Method of comprehensively recovering low-grade molybdenum from copper concentrate containing organic carbon

A technology of copper concentrate and organic carbon, applied in chemical instruments and methods, wet separation, improvement of process efficiency, etc., can solve problems such as difficult to obtain high-grade molybdenum concentrate products, poor use effect, waste of molybdenum resources, etc. , to avoid regrinding process, improve molybdenum grade and reduce leaching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

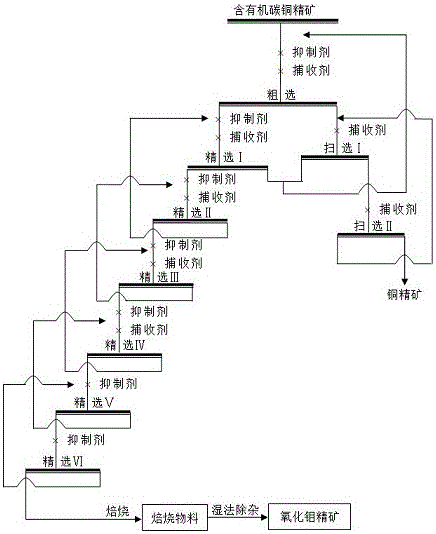

[0028] With organic carbon C content being 1.0%, the copper concentrate of Mo content 0.51% is raw material, utilizes technology of the present invention, carries out following steps, as figure 1 :

[0029] (1) Rough separation operation: For the copper concentrate containing organic carbon, first stir and adjust the pulp to control the pulp concentration to 30%, then add 20000g / t sodium thioglycolate and 150g / t diesel oil one by one, and carry out rough separation in the flotation equipment Operation, this operation obtains rougher molybdenum concentrate and rougher tailings, rougher molybdenum concentrate is used as raw material for further molybdenum concentration, and rougher tailings is used as raw material for molybdenum sweeping.

[0030] (2) Sweeping operation: use the rougher tailings as the raw material for molybdenum sweeping operation, add it to the sweeping tank for sweeping operation, first stir and adjust the slurry, and add 75g / t of diesel oil to carry out swee...

Embodiment 2

[0035] With organic C content being 1.6%, the copper concentrate of Mo content 0.38% is raw material, utilizes technology of the present invention, carries out following steps, as figure 1 :

[0036] (1) Rough separation operation: For the copper concentrate containing organic carbon, first stir and adjust the pulp to control the pulp concentration to 25%, then add 18000g / t sodium thioglycolate and 120g / t kerosene successively, and carry out rough separation in the flotation equipment Operation, this operation obtains rougher molybdenum concentrate and rougher tailings, rougher molybdenum concentrate is used as raw material for further molybdenum concentration, and rougher tailings is used as raw material for molybdenum sweeping.

[0037] (2) Sweeping operation: use rougher tailings as the raw material for molybdenum sweeping operation, add it to the sweeping tank for sweeping operation, first stir and adjust the slurry, and add 60g / t of kerosene to carry out sweeping I operat...

Embodiment 3

[0042] With organic C content being 1.2%, the high-quality copper concentrate of Mo content 0.25% is raw material, utilizes the technology of the present invention, carries out following steps, as figure 1 :

[0043] (1) Rough separation operation: For the copper concentrate containing organic carbon, first stir and adjust the slurry, control the concentration of the slurry to 20~30%, and then add 16000g / t of sodium thioglycolate and 100g / t of transformer oil successively, in the flotation equipment The roughing operation is carried out to obtain the roughing molybdenum concentrate and roughing tailings, the roughing molybdenum concentrate is used as the raw material for further molybdenum concentration, and the roughing tailings are used as the raw material for molybdenum sweeping.

[0044] (2) Sweeping operation: use rougher tailings as the raw material for molybdenum sweeping operation, add it to the sweeping tank for sweeping operation, first stir and adjust the slurry, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com