Welding joint and technique for longitudinal seam and circumferential seam of medium-thick plate

A technology of circumferential seam welding and process, applied in welding equipment, welding accessories, manufacturing tools, etc., can solve the problems of low welding efficiency and long processing time, and achieve the effect of improving welding quality, reducing welding quantity, and improving root cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] One material is S32168, and the specification is Φ4400×72 austenitic stainless steel welded joint:

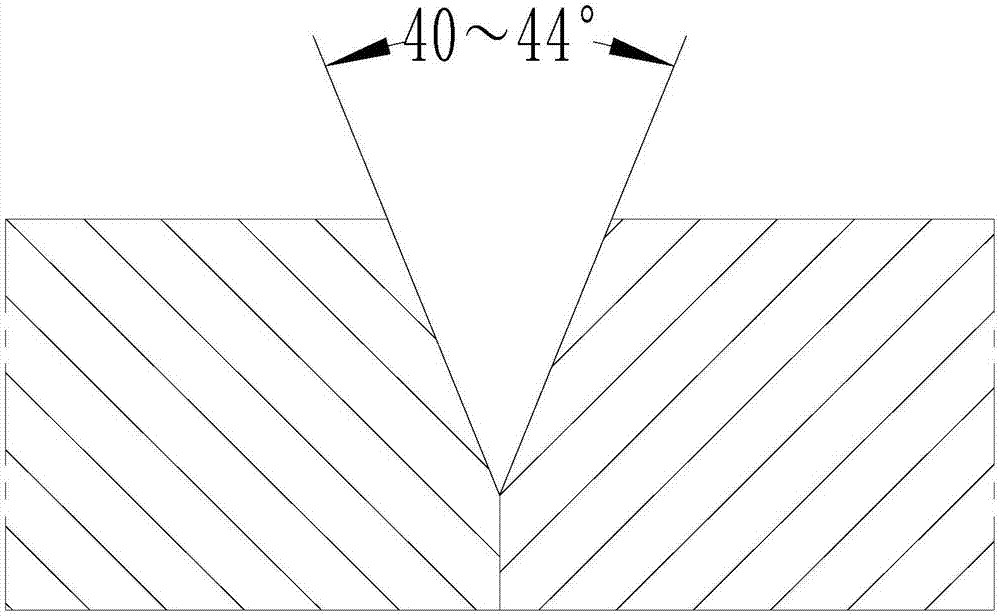

[0043] The thickness of the stainless steel plate is 72mm, and the groove of the joint is a "V" type internal groove and a "U" type external groove. The roots of the internal groove and the external groove overlap, and the groove depth of the "V" type groove is 40mm, unilateral angle of groove is 20°, root cleaning depth of "U" type groove is 40mm, arc of root is R=8mm, unilateral angle of groove is 8°.

[0044] One material is S32168, the specification is Φ4400×72 austenitic stainless steel welding method is as follows:

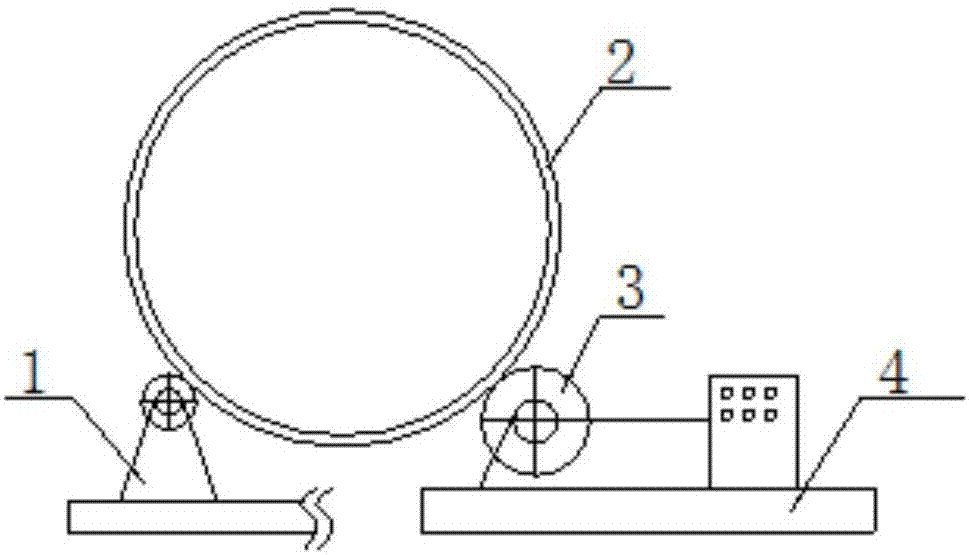

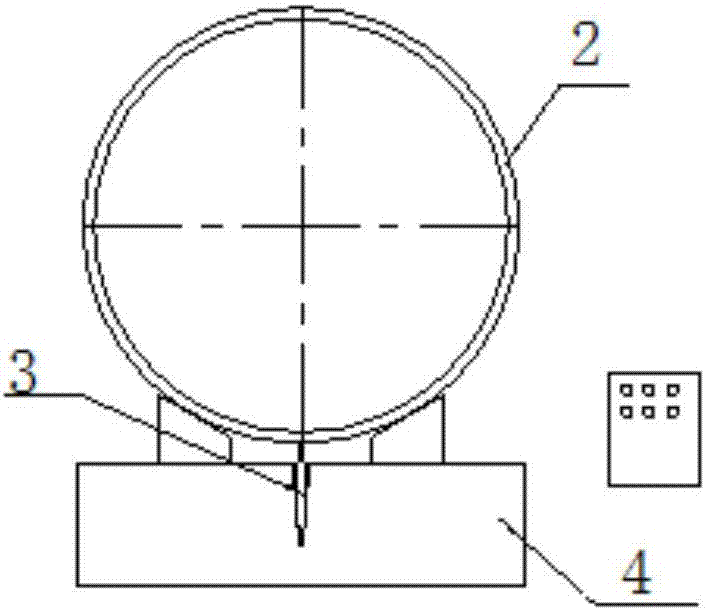

[0045] 1. The internal groove of the cylinder adopts V-shaped groove, and the groove is processed by mechanical processing methods such as edge milling machine. The single side angle of the groove is 20°, and the groove depth is 40mm. The processing form is as follows figure 1 shown.

[0046] 2. Clean up impurities such as oil stains and rust within ...

Embodiment 2

[0054] One material is Q345R, the specification is Φ5200×40 low-alloy steel welded joint:

[0055] The thickness of the stainless steel plate is 40mm, and the groove of the joint is an internal groove "V" type and an external groove "U" type groove. The roots of the internal groove and the external groove overlap, and the groove depth of the "V" groove is The angle of one side of the groove is 30mm, the angle of one side of the groove is 20°, the root cleaning depth of the "U" type groove is 20mm, the arc of the root is R=8mm, and the angle of one side of the groove is 8°.

[0056] One kind of material is Q345R, the specification is Φ5200×40 low-alloy steel welding method is as follows:

[0057] 1. The internal groove of the cylinder adopts V-shaped groove, and the groove is processed by mechanical processing methods such as edge milling machine. The single side angle of the groove is 22°, and the groove depth is 30mm. The processing form is as follows figure 2 shown.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com