

Owner:HUNAN UNIV OF SCI & TECH

Mechanical locking structure for leveling cylinder

The invention discloses a mechanical locking structure for leveling cylinder. The mechanical locking structure for leveling cylinder comprises a hydraulic cylinder and a screw mechanism, wherein a piston rod is arranged in the hydraulic cylinder; the piston rod and piston are integrally formed; the piston rod is fixedly connected with a ball screw pair; the ball screw pair is connected with the upper part of the hydraulic cylinder in the operational process in the hydraulic cylinder; the middle part of the piston rod is provided with a containing part; the ball screw pair in the hydraulic cylinder penetrates through the containing part; the piston rod is fixedly connected with the ball screw pair; one end of the ball screw pair is provided with a concave disk; and the screw mechanism can compact the concave disk and lock the ball screw pair in any position in the whole stroke of the hydraulic cylinder, so that the piston rod cannot retract.

Owner:BEIJING XINLI MACHINERY

Bearing seat and drying machine using same

InactiveCN106051432AEasy to operateAvoid burnsValve arrangementsManual lubricationEngineeringLubrication

The invention provides a bearing seat and a drying machine using the same. The bearing seat is provided with a self-service lubrication device which is relatively fixedly arranged with a shell, wherein the self-service lubrication device comprises an oil storage cavity; a piston and a press rod used for driving the piston to move downwards are arranged in the oil storage cavity; the self-service lubrication device further comprises an oil transmission tube communicating with the oil storage cavity; and the oil transmission tube communicates with an oil nozzle in the bearing seat. The problem of influence on the working efficiency due to difficult oil injection for lubrication for the bearing seat of a fan on the drying machine is solved.

Owner:CHINA TOBACCO HENAN IND

Special hydraulic tool for installation and disassembly of cantilever type impeller

A special hydraulic tool for installation and disassembly of a cantilever type impeller mainly comprises an adjusting nut capable of being connected with an impeller center bolt in matching mode, an inner cylinder and an outer cylinder which are mutually matched are sleeved in the adjusting nut, and an oil pressure cavity communicated with an external hydraulic pump is formed between an inner cylinder sleeve and an outer cylinder sleeve. A sleeve capable of abutting against the impeller end wall is connected with the connection center bolt side of the adjusting nut through threads. An inner sealing ring and an outer sealing ring are arranged at the position of the connection gaps at two ends of the inner cylinder sleeve and the outer cylinder sleeve, and a poking rod capable of being matched with an impeller locking nut in matching mode and locking the impeller locking nut is configured on the sleeve. The special hydraulic tool has the advantages of being simple in structure, light in weight, capable of providing large axial force, convenient to install and disassemble and the like.

Owner:杭州杭氧透平机械有限公司

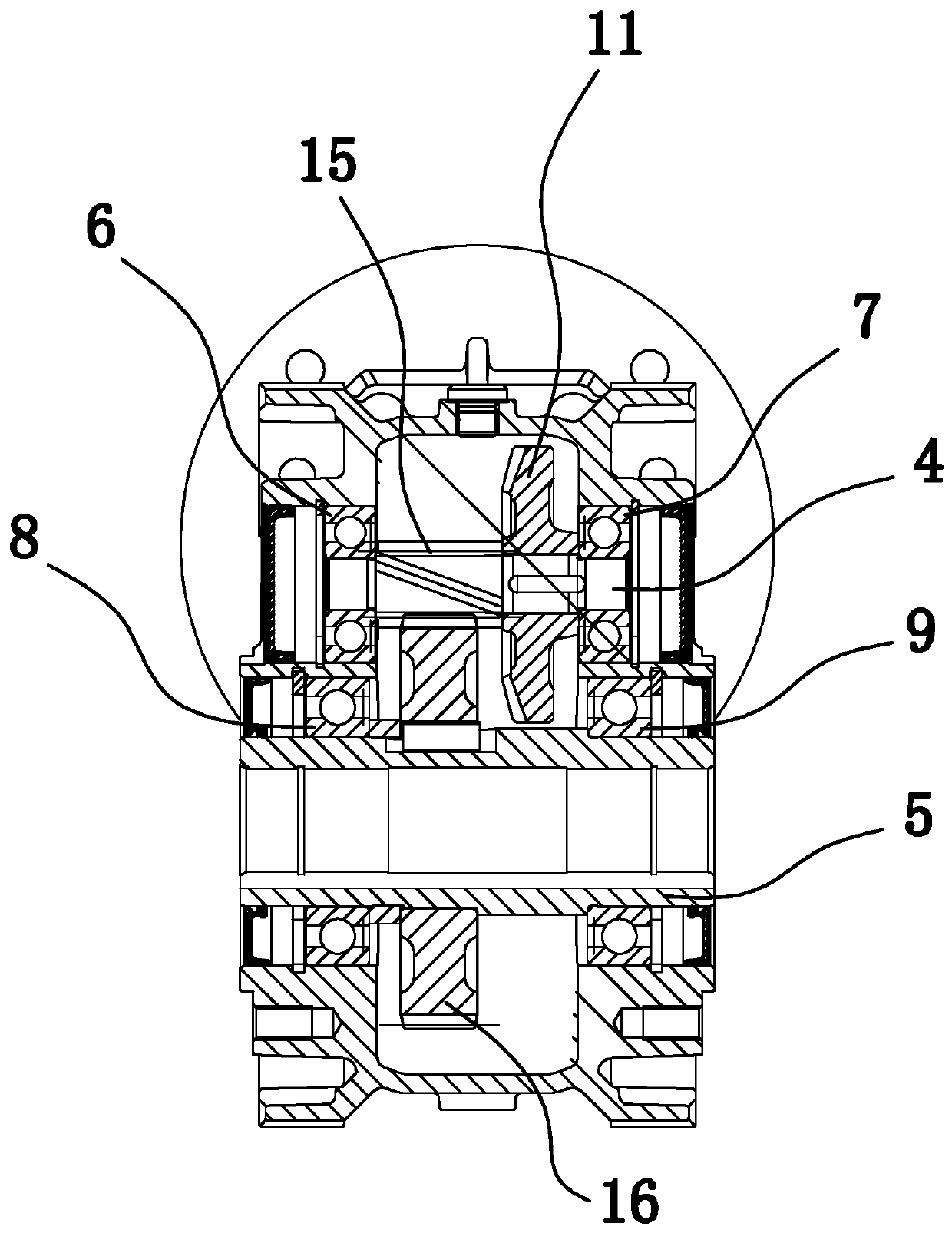

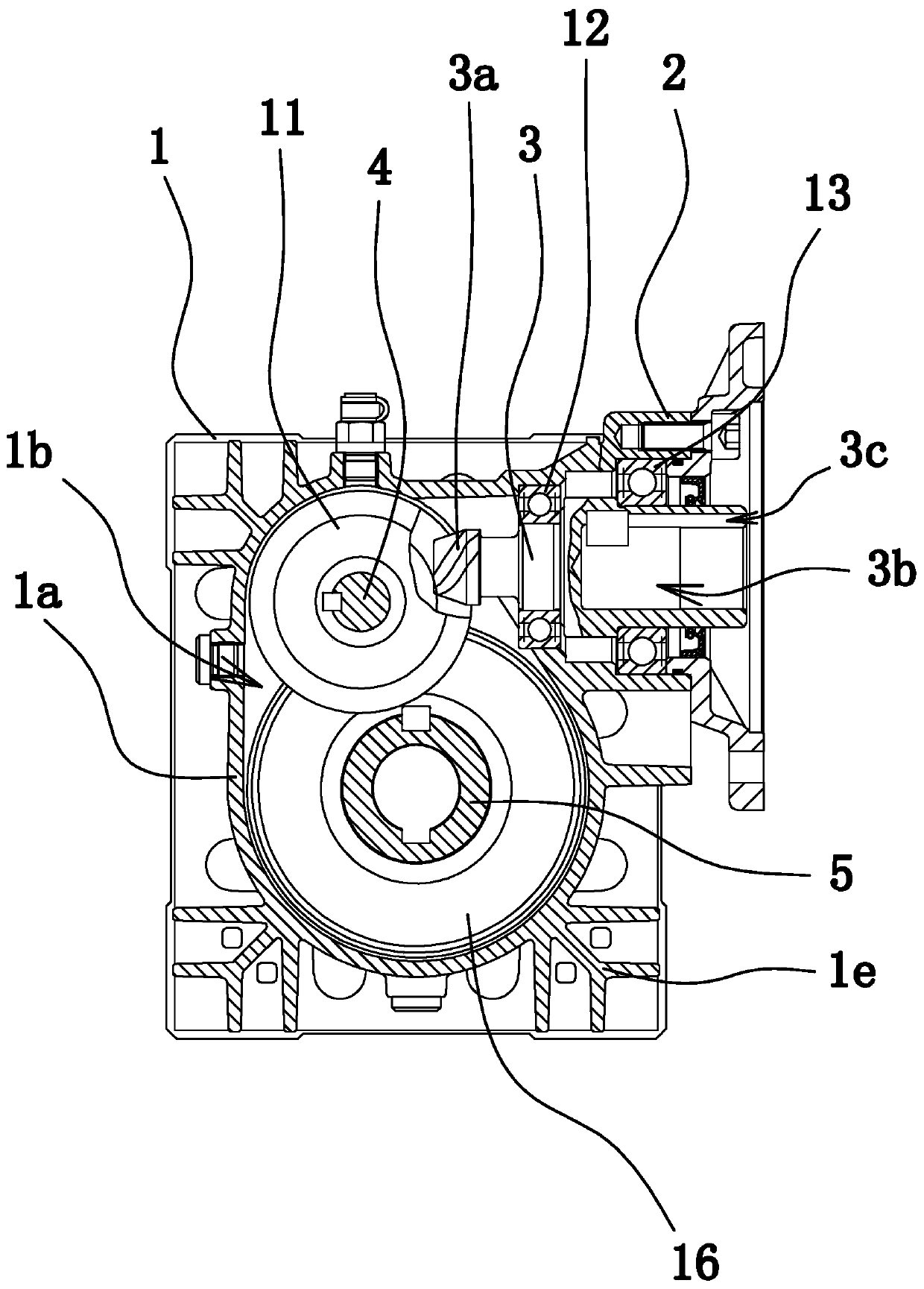

Cone-disk clutch

InactiveCN1395049ASolve application problemsCompact structureFriction clutchesDrive shaftEngineering

The present invention relates to a concial disk clutch, including conical driving disk and driven disk which are set on shaft, both are holden together by spring, at the same time equipped with control mechanism. It is characterized by that the control mechanism adopts screen separator whose structure is as follows: one end of driven shaft is equipped with disengaging claw, an axial channel is set on the driven shaft, in said axial channel an ejector pin is placed, one end of said ejector pin is placed against the dieengaging claw, and its another end is placed against driven disk, and the driving disk and driven disk are placed on same shaft.

Owner:葛玉明

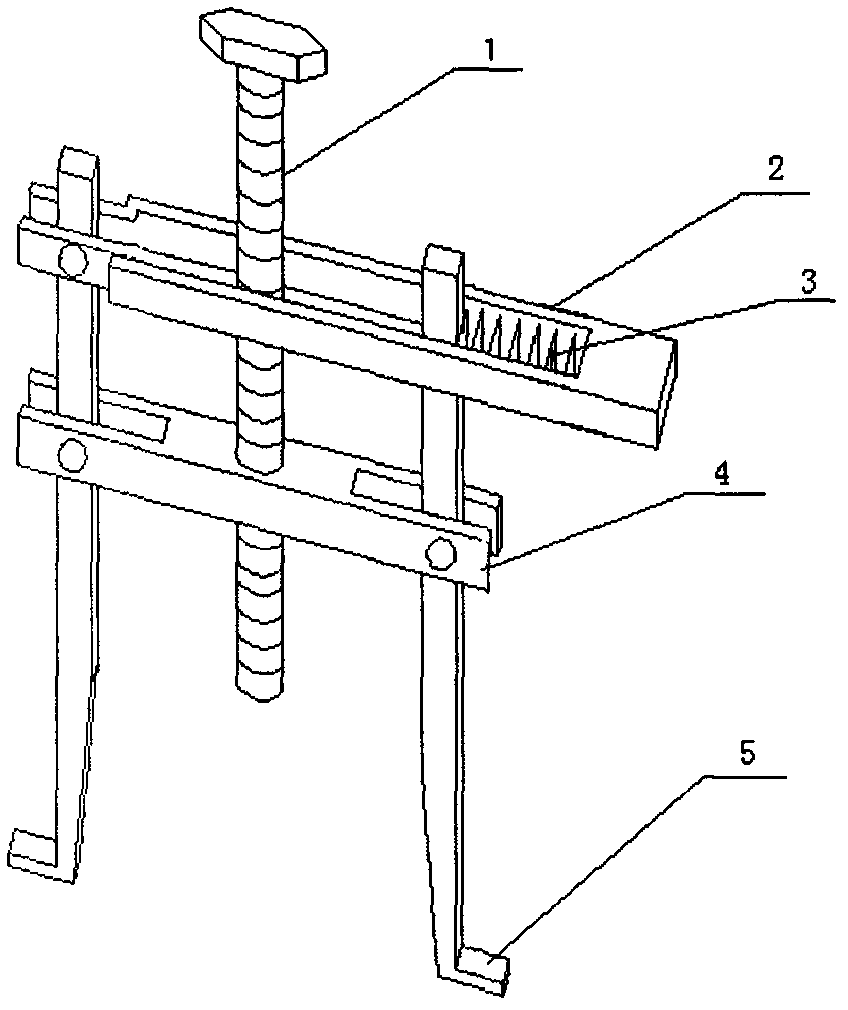

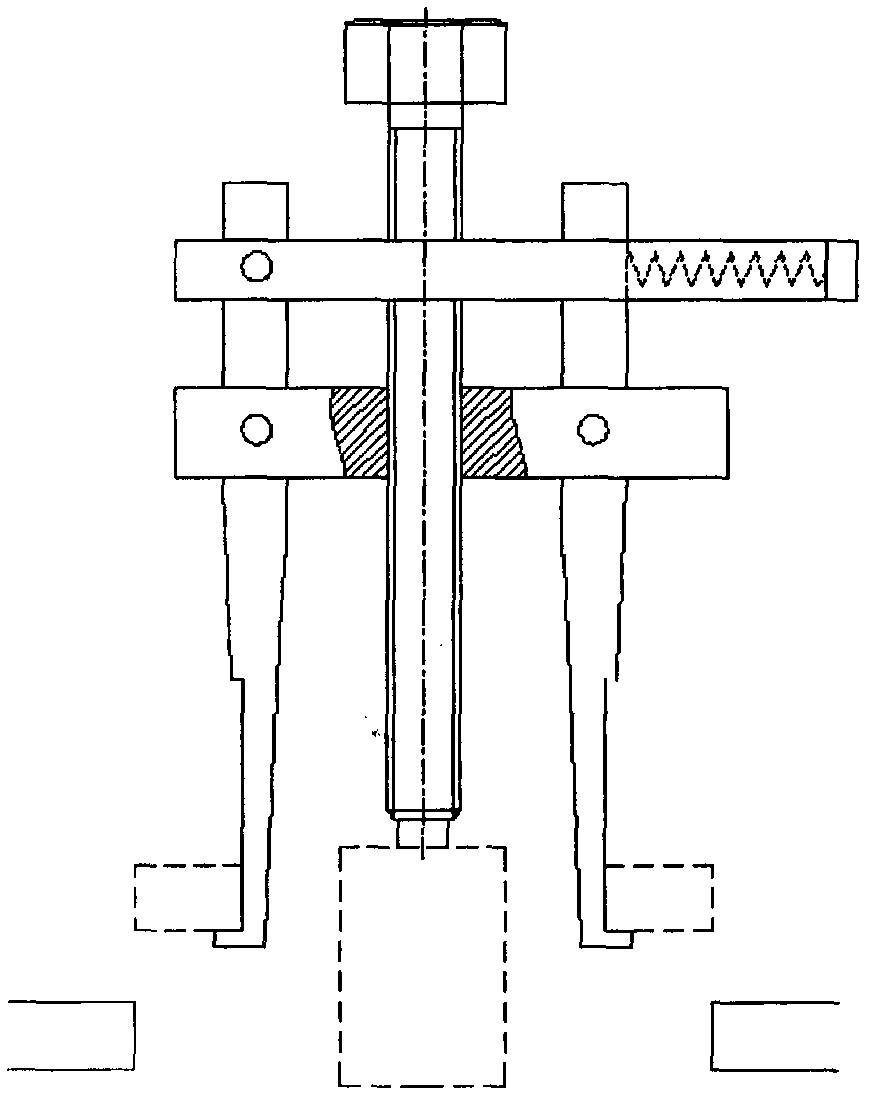

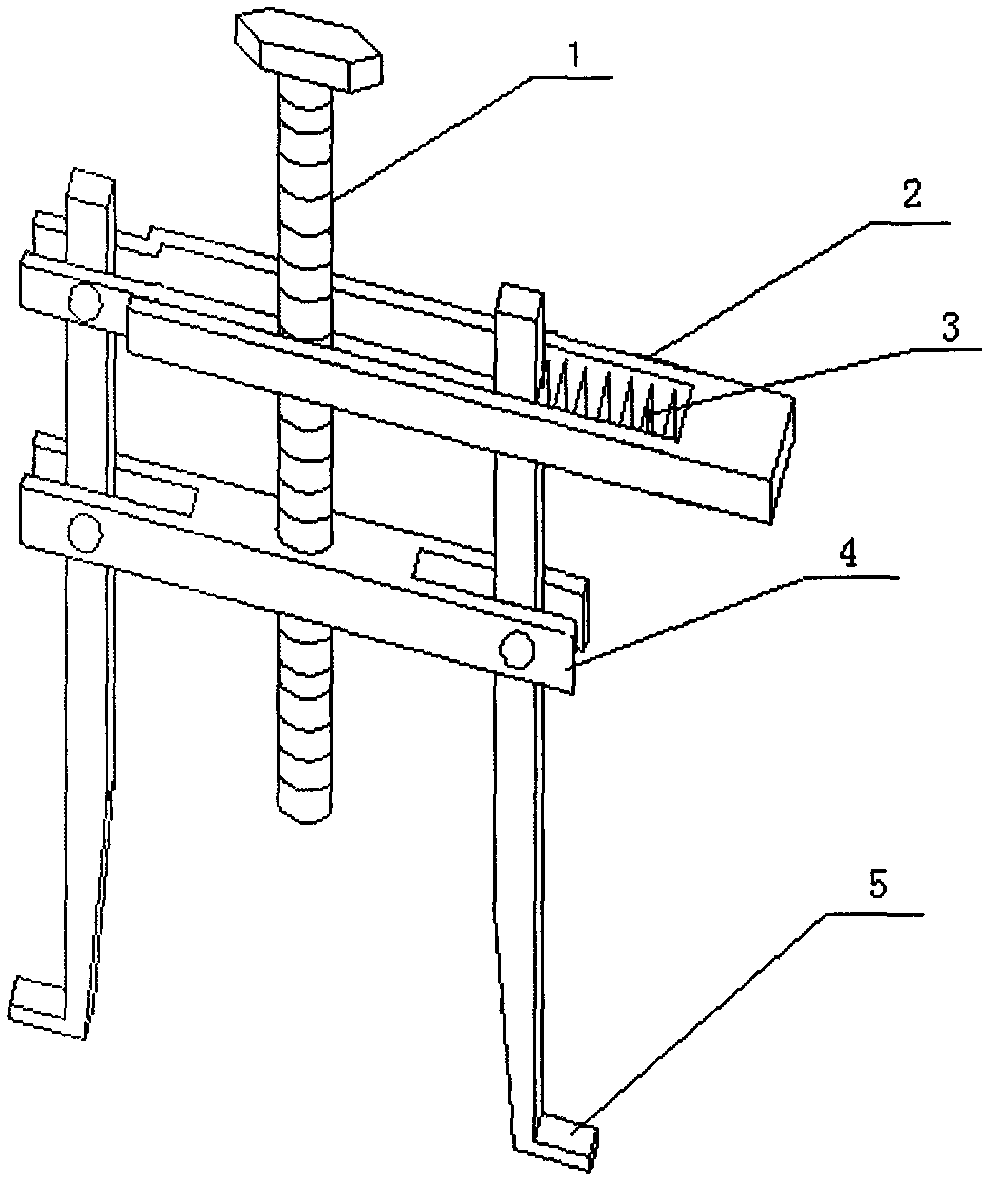

Special withdrawal tool for automatic transmission oil seal

InactiveCN102366945ALarge axial forceEasy to insertMetal-working hand toolsAutomatic transmissionSpring force

A special withdrawal tool for an automatic transmission oil seal belongs to the technical field of special automobile tools, and particularly relates to a special tool for dismantling the automatic transmission oil seal of Toyota A540. The special withdrawal tool is formed by a dismantling bolt, a tensioning arm, a spring, a central part and a pin. The dismantling bolt is connected with the central part through trapezoid threads, so the oil seal is removed from an automatic transmission through the axial force which is provided by screw drive. A cylindrical boss is arranged at the lower end of the removed bolt; and a cylindrical hole is processes at the right side of the tensioning arm, the spring is installed in the cylindrical hole, and the pin on the spring side is tightly pressed by one end of the spring through the spring force. The special withdrawal tool can realize the undamaged dismantling of the automatic transmission oil seal of Toyota A540, and has the characteristics of simple structure, convenience in operation, safety, reliability, low cost and the like, and is also suitable to dismantle the similar automatic transmission oil seals.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Cable arranging device

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Speed reducer structure

PendingCN111075908AHigh transmission precisionExtended service lifeGearboxesGearing detailsReduction driveDrive shaft

The invention provides a speed reducer structure, which belongs to the technical field of machinery, and solves the problems that an existing speed reducer is poor in transmission precision and is short in service life. The speed reducer structure comprises a housing, a flange, an input shaft, a transmission shaft and an output shaft, wherein the two ends of the transmission shaft are separately connected in the housing through a bearing I and a bearing II; the two ends of the output shaft are separately connected in the housing through a bearing III and a bearing IV; a coaming is arranged inthe housing, and a mounting cavity is enclosed in the housing; an opening is formed in the end surface of the housing, and the edge of the opening is detachably connected with an end cover; both the bearing I and the bearing III are arranged on the end cover; both the transmission shaft and the output shaft are positioned in the mounting cavity; a hypoid gear is arranged on the input shaft; a bevel gear which is engaged with the hypoid gear is arranged on the transmission shaft; and the dimension of the bearing II is greater than that of the bearing I. The bearing II can bear greater axial bearing force relative to the bearing I, so that stable and consistent transmission efficiency can be kept, and therefore, the speed reducer structure has relatively high transmission precision, and theservice life of the speed reducer structure is prolonged.

Owner:浙江通宇变速机械股份有限公司

Bamboo chip carbonizing and color mixing device

InactiveCN104669389ASimple structureLow costWood treatment detailsWood charring/burningBiochemical engineeringCoupling

The invention discloses a bamboo chip carbonizing and color mixing device which comprises a rack, a roller assembled on the rack, and a driving mechanism which is assembled on the rack and is used for driving the roller to rotate, wherein the roller is provided with a feeding / discharging mechanism used for loading and unloading bamboo chips; a heating assembly is fixedly assembled in the roller; the heating assembly comprises a supporting shaft and multiple electric heating tubes assembled on the supporting shaft; the roller comprises a cylinder, a fixing shaft which is fixedly connected to one end of the cylinder, and a hollow shaft which is fixedly connected to the other end of the cylinder; the fixing shaft and the hollow shaft are respectively arranged on the rack by virtue of a bearing assembly; one end of the supporting shaft is rotationally connected with the fixing shaft; the other end of the supporting shaft penetrates out of the hollow shaft and is fixedly arranged on the rack by virtue of a fixing assembly; and the fixing shaft is connected with the driving mechanism by virtue of a coupling. The bamboo chip carbonizing and color mixing device disclosed by the invention has the advantages of simple structure, low cost, small occupied space, long service life, stability and reliability in operation and the like.

Owner:湖南品篁高新技术有限公司

Hydraulic vice

ActiveCN109759873ACompact structureLarge clamping forcePositioning apparatusMetal-working holdersHydraulic cylinderLocking mechanism

The invention discloses a hydraulic vice. The hydraulic vice comprises an L-shaped fixed vice body, a guide rail integrally arranged on a horizontal part of the fixed vice body, a movable vice body capable of moving back and forth along the guide rail, a hydraulic system, a locking mechanism and a limiting mechanism; the hydraulic system comprises a pressure applying mechanism and a hydraulic cylinder connected with the pressure applying mechanism; the locking mechanism comprises a pressure transfer device connected with a working plunger, and limiting blocks which can move towards the side wall of the guide rail and form a combing structure with the guide rail; in the pressurizing initial stage, the pressure transfer device is pushed by the working plunger to move rightwards, and the limiting blocks move towards the corresponding side walls of the guide rail under action of the limiting mechanism till the limiting blocks are combined with the guide rail so that locking of the lockingmechanism and the fixed vice body can be achieved; pressurizing continues, the hydraulic cylinder is made to do reverse motion relative to the working plunger and drives the movable vice body to clampa workpiece. According to the hydraulic vice, through the hydraulic system, the locking mechanism and the limiting mechanism which are arranged in an interactional mode, the movable vice body is pushed to move, the whole structure is simple and compact, the clamping force is large, and the clamping efficiency is high.

Owner:HENAN UNIV OF SCI & TECH

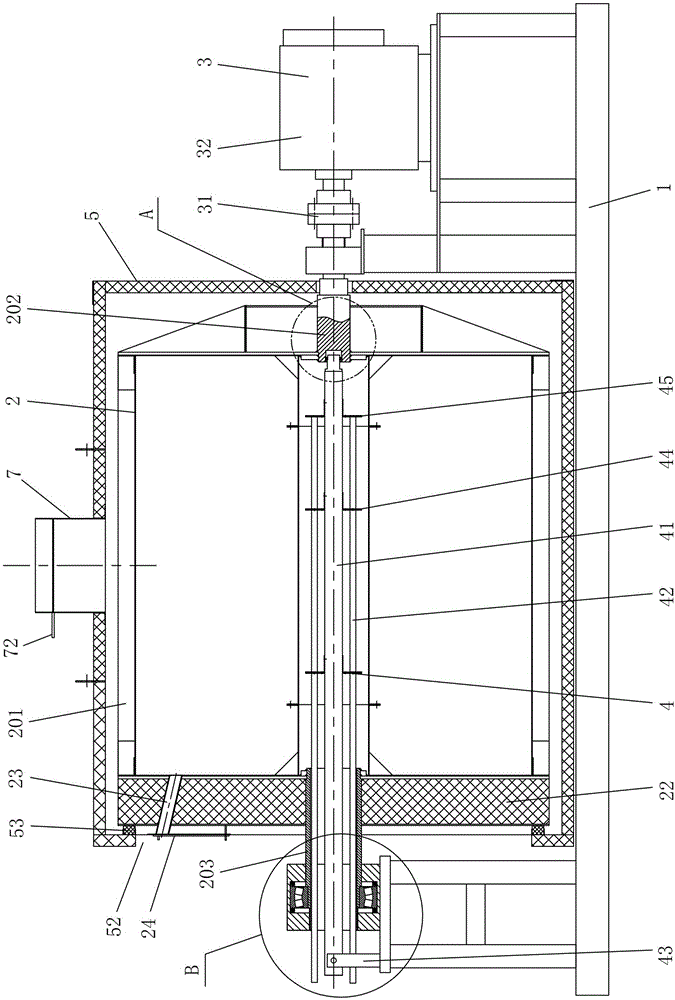

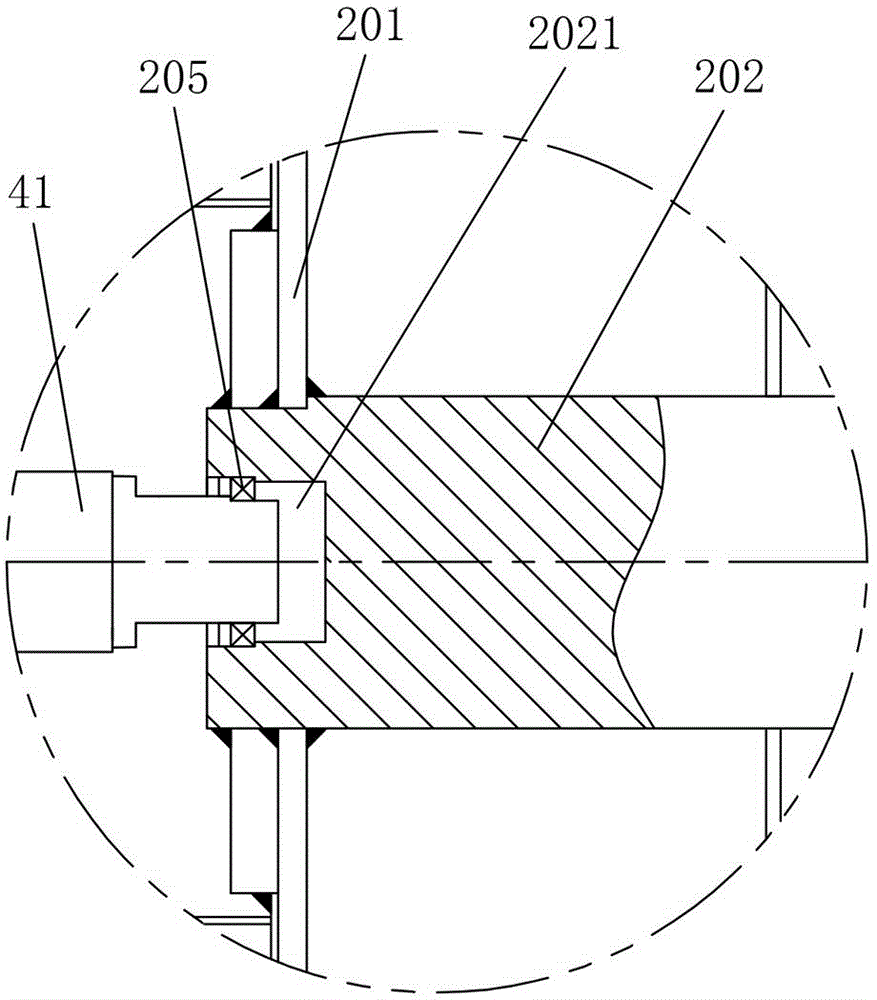

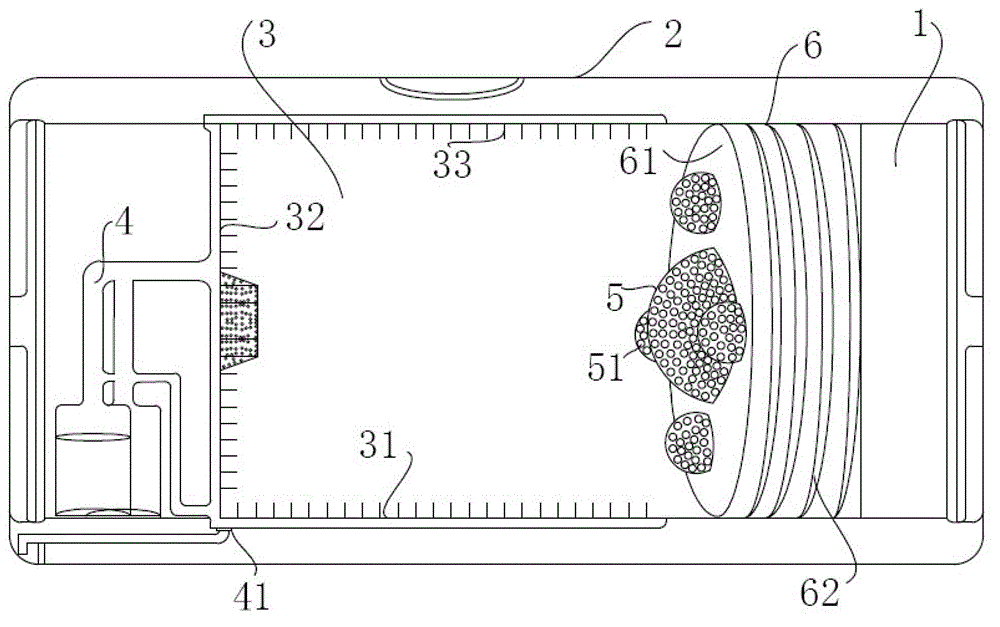

Spraying type washing machine

InactiveCN102978871APush fullyLarge axial forceOther washing machinesWashing machine with receptaclesWater flowPulp and paper industry

The invention relates to the technical field of household appliances, in particular to a spraying type washing machine which can wash and dry clothes. The washing machine comprises a motor, a water containing cylinder, a rolling cylinder arranged in the water containing cylinder, and a water and gas discharging system arranged on the rolling cylinder, and is characterized by also comprising a washing hand consistent to a central axle direction of the water containing cylinder, wherein the washing hand is connected with a retraction device. Usually, an axial washing hand is arranged on a basic mechanism of a conventional washing machine, so that axial force is added, clothes can be pushed and beat fully. Besides, an unconventional water inlet manner is adopted and high-pressure hyperfine water flow spraying is adopted, and the washing effect is improved greatly. Additionally, washing water containing dirt is purified through a sewage treatment system, the water is injected into the rolling cylinder again for recycling utilization, and the washing water can be saved substantially. Besides, a high-pressure gas is sprayed to dry the clothes through a high-pressure gas inlet after washing, and the washing efficiency is improved.

Owner:深圳市佳能宝节能环保科技有限公司 +1

Grade feeding device of roller mill used for processing steel slag

The invention relates to steel slag processing equipment, in particular to a grade feeding device of a roller mill used for processing steel slag. The grade feeding device comprises a bracket, wherein the bracket is provided with a motor and an outer tube; the bottom end of the outer tube is provided with a bottom plate fixedly connected with the outer tube; the top end of the outer tube is provided with a top plate; the upper part of the outer tube is provided with a first discharge hole and a second discharge hole; the inner part of the outer tube is provided with a sieve tube; the outer wall of the sieve tube is provided with a first spiral blade; a lower partition plate is arranged between the lower end of the sieve tube and the outer tube; a feeding cavity is arranged between the lower partition plate and the bottom plate; an upper partition plate is arranged between the upper end of the sieve tube and the outer tube; the upper partition plate is positioned between the first discharge hole and the second discharge hole; a rotary shaft coaxial with the sieve tube is arranged in the sieve tube; the rotary shaft, the bottom plate, the rotary shaft and the top plate are rotatably connected; the rotary shaft is connected with the motor; a second spiral blade is arranged between the rotary shaft and the sieve tube; and the first spiral blade and the second spiral blade are the same in rotary direction. The grade feeding device has the beneficial effect of improving steel slag production efficiency and saving production cost.

Owner:重庆市富环建筑材料有限责任公司

Automobile synchronizer

InactiveCN104154138AIncrease frictionLarge axial forceMechanical actuated clutchesEngineeringSynchronizing

The invention discloses an automobile synchronizer. The automobile synchronizer comprises a synchronizing gear hub (1), a synchronizing sliding sleeve (2), a synchronizing operating lever (3), a synchronizing ring (4) and a synchronizing conical hub (5). The synchronizing gear hub (1), the synchronizing operating lever (3), the synchronizing ring (4) and the synchronizing conical hub (5) are sequentially arranged in the synchronizing sliding sleeve (2) from head to end, the synchronizing sliding sleeve (2) is arranged on the synchronizing gear hub (1) in a sleeved mode and is connected with the synchronizing gear hub (1), an annular groove (6) is formed in the inner wall of the synchronizing sliding sleeve (2), the synchronizing sliding sleeve (2) is arranged on the synchronizing ring (4) in a sleeved mode and is connected with the synchronizing ring (4), and one side face of the synchronizing ring (4) is in transmission connection with the synchronizing conical hub (5).

Owner:李汉祥

Novel drilling driver

InactiveCN103726787AReduce areaAchieve cycleBorehole drivesDrilling machines and methodsElectric machineWell drilling

The invention discloses a novel drilling driver comprising an electrohydraulic composite tube (11) at the rear end, a drive device used for driving the drilling driver to move forward, a drive motor (13), an exciter (14), and a drill bit (15). The drive motor (13), the exciter (14) and the drill bit (15) are fitly connected in sequence. Two centralizers (12) are connected to front and rear ends of the drive device respectively. The drive device and the centralizers (12) are all provided with inner passages communicated with the electrohydraulic composite tube (11) and allowing drilling fluid to pass. The drive device further comprises a passage B (2) allowing returning fluid to flow through. The novel drilling driver has the advantages that land drilling rigs or marine drilling platforms are no longer used together in the process of oil-gas well exploration and development, continuous drilling is done using the drilling driver, drilling fluid circulation and high-speed communication are achieved through the electrohydraulic composite tube, and safe, efficient and economic drilling is maximally achieved.

Owner:SOUTHWEST PETROLEUM UNIV

Twin-worm drive swing driving device

InactiveCN103244610ASimple structureReasonable designToothed gearingsGearing detailsWorm driveEngineering

The invention discloses a twin-worm drive swing driving device which comprises a base and a swing bearing. The swing bearing comprises an inner ring, an outer gear ring and balls, the balls are embedded between the inner ring and the outer gear ring, the inner ring is fixed above a base ring of a base, a first shaft housing and a second shaft housing are symmetrically arranged on the outer side of the base ring of the base, the axis lines of the first shaft housing and the second shaft housing are spatially perpendicular to the axis line of the base ring, a first worm is mounted in the first shaft housing, a second worm is mounted in the second shaft housing, and both the first worm and the second worm are engaged with the outer gear ring. The two worms are used for driving the outer gear ring of the swing bearing, translational acting force of the two worms on the outer gear ring is mutually offset, the gap between each worm and the outer gear ring is 'eliminated', and the rotation angle of the outer gear ring is accurately positioned. The twin-worm drive swing driving device is simple in structure and reasonable in design, and can be widely applied to industries such as engineering machinery, building machinery and solar photovoltaics.

Owner:江阴凯迈机械有限公司

Double-wedge-shaped hydraulic chuck for drilling machine

InactiveCN104005721ANovel and reasonable structureSimple structureDrilling rodsDrilling casingsEngineeringSingle loop

The invention relates to a hydraulic chuck for a drilling machine, in particular to a double-wedge-shaped hydraulic chuck for a drilling machine. The double-wedge-shaped hydraulic chuck for the drilling machine is applied to the drilling machine for tightly clamping a drill rod arranged on a rotating device, transmitting the torque to the drill rod and realizing the rotating movement of a drilling tool. The double-wedge-shaped hydraulic chuck comprises an inner cylinder body, an inner cylinder body sealing ring, a back outer cylinder body, a back ring sleeve, an inner cylinder body-ring sleeve sealing ring, a buffer gasket, double-wedge-shaped slips, a spring group, an outer cylinder body connecting screw bolt group, a front ring sleeve, a front outer cylinder body, a front cylinder body-front ring sleeve connecting screw group and a buffer gasket locking screw group. The double-wedge-shaped hydraulic chuck for the drilling machine has the advantages that the double-wedge-shaped slip clamping is realized through the pressure of hydraulic oil, the double-wedge-shaped slip releasing is realized through the spring reset force, the structure is novel and reasonable, the double-wedge-shaped hydraulic chuck is of a double-wedge-shaped slip structure, two-way clamping is adopted, the clamping force is great, the clamping is fast, the structural dimension is small, and in addition, the axial stress is zero; after the drill rod is released, the chuck is released only through the spring reset force; an oil path of the double-wedge-shaped slip structure is a single loop, the structure is simple, and the control is simple and convenient.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com