Novel dual-transmission combined efficient sorting machine

A dual-drive, combined technology, applied in centrifuges and other directions, can solve the problems of low cleaning rate, high system energy consumption, and increase production costs, and achieve the effects of reducing production costs, improving powder selection efficiency, and reducing steel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

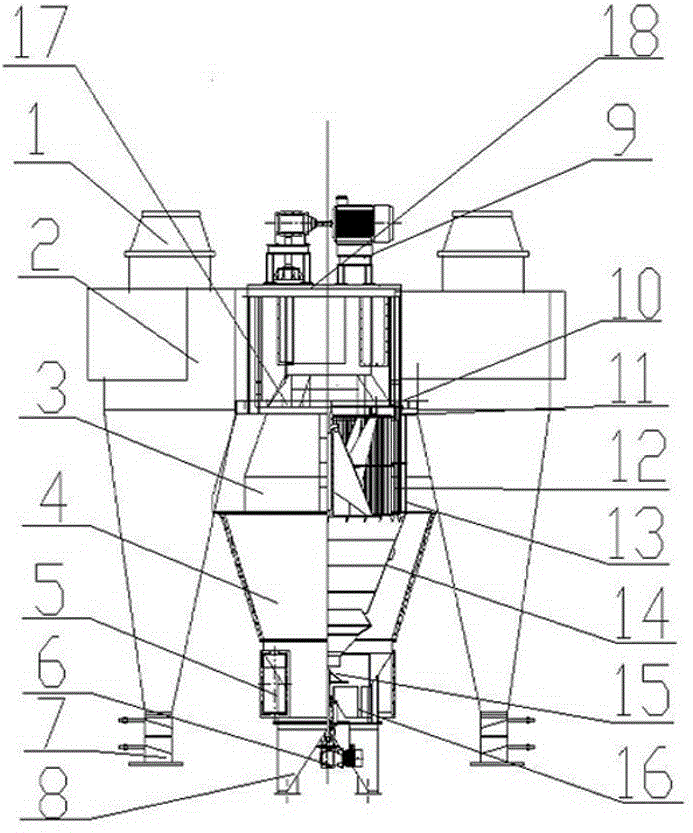

[0020] A new double-drive combined high-efficiency separator, such as figure 1 As shown, it includes feed inlet 17, finished product collector 2, upper powder selection chamber 3, middle powder selection chamber 4, material spreading plate 10, baffle plate 11, upper rotor 12, guide vanes 13, middle cone 14, lower Powder selection chamber 16, main support 18; the main support 18 runs through and fixes the upper powder selection chamber 3, the middle powder selection chamber 4 and the lower powder selection chamber 16, the upper powder selection chamber 3 is connected with the middle powder selection chamber 4, and the middle powder selection chamber The chamber 4 is connected with the lower powder selection chamber 16, the upper end of the upper powder selection chamber 3 is connected with the feed port 17, the two sides or surroundings of the upper powder selection chamber 3 are connected with the finished product collector 2, and the upper powder selection chamber 3 is provide...

Embodiment 2

[0025] This embodiment is further optimized on the basis of the above-mentioned embodiments, the lower end of the finished product collector 2 is provided with a finished product discharge port 7, the upper end of the described finished product collector 2 is provided with an air outlet 1, and the finished product discharge port 7 The setting is mainly convenient for operators to collect finely ground finished products from the lower end of the finished product collector 2, and the number of finished product collectors 2 is consistent with the number of discharge ports. Other structures involved in this embodiment are the same as those in the foregoing embodiment, and will not be repeated here.

Embodiment 3

[0027]This embodiment is further optimized on the basis of the above-mentioned embodiments. The structure of the new double-transmission combined high-efficiency separator also includes an upper transmission device 9, and the upper transmission device 9 is arranged on the upper end of the main support 18, and the main shaft and the upper The rotor 12 is connected. The upper transmission device 9 mainly provides power, and realizes the work of driving the upper rotor 12 through the main shaft. The high-speed rotation of the upper rotor 12 forms a horizontal vortex under the action of the guide vane 13, and the material is selected under the horizontal vortex area formed and its own gravity. , grading, wherein the upper transmission device 9 passes through the main shaft and the upper rotor 12, which is not a conventional technical means in the field. Other structures involved in this embodiment are the same as those in the foregoing embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com