Method for sorting ultrafine copper sheets

A copper sheet sorting technology, which is applied in the direction of the swirling flow can reverse the axial direction of the device, swirl device, etc., can solve difficult copper sheet product customization requirements, cost increase, production cycle lengthening and other problems, Achieve the effects of shortening the production cycle, avoiding waste of raw materials, and taking into account production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) The present invention uses PSD (D10: 2.3um; D50: 6.4um; D9011.6um) ultra-fine copper sheets as raw materials, which are loaded into the feeder. Among them, PSD ultra-fine copper sheet refers to the ultra-fine copper sheet with laser particle size distribution.

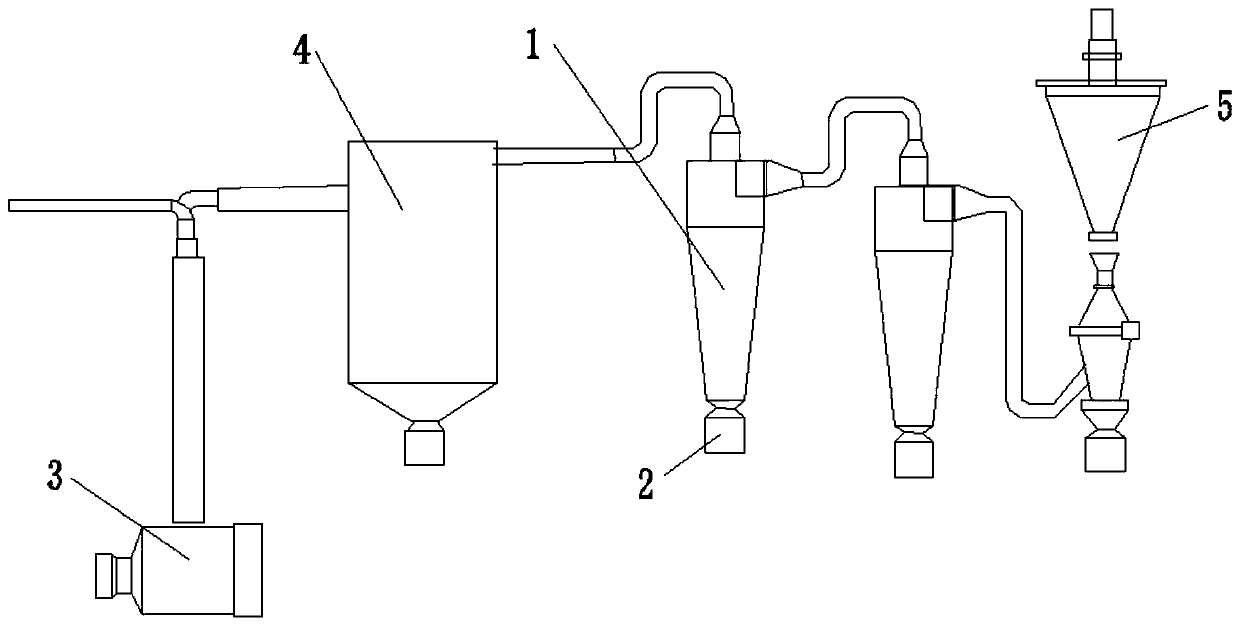

[0036] (2) Three cyclone classifiers are selected for classification, and three types of copper sheet products with different particle size distributions can be obtained in one classification.

[0037] (3) Choose the intake ring made of stainless steel, choose 1.3mm air hole diameter, and install it on the first cyclone classifier.

[0038] (4) On the premise of confirming that all valves in the pipeline are open, turn on the induced draft fan, and slowly adjust the induced air volume to 1000m3 / h through frequency conversion adjustment, and control the negative pressure of the system at -45kpa.

[0039] (5) After the negative pressure of the system and the induced air volume are stabilized, turn on the spee...

Embodiment 2

[0042] (1) The present invention uses PSD (D10: 2.3um; D50: 6.4um; D9011.6um) ultra-fine copper sheets as raw materials, which are loaded into the feeder.

[0043] (2) Three cyclone classifiers are selected for classification, and three types of copper sheet products with different particle size distributions can be obtained in one classification.

[0044] (3) Select the intake ring made of stainless steel, choose 2.0mm air hole diameter, and install it on the first cyclone classifier.

[0045] (4) On the premise of confirming that all valves in the pipeline are open, turn on the induced draft fan, and slowly adjust the induced air volume to 800m3 / h through frequency conversion adjustment, and control the negative pressure of the system at -40kpa.

[0046] (5) After the negative pressure of the system and the induced air volume are stable, turn on the speed control switch of the feeder, and feed the graded raw materials into the classifier, and the feeding speed is controlled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com