Patents

Literature

39results about How to "Avoid regrinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Welding joint and technique for longitudinal seam and circumferential seam of medium-thick plate

InactiveCN107442891AReduce fillingReduce the amount of weldingWorkpiece edge portionsWelding accessoriesThick plateEngineering

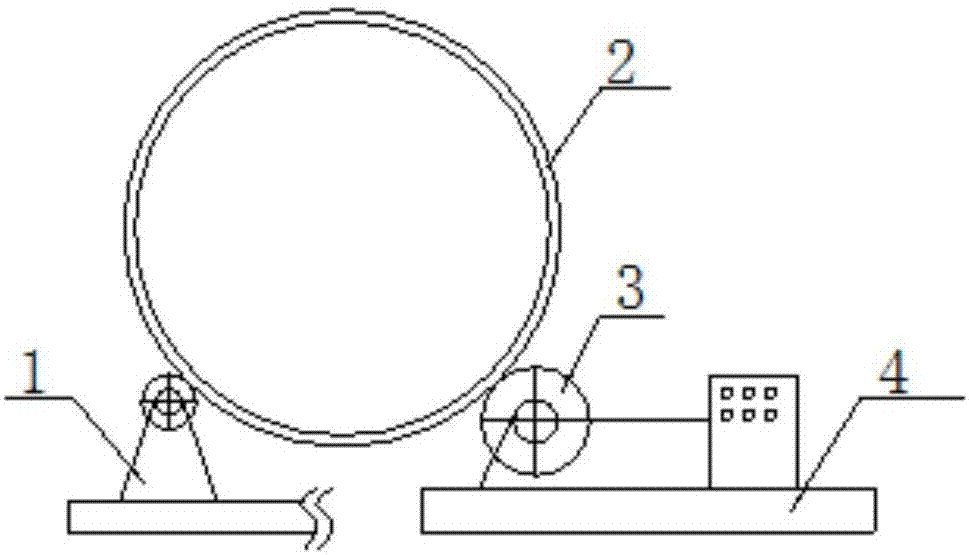

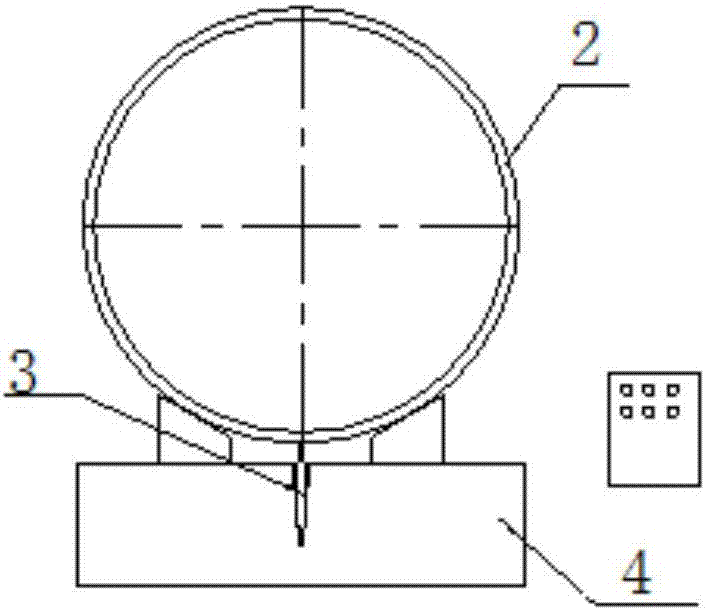

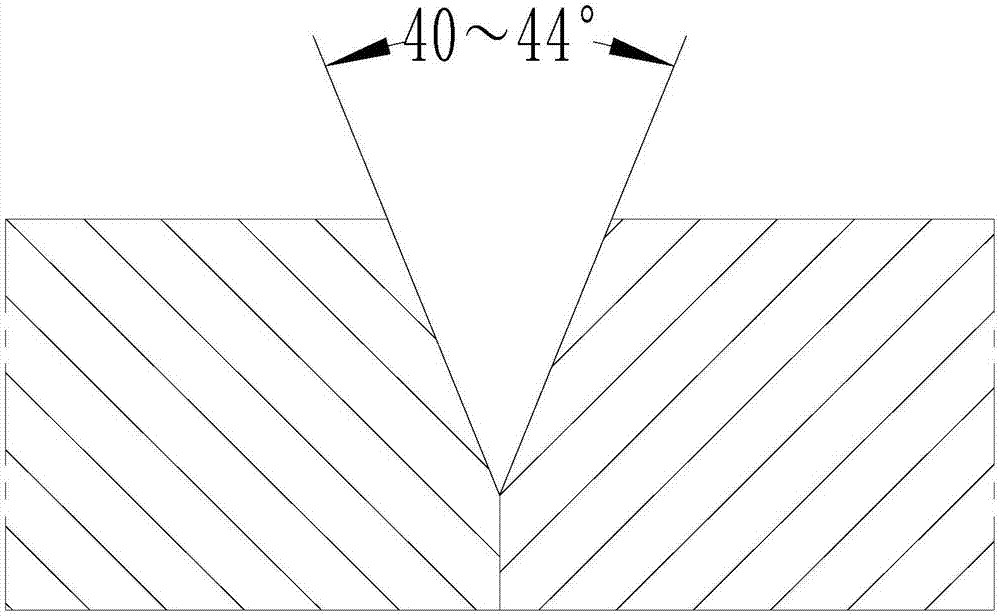

The invention discloses a welding joint and technique for a longitudinal seam and a circumferential seam of a medium-thick plate. The welding technique for the longitudinal seam and the circumferential seam of the medium-thick plate comprises the following steps that a groove inside the plate is machined; then, the surface and the two sides of the groove are cleaned; a priming layer, a filling layer and a surface covering layer of the internal groove are welded in a submerged-arc welding mode; then mechanical back chipping is conducted, and the back-chipped groove is detected nondestructively; and finally, a priming layer, a filling layer and a surface covering layer of an external groove are welded in a submerged-arc welding mode. By optimizing the groove type, the welding material filling amount is decreased, and the welding efficiency is improved; groove machining and welded seam back chipping are conducted through mechanical back chipping, base material hardening caused by rapid heating and cooling through carbon arc air gouging back chipping is avoided, the carburization phenomenon on the two sides of the groove of a stainless steel material is avoided, secondary polishing caused by using of a polishing machine is avoided, the back chipping efficiency is improved by about 50%, the labor intensity of workers is greatly reduced, the air environment is improved, and the welding quality of a cylinder is improved.

Owner:LUXI IND EQUIP

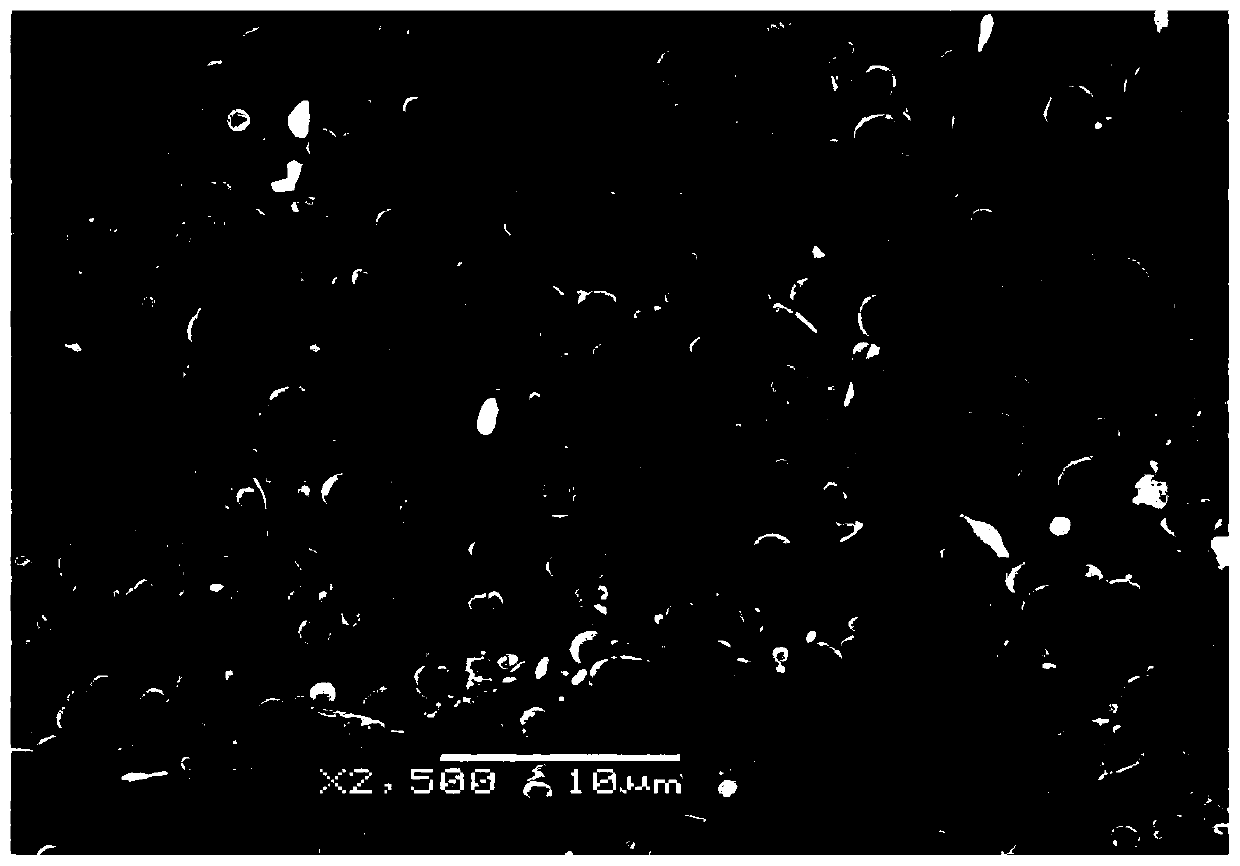

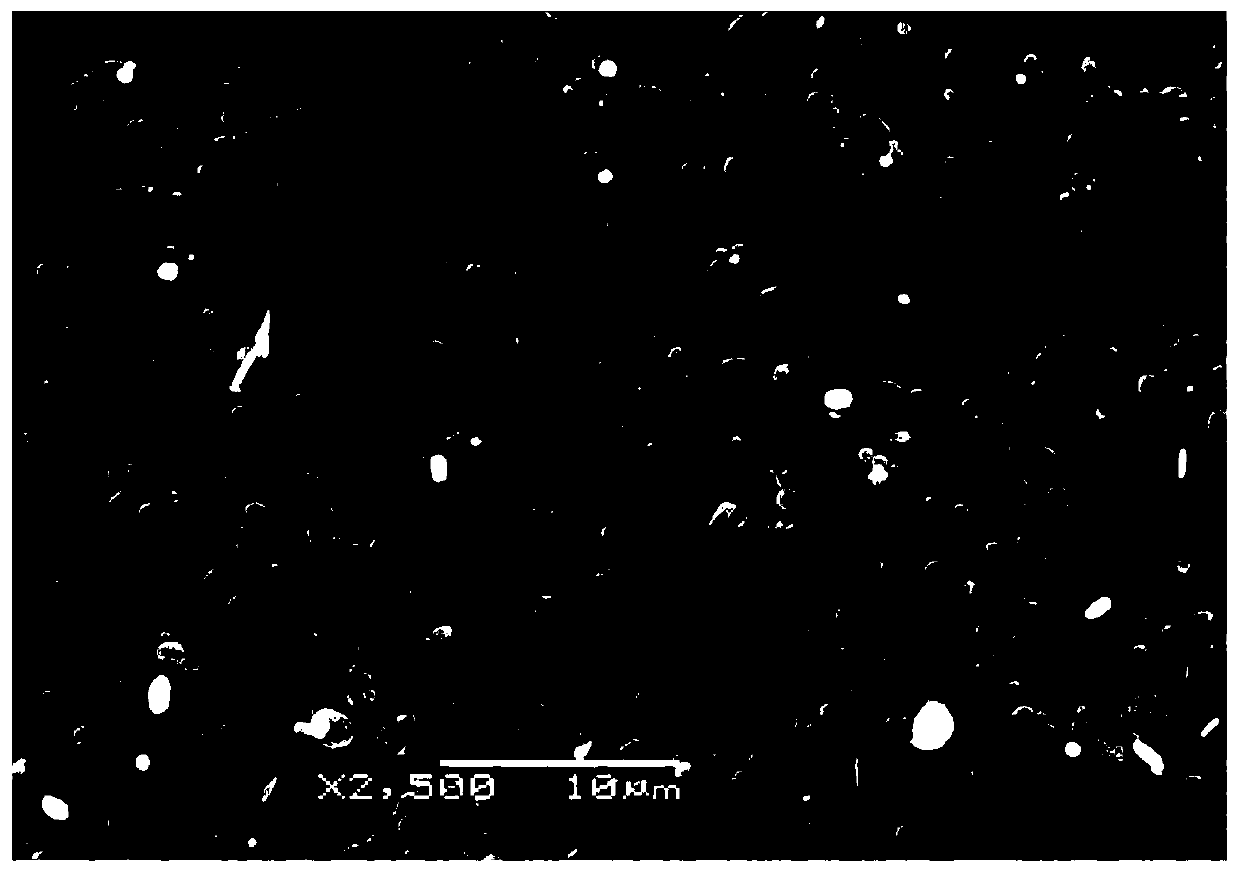

Preparation method of nickel-polytetrafluoroethylene coating

ActiveCN103225098AHigh temperature resistantReduce coefficient of frictionElectrolytic coatingsPolyvinyl chlorideSilica gel

The invention relates to the technical field of electroplating, and particularly relates to a preparation method of a nickel-polytetrafluoroethylene coating. According to the invention, nickel is combined with polytetrafluoroethylene, a fluorinated ethylene-propylene copolymer, a perfluoroalkoxy copolymer and other assistants to be used as an electroplating solution and used for electroplating under certain conditions. The invention can be widely applied to various base materials such as steel, copper alloys, wrought aluminum, cast iron, stainless steel and the like, and can be also perfectly used on various injection molding materials except pure rubber, such as silica gel, TPO0, PVC (polyvinyl chloride) and the like. The coating is favorable in wear resistance and non-corrosibility, has weldability and hardenability, and causes no negative effect on the surfaces of other molds.

Owner:模德模具(东莞)有限公司

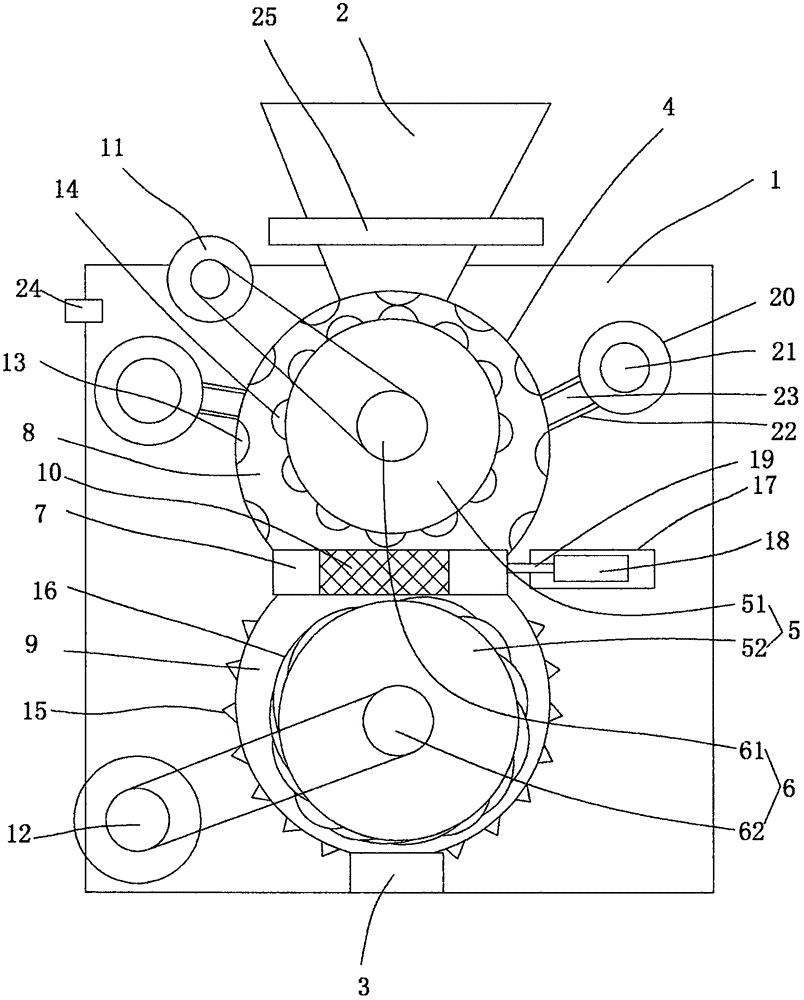

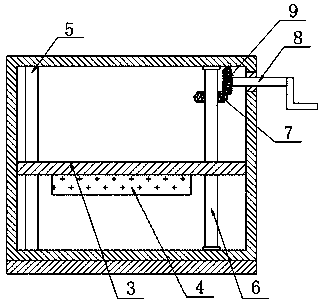

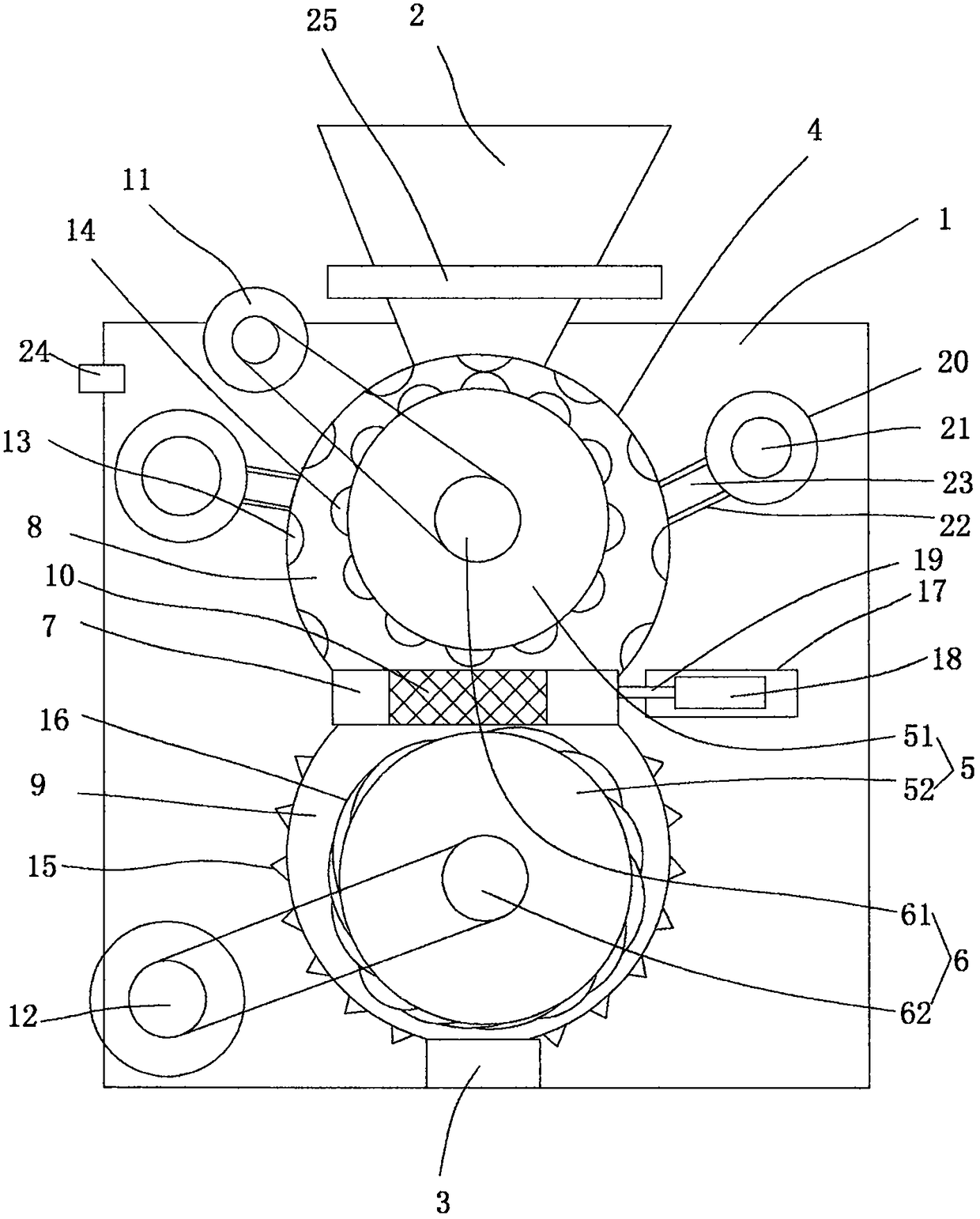

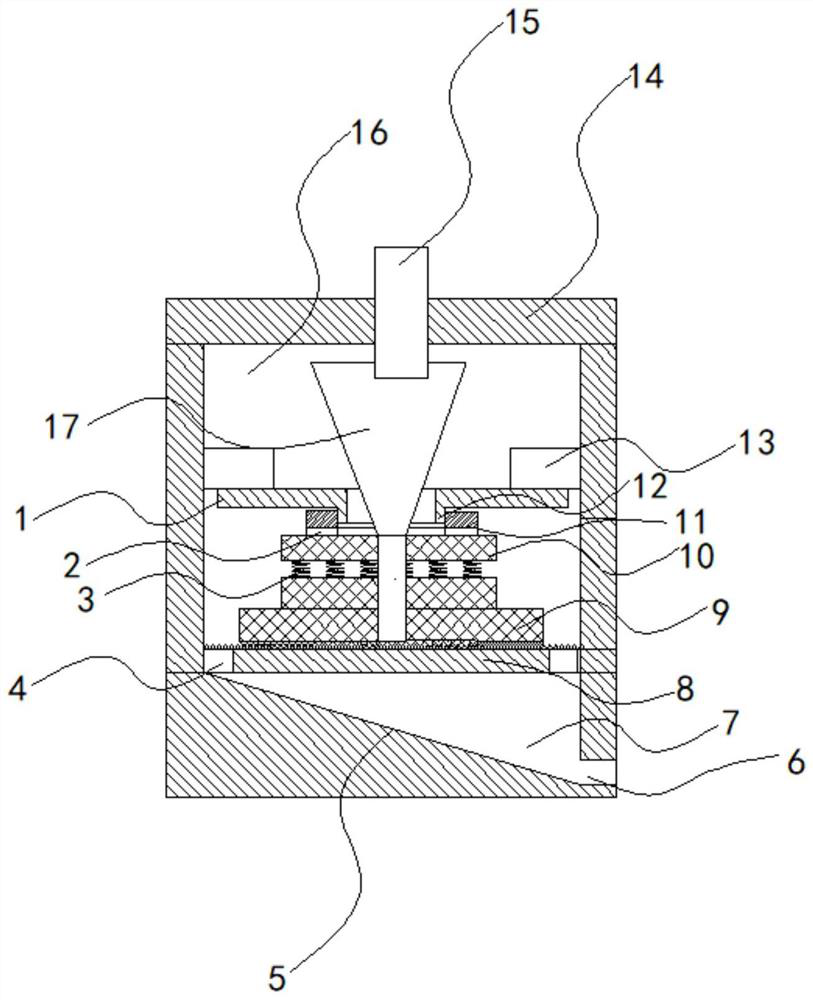

Layered grinding equipment

The invention discloses layered grinding equipment. The layered grinding equipment comprises a shell body which is provided with a feeding inlet, a discharging outlet and a grinding and pressing channel. The grinding and pressing channel is internally provided with grinding and pressing rollers, and rotating shafts connected with the grinding and pressing rollers, and a partition plate is arranged in the middle of the grinding and pressing channel. The direction of the partition plate is the same as that of the grinding and pressing channel. The grinding and pressing channel is divided into an upper grinding cavity and a lower grinding cavity through the partition plate. Screen nets are uniformly arranged on the partition plate. The grinding and pressing rollers comprise the upper-layer grinding and pressing roller and the lower-layer grinding and pressing roller. The rotating shafts comprise the upper-layer rotating shaft and the lower-layer rotating shaft. The feeding inlet communicates with the upper grinding cavity. The discharging outlet communicates with the lower grinding cavity. The shell body is provided with an upper driving motor and a lower driving motor. According to the layered grinding equipment, the structure is simple, operation is convenient, grinding is conducted through the up-down two-layer structure, and the situation of insufficient grinding can be effectively avoided; accordingly, regrinding is avoided, human and material resources are saved, and the machining cost is greatly reduced; and the using stability is good, the applicability is high, and the practicality is good.

Owner:陕西阿姑农业发展有限公司

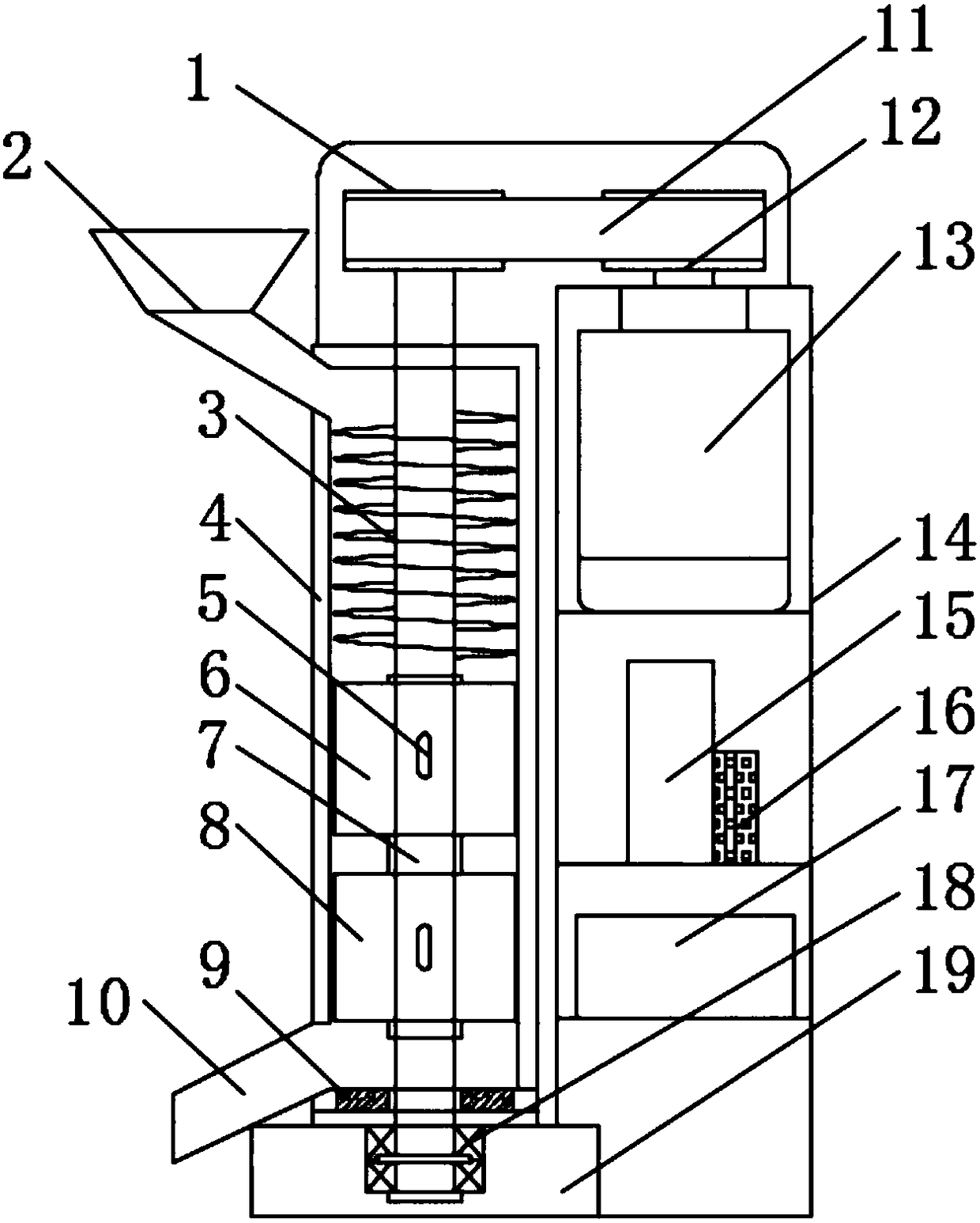

Glass fiber crushing and grinding equipment for machining glass fiber powder

ActiveCN111111861AReduce consumptionGuaranteed pass rateGlass recyclingGrain treatmentsGlass fiberMachining process

The invention relates to the technical field of glass fiber powder machining, and discloses glass fiber crushing and grinding equipment for machining glass fiber powder. The glass fiber crushing and grinding equipment comprises a box body, and the top of the box body is provided with a feed port; the right and left inside walls of the box body are each provided with a transverse plate fixedly, andthe length of the transverse plate located on the right side is larger than the length of the transverse plate located on the left side; the top of each transverse plate is fixedly provided with a sliding rod, and each sliding rod is sleeved with a fixing plate movably; a support spring is fixed between the bottom of each fixing plate and the top of each transverse plate, and a crushing box is fixed between the side walls of the two fixing plates; a telescopic hose communicates between the top of the crushing box and the feed port, and a fixing frame is fixed to the middle part of the top ofthe crushing box; the fixing frame is of a door type, and the middle parts of the two side walls of the fixing frame are each provided with an open slot; and the inner top wall of the box body is fixedly provided with two support plates. According to the glass fiber crushing and grinding equipment, the problems of incomplete crushing, low efficiency, resource waste, dust overflowing in the machining process and environmental pollution are solved.

Owner:天长市天意玻璃制品有限公司

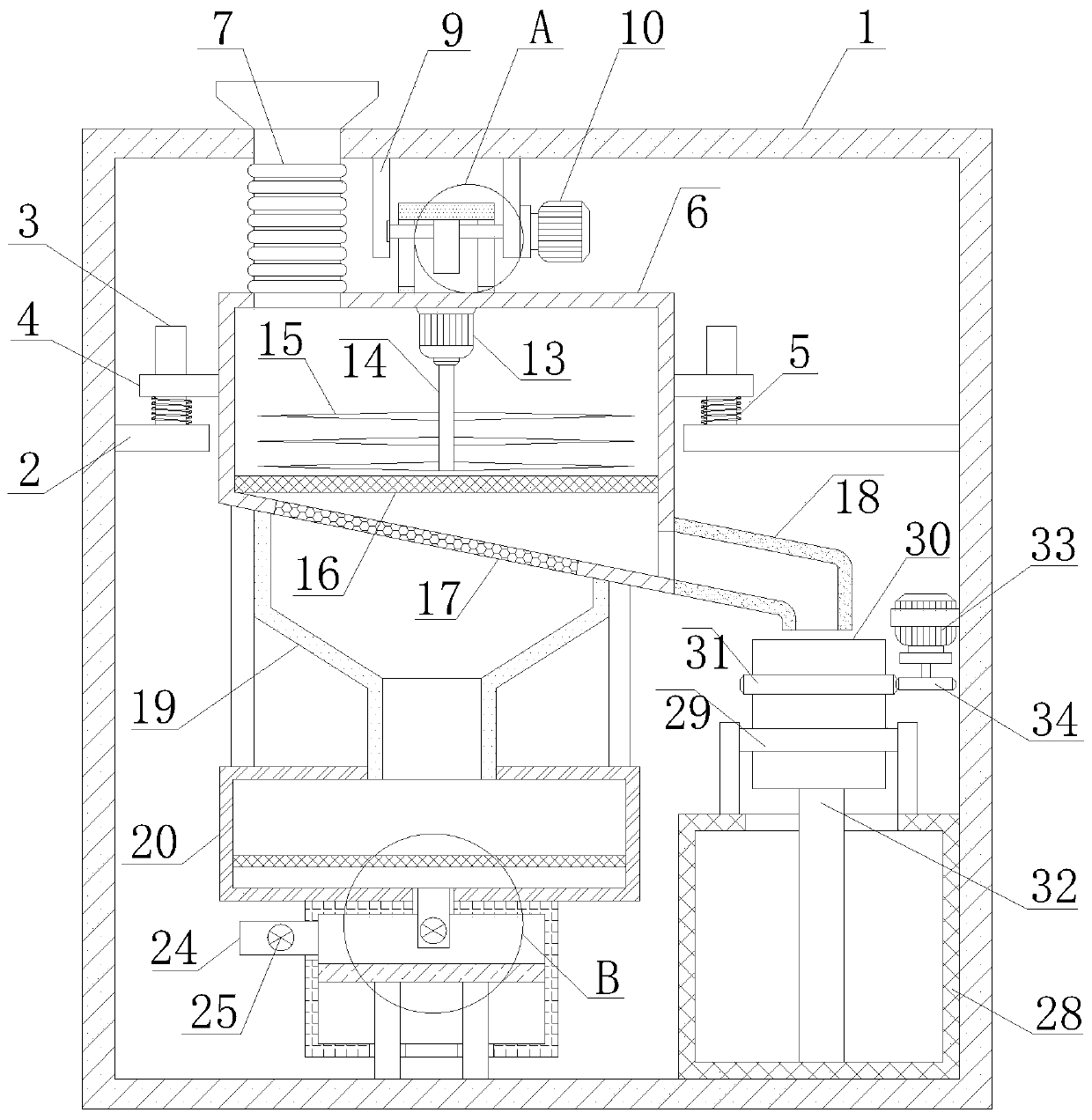

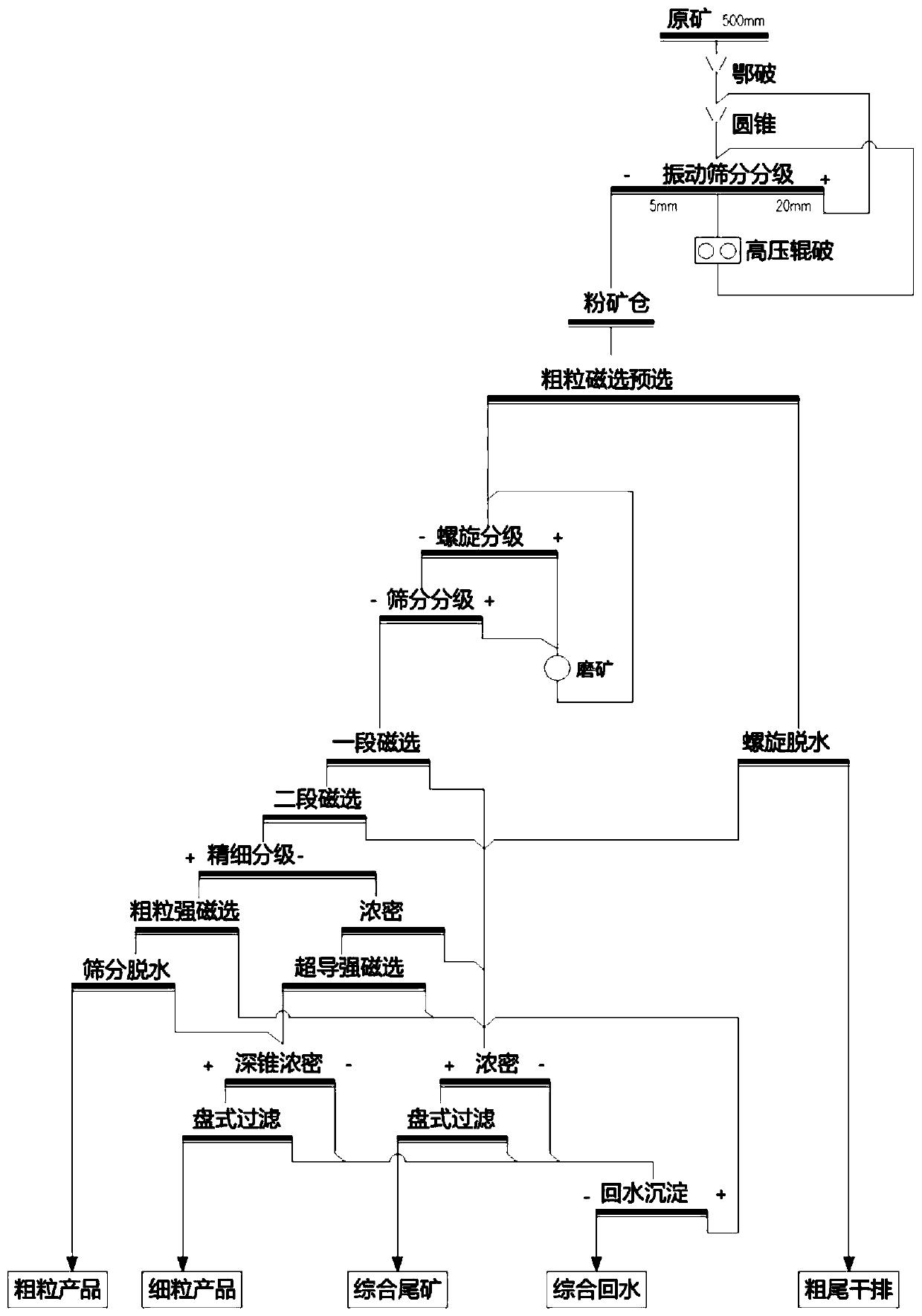

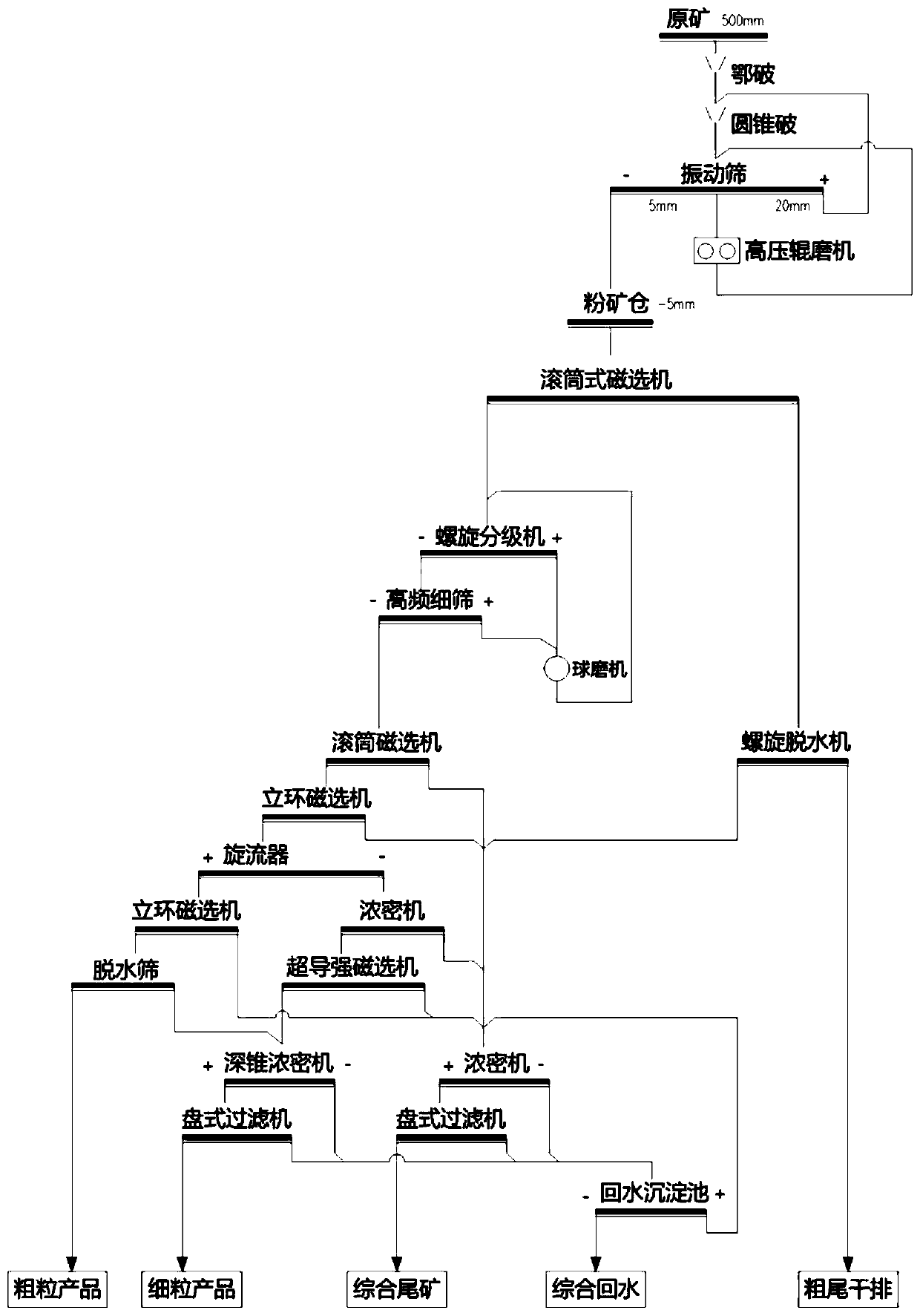

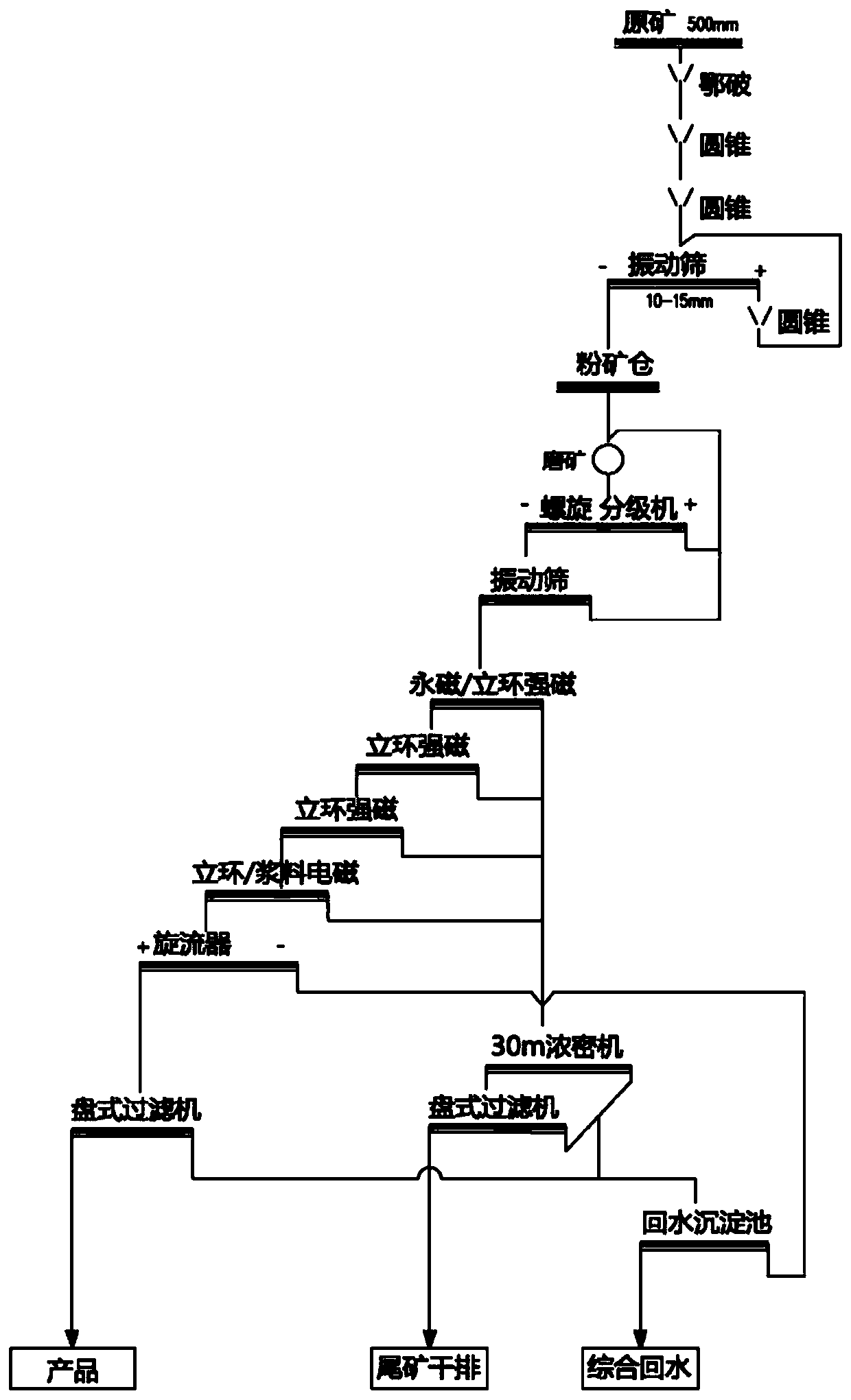

Method for improving quality, reducing cost and improving efficiency of ceramic raw materials prepared from granite stone waste rocks

ActiveCN110743684AImprovement of comprehensive technical and economic indicatorsIncrease throughputMagnetic separationGrain treatmentsMachining processGlass-ceramic

The invention provides a method for improving quality, reducing cost and improving efficiency of ceramic raw materials prepared from granite stone waste rocks. The method comprises the following steps: multi-stage crushing, laminated crushing, coarse grain pre-selection, pre-grading, partial ore grinding, multi-stage magnetic separation, grading separation, superconducting strong magnetic separation, grading dehydration and the like. The method is a pollution-free and environment-friendly physical technology in the whole process; compared with a traditional process, the comprehensive technicaland economic indexes are obviously improved, high-quality glass and ceramic raw materials with the K2O content of 6-10wt%, the Na2O content of 0.5-3.5wt%, the SiO2 content of 65-74wt% and the Fe2O3 content of 0.15wt% and the whiteness of 60-68 are obtained, the whiteness of the product is improved from 50-53 to 60-68 degrees, the yield is improved from 51-55% to 65-72%, and the treatment capacitycan be improved by 13-18%; the product structure is refined and diversified, and a proper product is provided for material homogenization, energy conservation and consumption reduction in the downstream glass and ceramic industry machining process.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

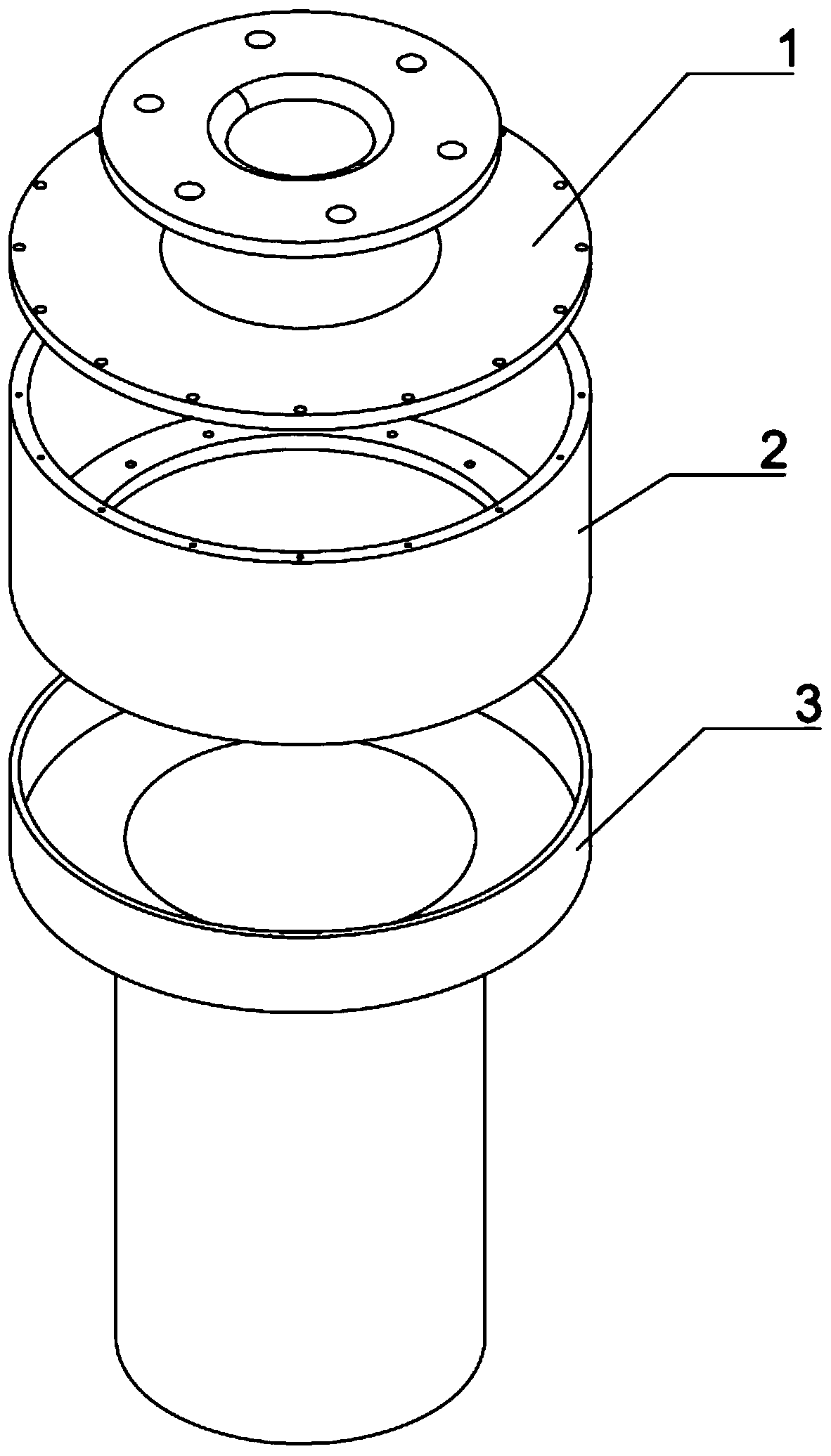

Adjustable rod body polishing equipment

ActiveCN109702633ALow costImprove grinding efficiencyEdge grinding machinesPolishing machinesArchitectural engineering

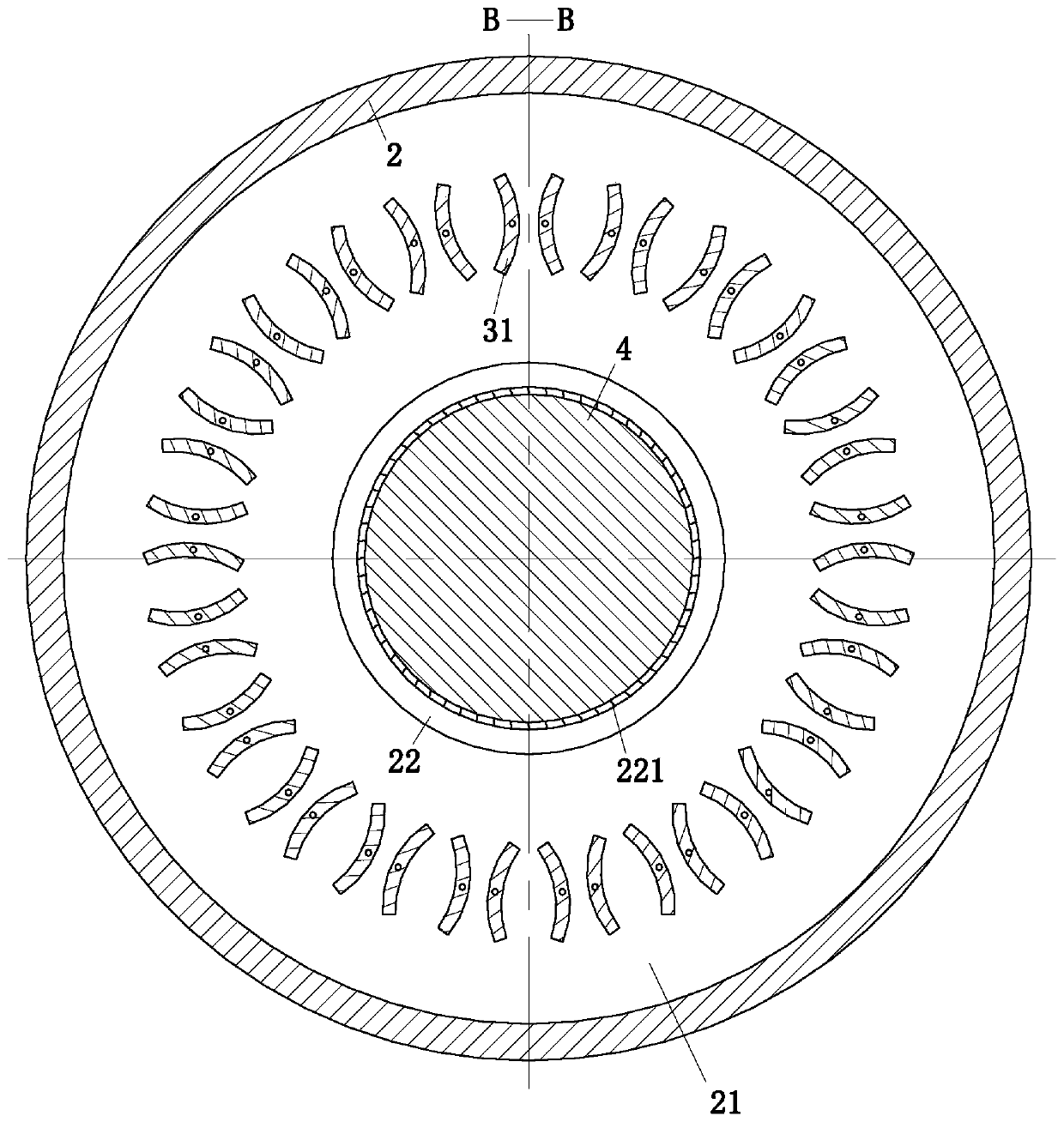

The invention belongs to the technical field of polishing equipment, and particularly relates to adjustable rod body polishing equipment. The adjustable rod body polishing equipment comprises a rack,an outer cylinder, an inner cylinder and a rod body, wherein the inner side of the rack is fixedly connected to the outer cylinder; through holes are formed in the top and bottom of the rack; the topend of the outer cylinder is fixedly connected to the inner cylinder; the inner side of the bottom end of the outer cylinder is fixedly connected to a baffle plate; a circular through hole is formed at a central position of the baffle plate; the outer cylinder is used for storing gravels; the bottom end of the inner cylinder extends to the inner side of the outer cylinder; a plurality of sets of rotating shafts are rotatably connected between the bottom end of the upper cylinder wall of the inner cylinder and the top of the baffle plate; a plurality of sets of curved plates are arranged correspondingly on the plurality of sets of rotating shafts; an adjustment module is arranged at the inner side of the top end of the inner cylinder; and the bottom end of the rod body sequentially passes through the through hole at the top of the rack, the inner cylinder, the outer cylinder, the circular through hole and the through hole at the bottom of the rack. The adjustable rod body polishing equipment can adjust the polishing precision of the rod body, improves the polishing efficiency, and can perform axial and circumferential polishing on the rod body to improve the polishing quality.

Owner:ANHUI SUNMIRO AGRI TECH

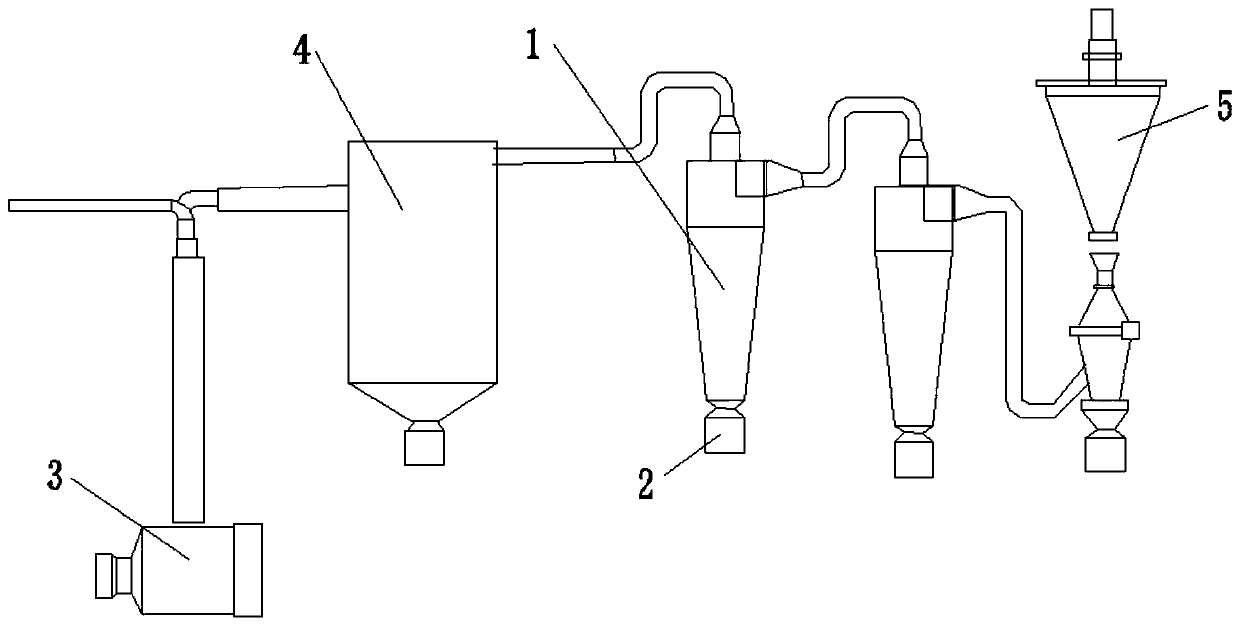

Method for sorting ultrafine copper sheets

InactiveCN110976106AMeet customized needsAvoid wastingReversed direction vortexAir volumePhysical chemistry

The invention discloses a sorting method of ultrafine copper sheets. The method comprises the following steps: taking PSD (D10: 1.0-5.0 [mu]m; D50: 6.0-9.0um; D90: 10.0-13.0 [mu]m) ultrafine copper sheets as raw materials; sorting the copper sheets through the multi-channel cyclone classification technology; controlling the particle size distribution and yield of products by controlling the gas flow rate and the air volume of an induced draft fan, wherein the gas flow rate is influenced by the pore diameter of a gas ring, the pore diameter of a gas hole is controlled to be 1.0-3.0 mm, and theflow of the induced draft fan is controlled to be 600-1,200 m<3> / h. Through the fine control of each operation parameter, products of different specifications can be produced through one-time operation, the customization requirements of different customers for the products are met, and the cost is saved.

Owner:JIANGSU BOQIAN NEW MATERIALS

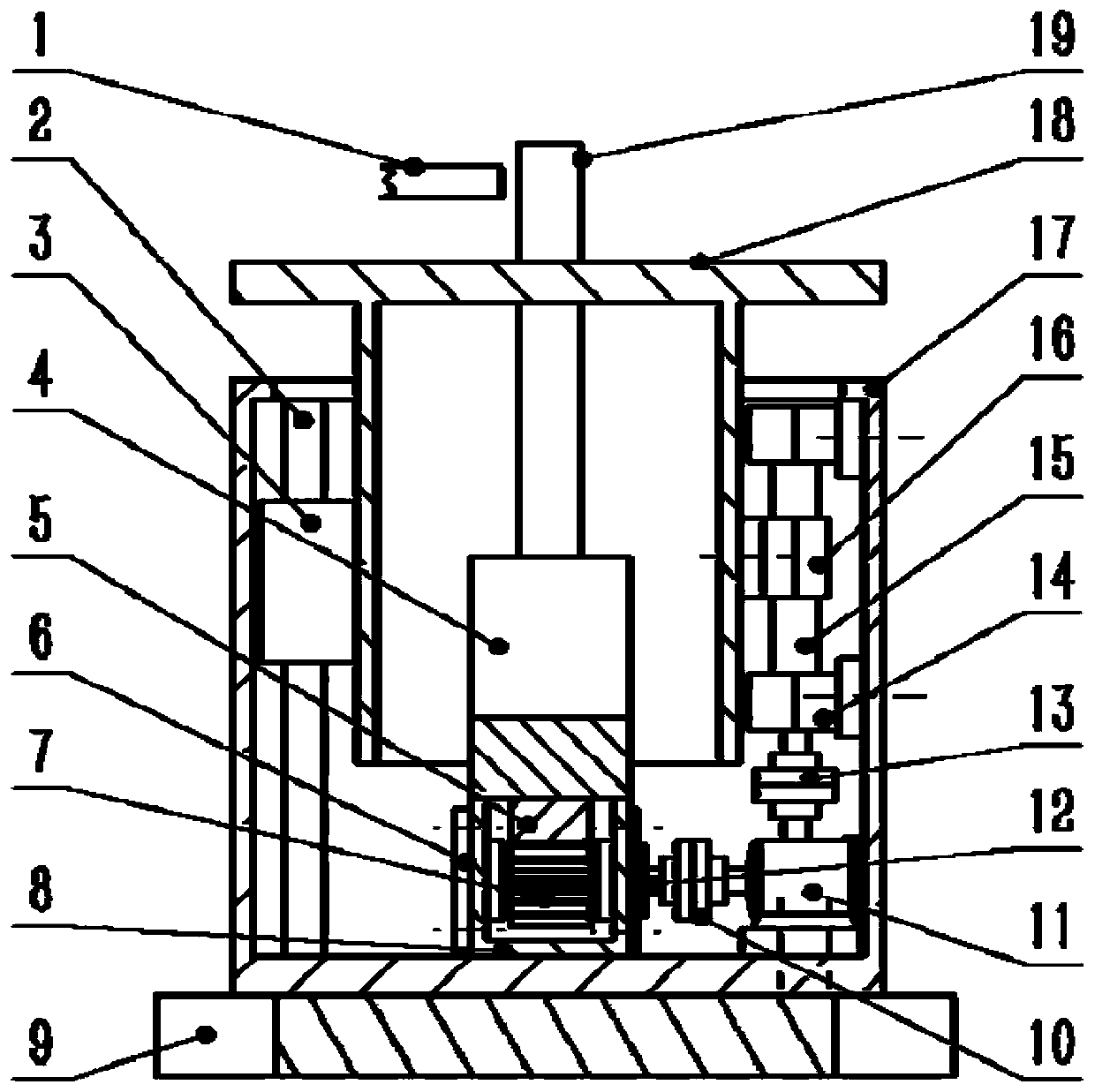

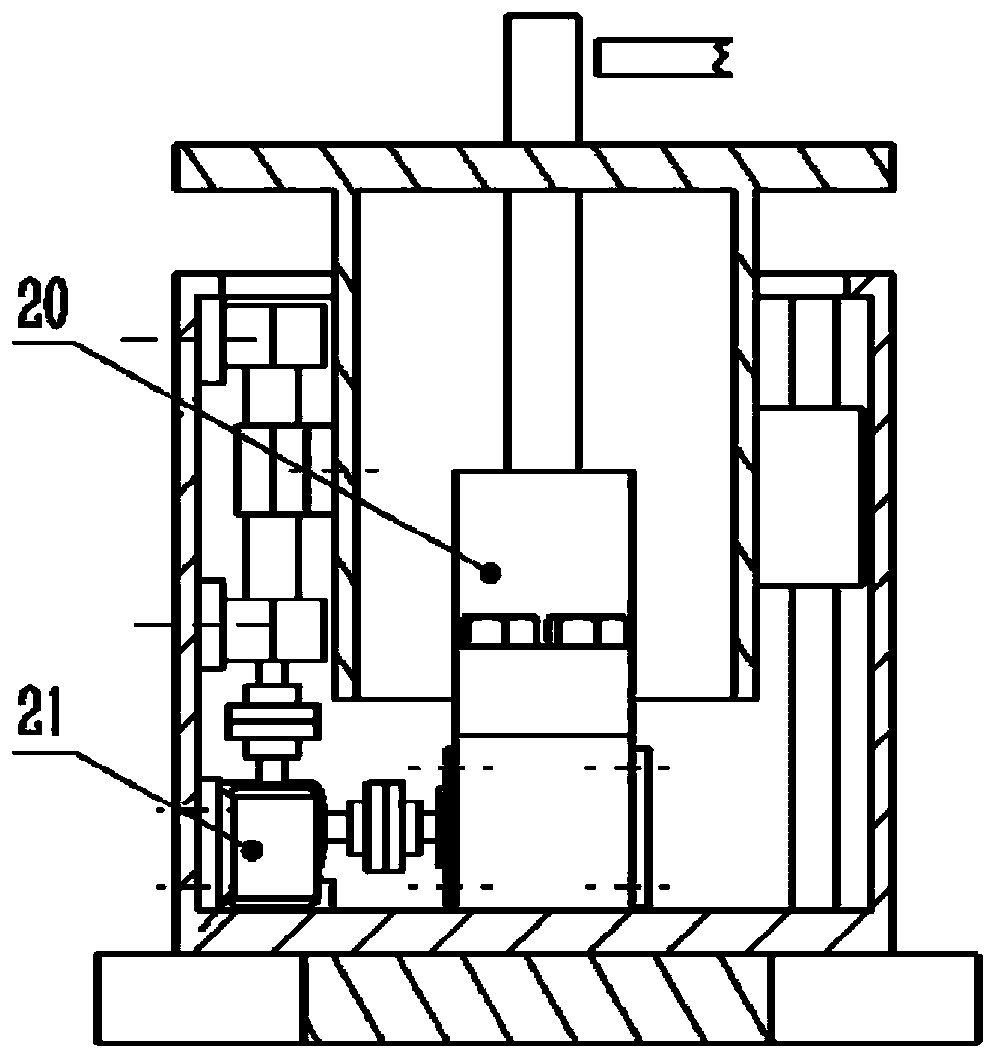

Machining device for side grooving and end face machining of honeycomb plate and double-side machining equipment of honeycomb plate

PendingCN112045431ALow costHigh positioning accuracyOther manufacturing equipments/toolsMilling cutterHoneycomb

The invention relates to a machining device for side grooving and end face machining of a honeycomb plate and double-side machining equipment of the honeycomb plate, and belongs to the technical fieldof honeycomb plate machining. The machining device for the side grooving and end face machining of the honeycomb plate comprises a mounting seat provided with a vertical sliding rail, a cutting assembly capable of moving along the vertical sliding rail, and a height adjusting mechanism for adjusting a position of the cutting assembly relative to the vertical sliding rail; the cutting assembly comprises a mounting frame connected to the vertical sliding rail in a sliding mode, a driving device fixed to the mounting frame and a cutter assembly connected to the driving device; the cutter assembly comprises a conversion shaft connected to the driving device and a cutter arranged on the conversion shaft, wherein the conversion shaft comprises a center shaft which is vertically arranged and connected to the output end of the driving device and an adjusting sleeve arranged on the center shaft in a sleeve mode; and the cutter comprise two cutter bodies located at the two ends of the adjustingsleeve correspondingly, and the cutter bodies are milling cutters or saw blades. According to the machining device, two functions of saw cutting and milling are achieved on one piece of equipment, and the cost of the machining device is reduced.

Owner:辽宁忠旺全铝智能家具科技有限公司

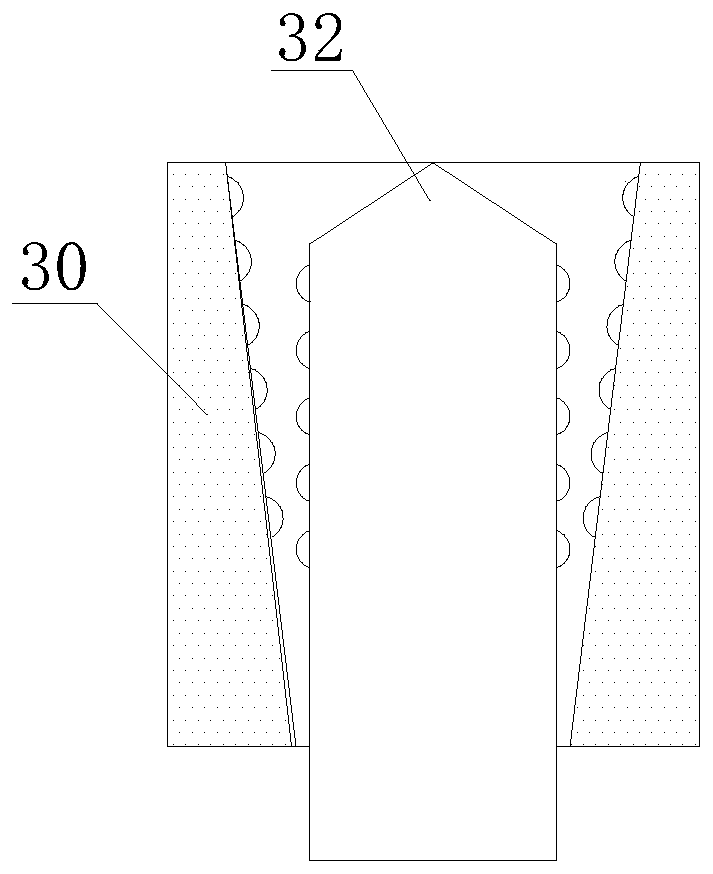

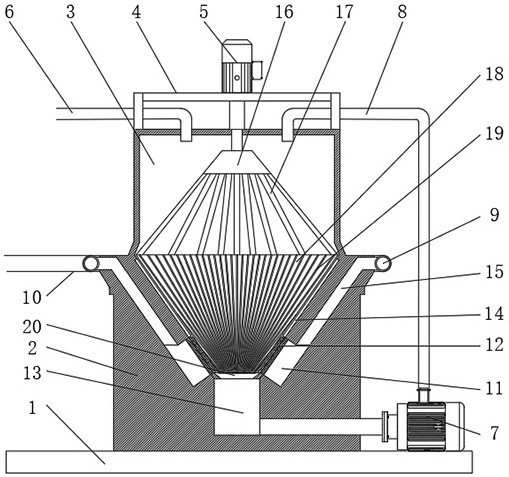

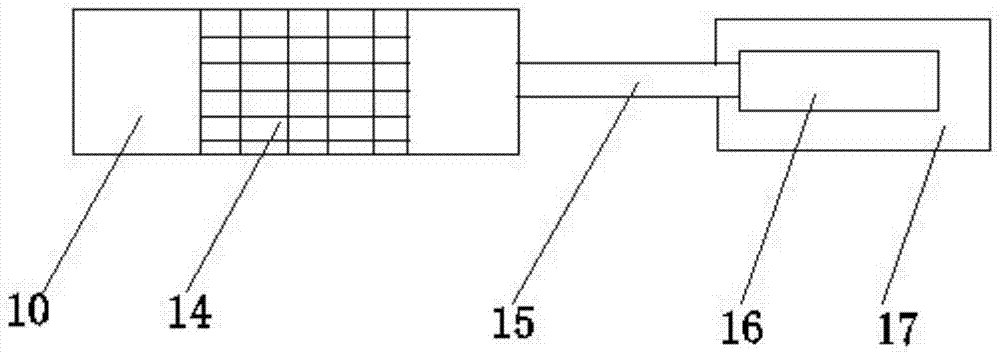

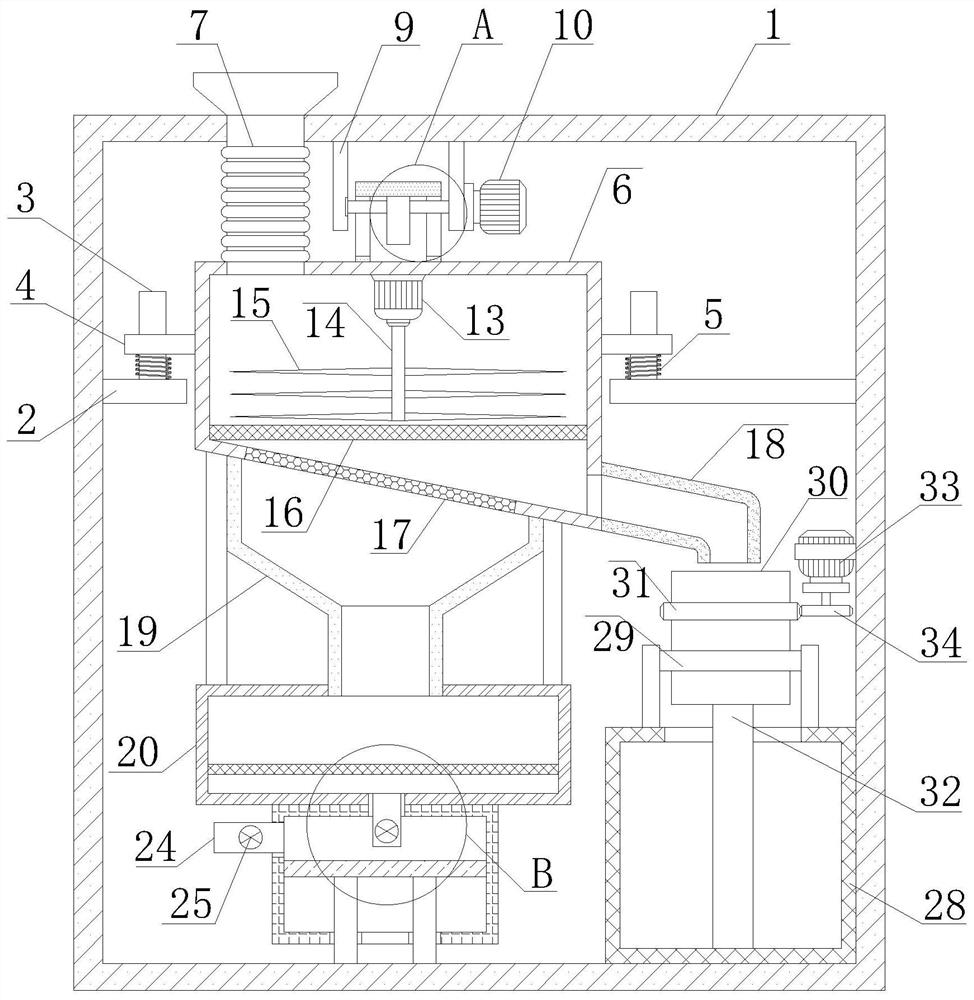

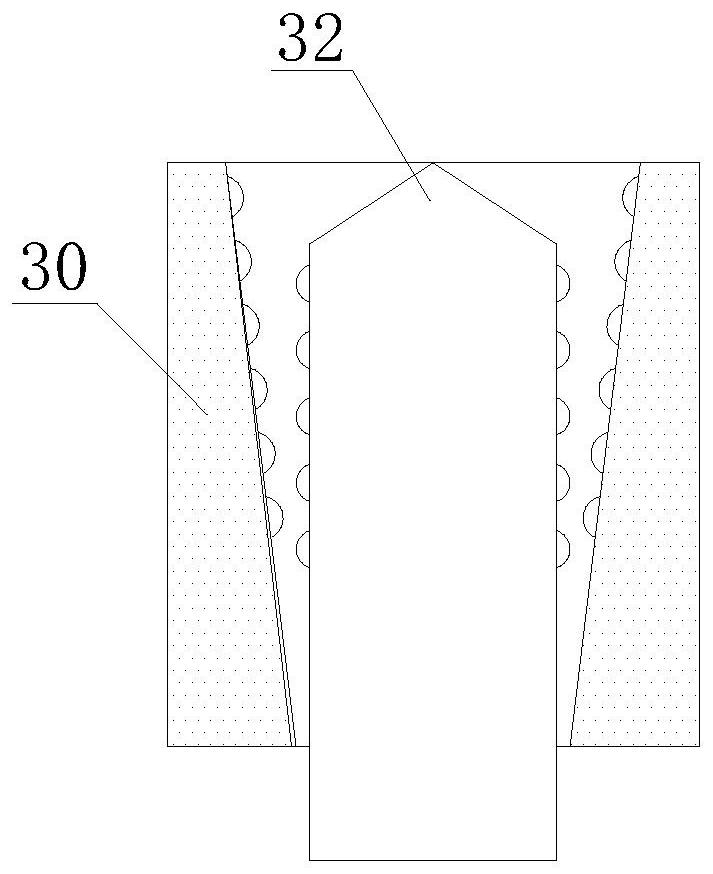

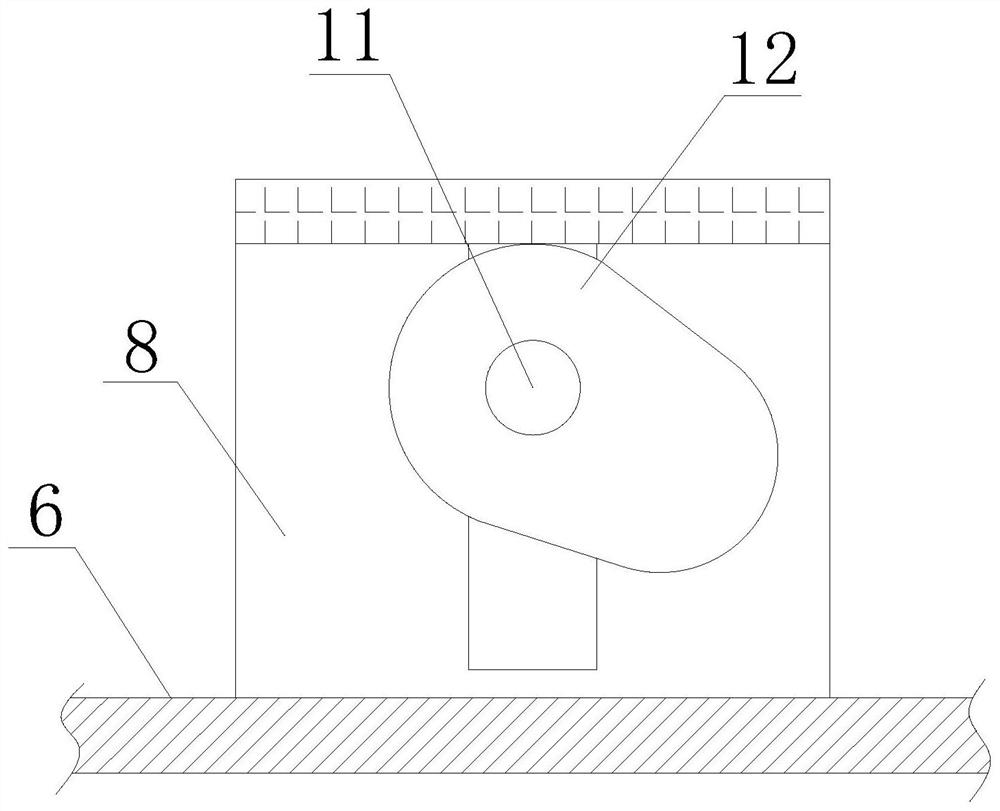

Efficient raw material grinding device

PendingCN113996378AAvoid regrindingNo manual operationGrain treatmentsProcess engineeringIndustrial engineering

The invention discloses an efficient raw material grinding device. The device comprises a driving assembly, a grinding assembly, a circulating material returning assembly and a discharging assembly, the driving assembly is installed at the top of the grinding assembly and fixedly connected with the grinding assembly, the circulating material returning assembly is installed on one side of the grinding assembly, one end of the circulating material returning assembly is connected with the bottom of the grinding assembly, the other end of the circulating material returning assembly is connected with the top of the grinding assembly, and the material discharging assembly is installed at the position of the grinding assembly. According to the efficient raw material grinding device, materials can be ground and smashed through the driving assembly and the grinding assembly, powder reaching the preset size is discharged through the discharging assembly, and due to the fact that negative pressure exists in the discharging assembly, the powder basically enters the discharging assembly, excessive raising cannot be generated, and repeated grinding of the powder is avoided; and the powder which does not reach the size is conveyed to the grinding assembly again through the circulating material returning assembly to be ground, manual operation is not needed, and the production efficiency is effectively guaranteed.

Owner:ZANHUANG JINYU CEMENT

Grinding device for processing wooden door

InactiveCN110774078AHeight adjustableAvoid regrindingGrinding carriagesGrinding feedersStructural engineeringMechanical engineering

The invention discloses a grinding device for processing a wooden door, and particularly relates to the technical field of wooden door grinding. The grinding device comprises a supporting plate. A grinding frame is arranged on the top of the supporting plate. A grinding mechanism is arranged in the grinding frame. The grinding mechanism comprises a movable plate. A grinding brush is arranged at the bottom of the movable plate. Limiting rods are arranged at the four corners of the top of the movable plate correspondingly. The top ends of the four limiting rods are all fixedly connected with thetop of an inner cavity of the grinding frame. The bottom ends of the four limiting rods all penetrate through the movable plate and extend out of the bottom of the movable plate. The bottom ends of the four limiting rods are all fixedly connected with the bottom of the inner cavity of the grinding frame. A threaded rod is arranged on one side of the movable plate. By designing the grinding mechanism, the height of the movable plate and the grinding brush can be adjusted, the grinding brush at the bottom of the movable plate can always make contact with a door board so as to have a grinding effect on the surface of the door board, the door board is prevented from being repeatedly ground, and meanwhile resources are saved to a certain extent.

Owner:徐州世纪华腾木制品股份有限公司

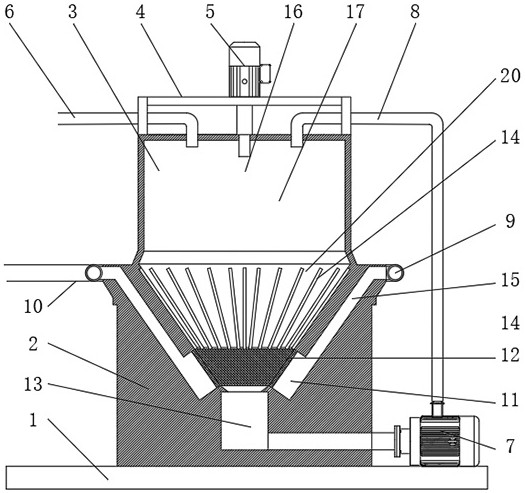

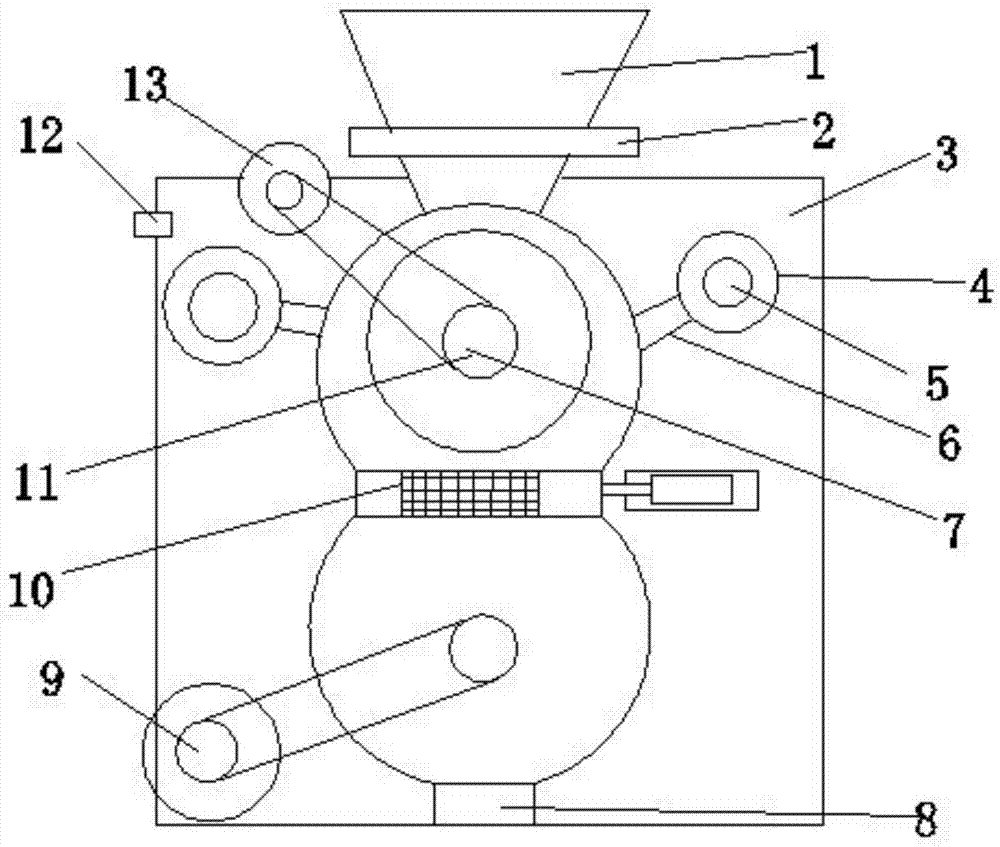

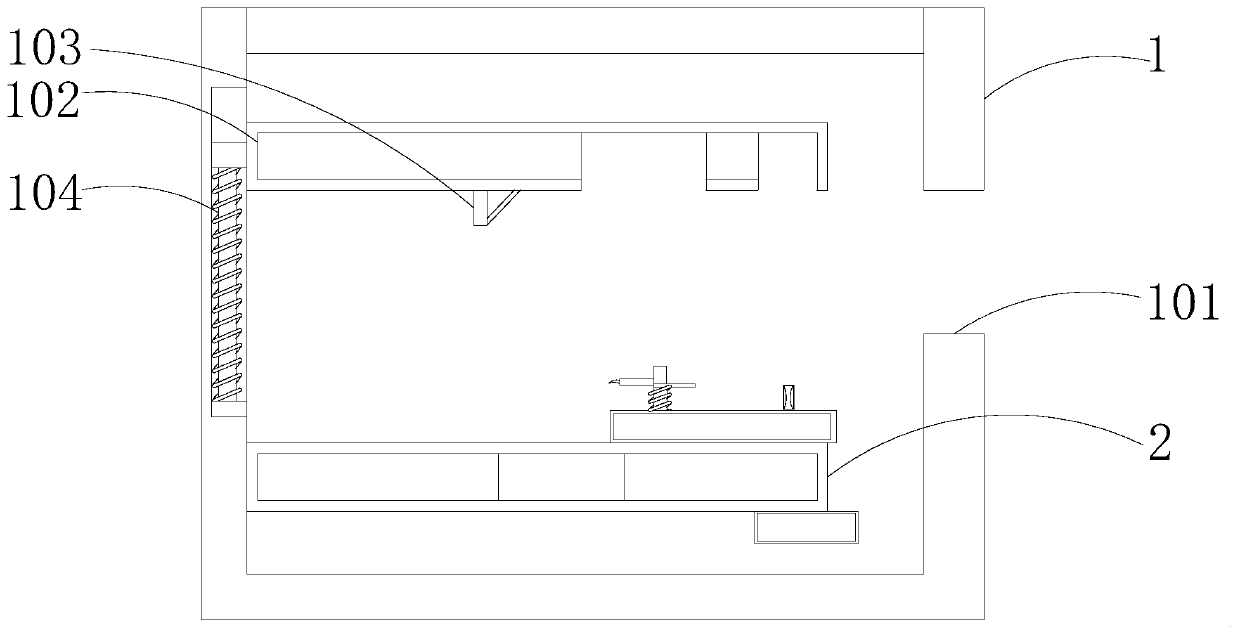

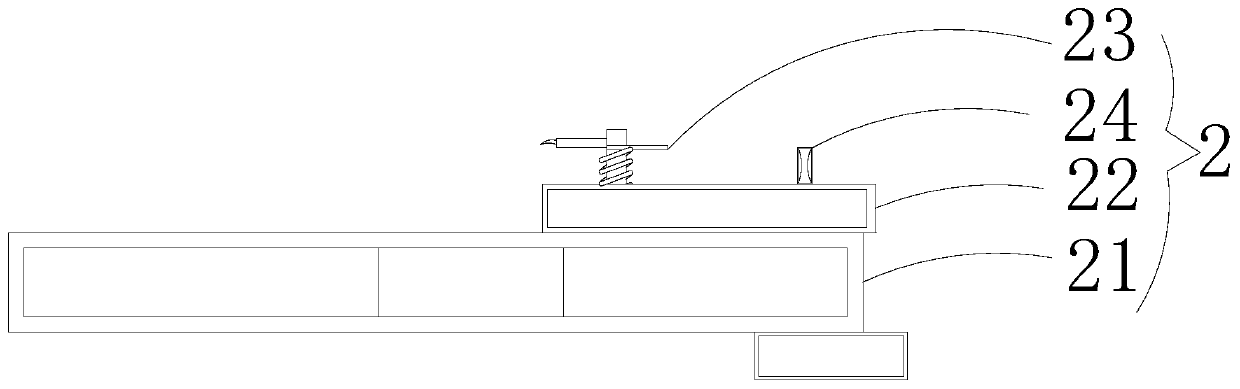

Layered grinding type uniform elastic distribution method for outsole and intelligent device

InactiveCN107538639AAvoid UndermillingAvoid regrindingDomestic articlesEngineeringMaterial resources

The invention discloses a layered grinding type uniform elastic distribution method for an outsole and an intelligent device. The intelligent device comprise a shell body, rotating shafts, a connecting plate and an upper driving motor, a feeding port is formed in the upper end of one rotating shaft, and inserting holes are formed in the upper surface of the shell body; a discharging port is formedin the bottom end of the other rotating shaft, the discharging port is fixedly connected with the shell body, and a screen is arranged on the upper surface of the connecting plate; and a vibration rod and a vibrator are arranged on one side of the connecting plate, a concave cavity is formed in the outer surface of the vibrator, and the concave cavity is fixedly connected with the vibrator. According to the layered grinding type uniform elastic distribution method for the outsole and the intelligent device, a feeding regulating valve, the connecting plate and temperature guide holes are provided, and the device is simple in structure and convenient and fast to operate; an up and down double-layer structure is adopted for grinding so that the situation that grinding is not sufficient can be effectively avoided, and re-grinding can be avoided; and manpower and material resources are saved, the processing cost is greatly reduced, the use stability is good, the method and the device are suitable for different working conditions, and a better application prospect is brought.

Owner:东莞市鹏翼自动化科技有限公司

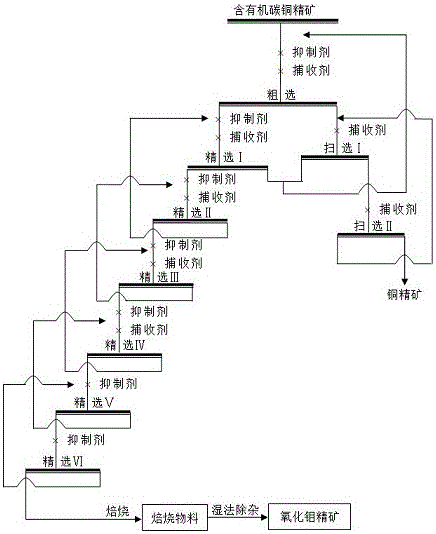

Method of comprehensively recovering low-grade molybdenum from copper concentrate containing organic carbon

ActiveCN106269206ARaise the gradeEasy to removeProcess efficiency improvementWet separationFiltrationTotal organic carbon

The invention discloses a method of comprehensively recovering low-grade molybdenum from copper concentrate containing organic carbon. The method comprises the following steps of: (1) rougher flotation operation; (2) scavenging operation; (3) concentration operation; (4) roasting operation: by taking flotation molybdenum concentrate as a raw material, adding the raw material into roasting equipment to be roasted to remove organic carbon in the molybdenum concentrate, wherein the roasting temperature is 400-600 DEG C and the roasting time is 1-3h; and (5) wet-process impurity-removal operation: by taking the roasted material as a raw material, adding the raw material into a 1-3% diluted hydrochloric acid solution, and stirring the mixture for 1-3h to remove carbonate minerals which are entrained and are not dissociated in the molybdenum concentrate, and then performing washing and filtration many times to obtain the final molybdenum oxide concentrate. The method disclosed by the invention can effectively improve the grade of the molybdenum concentrate and remove harmful element carbon in the molybdenum concentrate, avoids a re-grinding step required by guaranteeing molybdenum leaching rate in a follow-up wet-process molybdenum-extracting operation, and meanwhile, shortens the leaching time and reduces the dosage of an agent, reduces the loss of molybdate ions in organic carbon adsorption, and is remarkable in economical benefit.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

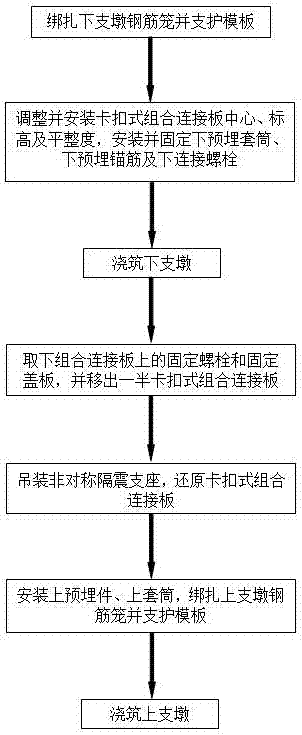

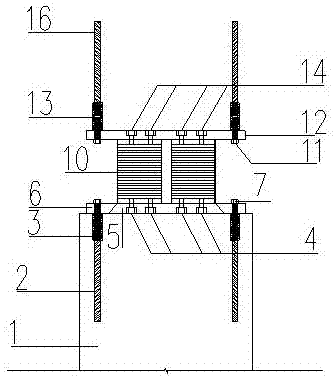

Mounting method for buckle-type asymmetric flange plate seismic isolation support

ActiveCN107574943AReduce positioningLow costBridge structural detailsProtective buildings/sheltersButtressEngineering

The invention relates to a mounting method for a buckle-type asymmetric flange plate seismic isolation support and belongs to the technical field of seismic isolation of constructional engineering. According to the mounting method, a buckle-type asymmetric combined connecting plate is used for connecting of the seismic isolation support, the upper portion of the asymmetric flange plate seismic isolation support is connected through an upper flange plate, and the lower portion of the asymmetric flange plate seismic isolation support is connected through combination of the buckle-type combined connecting plate and a cone-frustum-shaped flange plate. The buckle-type combined connecting plate is also used as a positioning plate, therefore, positioning pre-embedded plates can be omitted, and the positioning and mounting processes of the positioning pre-embedded plates are omitted; secondary polishing caused by the uneven top face of a poured lower buttress due to the low rigidity of the positioning pre-embedded plates can be avoided, and secondary grouting caused by uncompacted pouring and tamping of concrete can be also avoided; and the working efficiency and the mounting quality are improved, the engineering cost is also saved, and the seismic isolation support can be conveniently replaced in the future.

Owner:KUNMING UNIV OF SCI & TECH

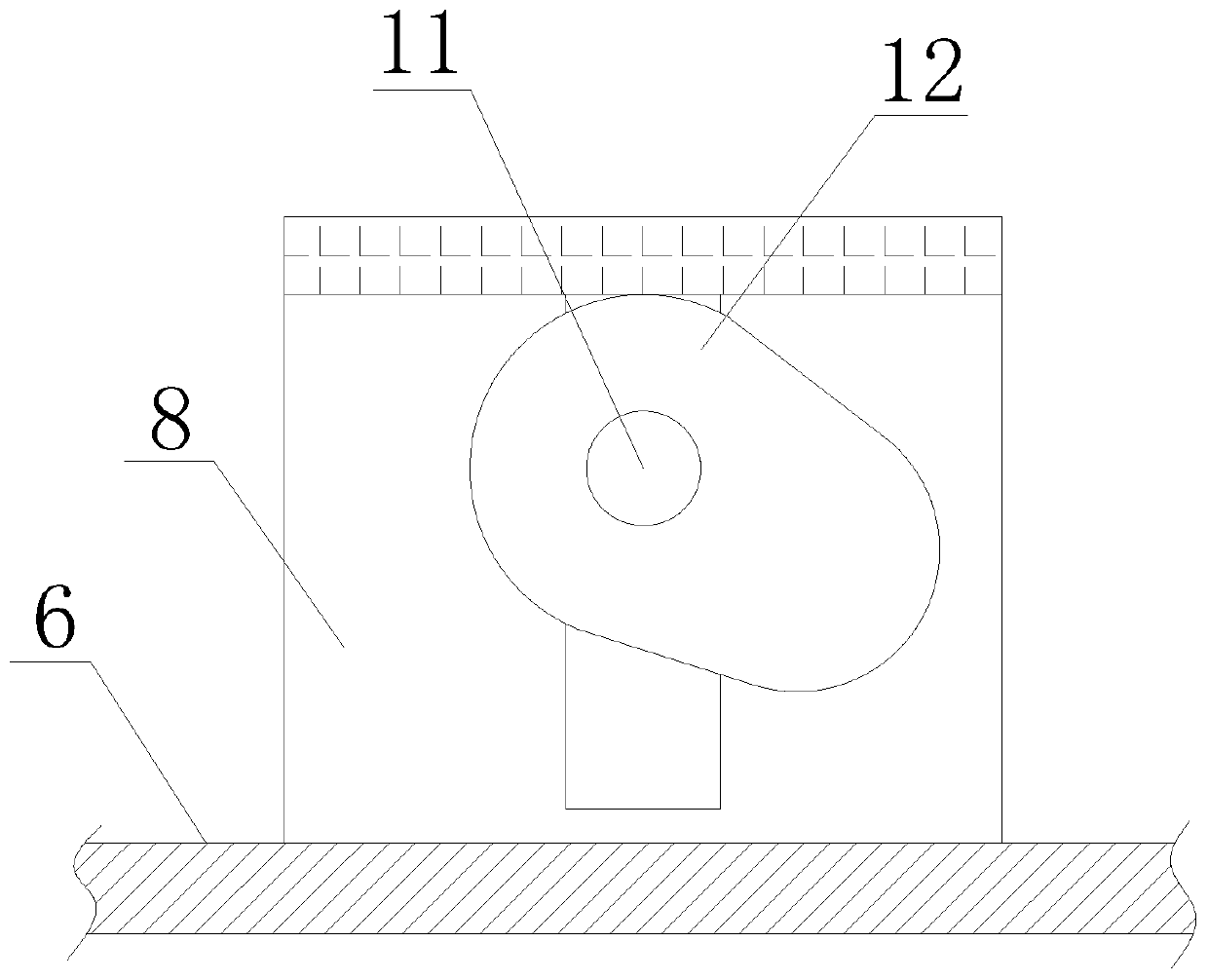

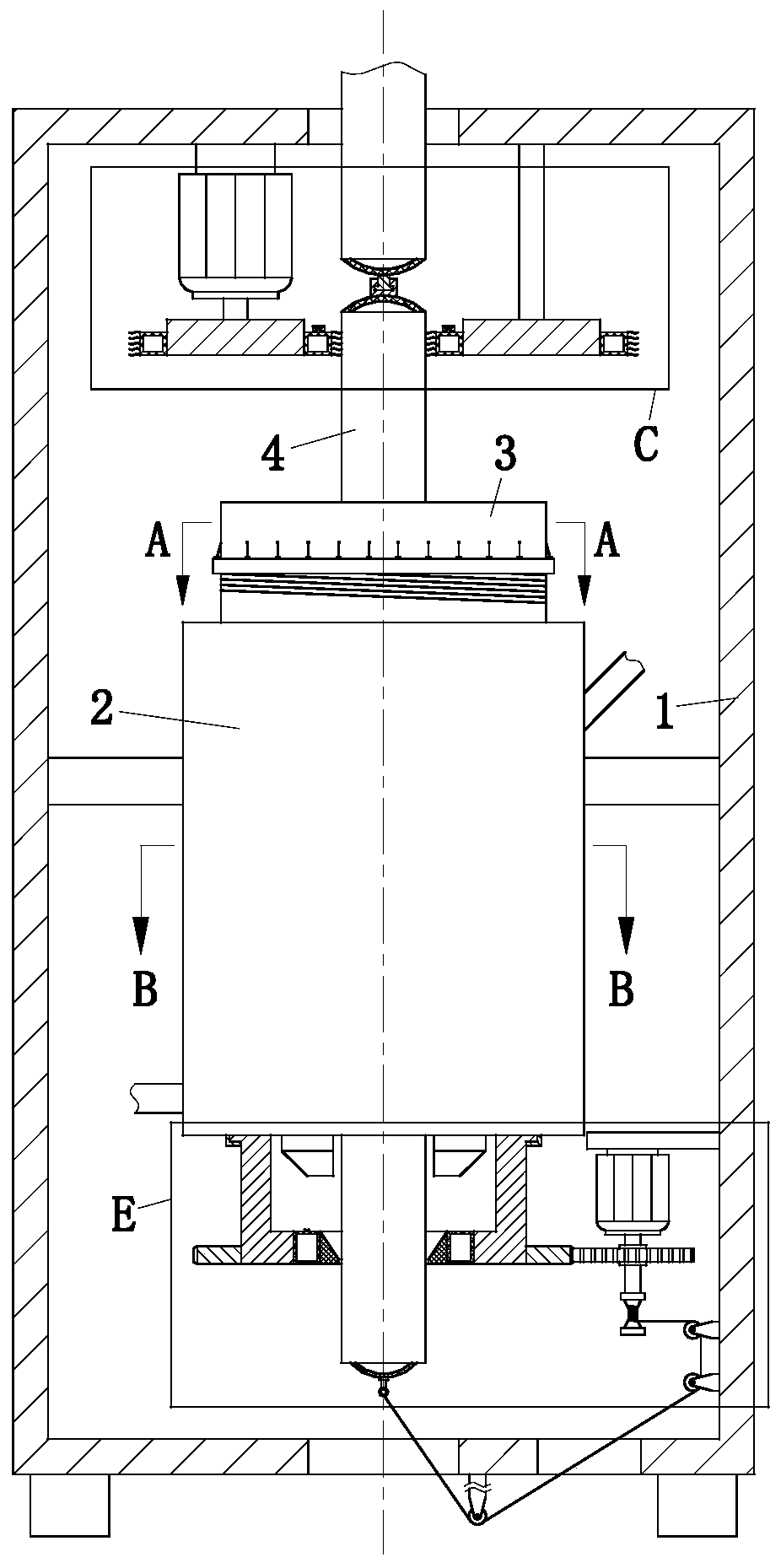

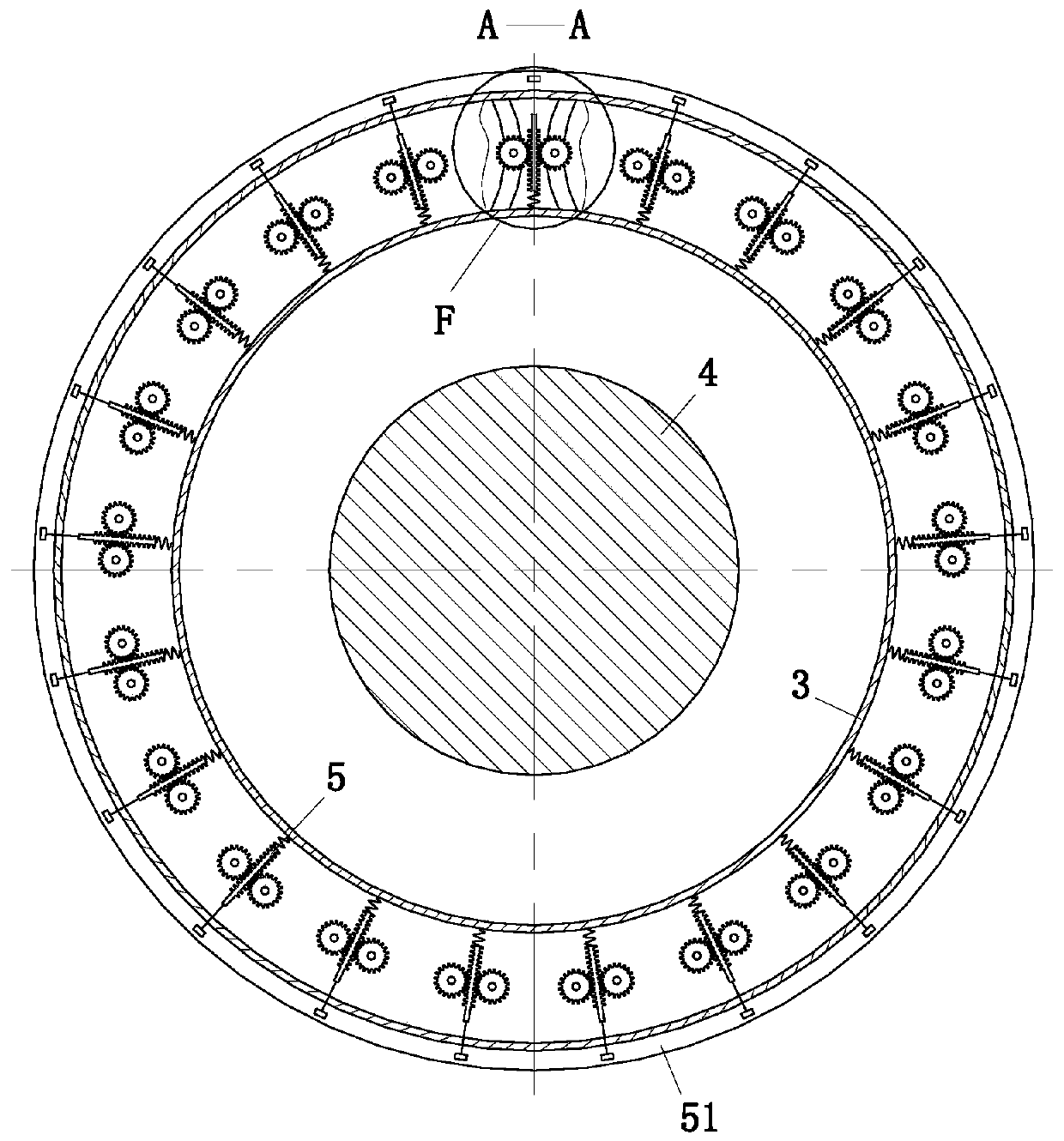

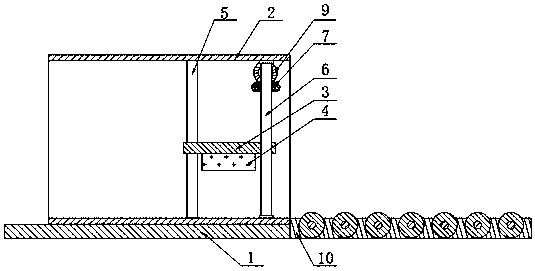

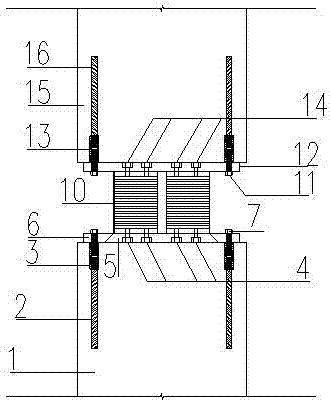

Novel dual-transmission combined efficient sorting machine

InactiveCN104549780AImprove powder selection efficiencyAvoid regrindingCentrifugesEngineeringMechanical engineering

The invention discloses a novel dual-transmission combined efficient sorting machine. The machine comprises a feeding port, a finished product collector, an upper powder selection chamber and a main support. The main support penetrates and fixes the upper powder selection chamber, a middle powder selection chamber and a lower powder selection chamber. The upper powder selection chamber is connected with the middle powder selection chamber which is connected with the upper powder selection chamber. The upper end of the upper powder selection chamber is connected with the feeding port, and two sides or the periphery of the upper powder selection chamber are or is connected with the finished product collector. A guide blade and an upper rotor are arranged in the upper powder selection chamber, and the upper rotor is disposed on the inside of the guide blade. A scattering plate is arranged above the retaining plate which is arranged above the upper rotor and the guide blade. A middle tapered element is arranged in the middle powder selection chamber, and the upper end of the middle tapered element is connected with the upper powder selection chamber. A coarse powder returning port is formed in the lower end of the lower powder selection chamber, and a lower rotor is arranged in the lower powder selection chamber. By means of the machine, the efficiency and the yield of grinding equipment are improved, and steel consumption and power consumption of the grinding equipment are reduced.

Owner:MIANYANG LANAO HEAVY MACHINERY MFG

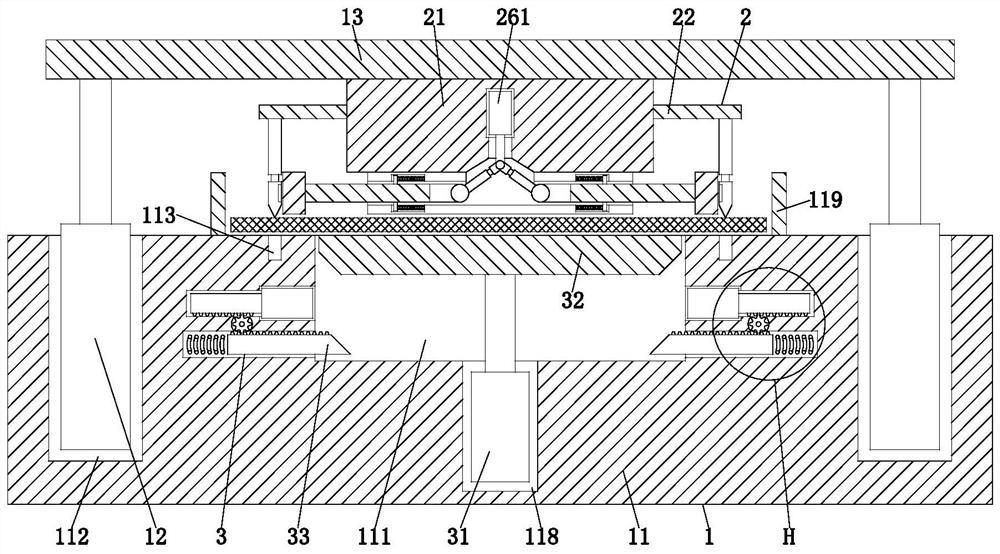

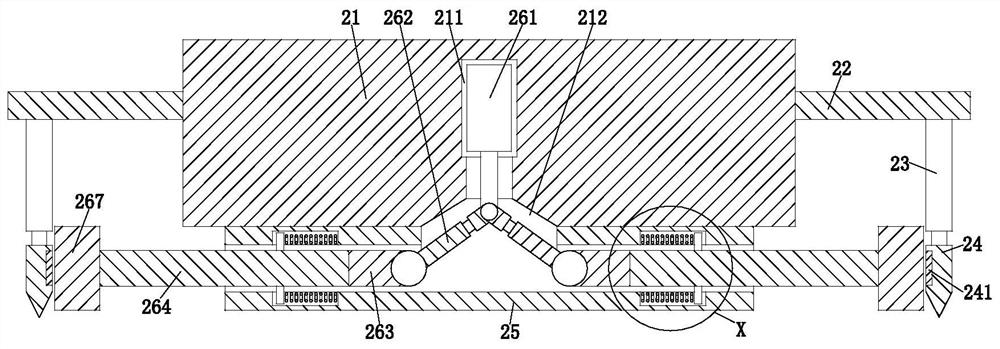

High-voltage electric cabinet manufacturing and forming method

ActiveCN112718957AReduce workloadImprove work efficiencyEdge grinding machinesGrinding machine componentsMoulding deviceStructural engineering

Owner:国网安徽省电力有限公司肥西县供电公司

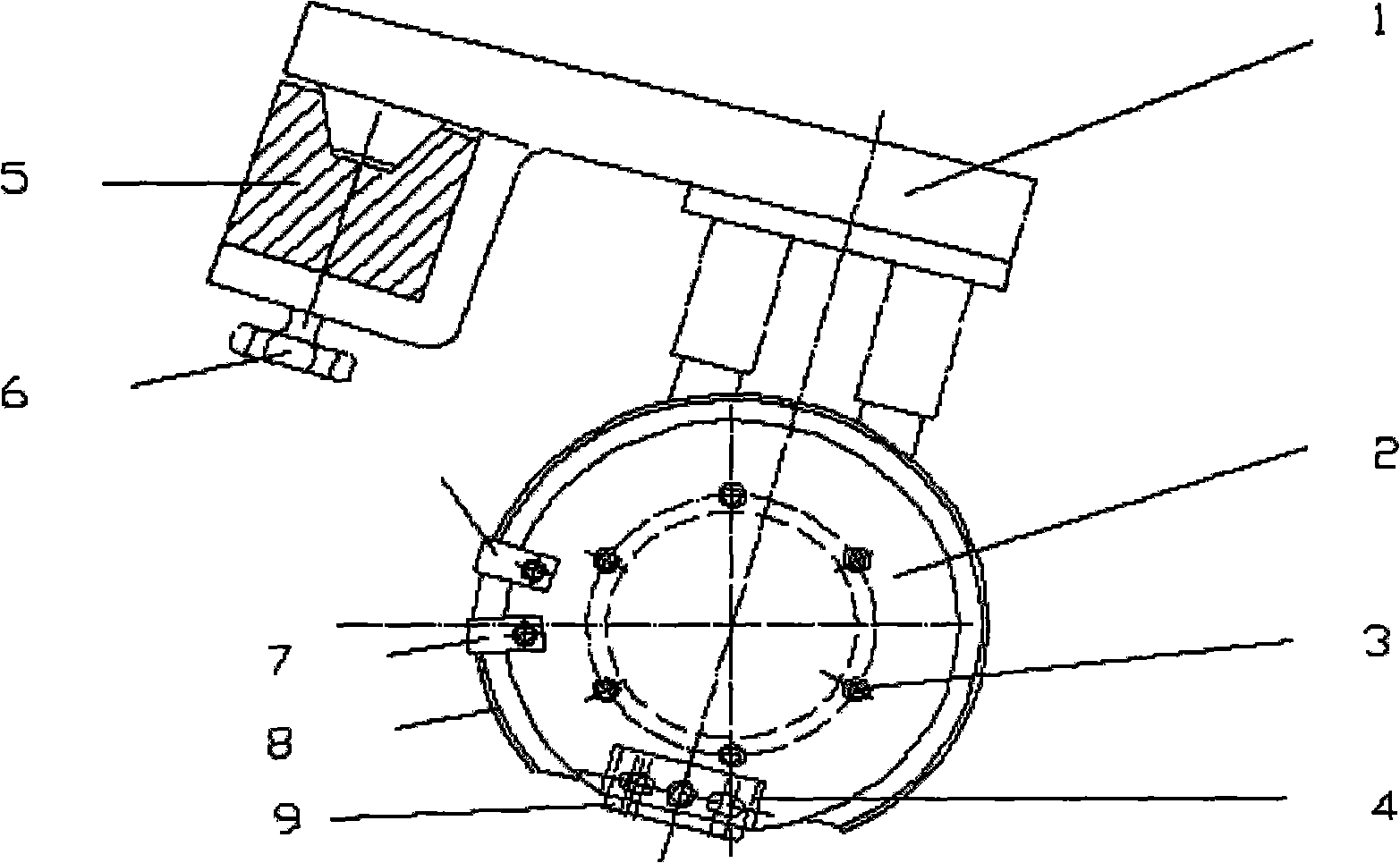

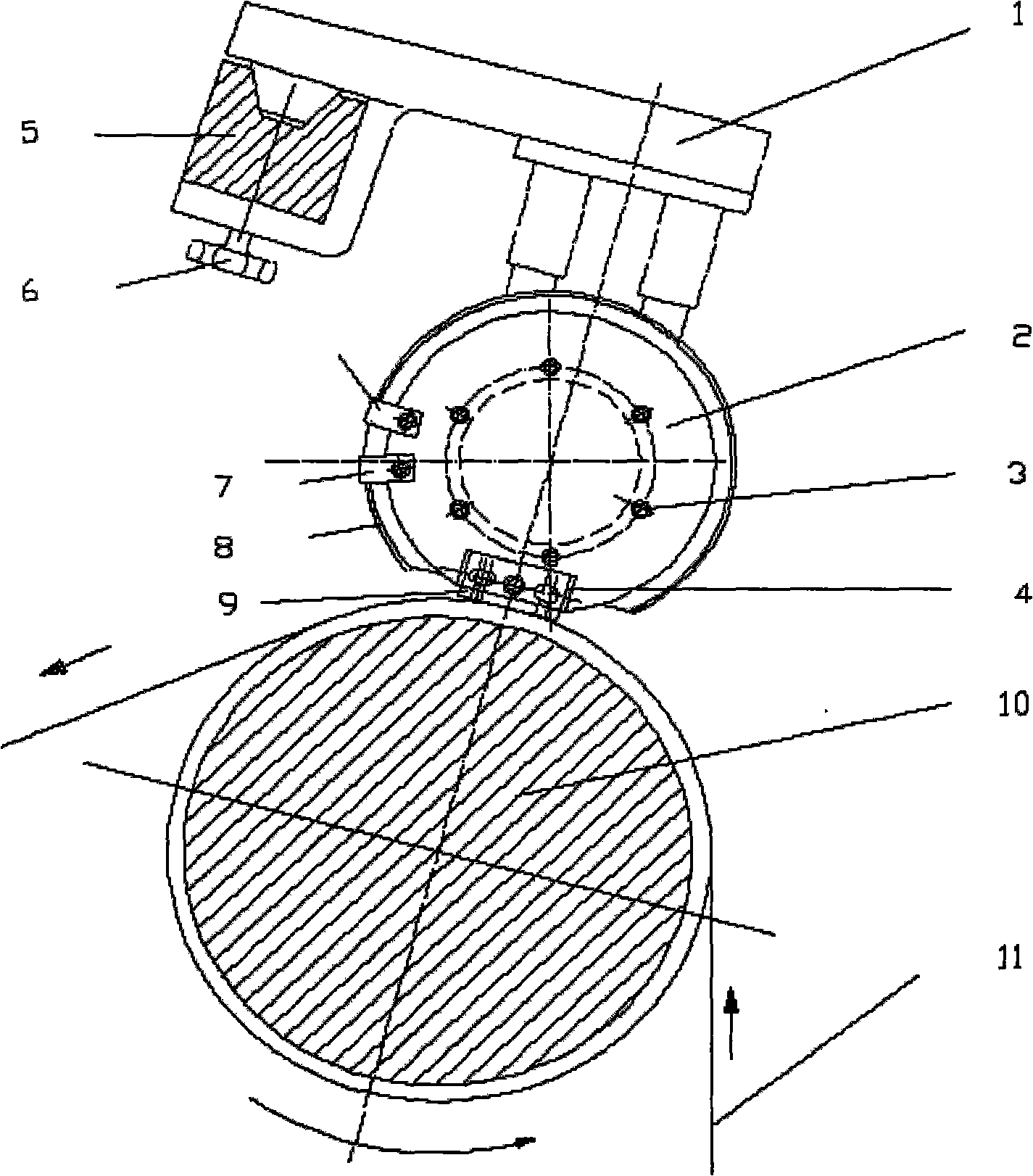

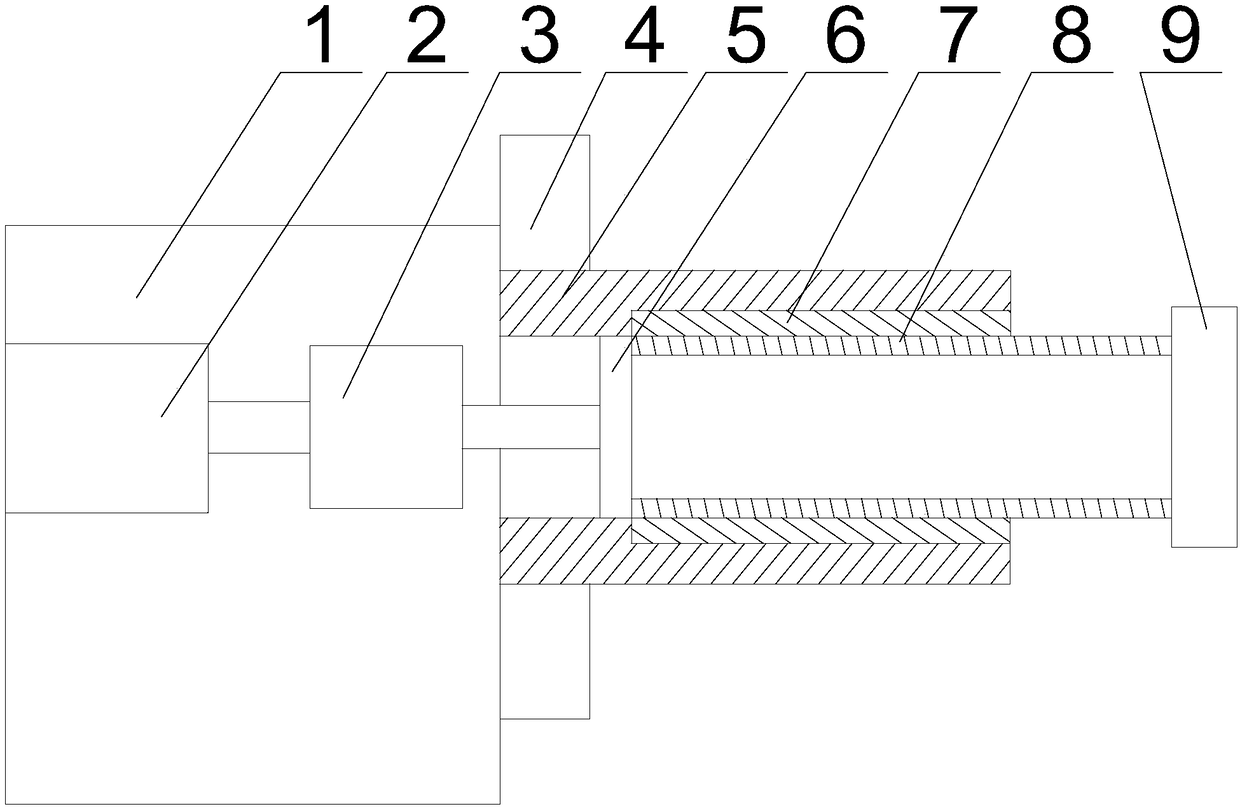

Selvedge trimming device of folding coiler

InactiveCN101314227AAdjustable use angleNo wear and tearMetal working apparatusEngineeringAluminum foil

The invention relates to an edge cutting device of a doubler, in particular to an edge cutting device of a doubler blade, which can improve the doubled edge cutting quality of aluminum foil and reduce the use cost for an edge cutting tool. The invention belongs to the edge cutting device technical field. The edge cutting device of the doubler comprises a tool post 1 fixed on a cross beam 5; the device is characterized in that: a wafer 2 is fixed on the tool post 1; a tool post protecting hood 8 is arranged on the wafer 2; an opening of the tool post protecting hood 8 is provided with a rotation retaining plate 7; and a blade 9 is fixed on the wafer 2. The edge cutting device of the doubler can adjust or fix a use angle of the blade, controls a cutting depth and a centerline of a cutter groove in a certain scope for normal use and makes the tool adjusting operation simple and efficient; a cutting edge of the blade falls on the centerline of the cutter groove of a cutting shaft, and can not cause the abrasion of the cutting edge of an edge cutting shaft of the doubler; the edge cutting device adopts a cheap blade for edge cutting, avoids the cutting tool from re-grinding and reduces the use cost for the edge cutting tool; the end face of the doubled aluminum foil is very smooth and flat and has no disadvantages of burr, aluminum crumb, etc.; and the aluminum foil has high quality of edge cutting and is favorable for doubled rolling.

Owner:SHANDONG NANSHAN ALUMINUM

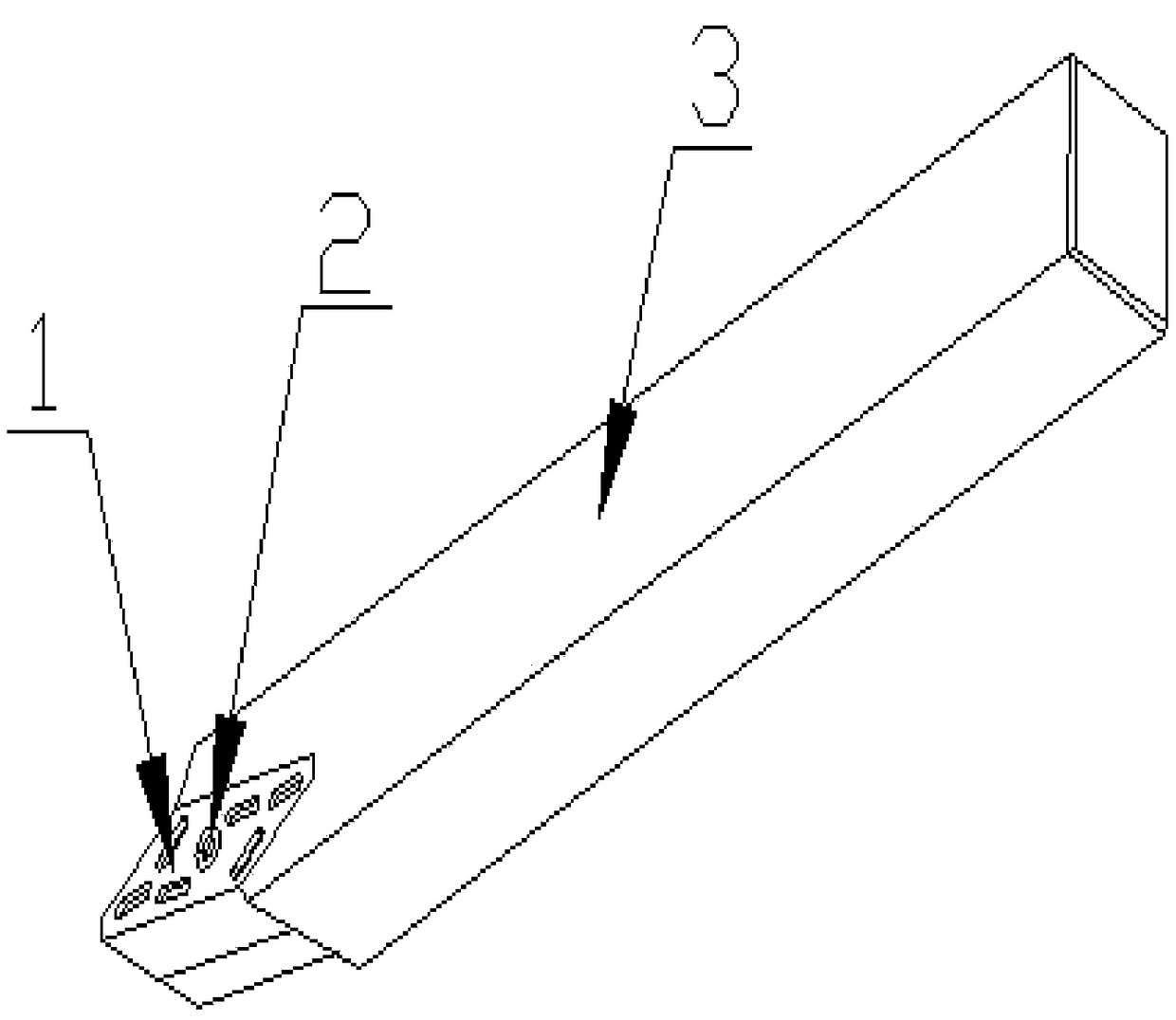

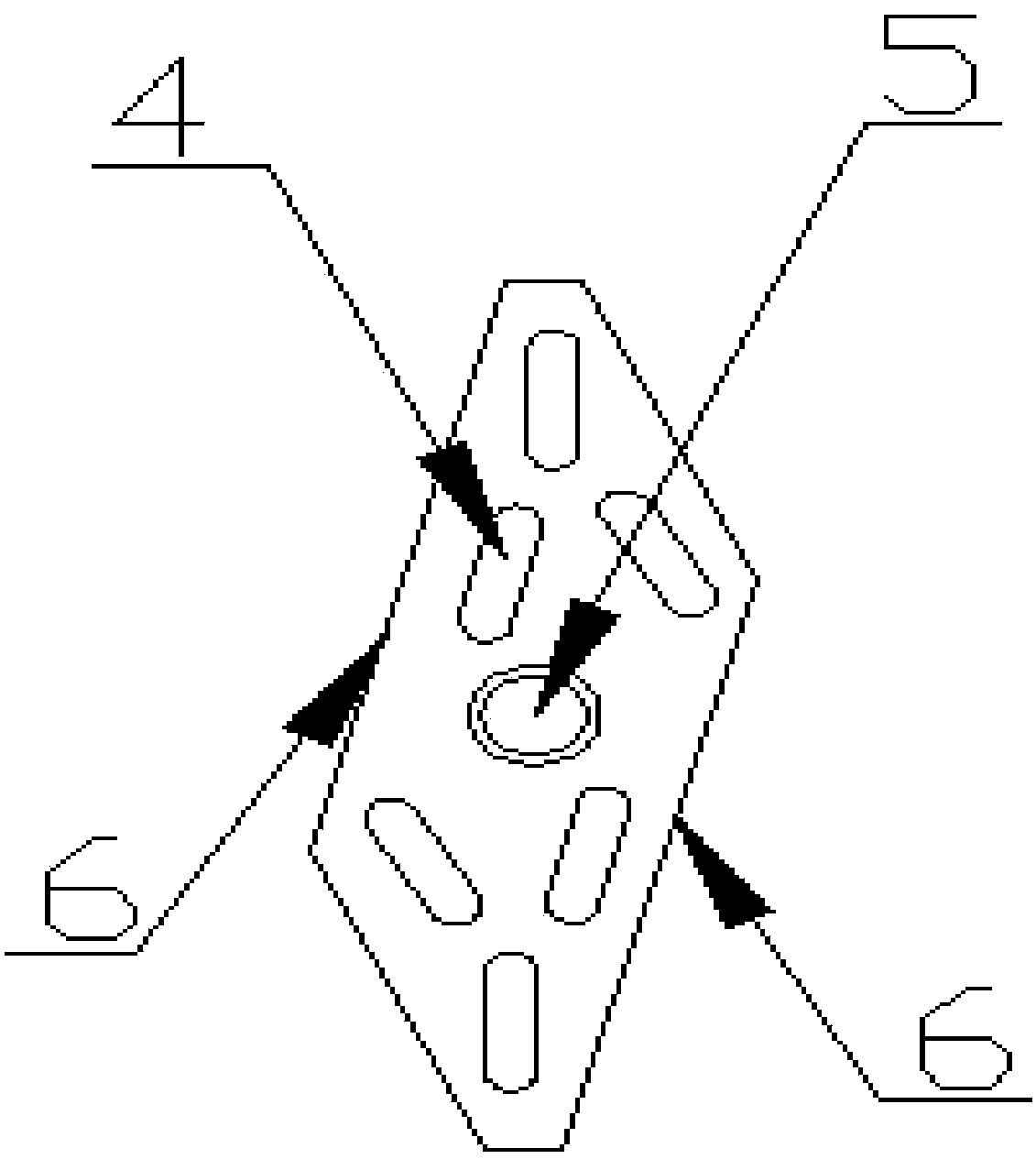

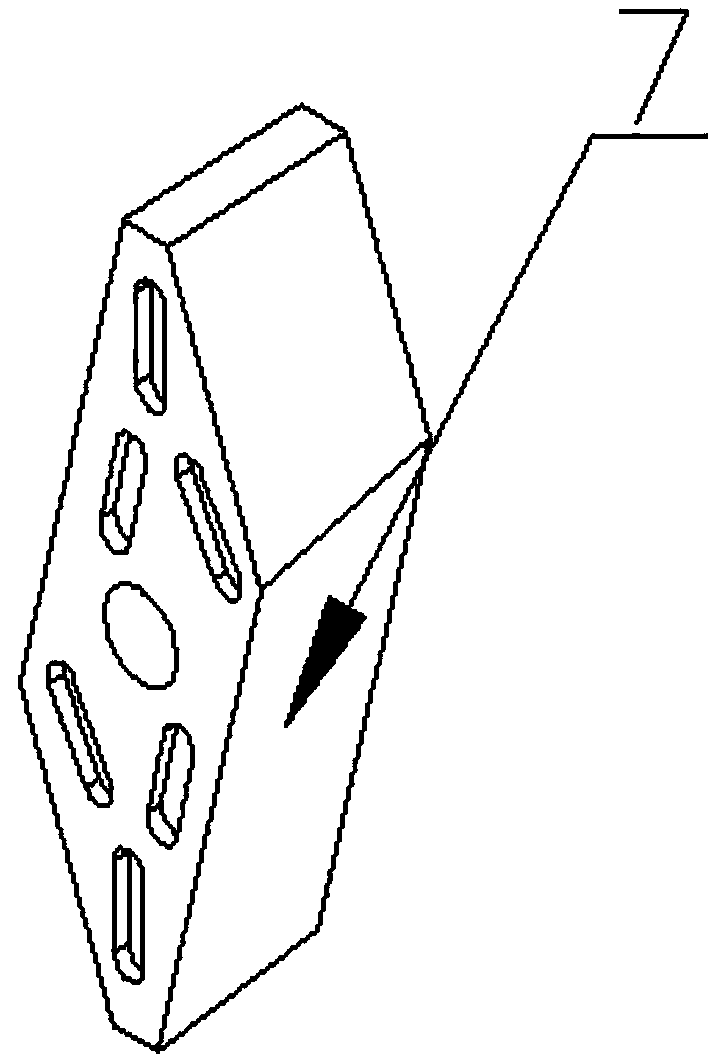

Convertible milling edge-type milling cutter bar for processing constant-depth tooth arc-bevel gear

The invention discloses a convertible milling edge-type milling cutter bar for processing a constant-depth tooth arc-bevel gear, and belongs to the technical field of cutters, and solves the problemsthat a rhombic cutter blade is liable to wear and be in failure, and there is only one cutter edge on one rhombic cutter blade. The convertible milling edge-type milling cutter bar includes a cutter body, wherein a half of rhombic groove is formed on one end thereof; a rhombic bearing sheet is arranged on the bottom of the groove and a rhombic cutter blade is arranged on the rhombic bearing sheet.The rhombic cutter blade is fixed to the rhombic bearing sheet via bolts. Three recess grooves are formed respectively at each of two sides of the diagonal line of the rhombic cutter blade. Cutting edges are arranged on a pair of opposite edges of the rhombic cutter blade. If the cutting edges on one side of the cutter bar are damaged, the rhombic cutter blade can be rotated by 180 degrees for installation just by loosening the bolt without detachment of the cutter blade from a cutter head, so that resharpening and reinstallation of the cutter bar are avoided, and utilization rate of the cutter bar is improved. Abrasion on the rhombic cutter blade is reduced and service life of same is prolonged since the recess grooves are distributed on the front blade surface.

Owner:HARBIN UNIV OF SCI & TECH

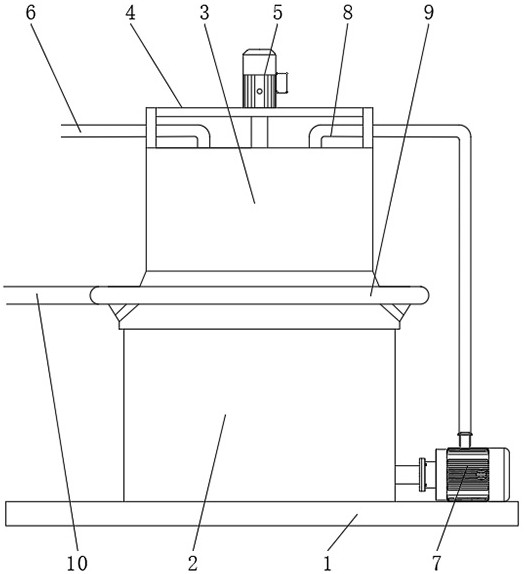

Low-energy-consumption colloid grinder type emulsifying machine

The invention discloses a low-energy-consumption colloid grinder type emulsifying machine. The two ends of a stator shell of the emulsifying machine are connected with a shell body and an end cover correspondingly. The shell body is internally provided with a main shaft. A shaft body of the main shaft of the emulsifying machine is sequentially connected with a coupler, a bearing and a rotor in a matched mode. One end of the rotor and one end of a stator are each provided with eight layers of conical grinding teeth. The rotor and the stator are engaged with each other through the grinding teeth. A fixing sleeve, a sliding sleeve and the baring of the emulsifying machine are located in the shell body and connected with one another. A sealing cover and a sealing ring are arranged between the main shaft and the sliding sleeve and are connected with each other. A gland and fillers are sequentially arranged between the stator shell and the main shaft of the emulsifying machine. A paper washer is arranged between the stator and the end cover. A sealing washer is arranged at one end of the stator. The emulsifying machine has super high shearing and grinding functions, the production efficiency is high, energy consumption is low, the overall sealing performance of the emulsifying machine is remarkably improved, and the service life of the emulsifying machine is significantly prolonged.

Owner:太仓液压元件有限公司

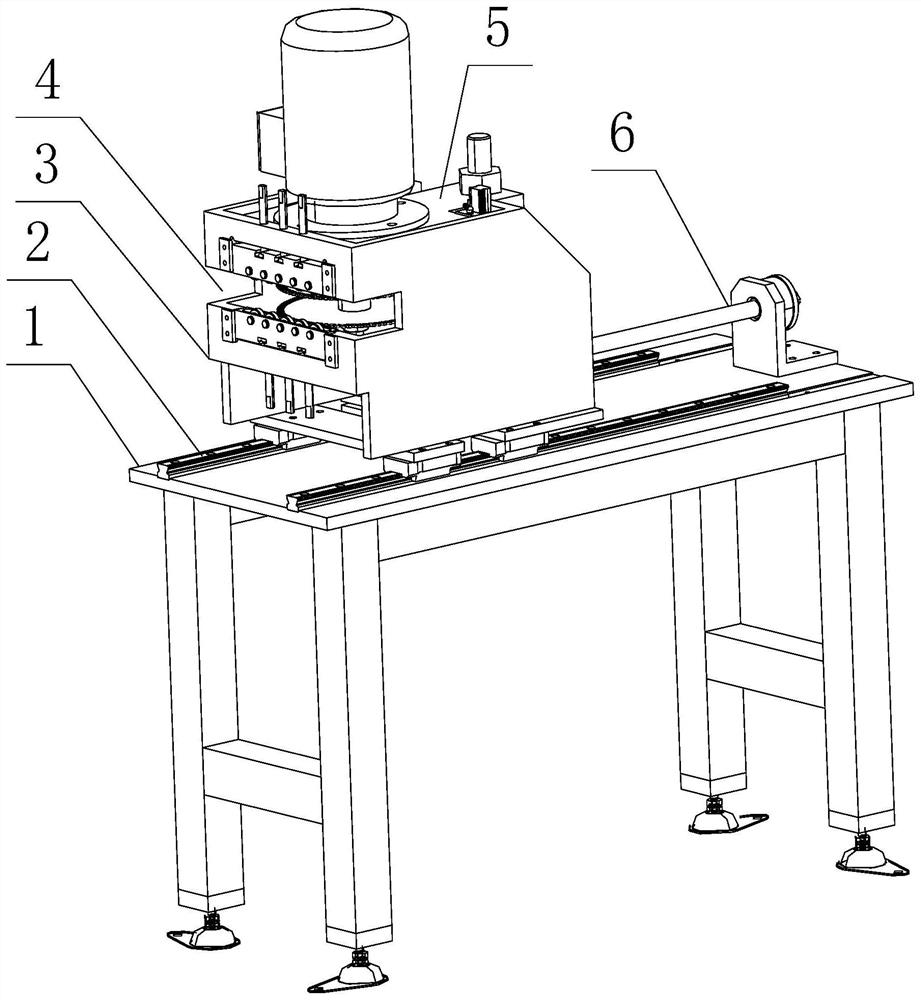

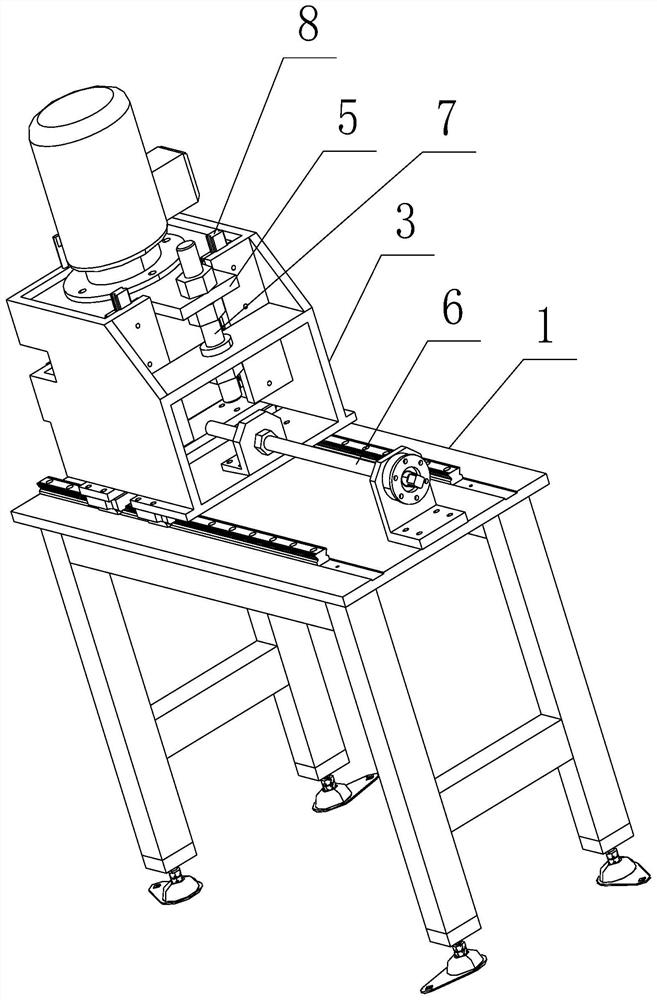

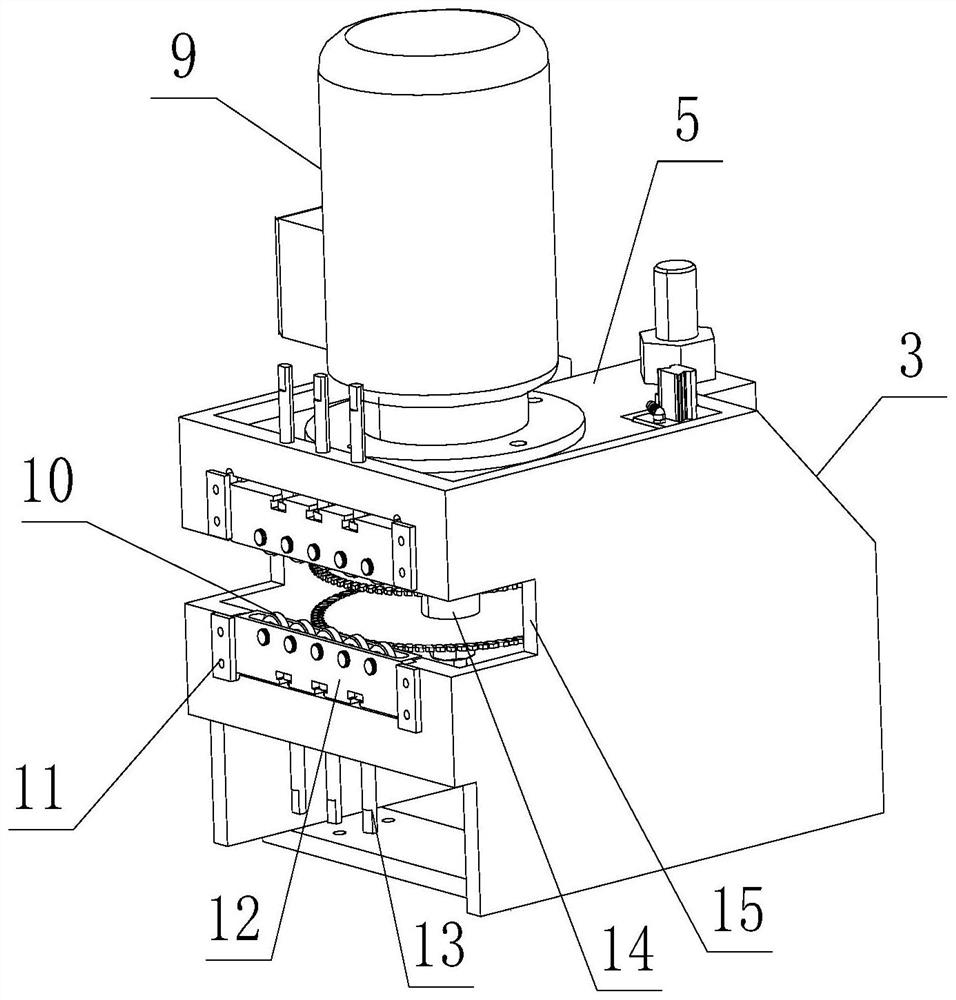

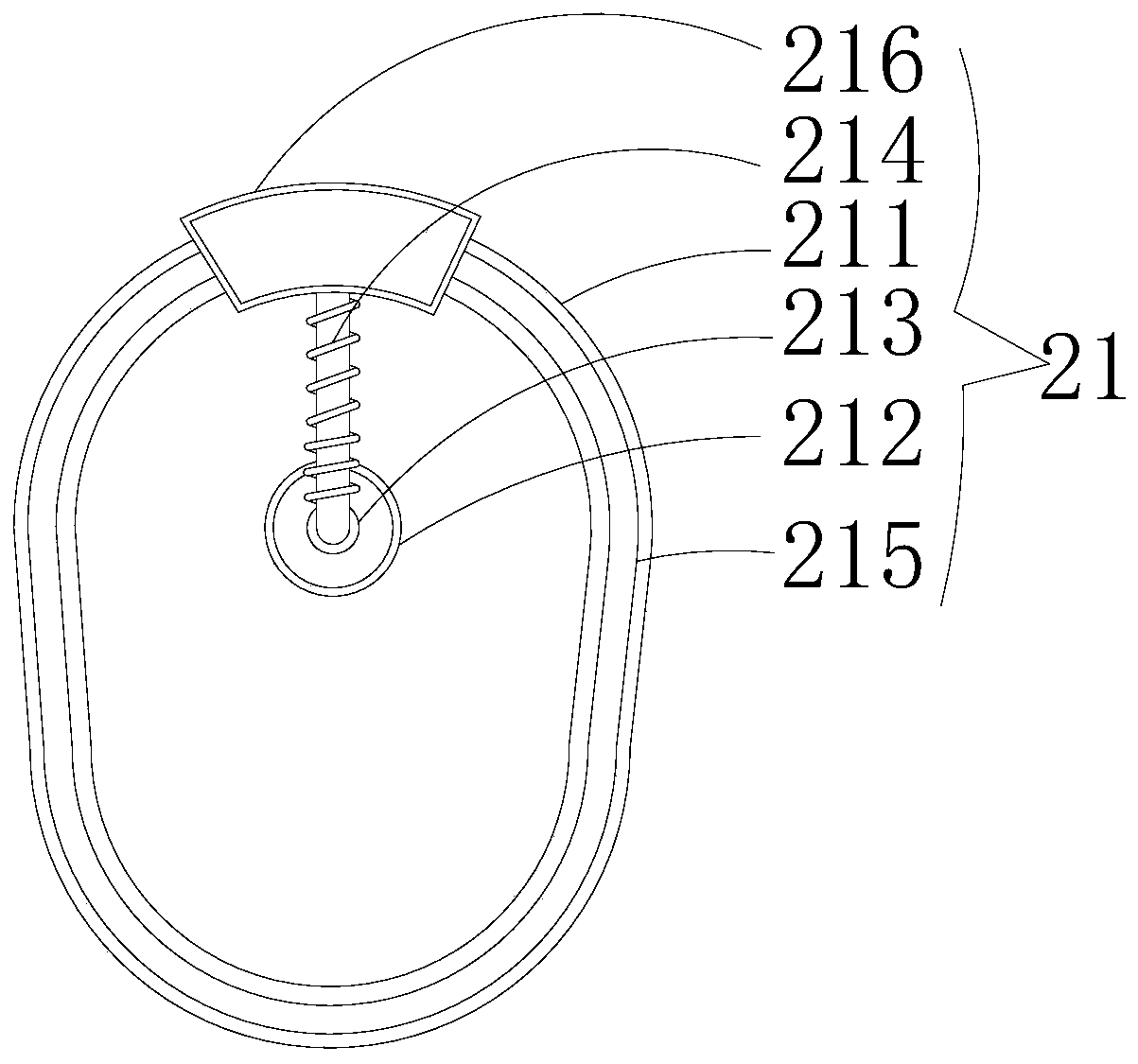

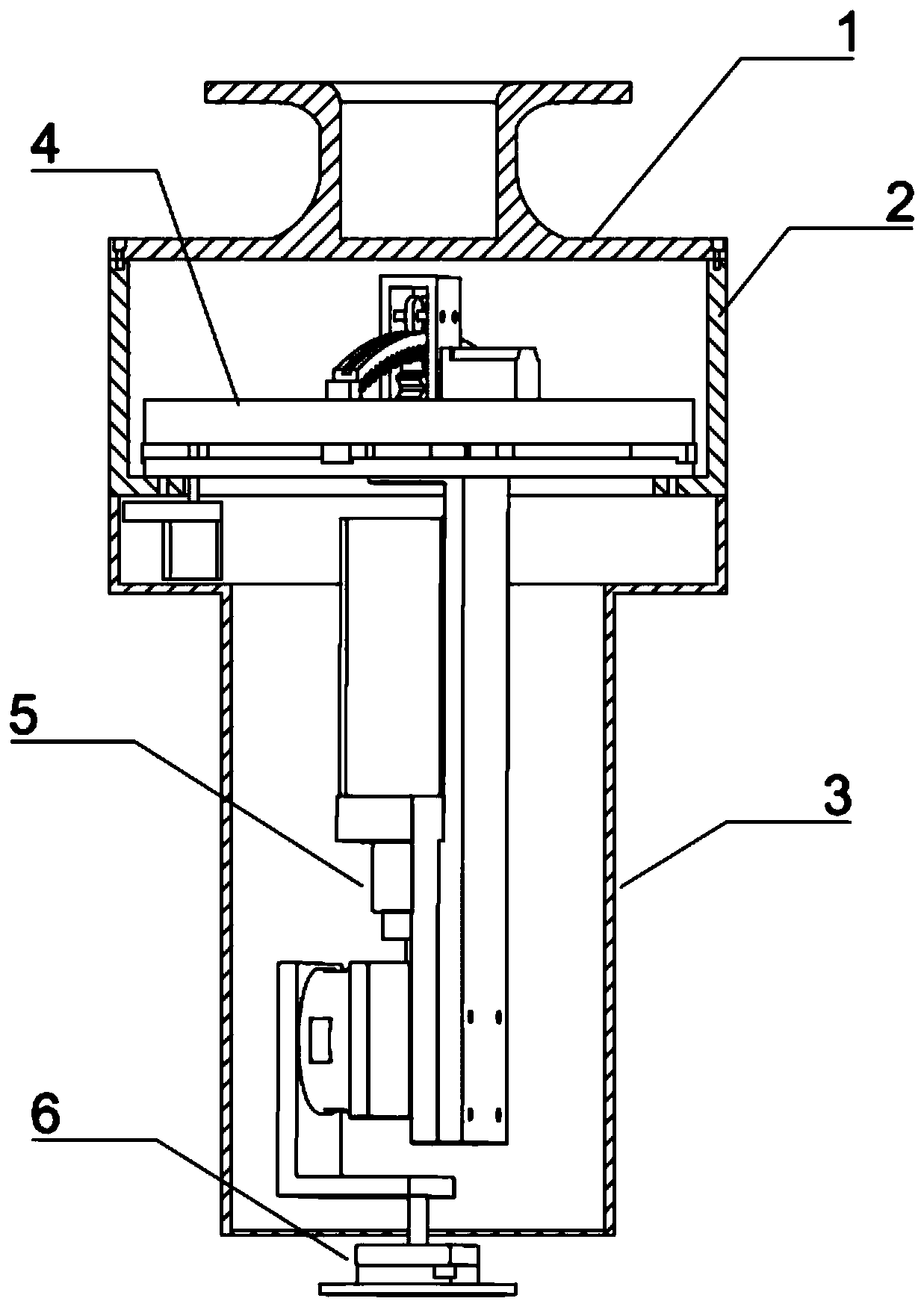

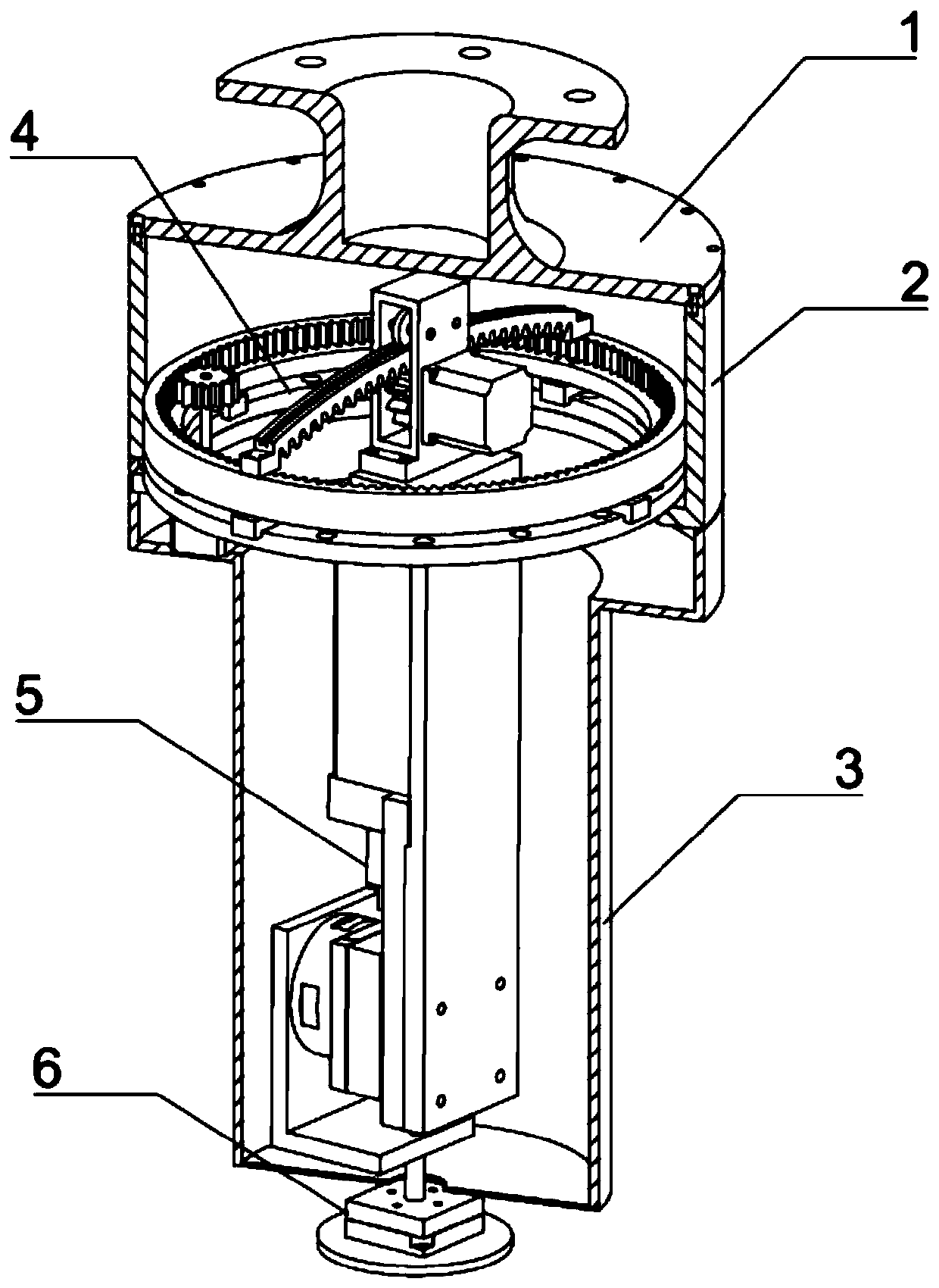

Hoof trimming mechanism for artificially-bred equidae animals

ActiveCN110215306AFast and efficient pruningEffective sandingSurgical veterinaryEquidaePower apparatus

The invention provides a hoof trimming mechanism for artificially-bred equidae animals and relates to the technical field of hoof trimming devices for the equidae. The effect of quickly and conveniently trimming hooves is achieved. The hoof trimming mechanism for the artificially-bred equidae animals comprises a shell and a trimming mechanism body, the trimming mechanism body is slidingly connected into the shell and comprises a power device, an installation device, a middle trimming device and a front trimming device, the installation device is located at the top of the power device, the middle trimming device and the front trimming device are located in the installation device, the front trimming device is located at the right side of the middle trimming device, the power device comprises an ellipsoid, a motor is fixedly installed in the ellipsoid, and a rotation disc is connected to the output end of the motor. According to the hoof trimming mechanism for the artificially-bred equidae animals, through cooperation with polishing sheets and a polishing rod, front hooves and middle hooves can be quickly and effectively polished and trimmed at the same time, and secondary polishingis avoided.

Owner:金寨智行知识产权运营有限公司

A wheat flour milling process without repeated grinding

ActiveCN104549610BEasy to monitorSimple and flexible operationGrain treatmentsBiochemical engineeringControl parameters

The invention relates to a wheat milling technology free of repeated grinding, which comprises the steps of cleaning, primary grinding, secondary grinding, purification and layered sieving. The layered sieving step is divided into three layers by improving operation standards and control parameters of the cleaning, primary grinding, secondary grinding, purification steps, and flour standards of the layers are strictly controlled, so that upper and middle layer flour can meet a quality requirement of flour and is directly packaged, and lower layer flour can mostly or fully meet the quality requirement of the flour and is partially or fully packaged; and a tee switching plate is arranged at the lower layer flour, so that when the lower layer flour fails to meet the quality requirement of the flour, the lower layer flour is guided to the sieving step via the switching plate. The technology can control the quality, is simple and flexible to operate, avoids stop and repeated grinding of the lower layer flour, improves the production efficiency and the product quality, increases the flour yield, lowers the production cost, saves a resource, and facilitates flour quality monitoring.

Owner:HENAN SHIJIA FLOUR

A kind of preparation method of nickel-polytetrafluoroethylene coating

The invention relates to the technical field of electroplating, and particularly relates to a preparation method of a nickel-polytetrafluoroethylene coating. According to the invention, nickel is combined with polytetrafluoroethylene, a fluorinated ethylene-propylene copolymer, a perfluoroalkoxy copolymer and other assistants to be used as an electroplating solution and used for electroplating under certain conditions. The invention can be widely applied to various base materials such as steel, copper alloys, wrought aluminum, cast iron, stainless steel and the like, and can be also perfectly used on various injection molding materials except pure rubber, such as silica gel, TPO0, PVC (polyvinyl chloride) and the like. The coating is favorable in wear resistance and non-corrosibility, has weldability and hardenability, and causes no negative effect on the surfaces of other molds.

Owner:模德模具(东莞)有限公司

Layer milling equipment

The invention discloses layered grinding equipment. The layered grinding equipment comprises a shell body which is provided with a feeding inlet, a discharging outlet and a grinding and pressing channel. The grinding and pressing channel is internally provided with grinding and pressing rollers, and rotating shafts connected with the grinding and pressing rollers, and a partition plate is arranged in the middle of the grinding and pressing channel. The direction of the partition plate is the same as that of the grinding and pressing channel. The grinding and pressing channel is divided into an upper grinding cavity and a lower grinding cavity through the partition plate. Screen nets are uniformly arranged on the partition plate. The grinding and pressing rollers comprise the upper-layer grinding and pressing roller and the lower-layer grinding and pressing roller. The rotating shafts comprise the upper-layer rotating shaft and the lower-layer rotating shaft. The feeding inlet communicates with the upper grinding cavity. The discharging outlet communicates with the lower grinding cavity. The shell body is provided with an upper driving motor and a lower driving motor. According to the layered grinding equipment, the structure is simple, operation is convenient, grinding is conducted through the up-down two-layer structure, and the situation of insufficient grinding can be effectively avoided; accordingly, regrinding is avoided, human and material resources are saved, and the machining cost is greatly reduced; and the using stability is good, the applicability is high, and the practicality is good.

Owner:陕西阿姑农业发展有限公司

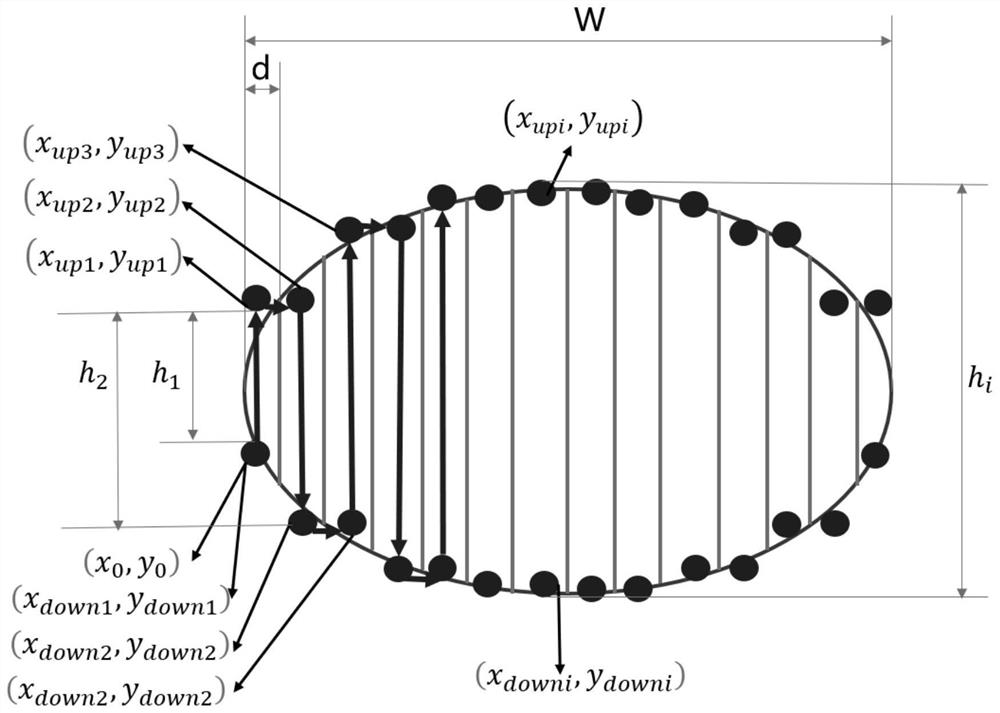

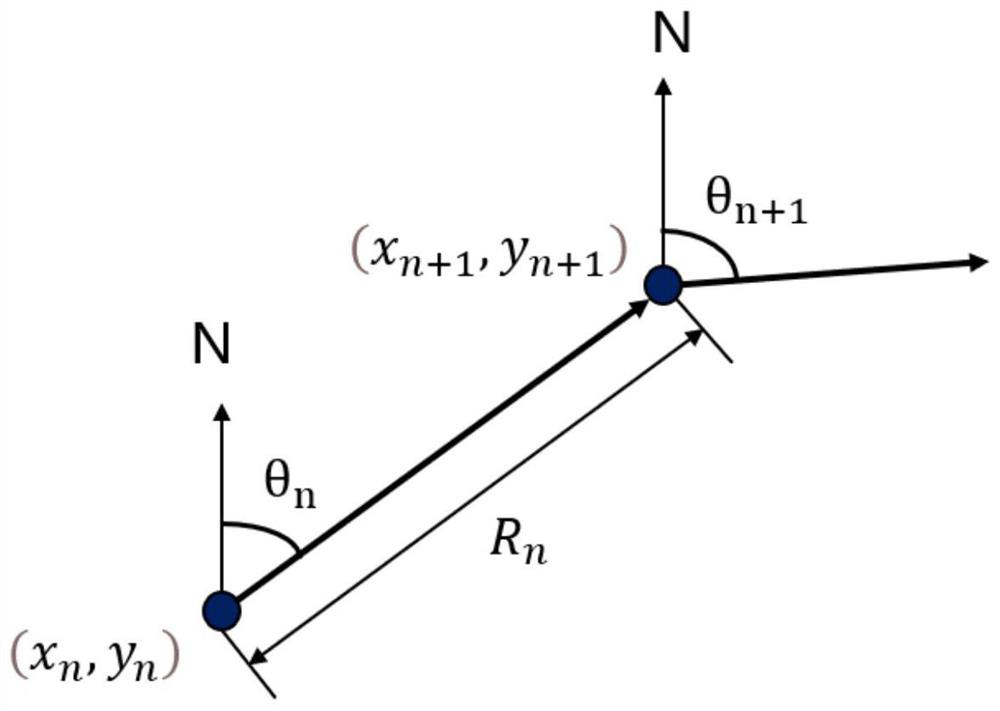

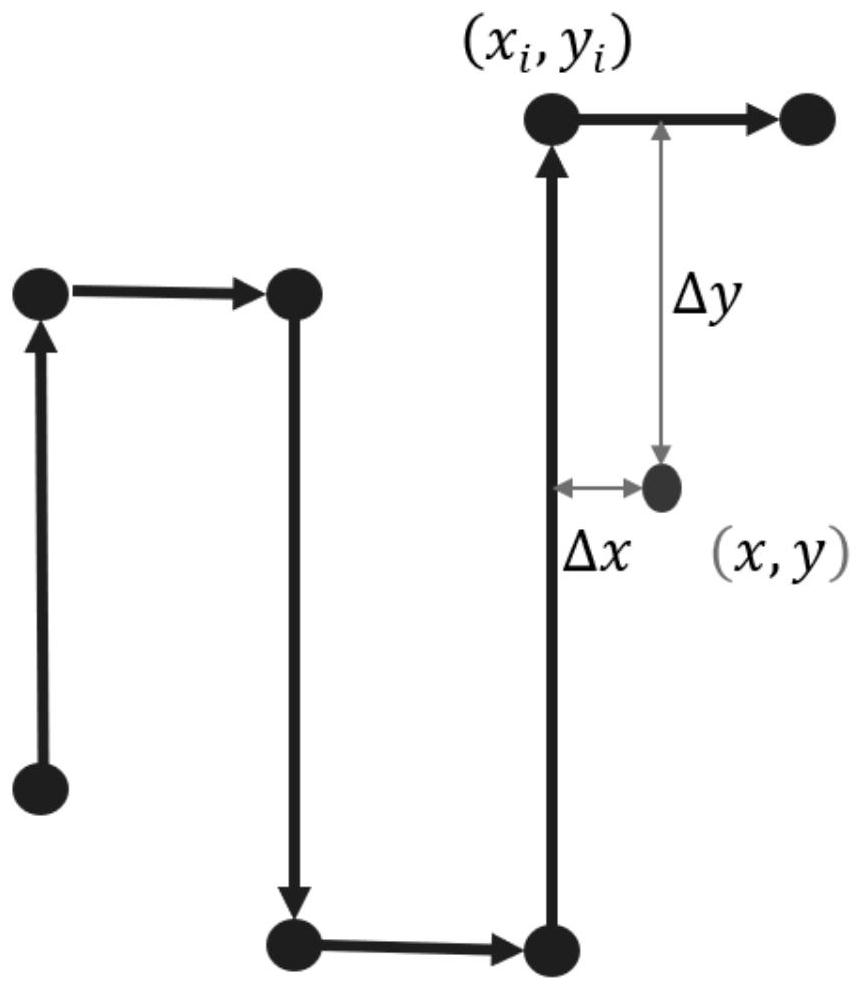

Grinding and polishing unit pose perception method, grinding method and grinding and polishing unit

ActiveCN113199487BEnsure consistencyAvoid regrindingProgramme-controlled manipulatorGrinding feed controlControl engineeringProcess engineering

The invention provides a method for sensing the position and posture of a grinding and polishing unit, a grinding method and a grinding and polishing unit, which acquire the deviation between the initial coordinates of the grinding and polishing unit and the target coordinates, and the robot controls the grinding and polishing unit to run from the initial coordinates to the target coordinates , use the attitude sensor to obtain the running angle of the grinding and polishing unit every preset time, and use the optical flow sensor to obtain the moving distance of the grinding and polishing unit between adjacent moments, and based on the dead reckoning algorithm, the coordinates of the grinding and polishing unit at the current moment can be obtained ; According to the deviation between the current coordinates of the grinding and polishing unit and the target coordinates, the robot controls the grinding and polishing unit to run from the current coordinates to the target coordinates until it reaches the target coordinates. The robot obtains the position and motion posture of the grinding and polishing unit to adjust the direction of the next step. It can adjust the trajectory of the grinding and polishing unit in real time, so that the grinding and polishing unit continues to move to the target coordinates, ensuring that the actual trajectory of the grinding and the planned trajectory are consistent. Consistency, avoid repeated grinding.

Owner:武汉数字化设计与制造创新中心有限公司

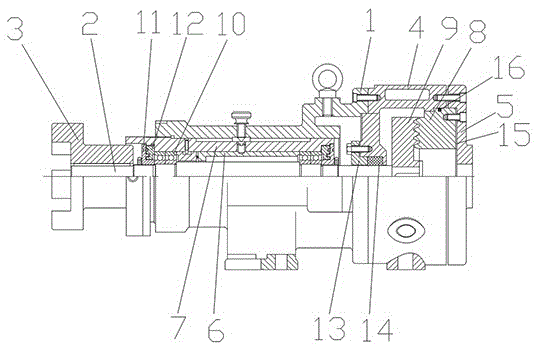

Clamping device for grinding screw tap

InactiveCN109732480AAvoid regrindingAccurately control the rotation angleGrinding drivesOther manufacturing equipments/toolsEngineeringMachining

The invention relates to a clamping device for grinding a screw tap, and belongs to the technical field of clamping equipment for tool machining. The clamping device aims to solve the technical problem that existing screw tap machining equipment is not obvious in grinding and non-grinding region distinguishing and easily cause repeated machining errors of machined surfaces. According to the technical scheme, the clamping device for grinding the screw tap comprises a disc connected with a rotating device, and further comprises a clamp part and a protecting part, the clamp part and the protecting part are used for clamping the screw tap, and the clamp part is composed of a first screw tap clamping block, a rack, a bearing, a gear, a clamp base, a first coupler, a first motor, a shaft and a second screw tap clamping block; and the protecting part is composed of a guide rail, a sliding block, a second coupler, two bearings, a bearing seat, a lead screw, an opening and closing nut, a supporting shell, a protection cover and a second motor. The clamping device has the advantages that the structure is reasonable, and the machined screw tap can be well protected and is dustproof and the like.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Efficient vertical type grinder

InactiveCN108970743AImprove crushing efficiencyCompact structureGrain treatmentsUltrasonic sensorAgricultural engineering

The invention discloses an efficient vertical type grinder. The efficient vertical type grinder comprises a driven belt pulley, a first grinding wheel, a discharging opening, a control cabinet and a control panel. A motor is installed on the upper side in the control cabinet. A controller is arranged on the right side of a frequency converter. The control panel is arranged in the middle of the side face of the control cabinet. A driving belt pulley is installed on the top of the motor. The bottom end of the rotating shaft penetrates through a grinding device shell to be connected with a bearing. A spiral smashing blade is fixed to the upper side of the rotating shaft in the grinding device shell. A second grinding wheel is installed below the first grinding wheel. A feeding opening is formed in the upper left side of the grinding device shell. The discharging opening is installed on the lower left side of the grinding device shell. An ultrasonic transducer is installed at the bottom ofthe grinding device shell. The efficient vertical type grinder is compact in structure, convenient to use, high in powder crushing efficiency and good in market prospect.

Owner:湖北嘉麟杰纺织品有限公司

Ultramicro wall-breaking grinding mechanism for medicines

PendingCN114749255AAvoid regrindingImprove grinding efficiencyGrain treatmentsMedicinal herbsPharmacy medicine

The invention discloses a medicine ultramicro wall-breaking grinding mechanism which comprises a grinding tank, a lower grinding plate, an upper grinding plate, a vibration assembly and a feeding hopper, and the lower grinding plate, the upper grinding plate, the vibration assembly and the feeding hopper are arranged in the grinding tank. The lower grinding plate is arranged in the grinding tank to divide an inner cavity of the grinding tank into a grinding cavity located on the upper portion and a powder discharging cavity located on the lower portion, a plurality of discharging openings communicating with the grinding cavity and the powder discharging cavity are formed in the inner edge of the lower grinding plate, and lower sawteeth are distributed on the top face of the lower grinding plate. In the direction from the center of the lower grinding plate to the blanking port, the sectional area and the height of the lower sawteeth are gradually reduced; upper sawteeth are distributed on the bottom face of the upper grinding plate, and the sectional area and the height of the upper sawteeth are gradually reduced in the direction from the center of the upper grinding plate to the outer edge of the upper grinding plate. The technical scheme is used for solving the problems of large ground particles, dust pollution and high energy consumption of an existing medicinal material grinding device.

Owner:广东逢春制药有限公司

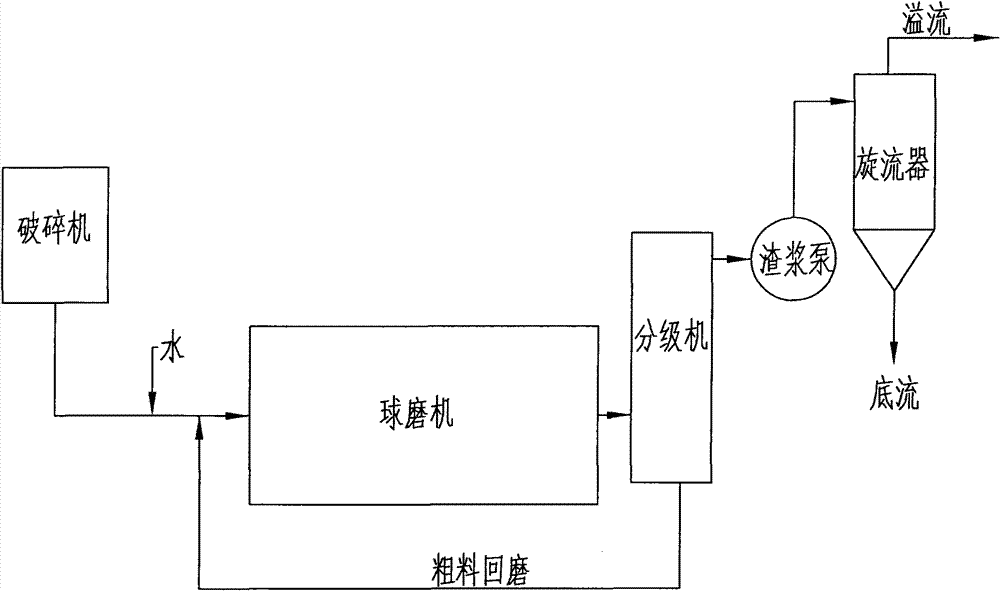

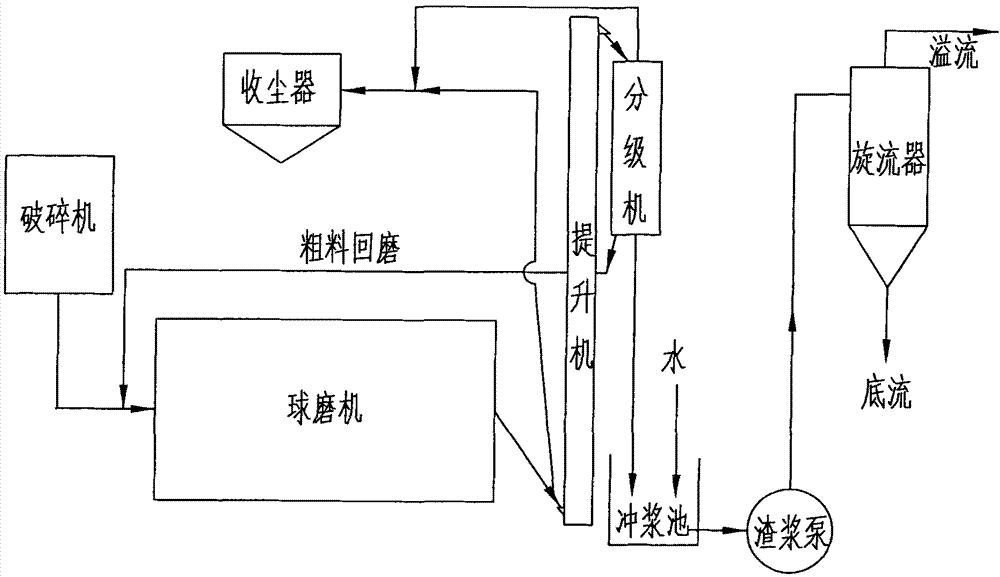

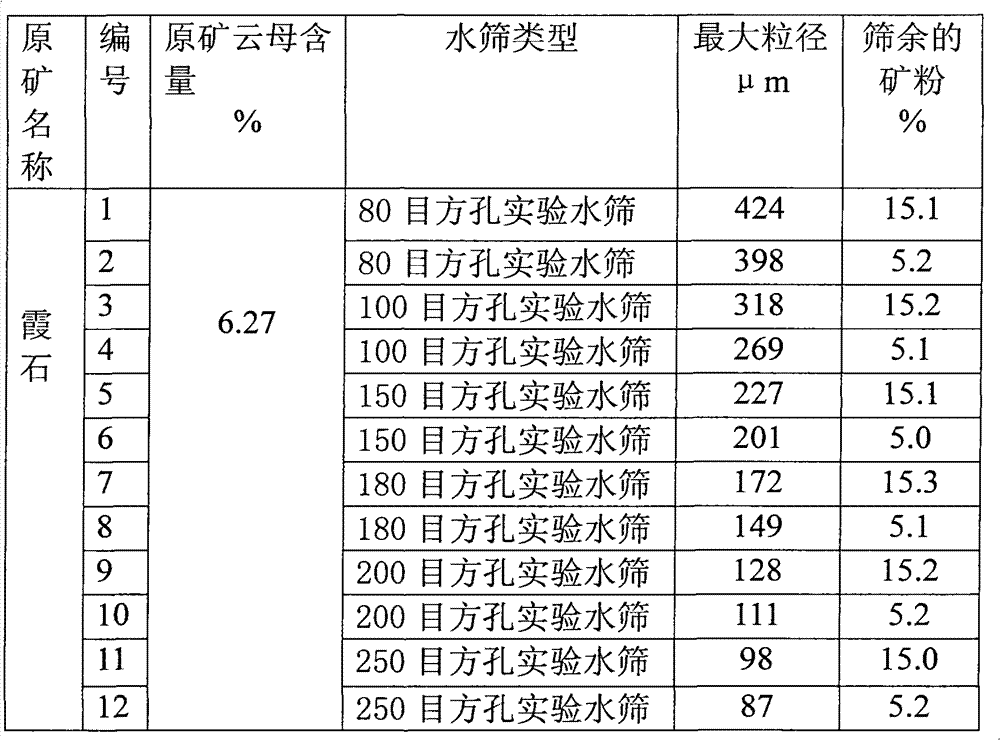

Method for removing micas in nephelite by using cyclone

The invention discloses a method for removing micas in nephelite by using a cyclone, which comprises the following steps of: (1) preprocessing a nephelite raw ore into an ore pulp consisting of nephelite powder, mica powder and water; (2) pumping the ore pulp into the cyclone by using a slurry pump; and (3) under the action of the centrifugal force of vortex, throwing spherical nephelite particles to a side wall of the cyclone to ensure that the spherical nephelite particles lose energy and are settled down, and then serve as underflows to flow out from the bottom of the cyclone, wherein the fluid resistance endured by sheet mica particles is greater than that of the spherical nephelite particles to ensure that the sheet mica particles cannot be thrown to the side wall of the cyclone to lose energy and be settled down; the fluid resistance endured by the sheet mica particles during settling down is greater than that of the spherical nephelite particles to ensure that the settling speed is slow; and the sheet mica particles are suspended in solid-phase two-phase flow to serve as an overflow which flows out from the top part of the cyclone under the pressure of a slurry pump. A product processed by the process method has a higher yield compared with the nephelite raw ore, and the mica content in the product is low.

Owner:广东奥胜新材料有限公司

A kind of glass tube polishing treatment method

ActiveCN107116402BAvoid regrindingAvoid useless workRevolution surface grinding machinesGrinding drivesElectric machinePipe

The invention discloses a glass pipe polishing treatment method. The glass pipe polishing treatment method comprises the following steps: firstly, a cylinder is started to push a motor to move; a clamping column moves in a direction far from a base at the same time until a horizontal section of the clamping column is totally shifted out of a sleeve; then, a glass pipe sleeves the horizontal section of the clamping column; the end part of the glass pipe is fixed through an end cover; the motor is started; an output end of the cylinder shrinks back at the same time to drive the clamping column and the glass pipe to move in the axis direction of the sleeve to a direction near the base; the outer wall of the glass pipe is polished by a polishing layer; and when the glass pipe moves in the peripheral direction and the axial direction at the same time, the polishing layer skims over the outer wall of the glass pipe in sequence. The glass pipe polishing treatment method uses the polishing layer for annularly polishing the outer wall of the glass pipe, and reasonably adjusts the cylinder and the motor to prevent repeated polishing of local outer wall of the glass pipe by the polishing layer when removing a raw material layer of an electric heating film projected on the outer wall of the glass pipe so as to guarantee the heating efficiency of a heating pipe.

Owner:CHENGDU YANGZHONG NEW ENERGY TECH

A three-degree-of-freedom surface adaptive intelligent force-controlled flexible grinding and polishing end effector

ActiveCN108581745BGood Expected Contact ForceNo displacementGrinding drivesGrinding feed controlElectricityTurbine blade

The invention discloses a three-degree-of-freedom curved surface self-adaption intelligent force-controlled flexible grinding and polishing end executive device. The three-degree-of-freedom curved surface self-adaption intelligent force-controlled flexible grinding and polishing end executive device comprises a two-dimensional attitude adjusting assembly, a linear servo force-controlled assembly,a grinding and polishing assembly and a controller. The linear servo force-controlled assembly realizes real-time control and feedback of grinding contact force by closed-loop control of contact forceto ensure constant contact force machining. The two-dimensional attitude adjusting assembly realizes the real-time adjustment of the grinding disc attitude by closed-loop control, so that the grinding surface always coincides with the local tangent plane of the curved surface to realize the curved surface self-adaption, the problems of uneven grinding, over-grinding and the like are effectively prevented, and the robot self-adaption flexible grinding and polishing machining is achieved. According to the three-degree-of-freedom curved surface self-adaption intelligent force-controlled flexiblegrinding and polishing end executive device, the grinding disc always do centering movement when the attitude is adjusted, so that unnecessary displacement can not be produced when the grinding discadapts to the change of the curved surface, repeated grinding and polishing on the polished area is effectively prevented, the uniformity and consistency required by the grinding and polishing processare ensured, and the three-degree-of-freedom curved surface self-adaption intelligent force-controlled flexible grinding and polishing end executive device is suitable for the self-adaption high-precision grinding and polishing of large free curved surface parts, especially large wind turbine blades.

Owner:HUAZHONG UNIV OF SCI & TECH

A glass fiber crushing and grinding equipment for processing glass fiber powder

ActiveCN111111861BReduce consumptionGuaranteed pass rateGlass recyclingGrain treatmentsGlass fiberMechanical engineering

The invention relates to the technical field of glass fiber powder processing, and discloses a glass fiber crushing and grinding equipment for glass fiber powder processing, which includes a box body, the top of the box body is provided with a feeding port, and the left and right inner walls of the box body are fixedly installed with The horizontal plate, the length of the horizontal plate on the right is greater than the length of the left horizontal plate, the top of the horizontal plate is fixed with a slide bar, the upper movable sleeve of the slide bar is connected with a fixed plate, and the bottom of the fixed plate and the top of the horizontal plate are fixed with a support The spring, the same crushing box is fixed between the side walls of the two fixing plates, the telescopic hose is connected between the top of the crushing box and the feeding port, and the middle part of the top of the crushing box is fixed with a fixed frame, which is a door type. Slots are provided in the middle of both side walls, and two support plates are fixed on the inner top wall of the box. The invention solves the problems of incomplete crushing, low efficiency of crushing equipment for glass fiber powder production, waste of resources, overflow of dust during processing, and environmental pollution.

Owner:天长市天意玻璃制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com