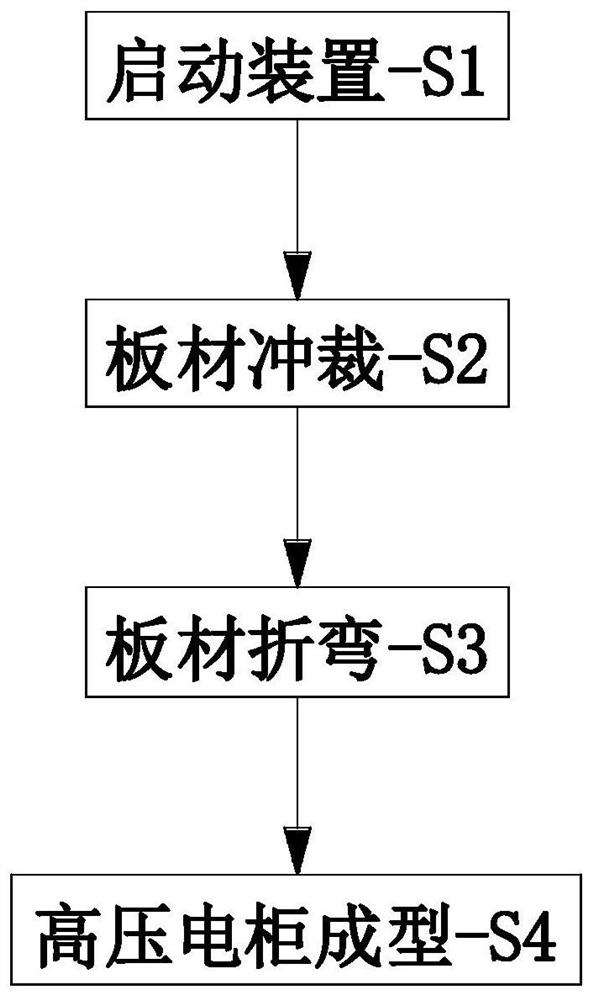

High-voltage electric cabinet manufacturing and forming method

A molding method and high-voltage technology, applied in the direction of manufacturing tools, feeding devices, positioning devices, etc., can solve problems such as increased workload, operator injury, and impact on work efficiency, so as to improve work efficiency, reduce safety hazards, The effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0033]In order to make the techniques of the present invention, the creation characteristics, the purpose and efficacy are readily understood, and the present invention is further illustrated in connection with the specific illustration. It should be noted that the features of the present application and the features in the embodiments in the present application can be combined with each other in the case of an unable conflict.

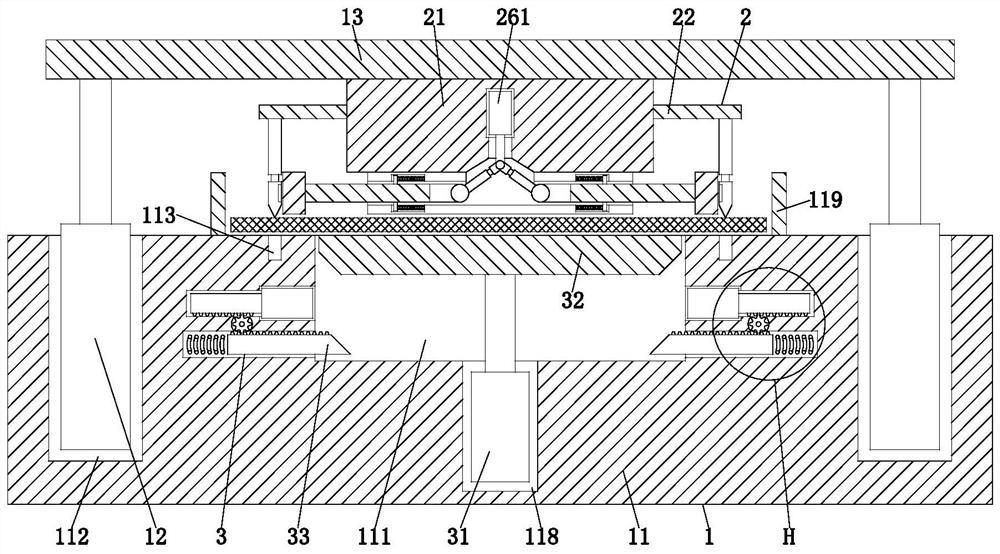

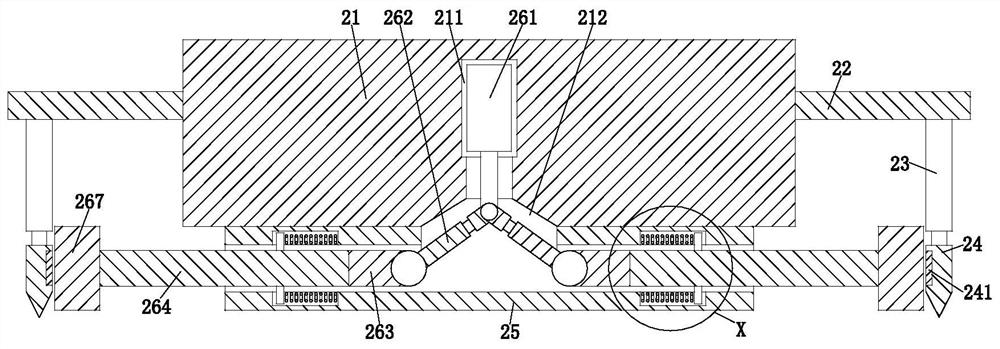

[0034]Such asFigure 1 to 8As shown, the present invention provides a high-voltage electric cabinet to produce a molding method, and the high-voltage electric cabinet is fabricated using a high-voltage electric cabinet, and the high voltage reservoir is made of forming means including susceptor 1, punching unit. 2 and bending unit 3, the upper end of the susceptor 1 is opened, and the punching unit 2 is mounted on the upper end of the base 1, and the bundle unit 3 is disposed inside the susceptor 1, wherein:

[0035]The susceptor 1 includes a base 11, a support cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com