Patents

Literature

147results about How to "Low fines content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of catalyst component for polymerization reaction of olefins and catalyst thereof

The invention provides a method for preparing a catalyst component for the polymerization reaction of olefins, which comprises the following steps: (1) dissolving magnesium halide in a solvent system comprised of an organic epoxy compound, an organic phosphorus compound and an inert diluent to form uniform solution; (2) mixing a titanium compound with the uniform solution formed by the step (1) and adding a precipitant to form a mixture, or adding the precipitant into the uniform solution formed by the step (1) first and mixing the uniform solution with the titanium compound to form a mixture; and (3) heating the mixture obtained by the step (2), adding any selected electronic donor compound during heating or after heating, and washing the resulting product with an inert diluent to obtain a magnesium / titanium-containing solid material, wherein the precipitant is a glycol ester compound. The catalyst component has high polymerization activity and stereoselectivity and causes little polymer fine powder when used in the polymerization reaction of olefins.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of catalyst component for olefin polymerization and catalyst

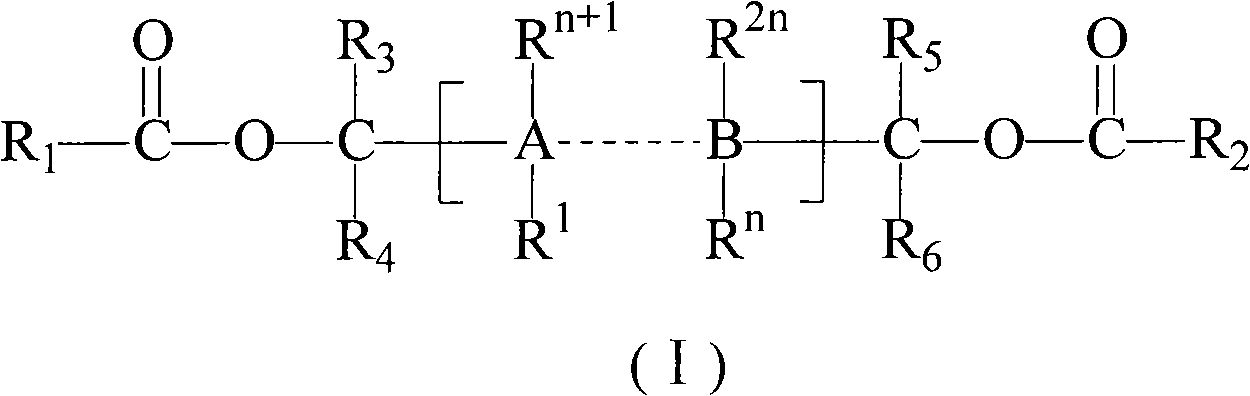

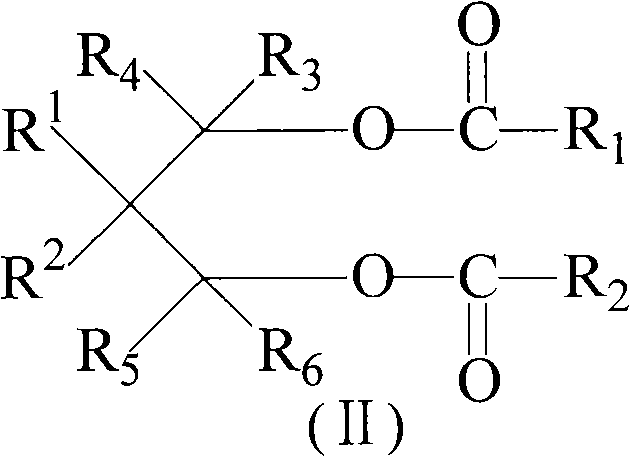

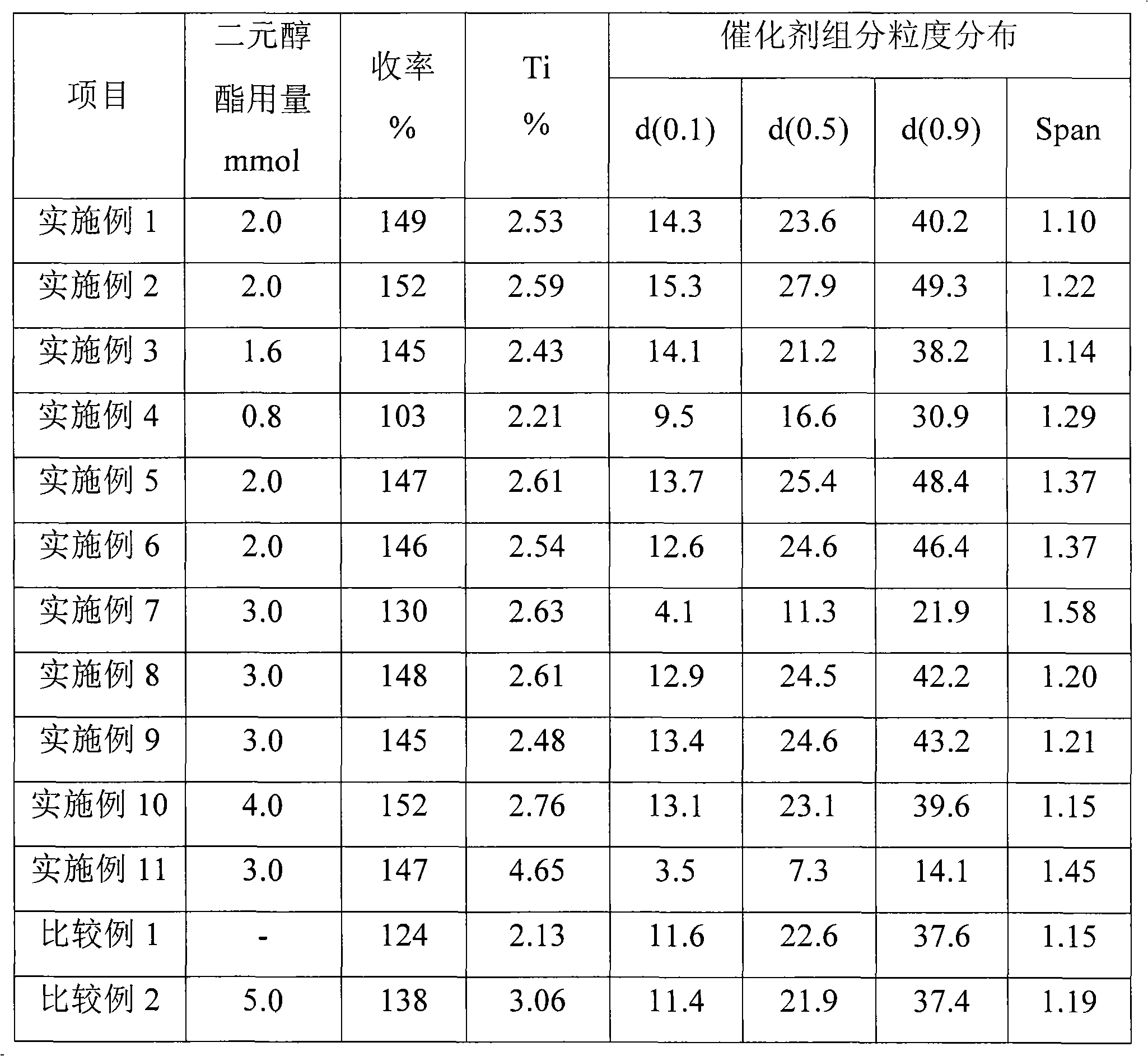

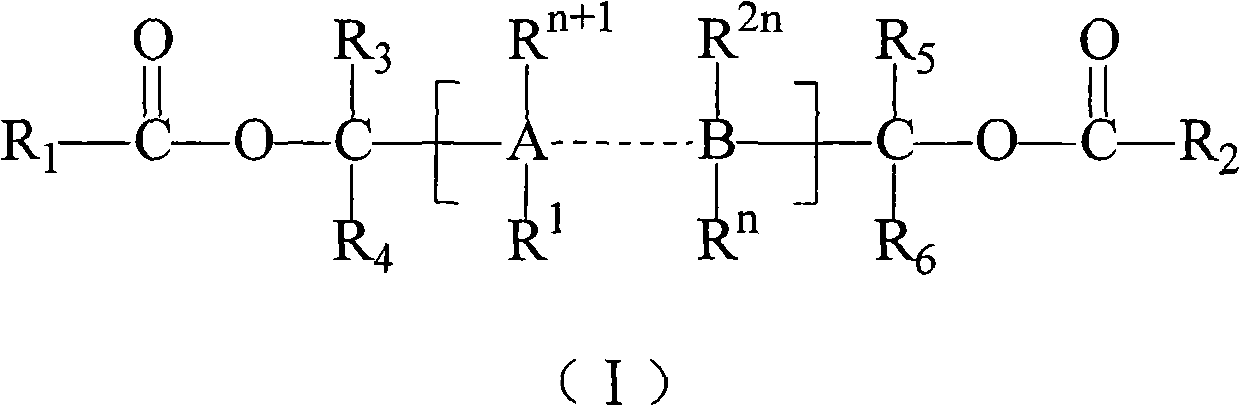

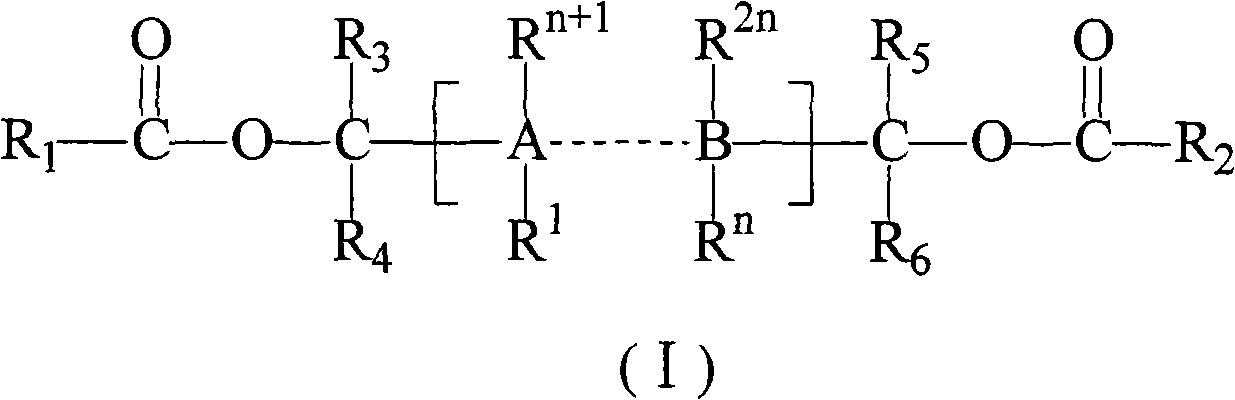

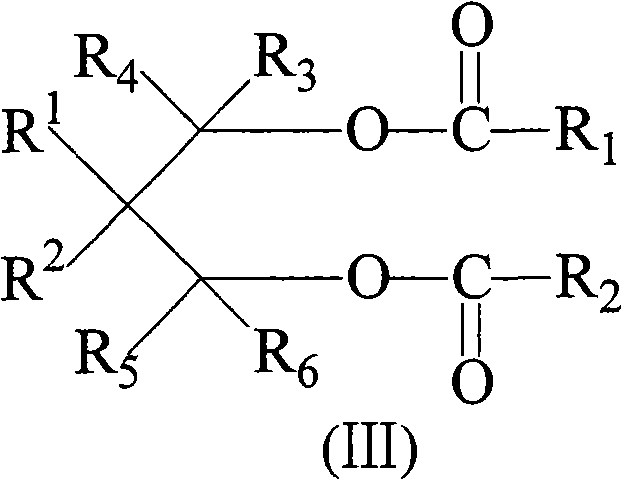

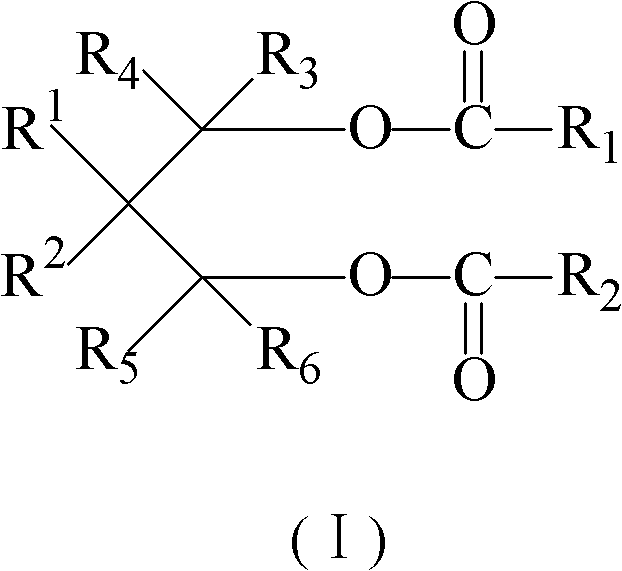

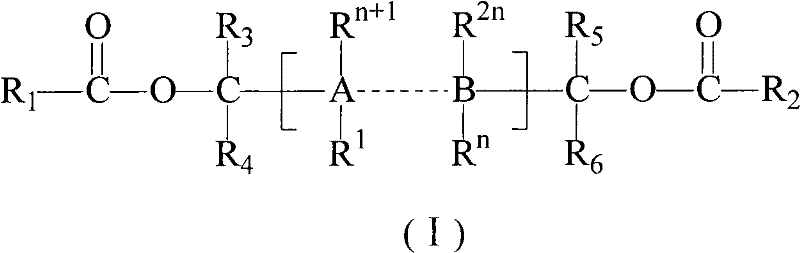

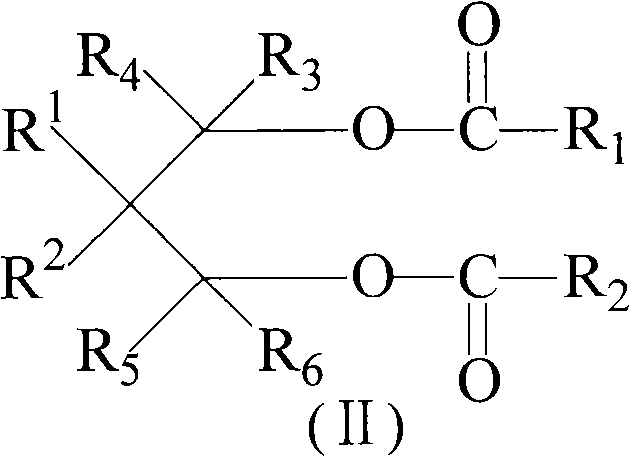

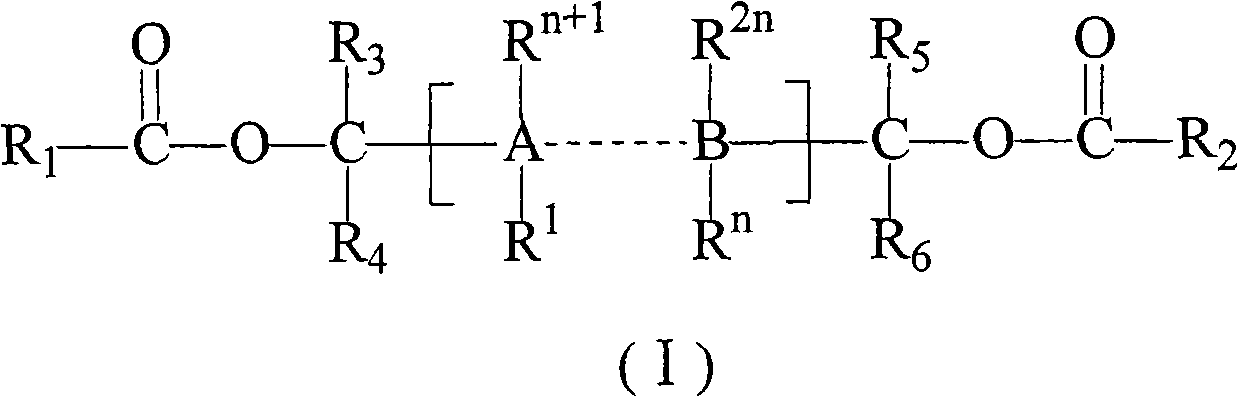

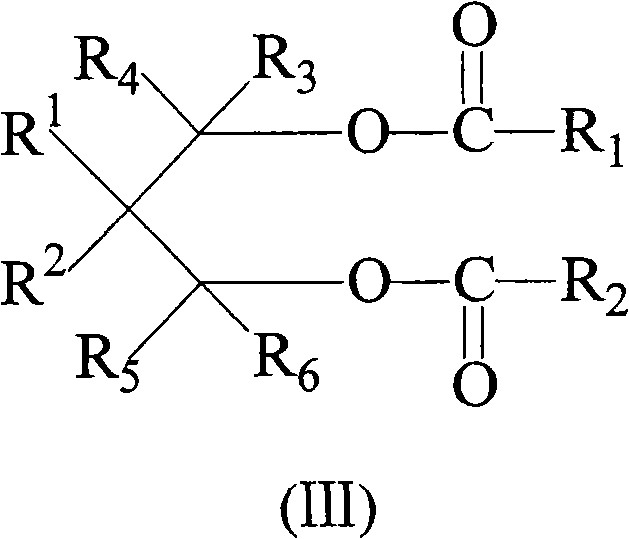

The invention provides a preparation method of a catalyst component for olefin polymerization. In the preparation method of the catalyst component, a separation assistant component consists of polyol ester compounds expressed by a general formula (I) and organosilane compounds expressed by the general formula (II) of RIaRIIbSi (ORIII) c; and the separation process of catalyst particles is effectively controlled through combining action of the organosilane compounds and the polyol ester compounds. Compared with the traditional catalyst, the catalyst has greatly improved activity and yield and has little polymer fine powder.

Owner:CHINA PETROLEUM & CHEM CORP +1

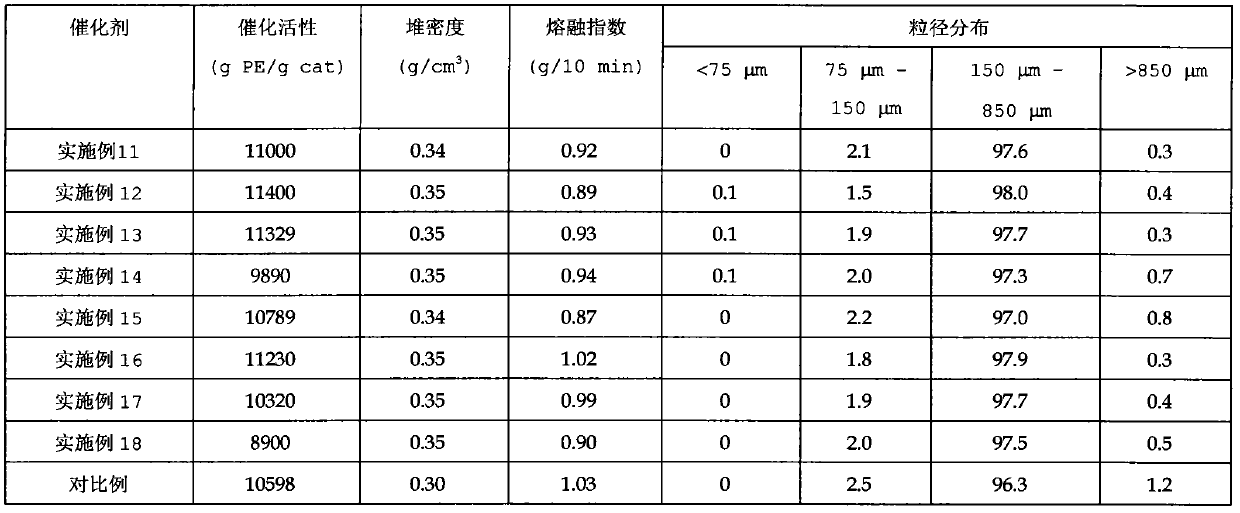

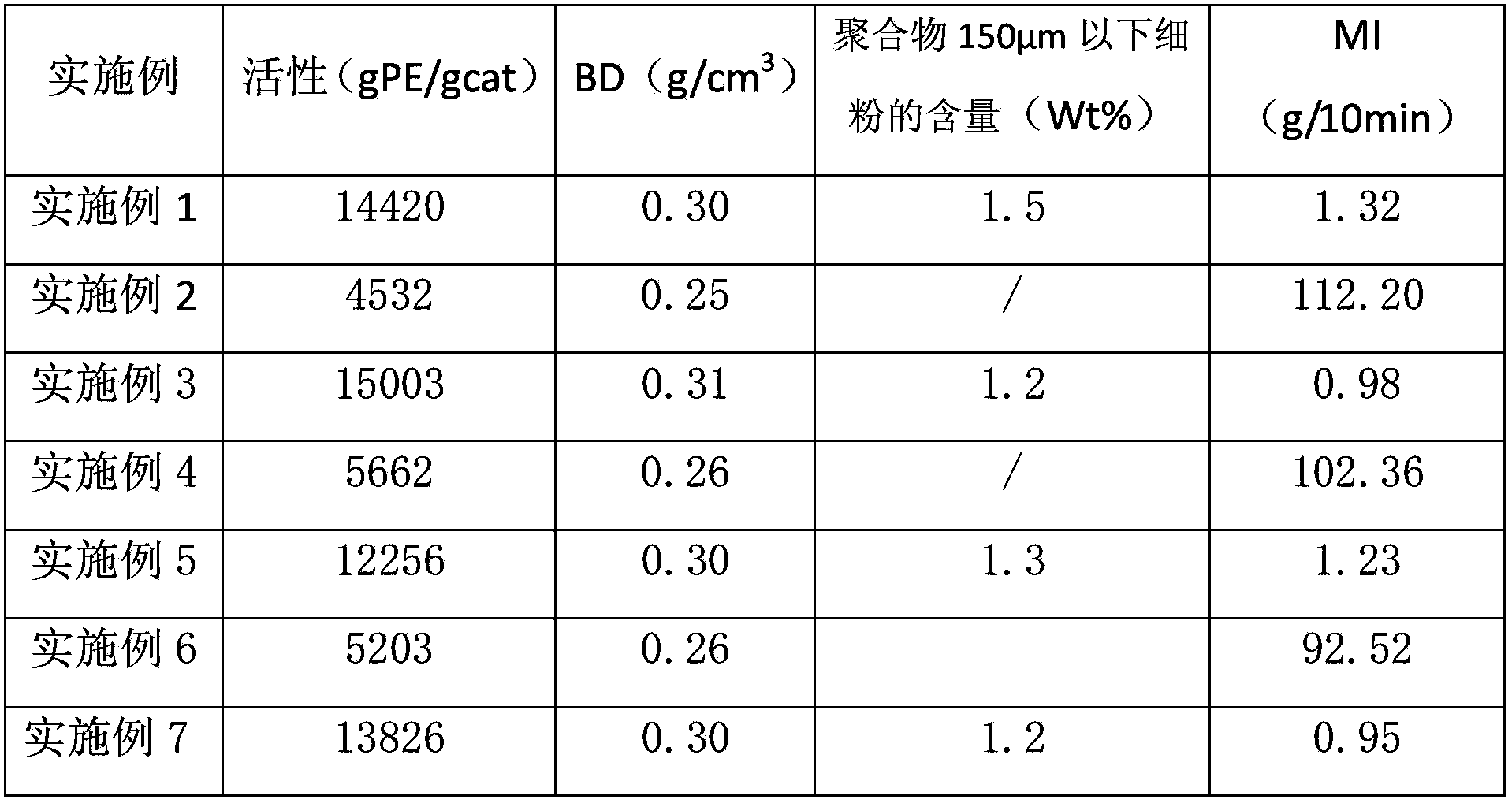

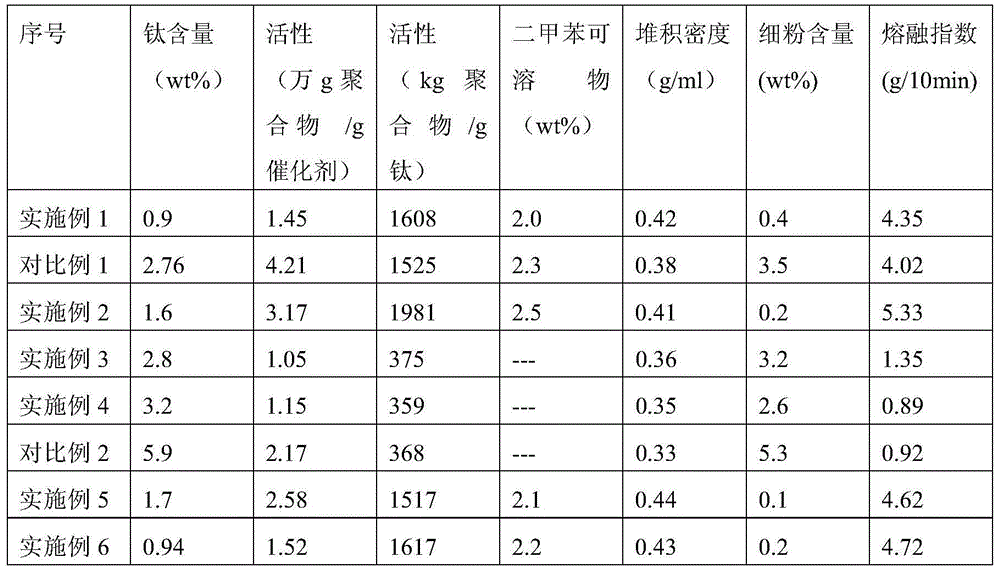

Preparation method of catalyst component for ethylene polymerization or copolymerization and catalyst thereof

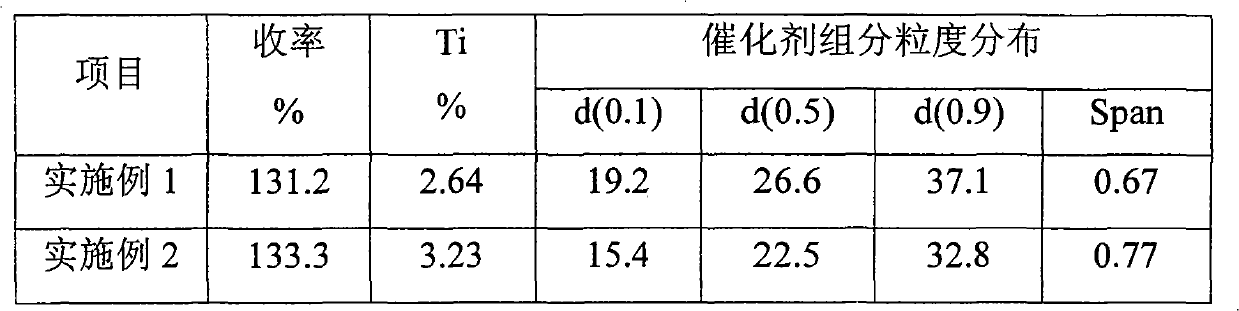

InactiveCN102875707AHigh catalytic activityNarrow particle size distributionSolid componentOrganotitanium compound

The invention relates to a preparation method of a catalyst component for ethylene polymerization or copolymerization and a catalyst thereof. The method comprises the following steps: (1) at a temperature of 50-90DEG, dissolving magnesium halide in a solvent system containing an organic epoxy compound and an organic phosphorus compound to form a uniform solution; adding an organic alcohol compound during or after the solution formation and leaving them to react for certain time so as to obtain a reaction solution; (2) in the presence of an organic titanium compound and at a temperature of -30DEG C-0DEG C, subjecting the solution and a titanium compound to a contact reaction, or adding the organic titanium compound after the contact reaction of the solution obtained in step (1) and the titanium compound, and raising the temperature of the mixture slowly to 50-120DEG C, leaving solids to precipitate gradually and form particles, after certain period of reaction, removing the unreacted material and the solvent, and conducting washing with an inert diluent so as to obtain a solid component; and (3) suspending the solid component in certain amount of the inert diluent, performing a contact reaction with an organic aluminium compound under a temperature of 0DEG C-50DEG C, and after certain reaction time, removing the inert diluent, thus obtaining the catalyst component. The catalyst provided in the invention has high catalytic activity and good hydrogen response.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst used for ethylene polymerization or copolymerization and its preparation method

A catalyst for the polymerizing and copolymerizing of ethene and its preparing process is disclosed. The active component of said catalyst is prepared through dissolving magnesium halide in organic epoxy compound, organic P compound, organic alcohol, or inertial deluent to obtain uniform solution, educing out the solid deposition contain Mg / Ti by adding educing assistant and Ti halide or its derivative, and treating the Ti contained component by hydrogenating improver. Its advantages are high activity, high hydrogenating sensitivity and good granular form.

Owner:CHINA PETROLEUM & CHEM CORP +1

Propylene polymerization or copolymerization and its multipolymer

Propylene polymerization or copolymerization and its polymer are disclosed. The process contains tree stage polymerization and is carried out by propylene pre-polymerizing at 2-1000g polymer / 1g catalyst, polymerizing at 50-90 degree and polymerizing at 95-150 degree in proportion of 0.3-3. It has excellent particular appearance and its bending modulus is >1.7Gpa and bending strength is >40MPa.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of catalyst component for polymerization reaction of olefins and catalyst thereof

The invention provides a method for preparing a catalyst component for the polymerization reaction of olefins, which comprises the following steps: (1) dissolving magnesium halide in a solvent system comprised of an organic epoxy compound, an organic phosphorus compound and an inert diluent to form uniform solution; (2) mixing a titanium compound with the uniform solution formed by the step (1) and adding a precipitant to form a mixture, or adding the precipitant into the uniform solution formed by the step (1) first and mixing the uniform solution with the titanium compound to form a mixture; and (3) heating the mixture obtained by the step (2), adding any selected electronic donor compound during heating or after heating, and washing the resulting product with an inert diluent to obtaina magnesium / titanium-containing solid material, wherein the precipitant is a glycol ester compound. The catalyst component has high polymerization activity and stereoselectivity and causes little polymer fine powder when used in the polymerization reaction of olefins.

Owner:CHINA PETROLEUM & CHEM CORP +1

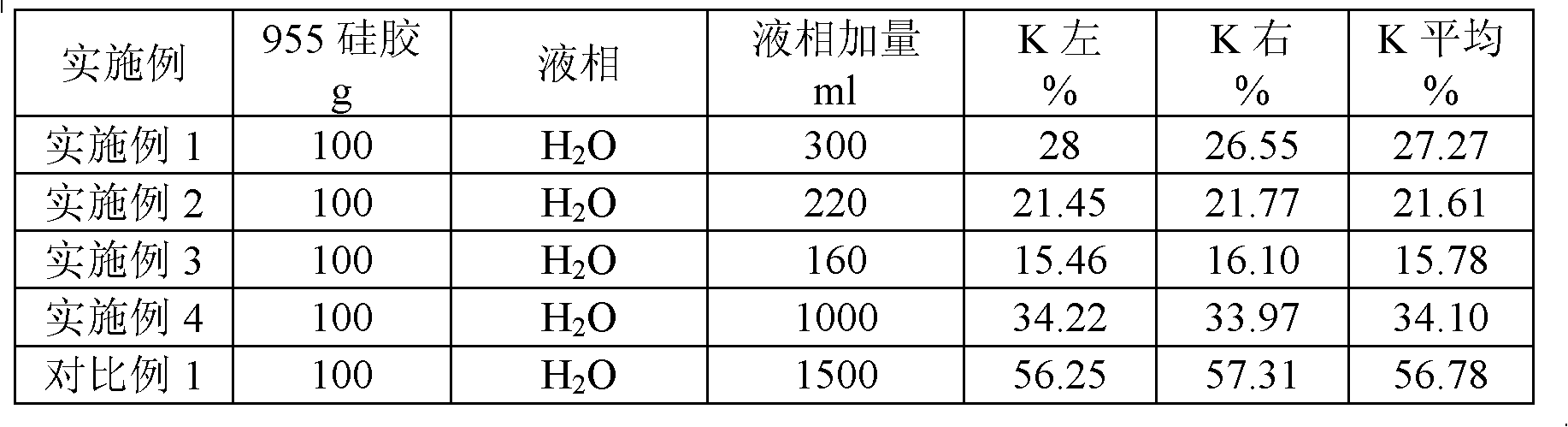

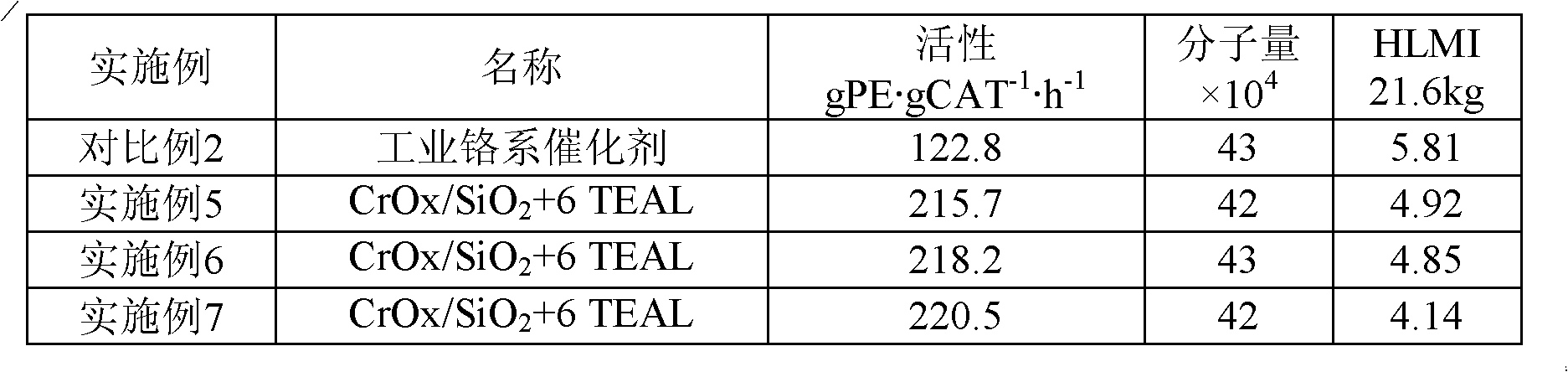

Chromium-polyethylene catalyst

The invention relates to a chromium-polyethylene catalyst, and belongs to the technical field of polyethylene catalysts. The chromium-polyethylene catalyst is composed of chromium salt, an inorganic metal oxide support and a promoter. A preparation method for the chromium-polyethylene catalyst comprises the following steps of: preparing the chromium salt into solution; mixing the solution with the inorganic metal oxide support; and sequentially pre-drying, as well as drying, roasting and reducing in an inert gas environment to prepare the chromium-polyethylene catalyst. According to the preparation method disclosed by the invention, a novel chromium-polyethylene catalyst higher in polymerization activity and strength than the traditional chromium-polyethylene catalyst is prepared by adjusting the ratio of the mass of the inorganic metal oxide support to the volume of the solvent during a catalyst soaking process; and the resin prepared form the catalyst is improved in particle strength and reduced in fine powder content.

Owner:CHINA PETROLEUM & CHEM CORP

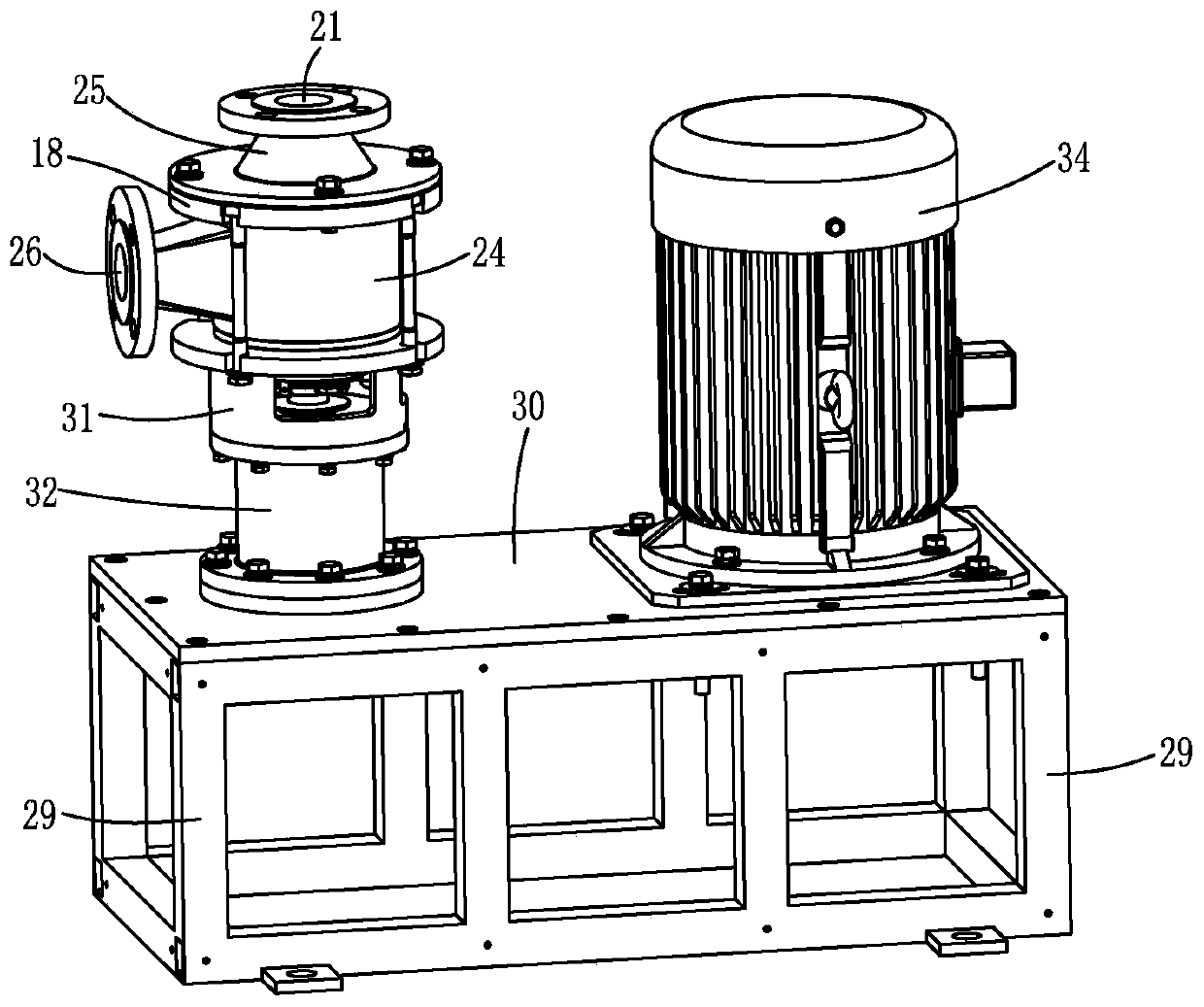

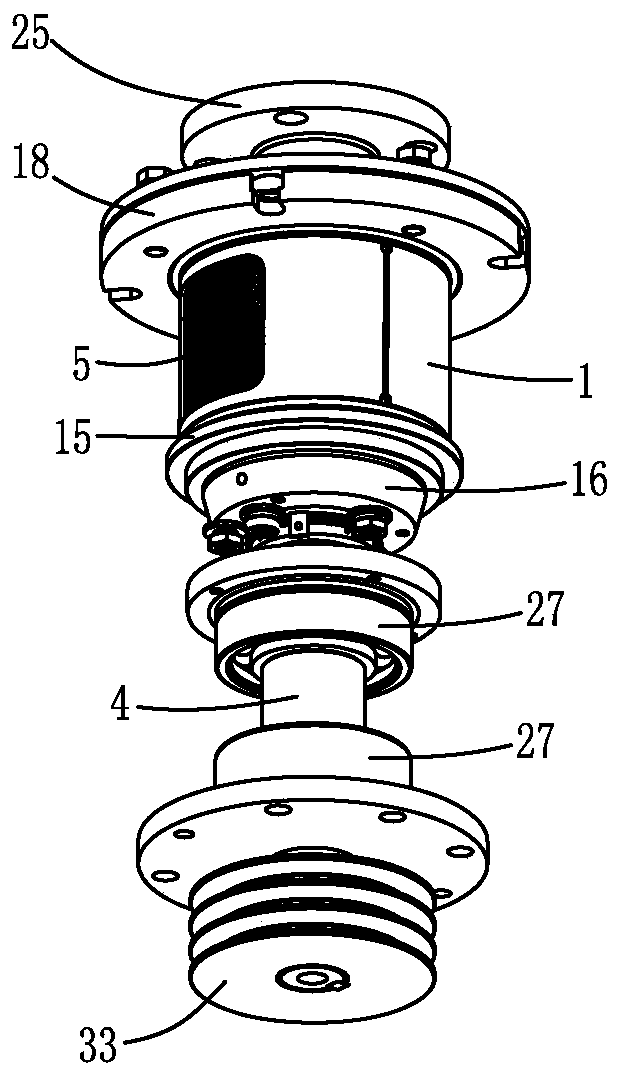

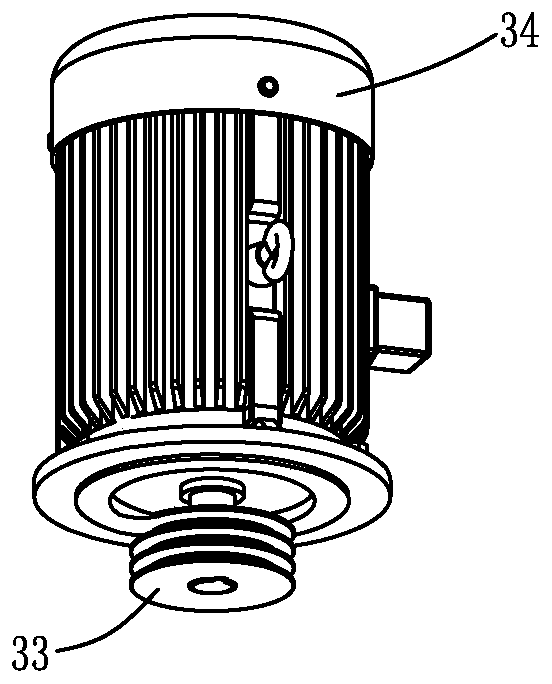

Vertical slurry crusher

PendingCN110142109AUniform particlesReasonable structureGrain treatmentsStructural engineeringSlurry

Provided is a vertical slurry crusher. The vertical slurry crusher comprises a crushing assembly driven by a rotating shaft (4). The crushing assembly comprises a barrel (1) and a rotor (2), the barrel (1) is provided with a screen net area (5), the inner wall of the barrel (1) is provided with a plurality of raised fixed teeth (7), and multiple rows of the raised fixed teeth (7) are arranged along the inner wall of the barrel (1). Each row comprises a plurality of the raised fixed teeth (7) arranged vertically, and a vacant section (8) is arranged between every two adjacent rows of the raisedfixed teeth (7) as a space needed for material falling. A plurality of raised rotary teeth (9) are arranged on the periphery of the rotor (2), at least two rows of the raised rotary teeth (9) are arranged along the periphery of the rotor (2), each row comprises a plurality of the raised rotary teeth (9) arranged vertically, and a vacant groove (23) is arranged between every two adjacent rows of the raised rotary teeth (9) as a space needed for material falling. The space needed for the sizes of material target particles is reserved between the meshing raised rotary teeth (9) and the raised fixed teeth (7). The crushed material particles are even, and the crushing efficiency is high.

Owner:宁波领智机械科技有限公司

Propylene polymerization or copolymerization and its multipolymer

Propylene polymerization or copolymerization and its polymer are disclosed. The process contains tree stage polymerization and is carried out by propylene pre-polymerizing at 2-1000g polymer / 1g catalyst, polymerizing at 50-90 degree and polymerizing at 95-150 degree in proportion of 0.3-3. It has excellent particular appearance and its bending modulus is >1.7Gpa and bending strength is >40MPa.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for ethylene homo-and co-polymerization

The present invention relates to a catalyst for homo-polymerization or co-polymerization of ethylene, or more particularly to a solid complex titanium catalyst for homo-polymerization or co-polymerisation of ethylene, said catalyst being produced by preparing a magnesium solution by contact-reacting a halogenated magnesium compound with alcohol, reacting said solution with an ester compound having at least one hydroxy group and a boron compound having an alkoxy group, and then reacting said solution with a mixture of a titanium compound and a silicon compound. The catalyst of the present invention has good activity, and the polymers produced by means of the catalyst herein has advantages in that the polymers have high bulk density with narrow particle distribution and a reduced amount of fines particles.

Owner:SAMSUNG GENERAL CHEMICALS CO. LTD

Olefin polymerization catalyst, and preparation method and application thereof

The invention discloses an olefin polymerization catalyst. The catalyst comprises a magnesium compound, an organic alcohol ether compound, an organophosphorus compound, an organic epoxy compound, a precipitation aid, an internal electron donor and a titanium compound. The catalyst has the advantages of high activity in olefin polymerization reactions, good hydrogen sensitivity, granule shape improvement and few polymer fine powder.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst component used for ethylene polymerization reaction, catalyst and preparation method thereof

The invention discloses a catalyst component used for an ethylene polymerization reaction, a preparation method thereof and a catalyst prepared therefrom. The catalyst component comprises a magnesium alcohol adduct, a titanium compound, acrylate and a derivative thereof, an organic aluminum compound, a monoester compound and a free radical initiator. The catalyst is high in mechanical strength and hydrogen regulation sensitivity and is not liable to break during polymerization. A prepared polyethylene powder material is high in stacking density, is very concentrated in particle size distribution and is less in contents of thick powder and fine powder.

Owner:CHINA PETROLEUM & CHEM CORP +1

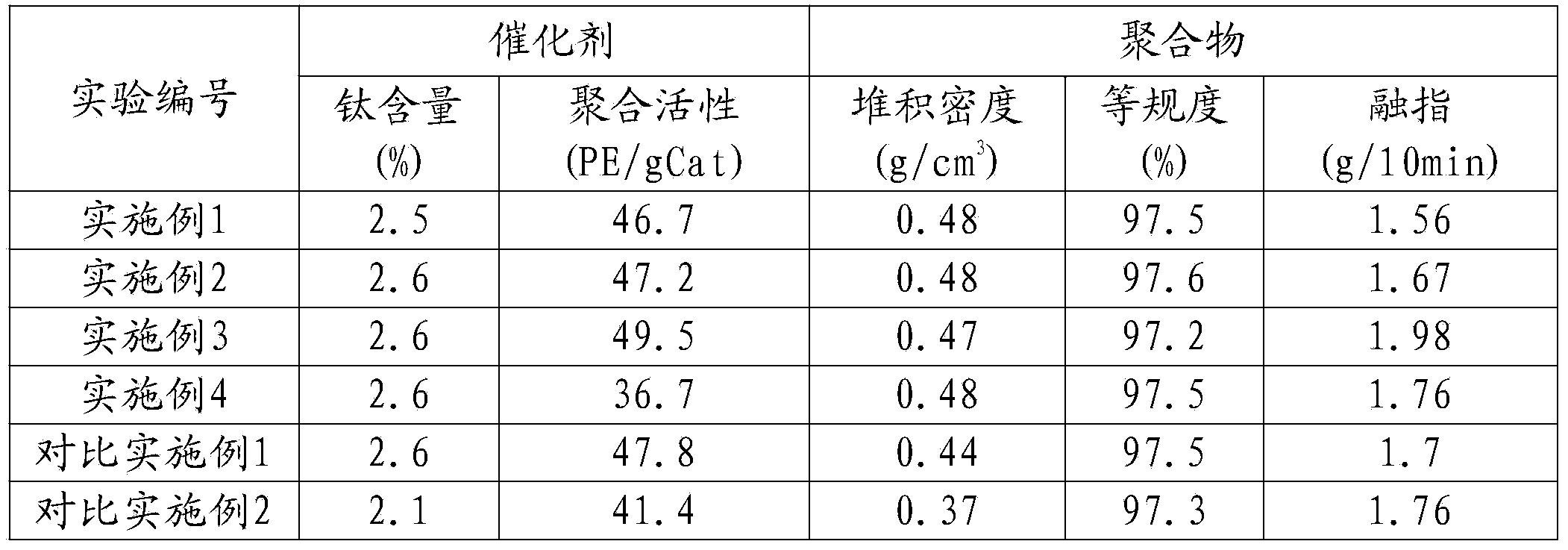

Polypropylene catalyst spherical carrier and solid catalyst and preparation method thereof

InactiveCN104177523AHigh polymerization activityLow fines contentBulk chemical productionSlurrySilica gel

The invention discloses a polypropylene catalyst spherical carrier and a solid catalyst and a preparation method thereof. The preparation method comprises the following steps: carrying out a heating reaction between a magnesium chloride alcohol compound formed by complexing magnesium chloride and alcohol and fumed silica in a dispersing medium, and forming uniform slurry containing the magnesium chloride alcohol compound; dispersing the slurry in an inert dispersing medium under the high shearing action, introducing the slurry into a low-temperature inert dispersing medium, and carrying out freeze curing to form the spherical particle carrier containing the magnesium chloride alcohol compound. A solid catalyst prepared by adopting the carrier is used for olefin polymerization, namely propylene polymerization, and has relatively high polymerization activity, relatively low fine powder content and good polymer particle form.

Owner:ZIBO XINSU CHEM

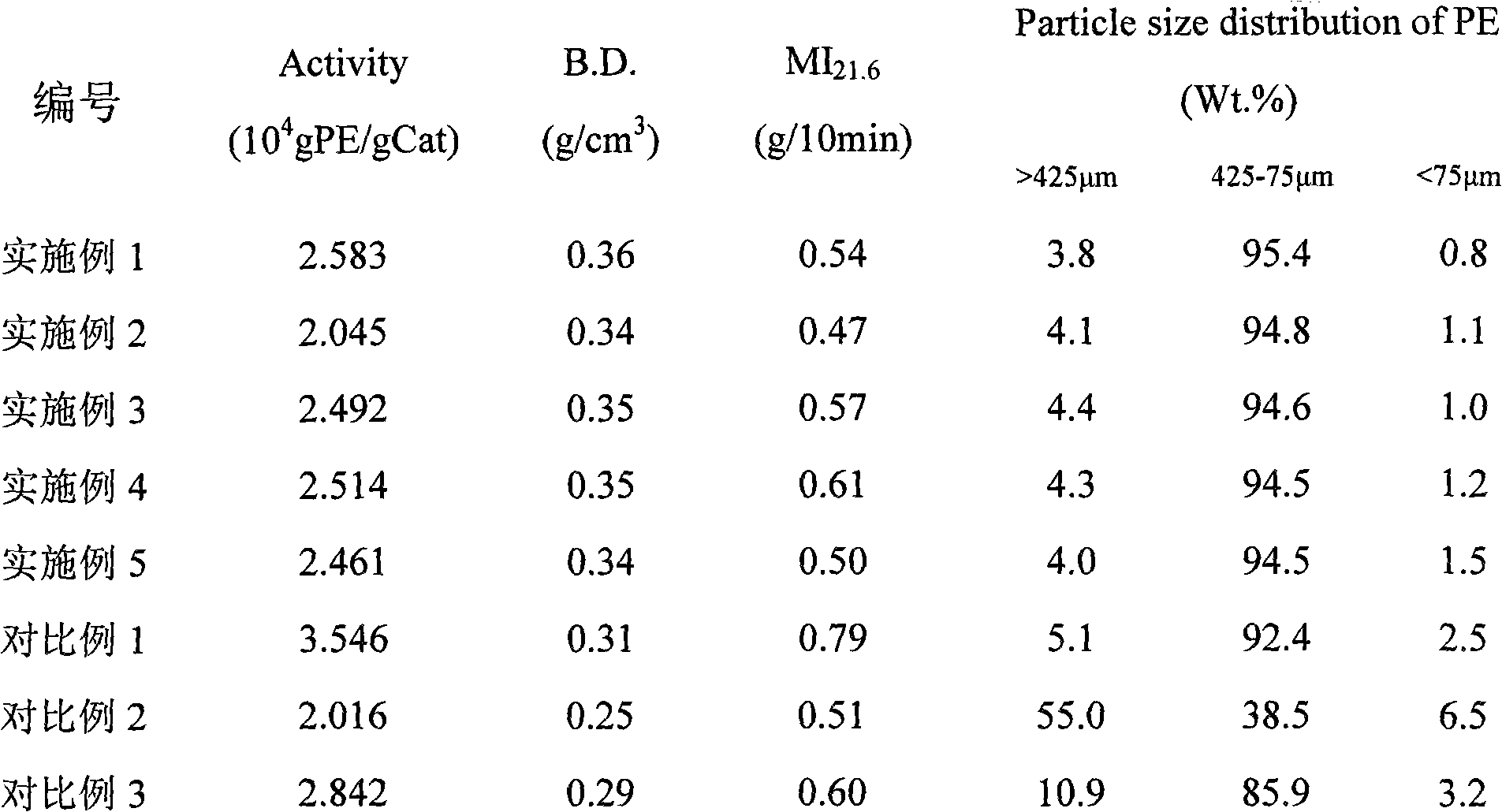

Catalyst component for ethylene polymerization and catalyst thereof

The invention provides a catalyst component for ethylene polymerization, which is prepared by a method comprising the following steps of: (1) reacting an alkoxy titanium compound (a) with a magnesium compound (b) to form a solution; (2) adding a porous inorganic oxide (d) and halogenated alkyl aluminum (e) to the solution prepared in the step (1) to separate out sediment; and (3) reacting a liquid titanium compound (h) with the sediment obtained in the step (2) to obtain a titanium-included solid catalyst component. The halogenated alkyl aluminum (e) can be one or more than one of organic aluminum compounds with the general formula of AlRnX3-n, wherein R represents alkyl, aralkyl and aryl with 1-20 hydrogen or carbon atoms, X represents halogen, and n represents an integer which is not less than 0 and not more than 3. The preparation method of the catalyst is simple and has low cost; and when applied to ethylene polymerization, the catalyst has higher activity, and the obtained ethylene polymers have centralized particle size distribution and less content of fine powder.

Owner:CHINA PETROLEUM & CHEM CORP +1

Olefin polymerization catalyst, its production and use

An olefin polymerization catalyst, its production and use are disclosed. The procedure is carried out by reacting magnesium compound with alcohol compound to form mono-magnesium composite, immersing it into carrier silica with halogenating agent, reacting it with titanium compound to obtain final product. It has better catalyst activity and wider polymer molecular weight distribution. It can be used for vinyl homopolymerization and copolymerization.

Owner:CHINA PETROLEUM & CHEM CORP +2

Catalyst component for olefin polymerization, preparation method thereof, catalyst and application of

The invention belongs to the field of catalysts, disclosed are a catalyst component for olefin polymerization, a preparation method thereof, a catalyst and application, the catalyst component comprises: (1) a reaction product of magnesium halide, a titanium-containing compound and an electron donor compound, the titanium-containing compound is a product of titanium halide and / or aluminum-reduced titanium halide, the general formula of the product of the aluminum-reduced titanium halide is TiXm.nAlXp, wherein n is greater than 0 and less than or equal to 1, m is greater than 0 and less than orequal to 3, p is greater than 0 and less than or equal to 3, and X is halogen; (2) an inorganic oxide carrier filler; and (3) at least one organic compound, wherein the organic compound is liquid hydrocarbon and / or silicon oil. The catalyst is low in particle content and is used for catalyzing ethylene polymerization; and obtained polyethylene powder has less fine powder content.

Owner:CHINA PETROLEUM & CHEM CORP +1

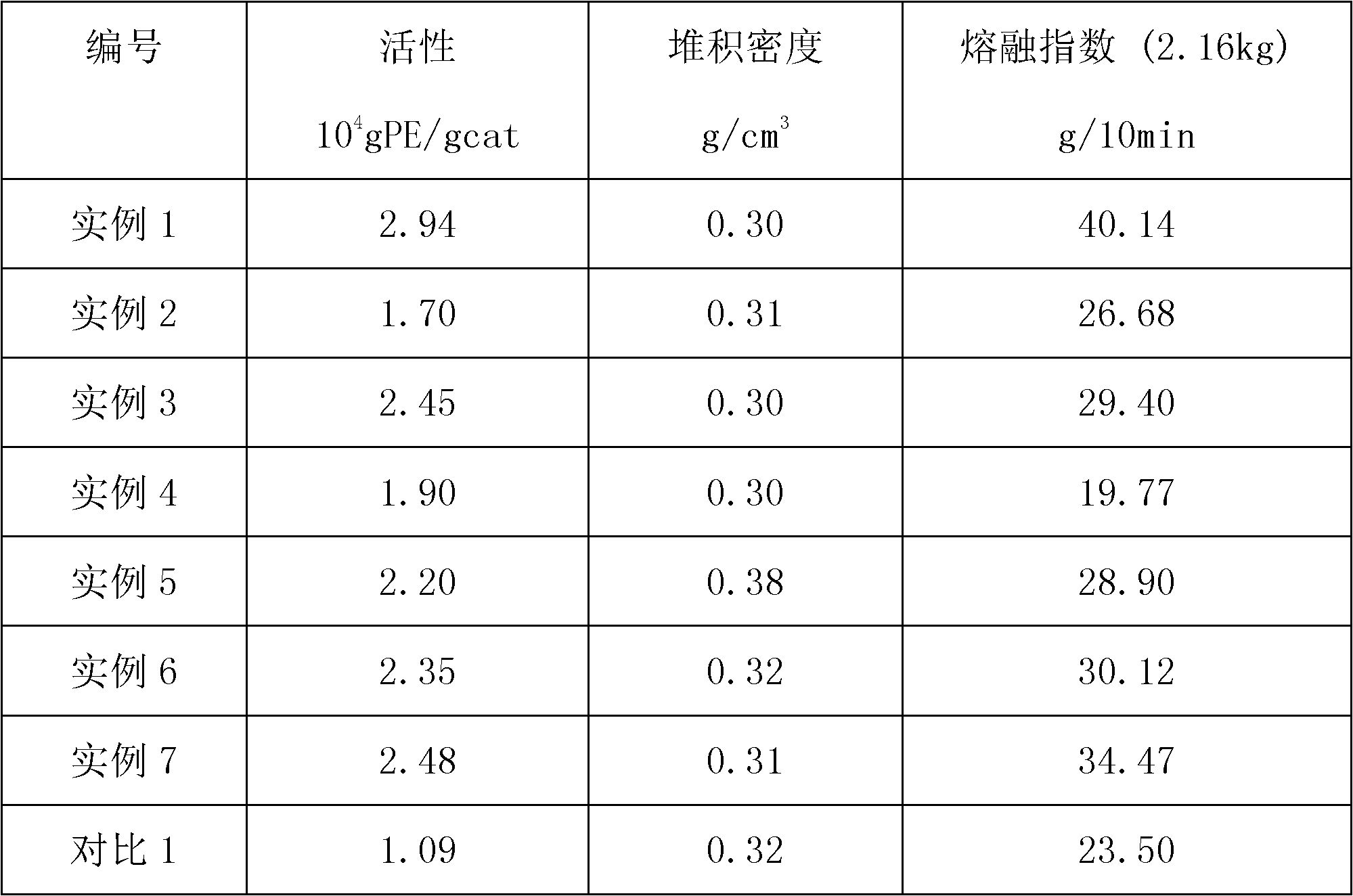

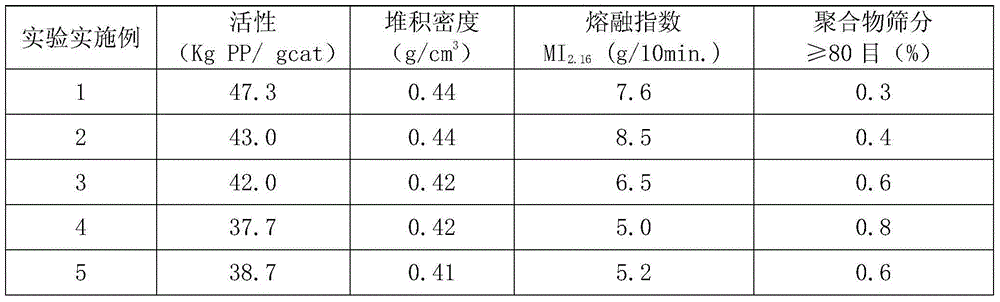

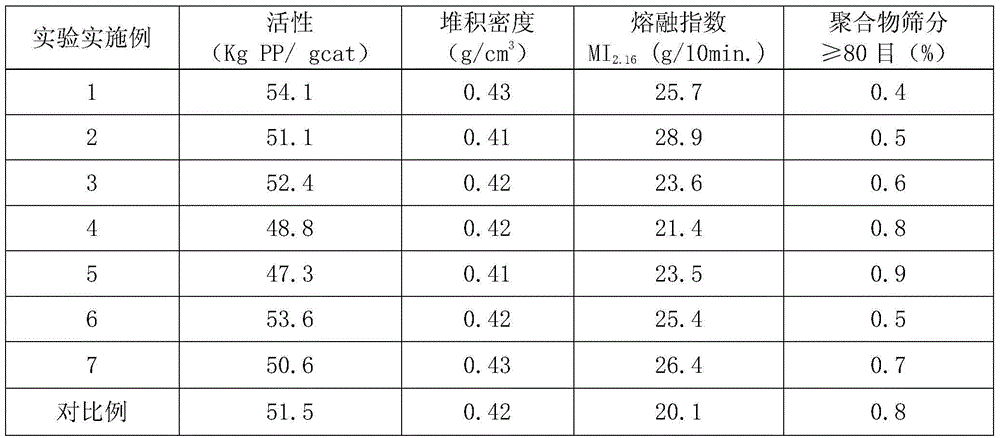

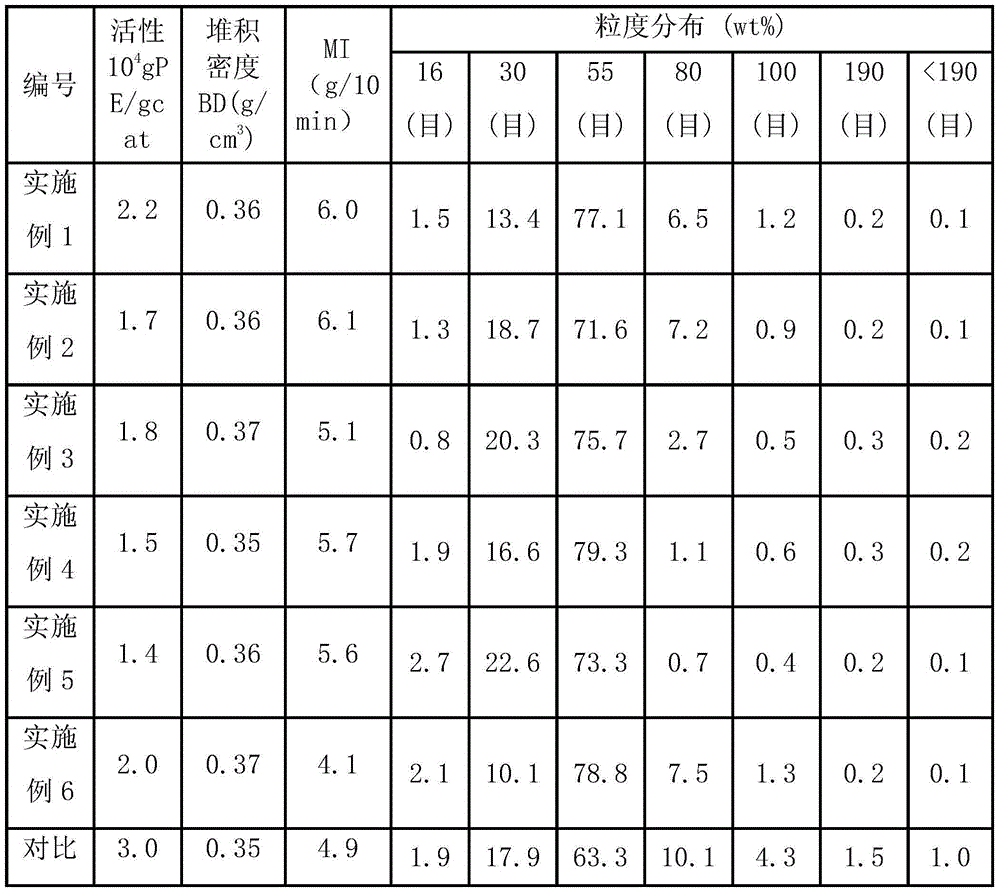

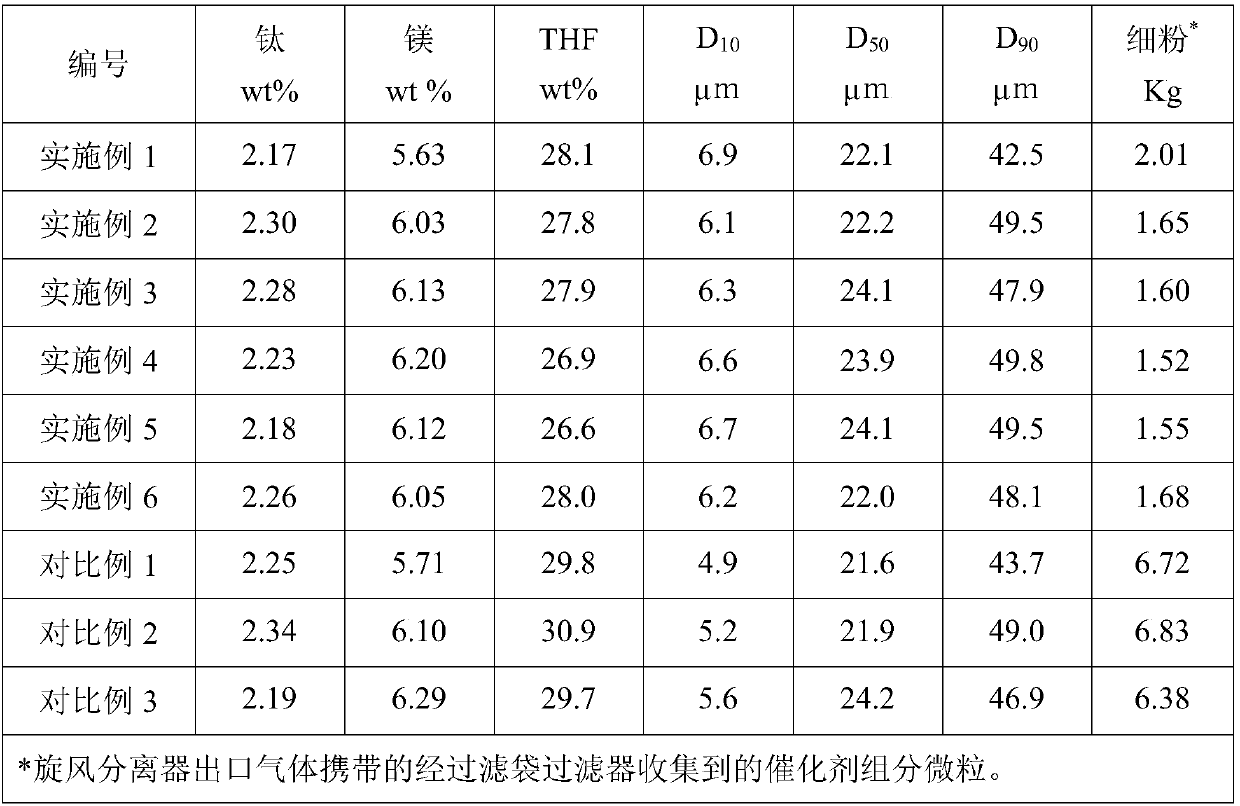

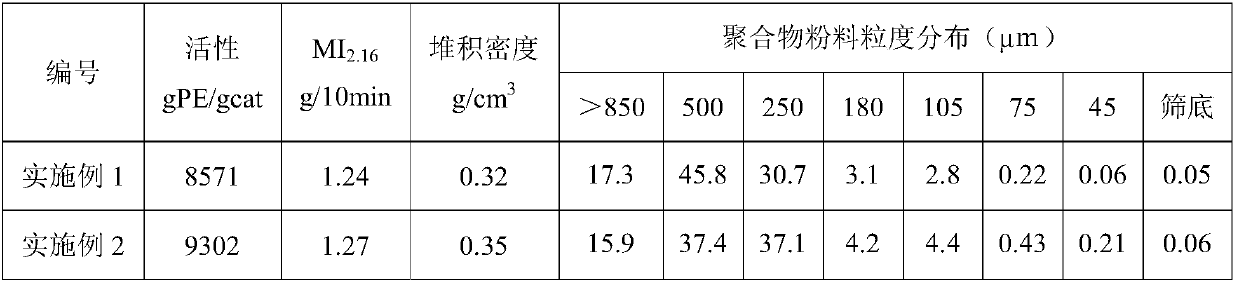

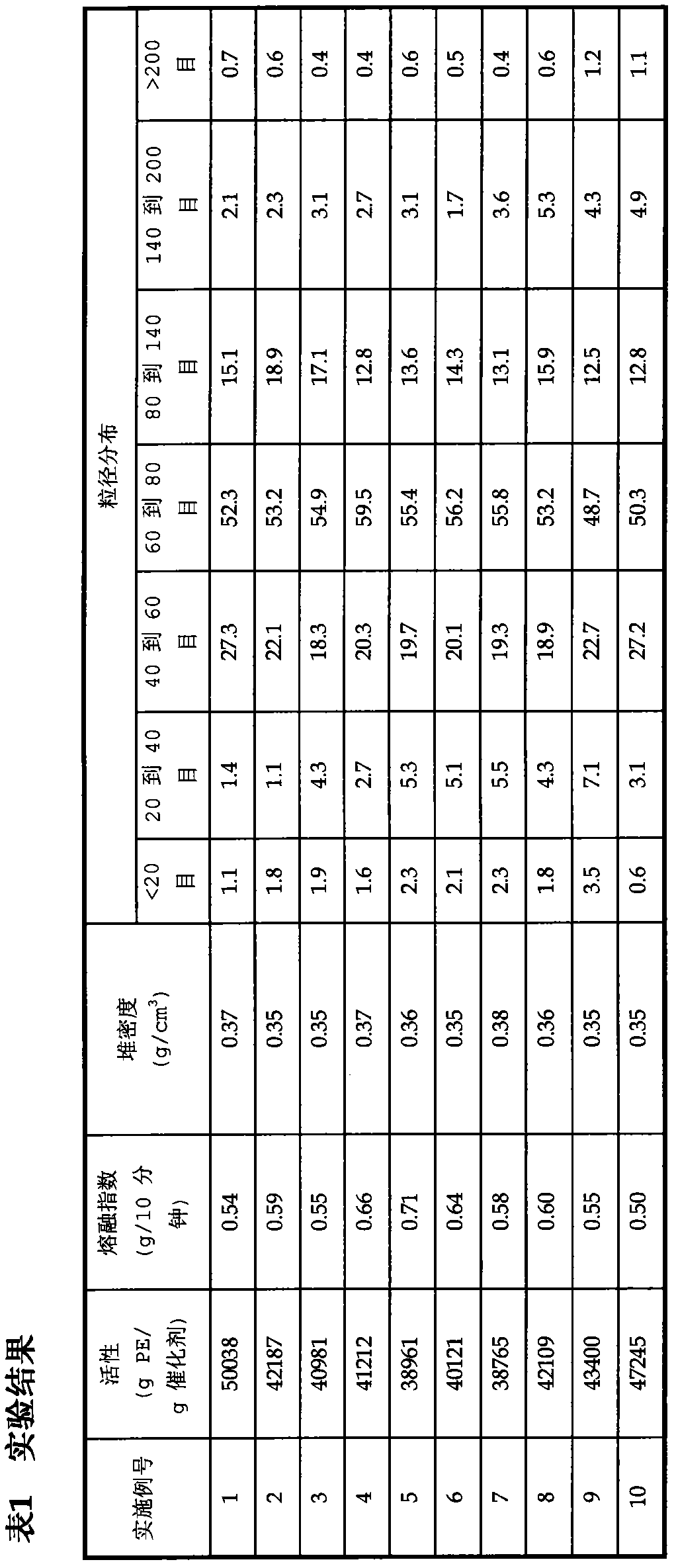

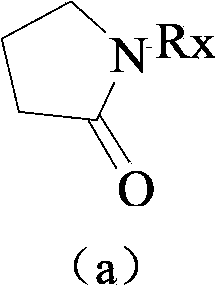

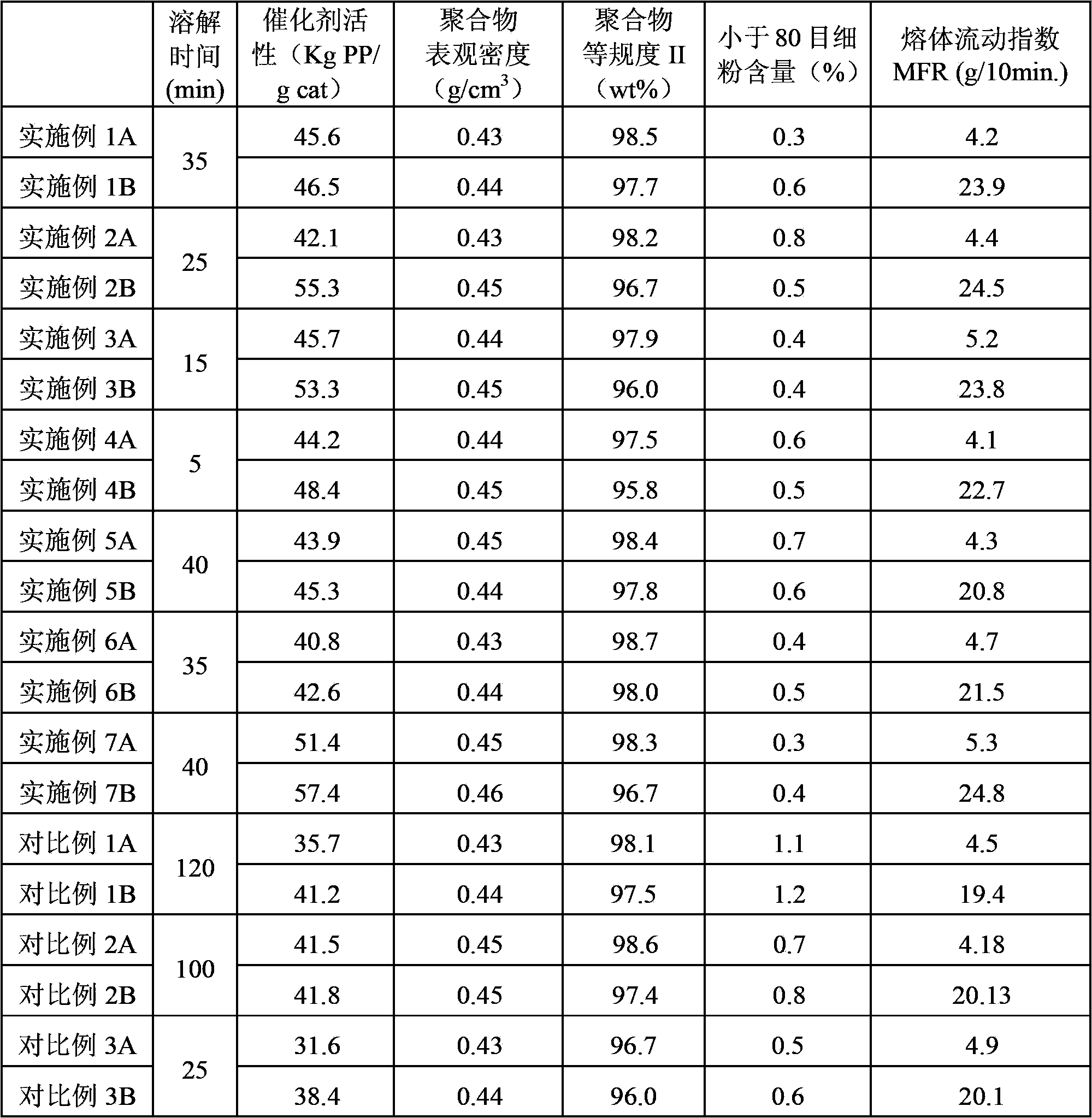

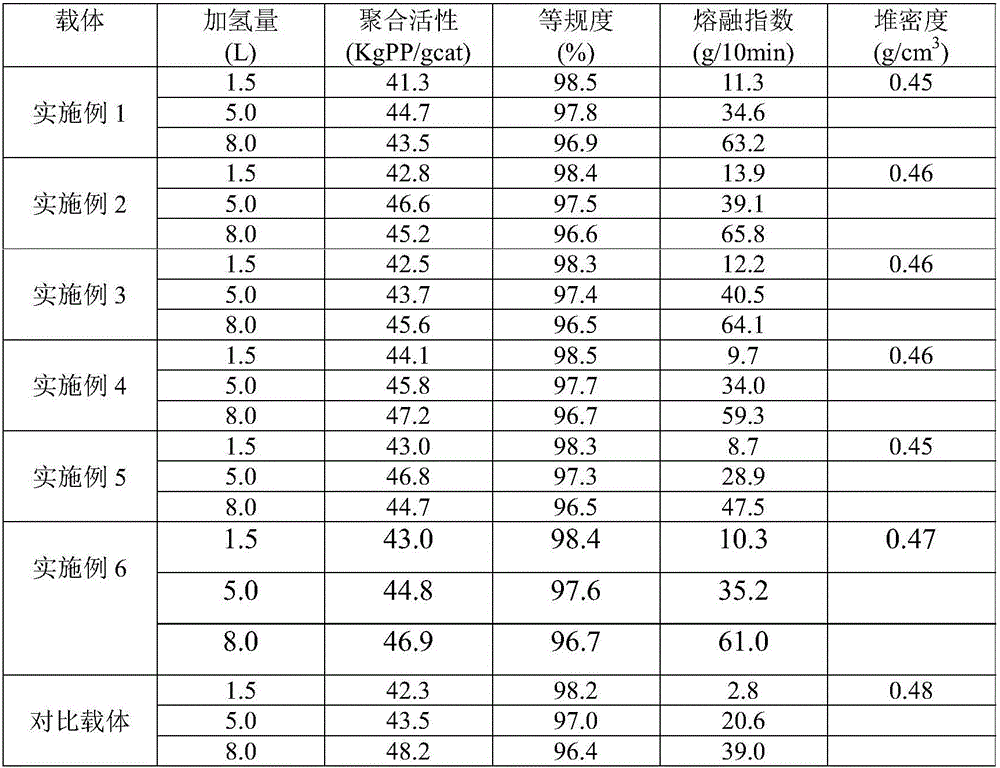

Preparation methods for olefin polymerization catalyst component and corresponding catalyst

The invention provides a preparation method for an olefin polymerization catalyst component. The preparation method comprises the steps: contacting a magnesium compound, an organophosphorus compound, a pyrrolidone compound and an organic epoxy compound in a solvent to form a uniform solution; in the presence of a precipitation aiding agent, contacting the uniform solution with a titanium compound to obtain a mixture; and then contacting the obtained mixture with an internal electron donor compound, and carrying out a reaction to obtain the olefin polymerization catalyst component, wherein at least one of the magnesium compound and the titanium compound is a halogen-containing compound. According to the preparation method, the addition of the pyrrolidone compound can effectively shorten the preparation time of the catalyst component, improve the particle morphology of a catalyst and greatly reduce the fine powder content of the polymer; and at the same time, after addition of the pyrrolidone compound, the catalyst activity can be basically maintained or improved, the apparent density of the polymer is relatively high, and the degree of isotacticity and the polymer melt flow index still maintain original relatively good performance of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

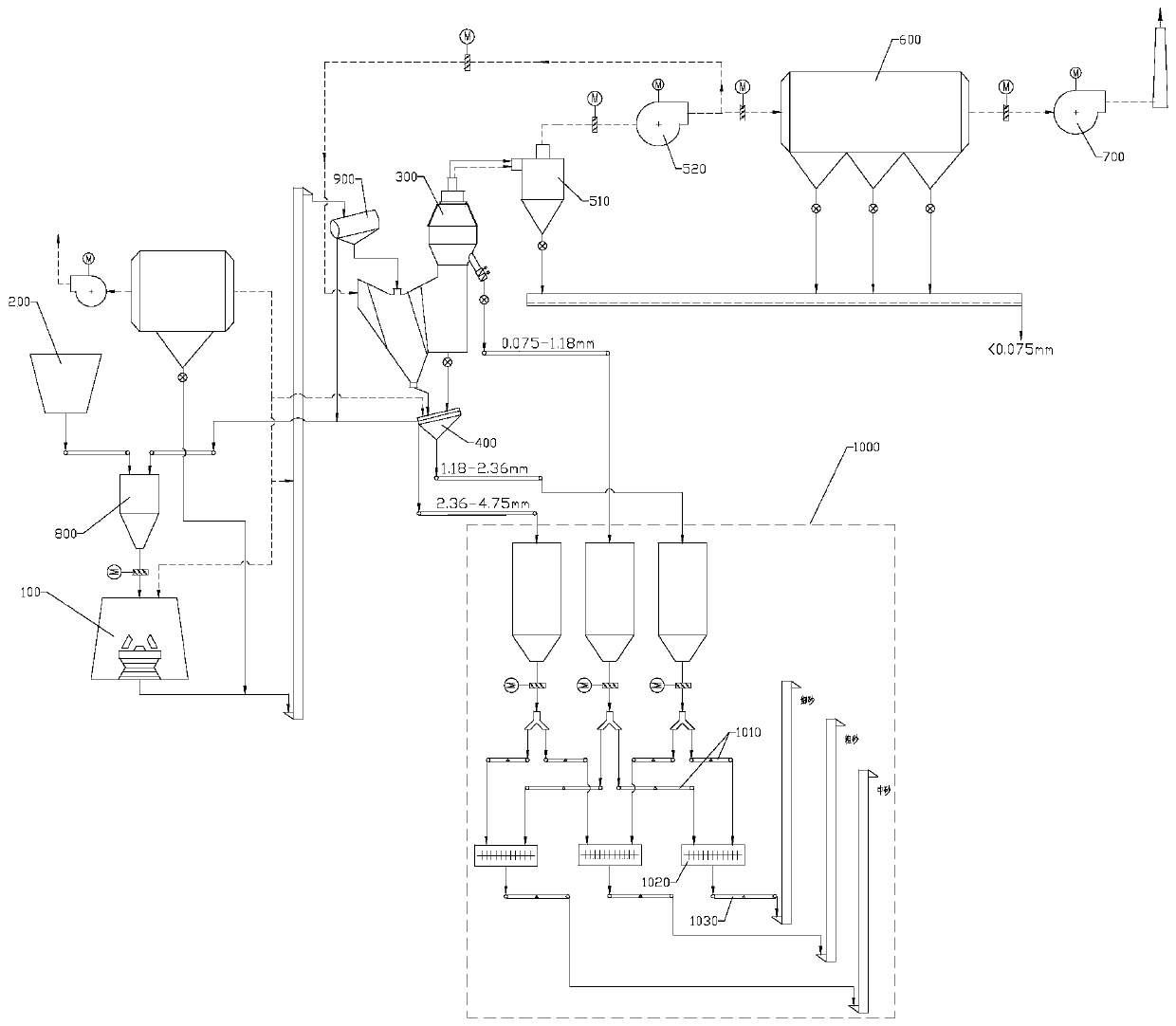

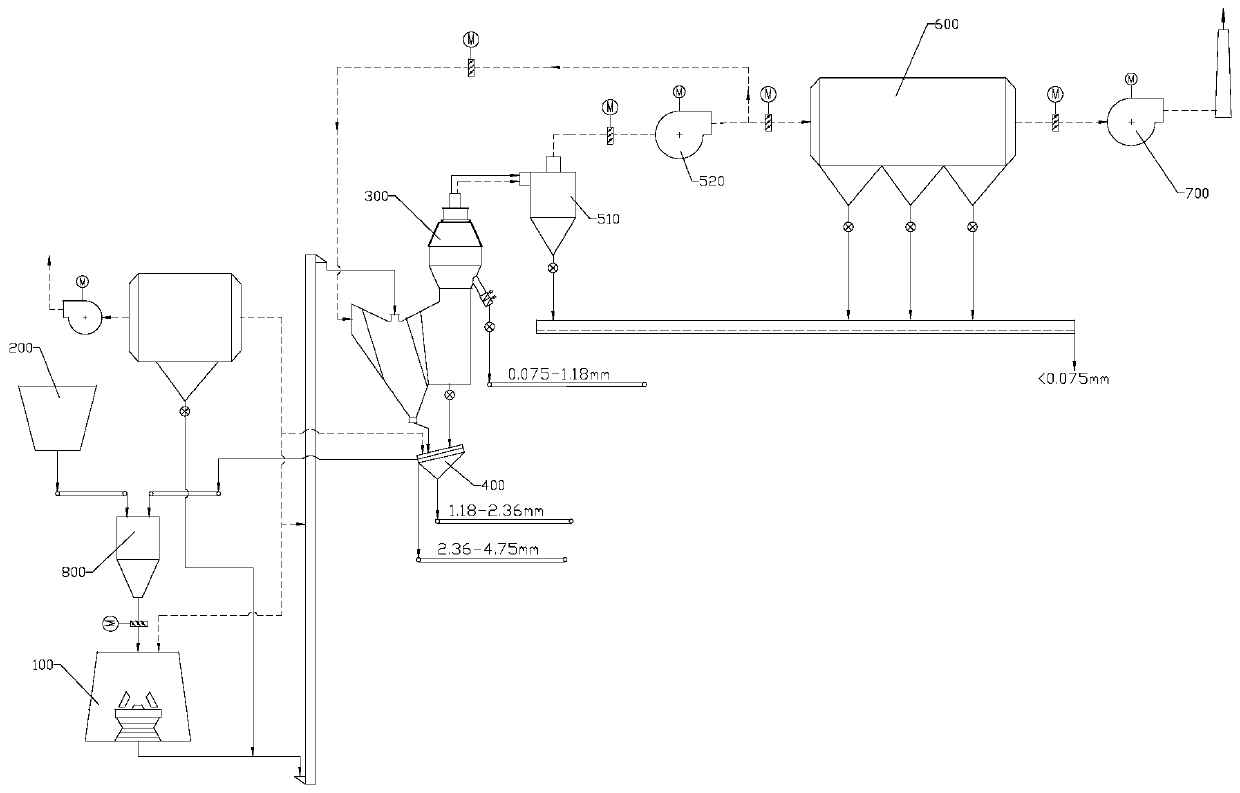

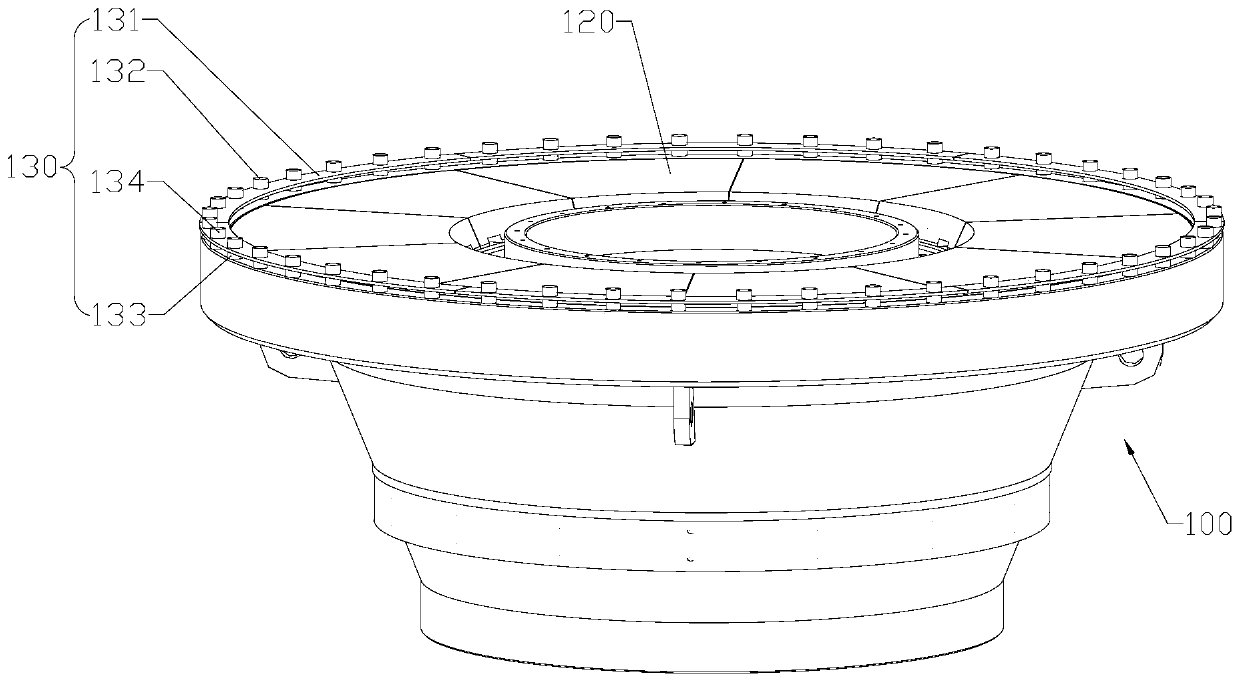

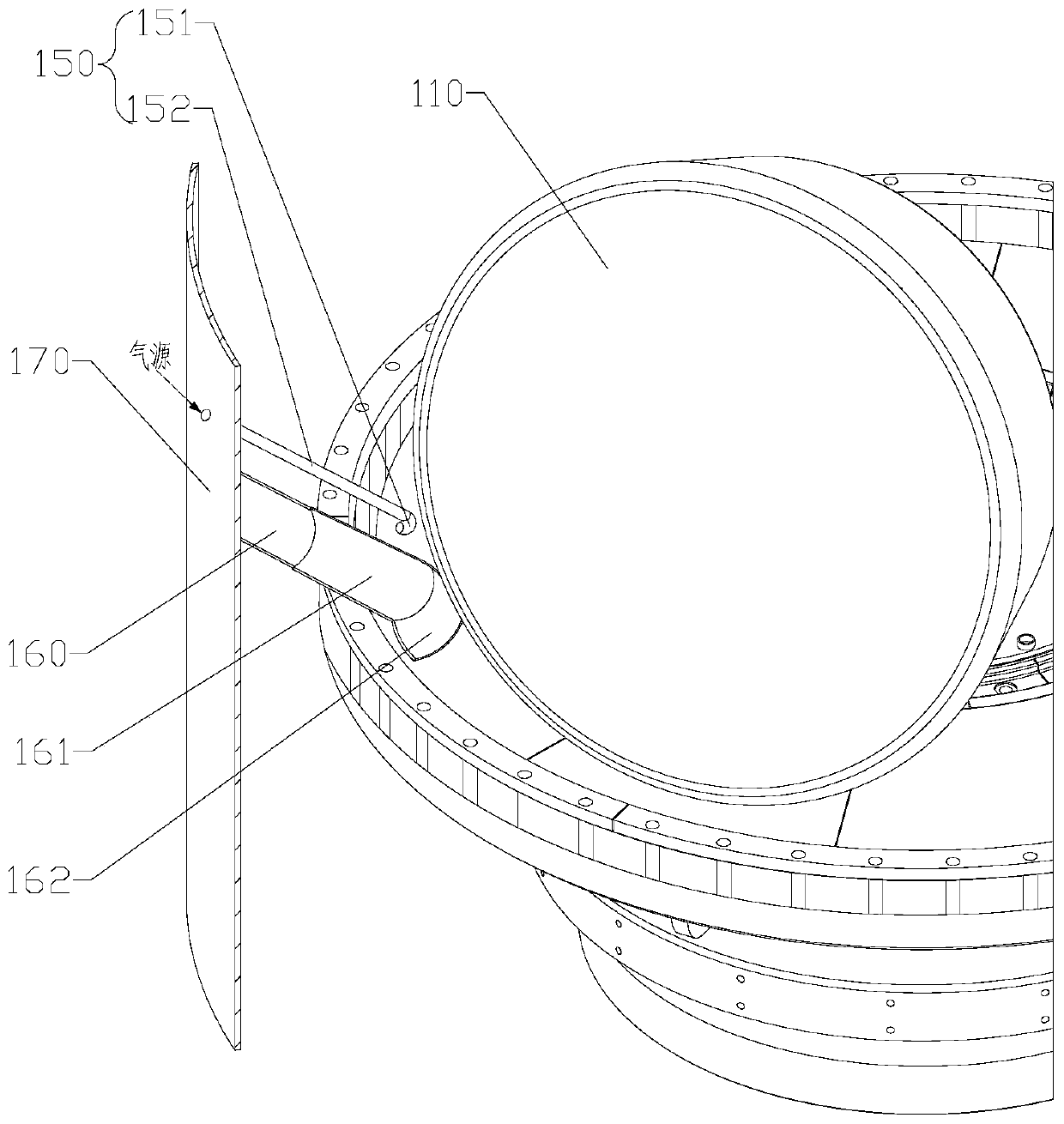

Process system for producing exquisite sand by adopting machine-made sand vertical mill

PendingCN110732383AAchieve multi-functionalityLow fines contentSievingScreeningProcess systemsProcess engineering

The invention discloses a process system for producing exquisite sand by adopting a machine-made sand vertical mill. The process system comprises a raw material cabin, the machine-made sand vertical mill, a combined powder concentrator, a vibrating screen, a cyclone and a circulating fan, wherein the raw material cabin, the machine-made sand vertical mill and the combined powder concentrator are sequentially connected; a bottom discharging opening of the combined powder concentrator is connected with the vibrating screen; the vibrating screen returns oversize products to the machine-made sandvertical mill; the air outlet of the combined powder concentrator is connected with the cyclone; the air outlet of the cyclone is connected with the circulating fan; a plurality of layers of screens with different pore diameters are arranged on the vibrating screen; a pre-screening device is arranged between the machine-made sand vertical mill and the combined powder concentrator; the process system further comprises a machine-made sand blending system for blending sand out of the combined powder concentrator and the vibrating screen; and the machine-made sand blending system comprises a weighing device, a mixing device, a conveying device and a storing device. The process system can realize high-quality machine-made sand production, can produce the machine-made sand meeting any fineness modulus requirement, meets different product demands and realizes multiple functions of a production system.

Owner:TIANJIN CEMENT IND DESIGN & RES INST +1

A kind of preparation method of titanium catalyst component and its titanium catalyst component, and a kind of preparation method of titanium catalyst and its titanium catalyst

The present invention relates to a method for preparing a titanium catalyst component, comprising the steps: reacting a magnesium halide in a solvent including an alcohol to obtain a homogeneous solution, reacting at least one organic boron compound with the homogeneous solution, reacting a titanium compound with the homogeneous solution, a titanium catalyst component obtainable by said method, a method for preparing a titanium catalyst and a titanium catalyst obtainable by said method.

Owner:SUD CHEM IP GMBH & CO KG

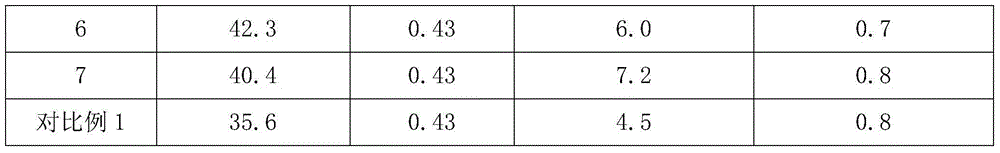

Preparation methods for olefin polymerization catalyst component and corresponding catalyst

The invention provides a preparation method for an olefin polymerization catalyst component. The preparation method comprises the steps: contacting a magnesium compound, an organophosphorus compound, a pyrrolidone compound and an organic epoxy compound in a solvent to form a uniform solution; in the presence of a precipitation aiding agent, contacting the uniform solution with a titanium compound to obtain a mixture; and then contacting the obtained mixture with an internal electron donor compound, and carrying out a reaction to obtain the olefin polymerization catalyst component, wherein at least one of the magnesium compound and the titanium compound is a halogen-containing compound. According to the preparation method, the addition of the pyrrolidone compound and the organosilane compound can effectively shorten the preparation time of the catalyst component, improve the particle morphology of a catalyst and greatly reduce the fine powder content of the polymer; and at the same time, the catalyst activity is substantially improved, the apparent density of the polymer is relatively high, and the degree of isotacticity and the polymer melt flow index still maintain original relatively good performance of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst component for ethylene polymerization, preparation method and application

ActiveCN103044586AHigh copolymerization catalytic activityLow fines contentPolymer scienceZiegler–Natta catalyst

The invention relates to a Ziegler-Natta catalyst component which comprises a Ti compound, MgCl2, silica gel, and alpha, omega-diether compound. The catalyst system has a relatively high catalytic activity when used for ethylene copolymerization, the obtained polyethylene is relatively narrow in molecular weight distribution, and polymer particles contain low fine powder.

Owner:CHINA PETROLEUM & CHEM CORP +1

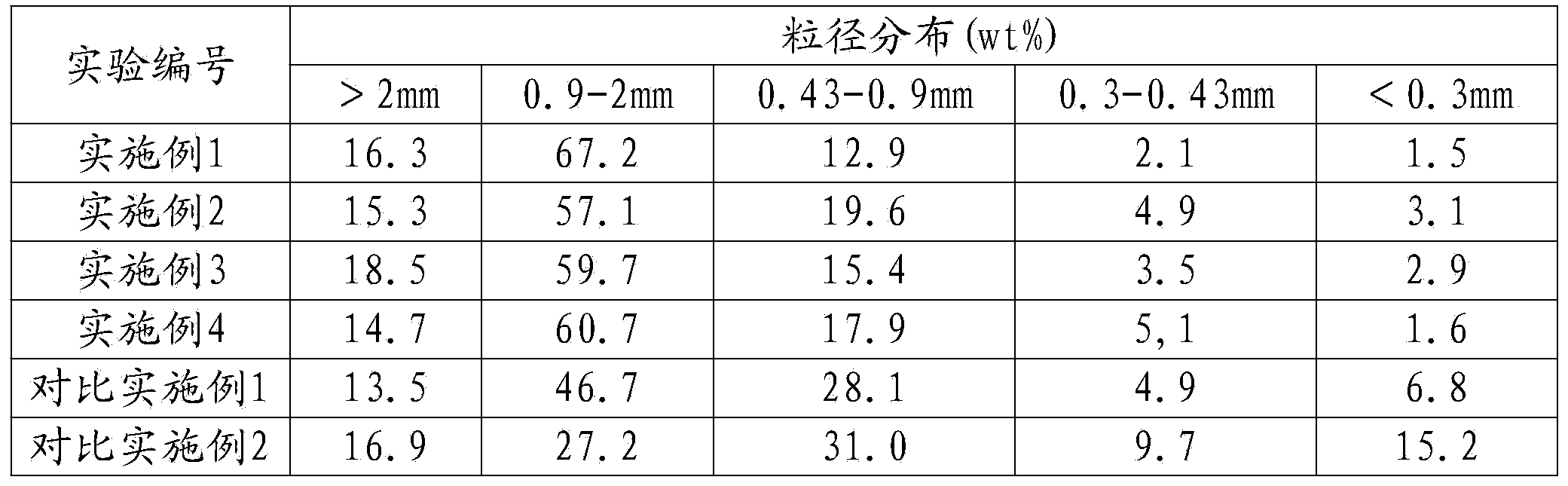

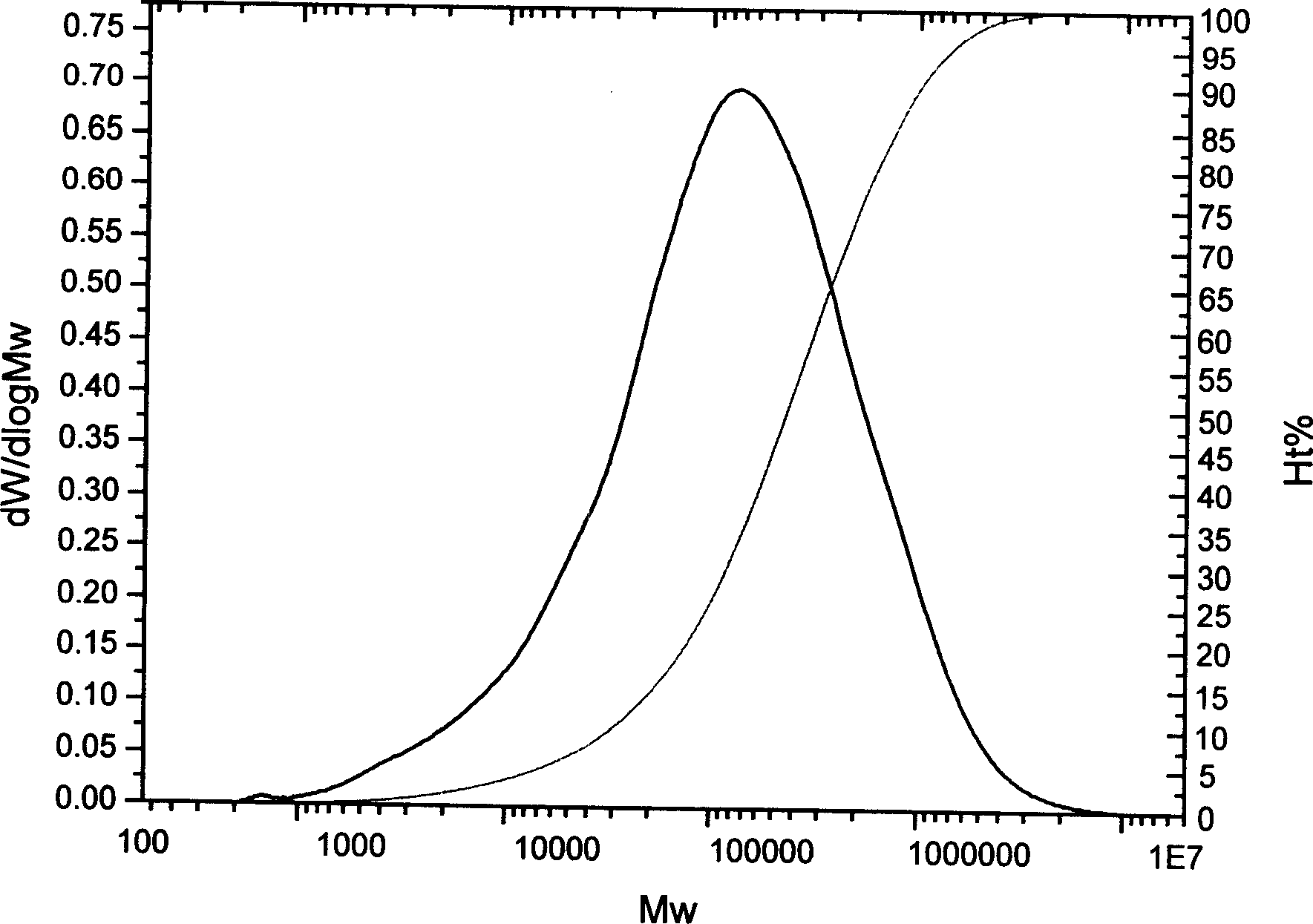

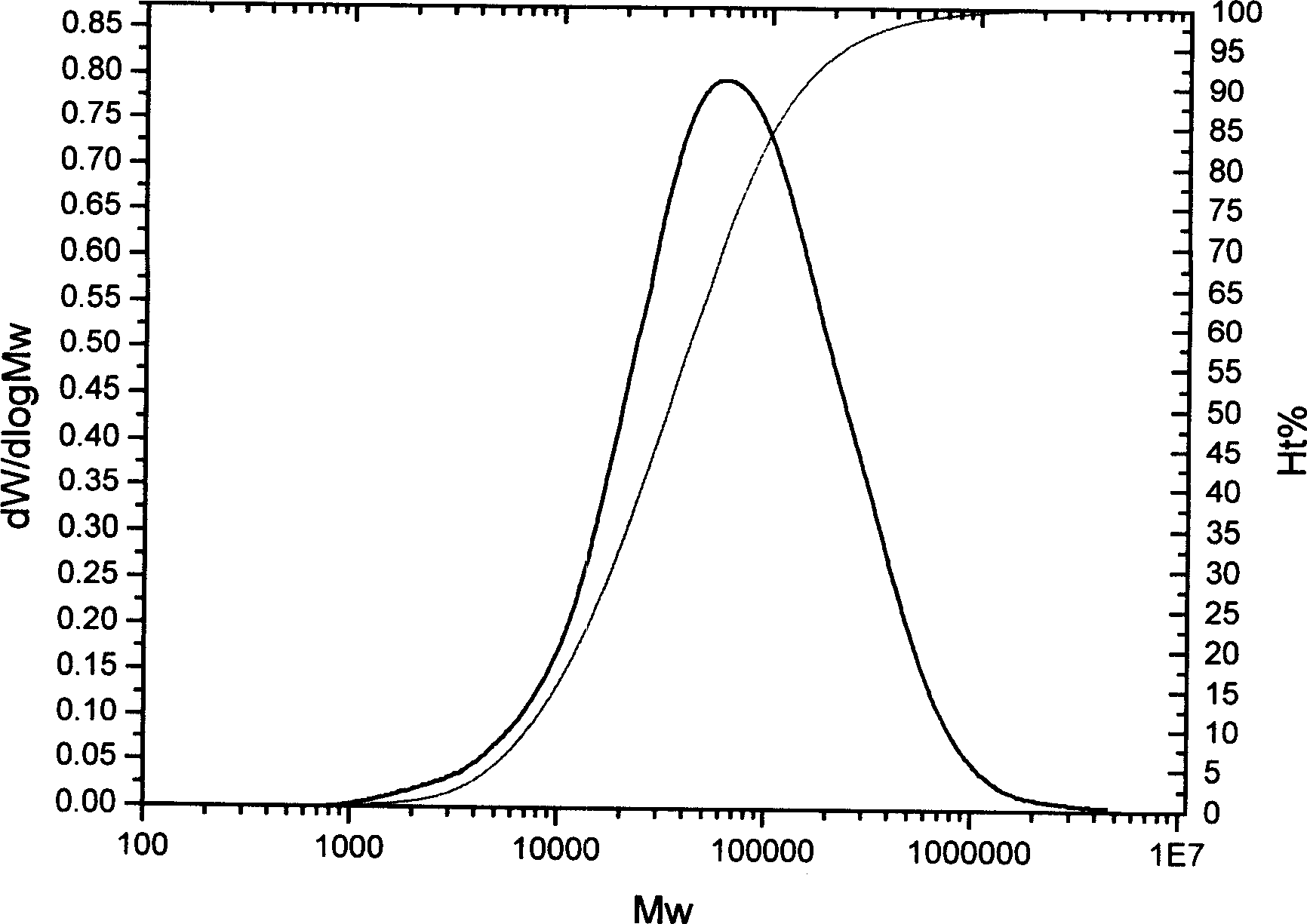

Catalyst component for ethylene polymerization and preparation method thereof

The invention relates to a catalyst component for ethylene polymerization and a preparation method thereof. According to the preparation method, magnesium compounds are dissolved into a solvent system containing organic alcohol compounds and titanate compounds to form a magnesium composite, and then the magnesium composite is contacted with toluene and titanium compounds to carry out reactions so as to prepare the catalyst component. The catalyst component and a catalyst containing the catalyst component have the advantages of high catalytic activity, uniform particle diameter, and good particle shape and can be applied to ethylene polymerization reactions; and the obtained polyethylene resin has the advantages of wide molecular weight distribution, high resin stacking density, concentrated particle size distribution of PE powder, little fine powder content, and long production period, and can be advantageously used to produce small hollow resins in INNOVENES technology by adopting a single peak mode.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst ingredient used for ethylene polymerization, and catalyst thereof

The invention relates to a catalyst used for ethylene polymerization. The catalyst comprises following ingredients, A, a titanium-containing solid catalyst ingredient, and B, an organic aluminium compound. The titanium-containing solid catalyst ingredient is prepared by following steps: magnesium halide is dissolved in an organic epoxy compound and an organic phosphorous compound; an electron donor compound is added so as to obtain a uniform solution; a silica compound and a precipitation accessory ingredient are added; and an obtained mixture is mixed with a halide or a derivative of titanium so as to obtain the titanium-containing solid catalyst ingredient; general formula of the organic aluminium compound is AlRX<3-n>, wherein R is used for representing alkyl with 1 to 20 hydrogen or carbon atoms, X is used for representing halogen atom, and n is an integer, 0

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst used for ethylene polymerization or copolymerization, its preparation method and application

A catalyst for the polymerizing or copolymerizing of ethene with wide distribution of molecular weights in dual reactors is composed of a solid carrier containining Mg / Ti, at least one Ti compound, at least one proper donor and at least one hydrogenating performance improver. Its advantages are very good hydrogenating sensitivity, high catalyst activity, and good granular form. Its preparing process is also disclosed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gas phase polyethylene catalyst and preparation method thereof

The invention relates to a gas phase polyethylene catalyst and a preparation method thereof. In the catalyst, anhydrous magnesium chloride and porous silica gel serve as a composite carrier, titanium-containing transition metal loaded on the composite carrier serves as an active component, an electron donor compound is added in the preparation process to serve as a modifier, and the electron donoris a silane compound with asymmetry. The problems that the common catalyst has low cavity, poor copolymerization ability and high product fine component content are solved, different silane electrondonor compounds are added in the preparation of the catalyst, polyethylene resin with different melt indexes is produced, in particular the gas phase polyethylene catalyst can be used for producing anethylene / 1-hexene copolymerization new product with high additional value, so that the performance of the product is improved, the processibility of the resin is improved, and the application field of the product is widened.

Owner:PETROCHINA CO LTD

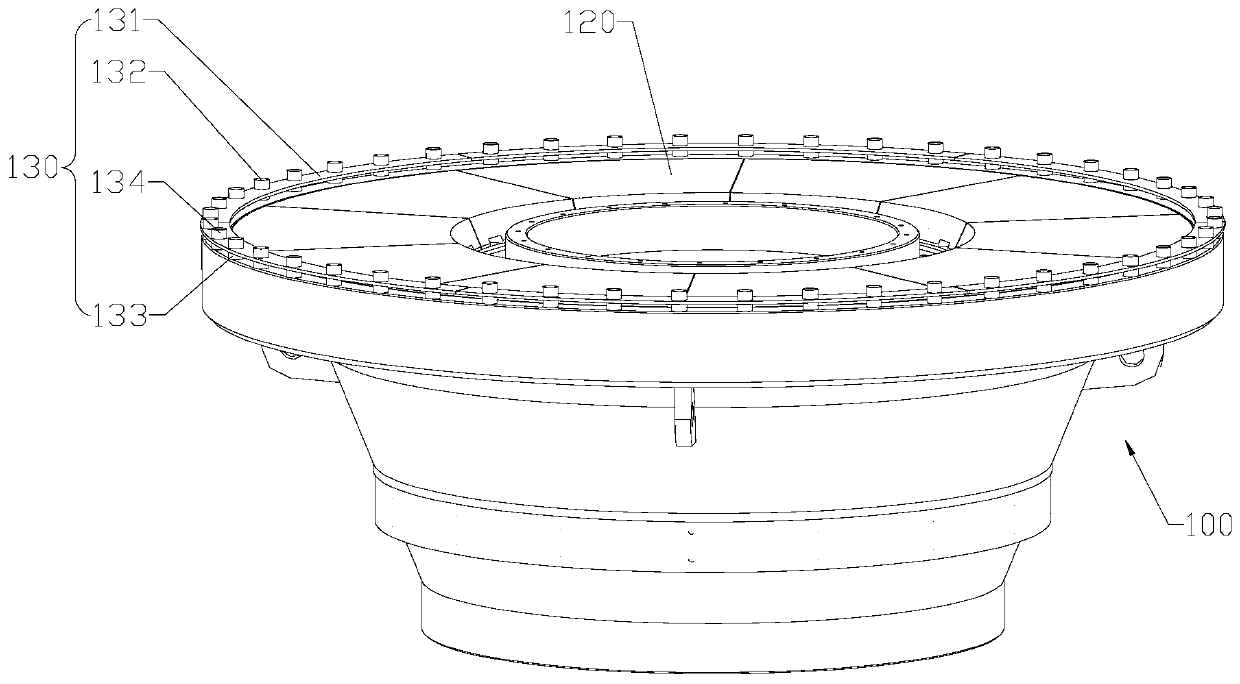

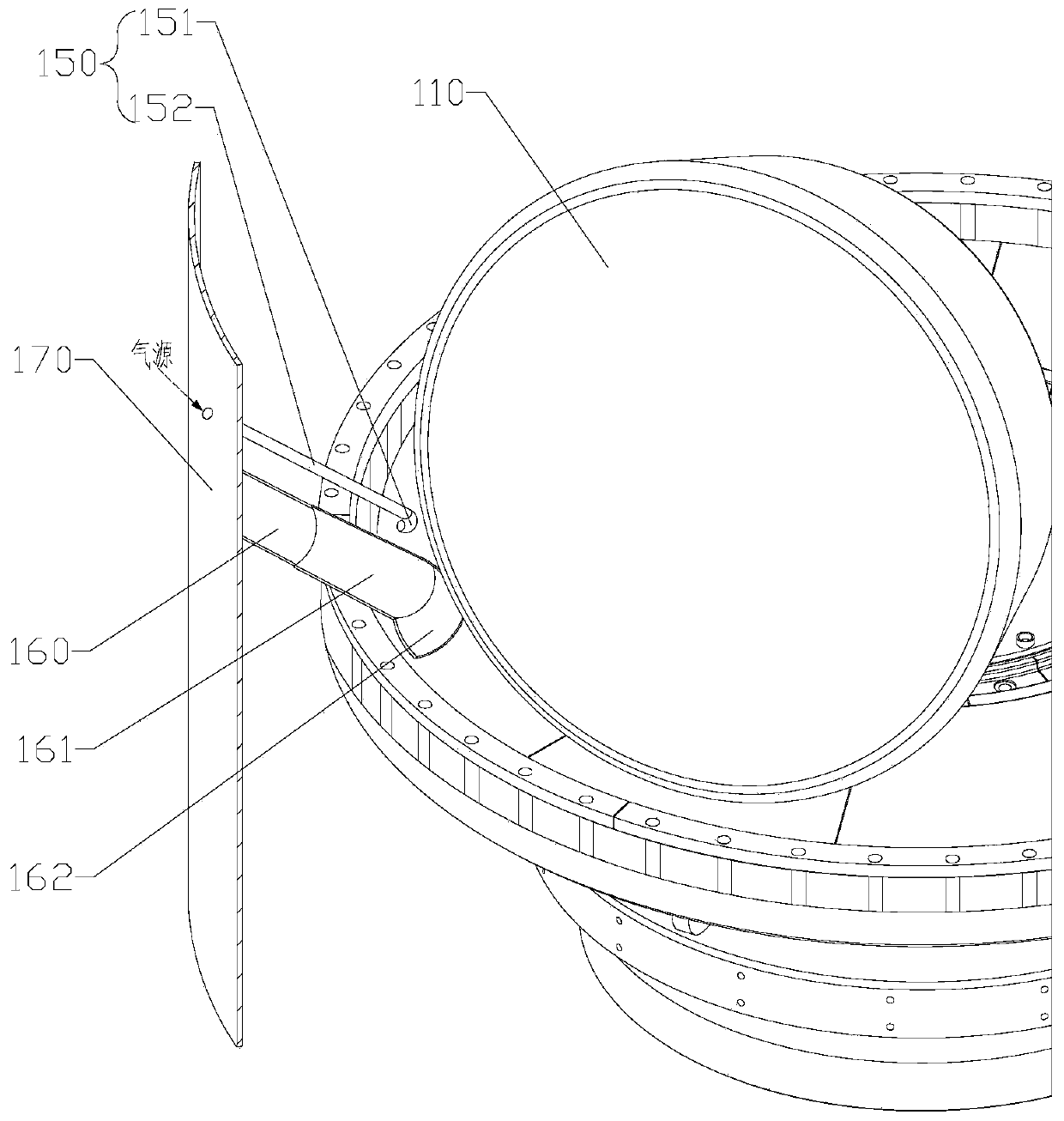

Carrier used for olefin polymerization catalyst and preparation method thereof

The invention relates to a carrier used for an olefin polymerization catalyst and a preparation method thereof. The carrier is (MgXY)m.[Mg(OR')Z]p.(ROH)n. The preparation method comprises the following steps: mixing magnesium halide as shown in MgXY, a compound as shown in ROH and a first inert medium; carrying out heating at 90 to 150 DEG C for 0.5 to 5 h; then emulsifying a liquid-state mixture obtained in the previous step; introducing an emulsification product to a second inert medium which has been cooled to -40 to 10 DEG C for rapid cooling and forming; carrying out solid-liquid separation so as to obtain a spherical carrier; and carrying out washing and drying so as to obtain the carrier. According to the invention, a forming agent and a grain-shape controlling agent are added during formation of an alcohol adduct of magnesium halide, so the obtained carrier has more concentrated particle size distribution; the catalyst prepared from the carrier has improved activity and hydrogen sensitivity when applied to olefin polymerization, especially to propylene polymerization; and an obtained polymerization product has moderate bulk density and is almost free of special-shaped materials.

Owner:营口风光新材料股份有限公司

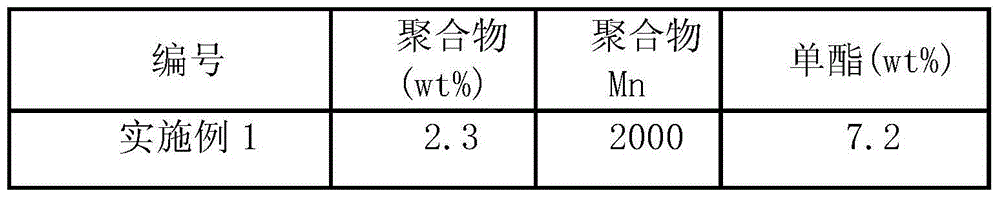

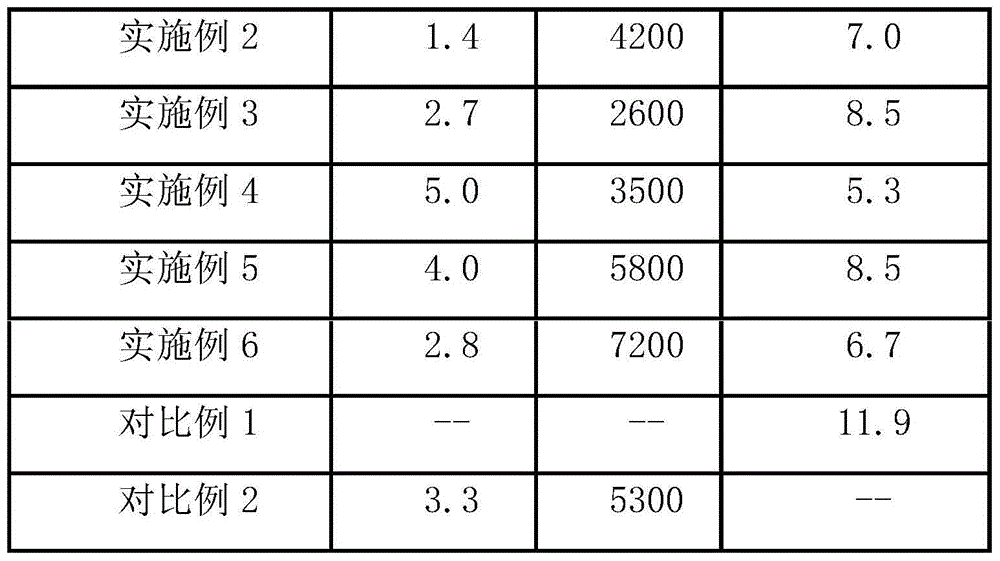

A catalyst component used for olefin polymerization, and a preparing method and applications thereof

The invention provides a catalyst component for olefin polymerization. The catalyst component comprises Ti, Mg, halogen, at least one electron donor compound and 1-99% of an olefin polymer. The catalyst component is used for olefin polymerization and has characteristics of high activity, high accumulation density and low fine-powder content. The catalyst component is free of ageing influences during room-temperature storage. Polymer particles are not liable to break. The catalyst component is especially suitable for synthesis of in-reactor alloying polymers with high rubber contents.

Owner:RENQIU LIHE TECH LTD +1

Production process system for producing multi-product machine-made sand

PendingCN111215220ALow fines contentImprove product qualitySievingGas current separationProcess systemsProcess engineering

The invention discloses a production process system for producing multi-product machine-made sand. The production process system comprises a raw material bin, a machine-made sand vertical mill, a combined-type powder concentrator, a vibrating screen, a cyclone and a circulating fan, wherein the raw material bin, the machine-made sand vertical mill and the combined-type powder concentrator are connected in sequence, a bottom discharging port of the combined-type powder concentrator is connected with the vibrating screen, the vibrating screen returns oversize products to the machine-made sand vertical mill, an air outlet of the combined-type powder concentrator is connected with the cyclone, and an air outlet of the cyclone is connected with the circulating fan; and a plurality layers of screens with different pore sizes are arranged on the vibrating screen. The cone angle of each grinding roller of the machine-made sand vertical mill is not larger than 20 degrees, and the total projection area of the grinding rollers on a grinding disc accounts for 20-35% of the area of the grinding disc. A retention ring is a cut-through screening and retention assembly or a cross-type retention ring, auxiliary discharging assemblies arranged on the grinding disc and are located behind each grinding roller in the rotation direction of the grinding disc. By means of the process system, production of the multi-product machine-made sand can be achieved, and scale production is facilitated; and meanwhile, the effect of environmental protection is better, and ultraclean discharge can be achieved.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Preparation method of catalyst component for olefin polymerization and catalyst

The invention provides a preparation method of a catalyst component for olefin polymerization. In the preparation method of the catalyst component, a separation assistant component consists of polyol ester compounds expressed by a general formula (I) and organosilane compounds expressed by the general formula (II) of RIaRIIbSi (ORIII) c; and the separation process of catalyst particles is effectively controlled through combining action of the organosilane compounds and the polyol ester compounds. Compared with the traditional catalyst, the catalyst has greatly improved activity and yield and has little polymer fine powder.

Owner:CHINA PETROLEUM & CHEM CORP +1

Moisture-retention dust suppression agent for coal and preparation method of moisture-retention dust suppression agent

ActiveCN109096996ALow fines contentTo achieve the purpose of dust suppressionOther chemical processesDust removalGlycerolDust particles

The invention relates to a moisture-retention dust suppression agent for coal and a preparation method of the moisture-retention dust suppression agent. The moisture-retention dust suppression agent comprises 800-1200 parts by weight of water, 1-3 parts by weight of alginic acid, 2-4 parts by weight of calcium lactate, 0.5-1.5 parts by weight of a dispersant, 400-600 parts by weight of soybean oiland 50-150 parts by weight of glycerol. The dust suppression agent for moisture retention of coal is water-in-oil emulsion; after the emulsion is sprayed, the effective components in the emulsion areadsorbed and complexed with pulverized coal, and fine pulverized coal prone to dust raising is bonded and agglomerated into non-raised dust particles with larger particle size, so that the content offine powder in upgraded coal is reduced, and the purpose of dust suppression is fundamentally achieved. By adding the moisture-retention dust suppression agent for coal in the transportation process,specific gravity is increased as compared with upgraded coal without the dust suppression agent under the condition of the same cargo compartment volume, so that the shortfall and road loss of upgraded coal in the transportation process are effectively reduced, and economic benefits of coal enterprises are increased.

Owner:北京首创大气环境科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com