Clamping device for grinding screw tap

A clamping device and tap technology, used in grinding drive devices, grinding/polishing safety devices, grinding workpiece supports, etc., can solve the repeated machining errors of the machined surface, the indistinct distinction between the ground and unground areas, etc. problems, to achieve the effect of improving processing quality, good protection and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

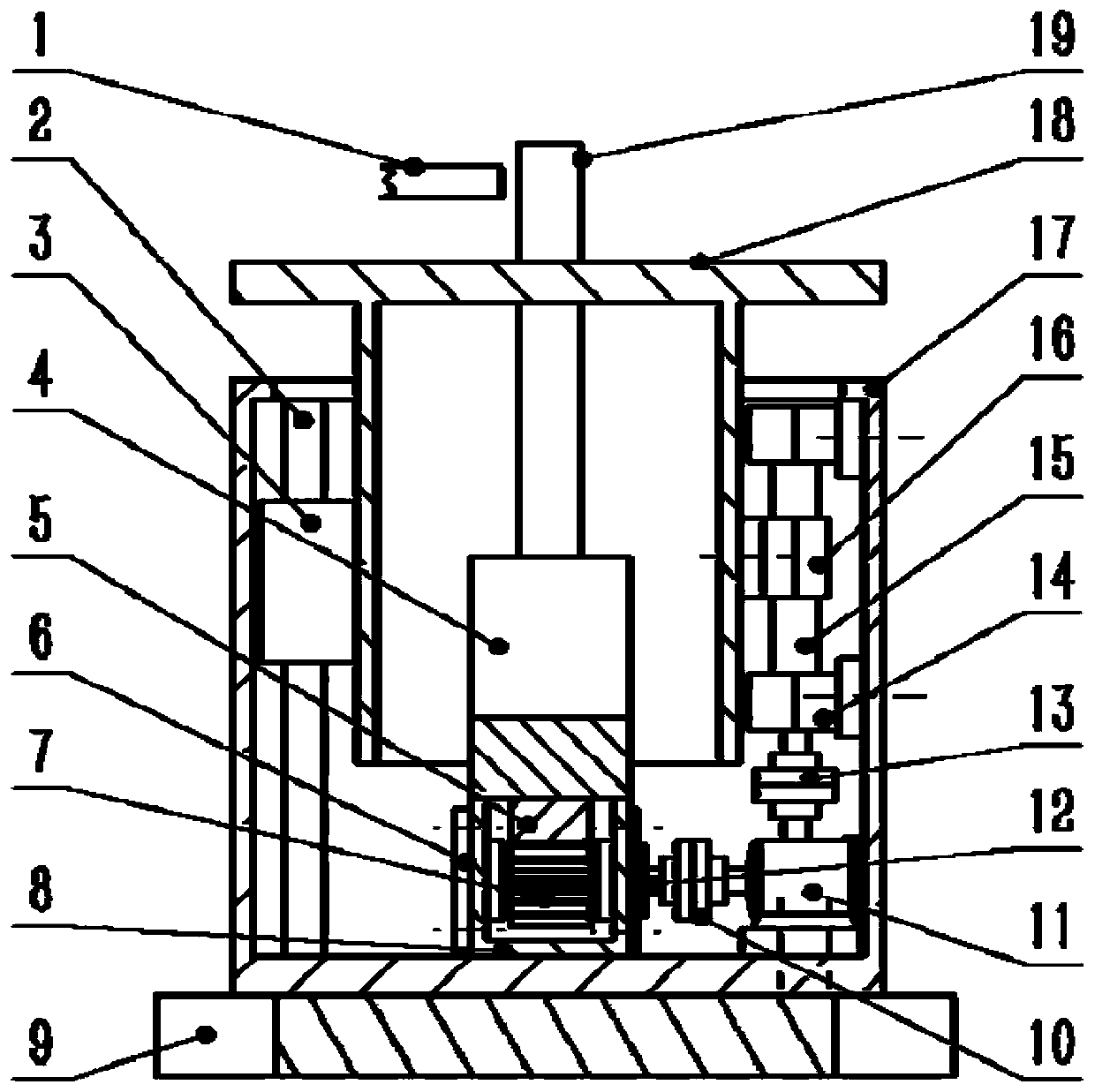

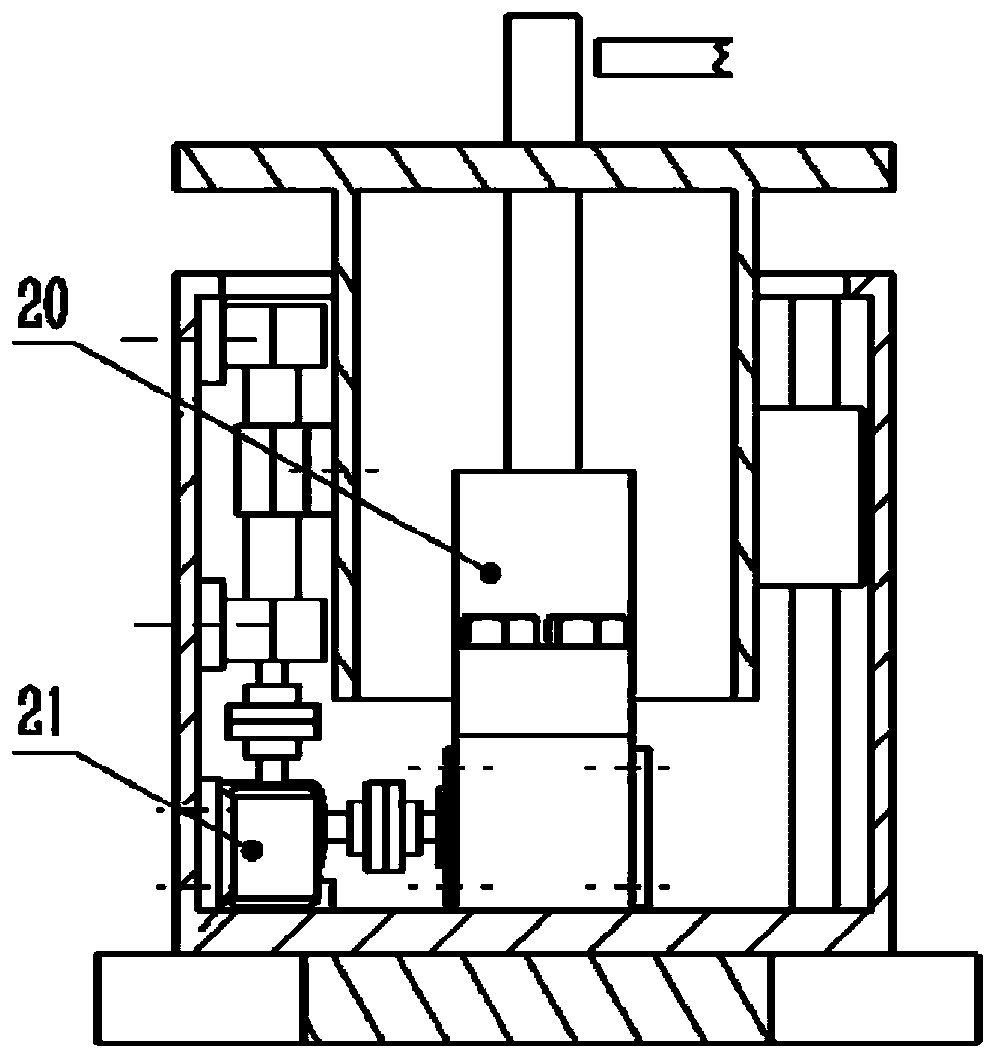

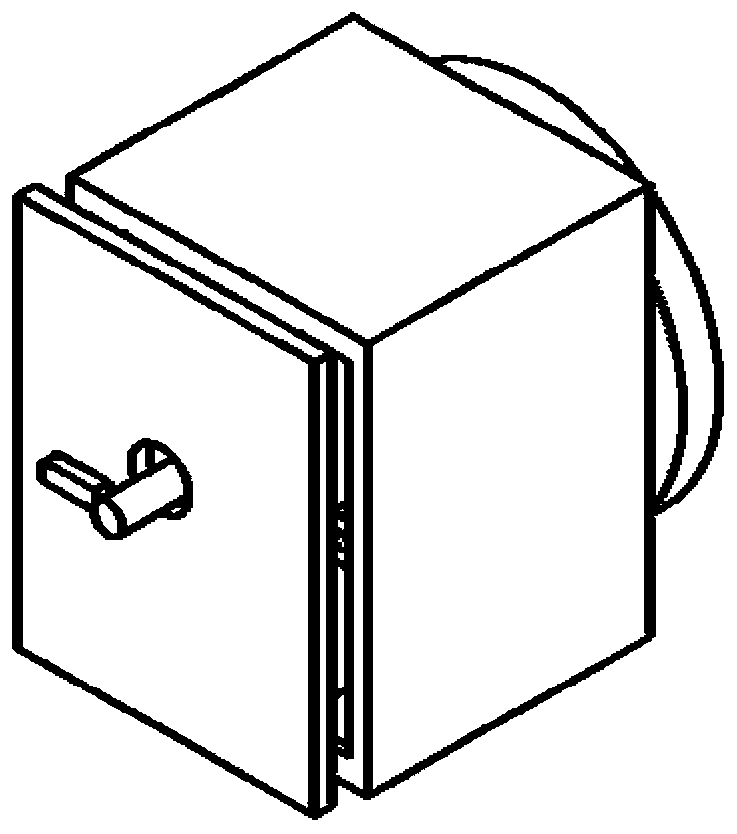

[0017] Such as Figure 1~5 As shown, a clamping device for tap grinding in this embodiment includes a disc 9 connected with a rotating device, wherein: it also includes a clamping part and a protective part for clamping a tap 19, and the clamping The components are composed of tap clamping block I4, rack 5, bearing 6, gear 7, fixture base 8, coupling I10, motor I11, shaft 12 and tap clamping block II20, and the rack 5 is set on the tap clamping On the bottom surface of the block I4, the tap clamping block II20 is installed on one side of the top surface of the fixture base 8, the other side of the fixture base 8 is provided with a cavity, and the bearings 6 are arranged on the two side walls of the cavity. In the bearing hole, the shaft 12 is installed on the bearing 6 and one end thereof is connected with the shaft of the motor I11 through the couplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com