Selvedge trimming device of folding coiler

A coiling machine and edge trimming technology, which is applied in metal processing and other directions, can solve the problems of difficult control of disc knife regrinding quality, burrs on the edge of aluminum foil, aluminum chips, and difficult quality control, etc., to achieve the benefit of double rolling Controlling, edge trimming quality improvement, and the effect of avoiding tool regrinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Hereinafter, with reference to the accompanying drawings, specific embodiments of the present invention are given to further illustrate the structure of the present invention.

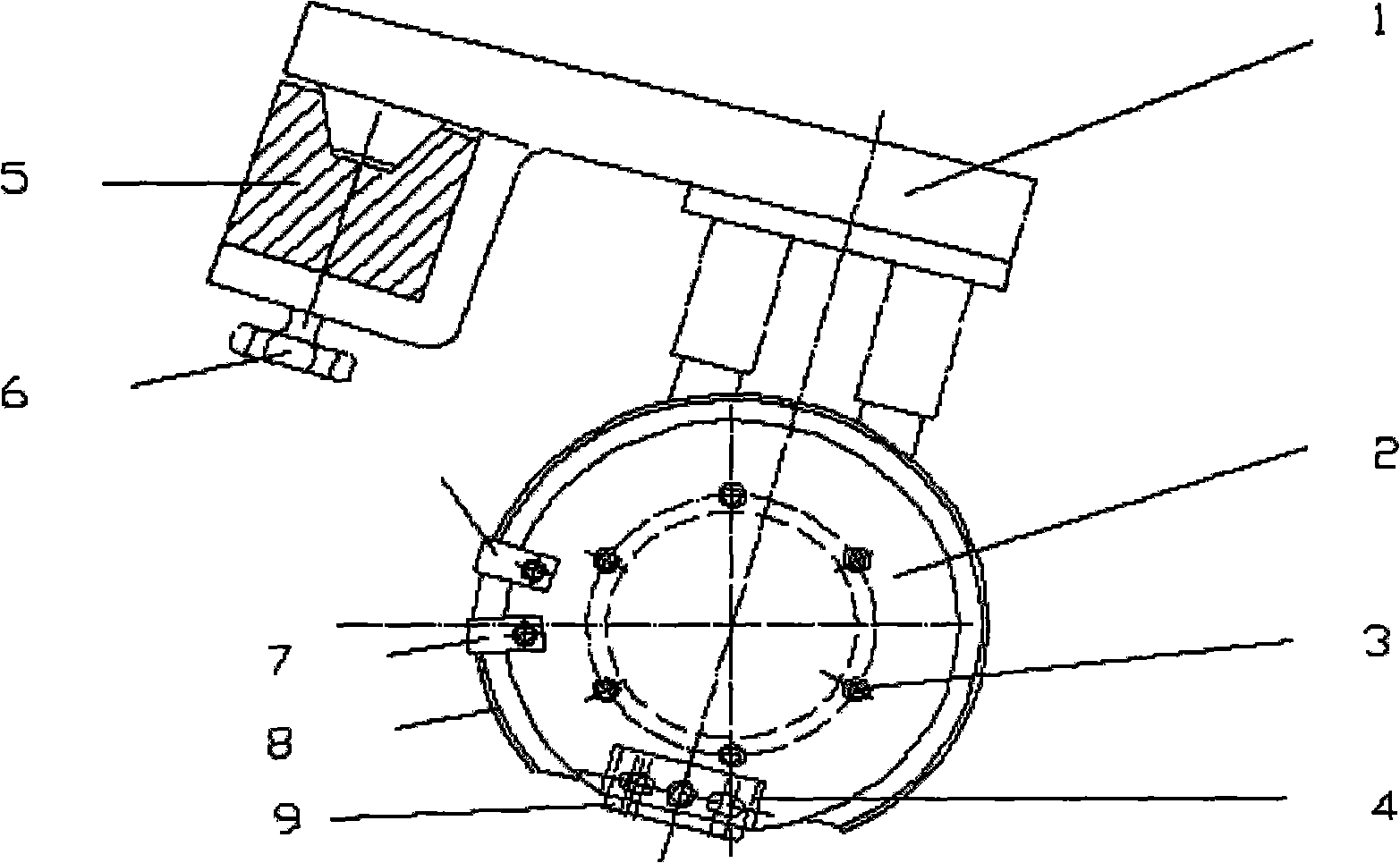

[0014] Reference for the trimming device of the winding machine of the embodiment figure 1 , 2 , figure 1 In this, the knife holder 1 is fixed on the beam 5, and the disc 2 is fixed on the knife holder 1 with the six screw holes on the edge trimming device through the fixing screws 3. The blade 9 is fixed on the disc with an M6 screw through the compression piece 4 2, the cutting edge of the blade 9 is aligned with the cutting groove of the lower shaft 10, and there is no contact with the cutting edge of the lower shaft. The disc 2 is provided with a knife holder shield 8, and two are provided on the disc 2. The anti-rotation piece 7 is embedded in the opening of the knife holder shield 8 to achieve the purpose of anti-rotation.

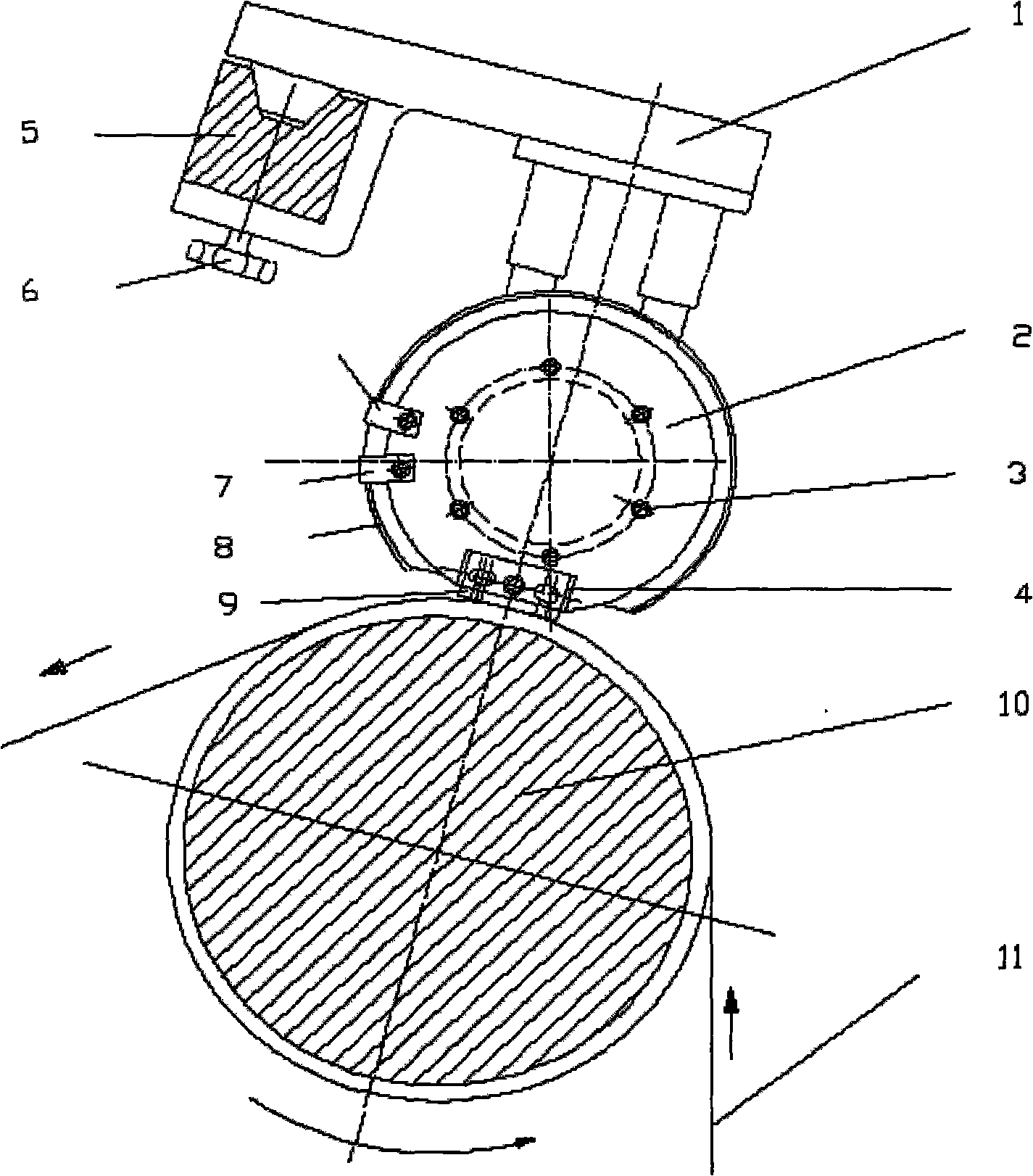

[0015] figure 2 In the middle, the centering of the blade 9 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com