Method for improving precision of preset model in multi-variety rolling mode

A model precision and pre-set technology, applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve problems such as unfavorable continuous production, affecting production efficiency, complicated operation, etc., and achieve the effect of meeting the customized needs of users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

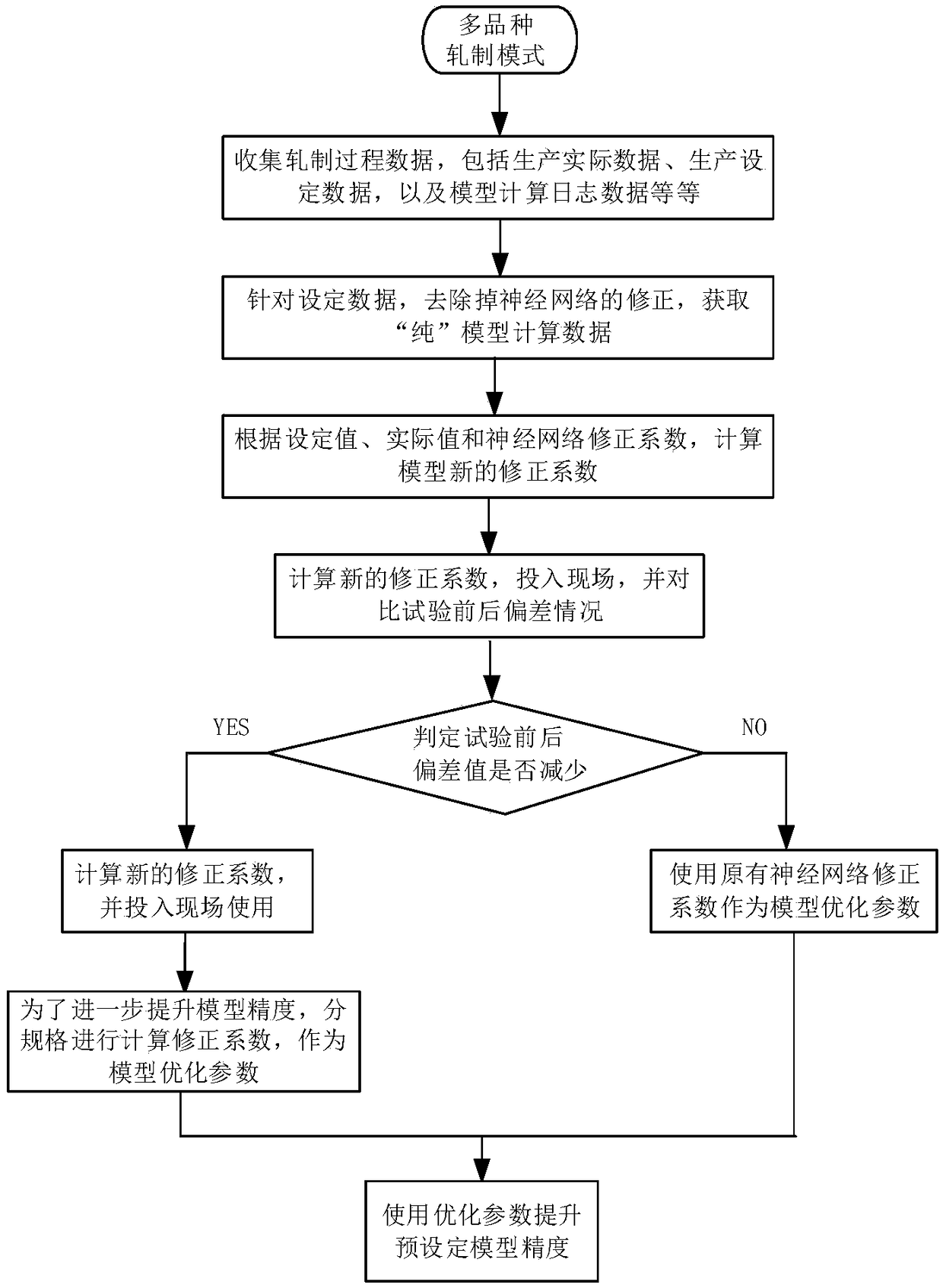

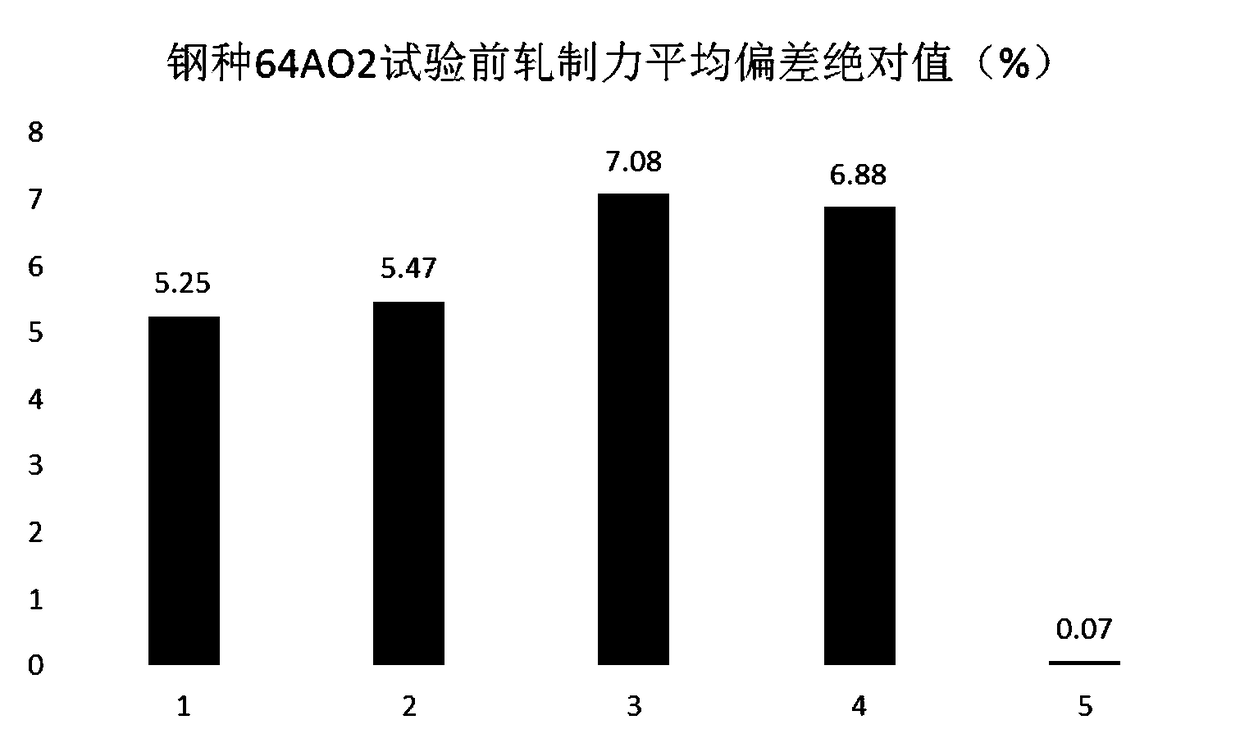

[0047] The invention provides a method for improving the accuracy of the preset model in the multi-variety rolling mode, such as figure 1 As shown, the general flow of the method is as follows:

[0048] (1) Collect the rolling process data of the production line, determine the setting data, that is, set the rolling force

[0049]

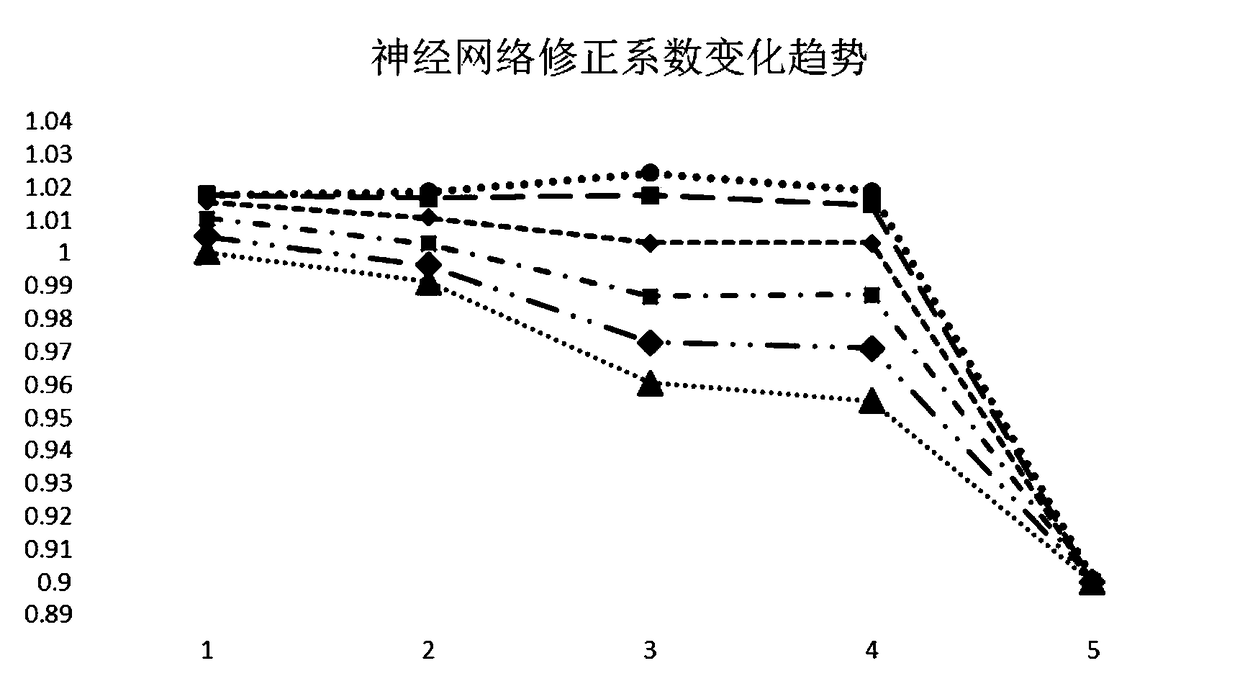

[0050] Among them, rfC i is the neural network correction coefficient corresponding to the steel type, is the actual rolling speed, is the actual rack inlet thickness, is the actual rack outlet thickness, is the actual rack inlet tensile stress, is the tensile stress at the outlet of the actual rack, kf is the deformation resistance, u is the friction coefficient, Rd is the roll data, and i is the rack number; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com