Carrier used for olefin polymerization catalyst and preparation method thereof

A technology of olefin polymerization and catalyst, which is applied in the field of carrier preparation, can solve problems such as instability in the preparation process of catalyst carrier, difficulty in forming spherical particles of small and large sizes, poor carrier molding effect, etc., and achieve improved hydrogen adjustment sensitivity and bulk density Moderate effect with good particle shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

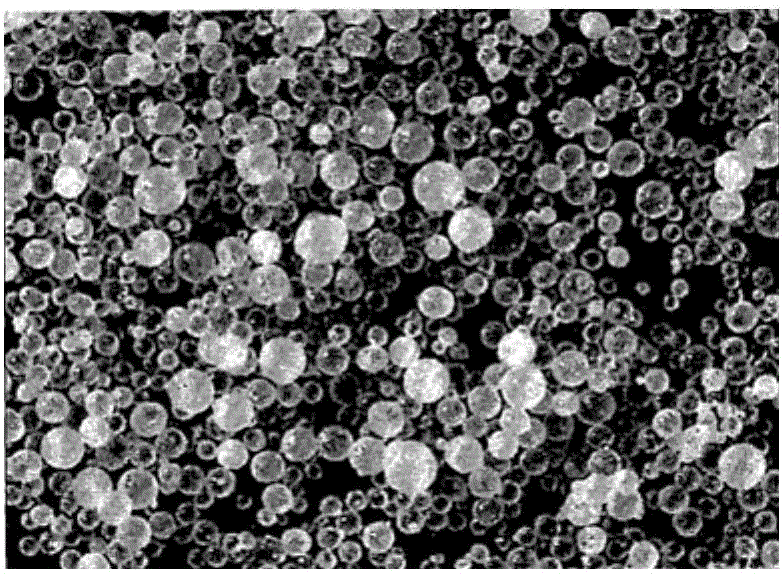

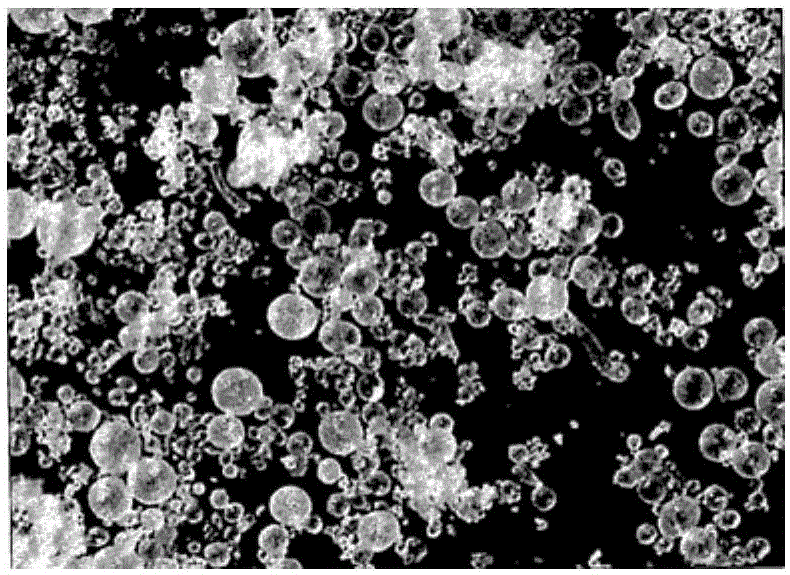

Image

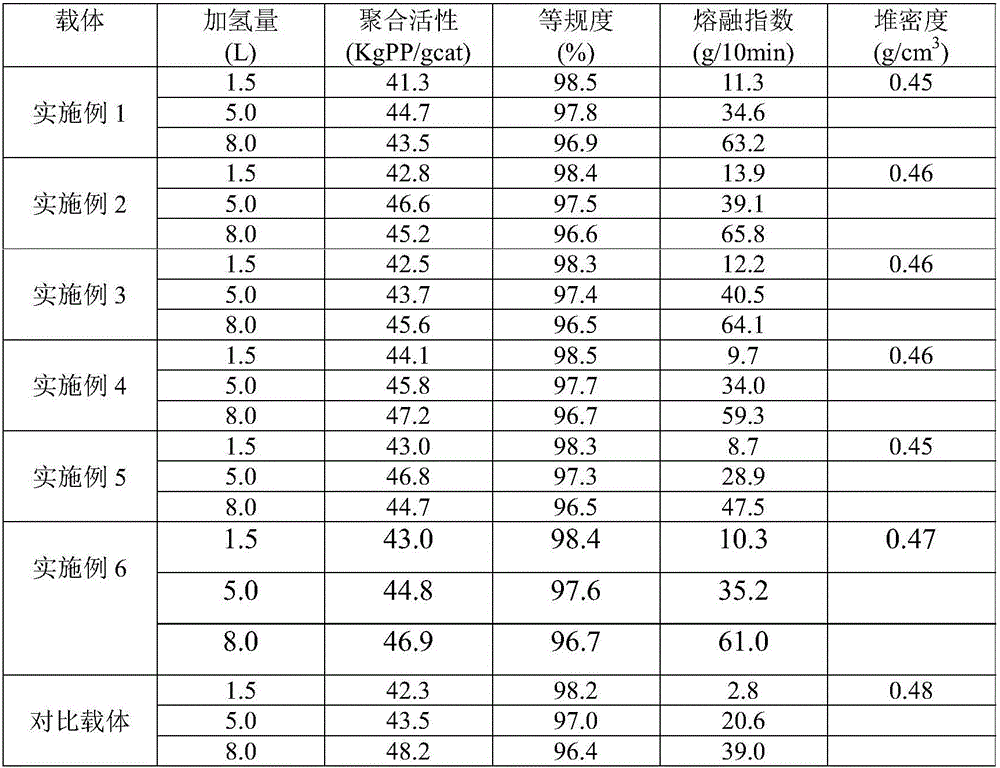

Examples

Embodiment 1

[0034] 1. In a 500ml reaction kettle, add 150ml of white oil, 30g of magnesium chloride, 50ml of absolute ethanol, 2.0g of diethoxymagnesium and 0.012g of sodium chloride, heat up to 125°C under stirring, and react at a constant temperature for 2 hours. A liquid mixture is obtained.

[0035] 2. Press the liquid mixture into 300ml of methyl silicone oil preheated to 125°C, stir at high speed (1600rpm) for dispersing and emulsifying for 30min.

[0036] 3. Introduce the emulsified product into 2L hexane solution pre-cooled to -35°C, and after rapid cooling, disperse into small droplets of MgCl 2 After the alcoholate melt is cooled and solidified, it becomes spherical particles. The liquid was removed by filtration, the solid was washed 5 times with 300 ml of hexane, and vacuum-dried at 30° C. for 1 hour to obtain a solid carrier of magnesium chloride alcoholate.

[0037] by infrared spectroscopy and 1 After HNMR nuclear magnetic measurement and analysis, it is determined that it...

Embodiment 2

[0041] 1. In a 500ml reaction kettle, add 150ml of white oil, 30g of magnesium chloride, 50ml of absolute ethanol, 4.0g of diethoxymagnesium and 0.012g of sodium chloride, heat up to 125°C under stirring, and react at a constant temperature for 2 hours. A liquid mixture is obtained.

[0042] 2. Press the liquid mixture into 300ml of methyl silicone oil preheated to 125°C, stir at high speed (1600rpm) for dispersing and emulsifying for 30min.

[0043] 3. Introduce the emulsified product into 2L hexane solution pre-cooled to -35°C, and after rapid cooling, disperse into small droplets of MgCl 2 After the alcoholate melt is cooled and solidified, it becomes spherical particles. The liquid was removed by filtration, the solid was washed 5 times with 300 ml of hexane, and vacuum-dried at 30° C. for 1 hour to obtain a solid carrier of magnesium chloride alcoholate.

[0044] by infrared spectroscopy and 1 After HNMR nuclear magnetic measurement and analysis, it is determined that ...

Embodiment 3

[0047] 1. In a 500ml reaction kettle, add 150ml of white oil, 30g of magnesium chloride, 50ml of absolute ethanol, 2.0g of diethoxymagnesium and 0.015g of manganese chloride, heat up to 125°C under stirring, and react at a constant temperature for 2 hours. A liquid mixture is obtained.

[0048] 2. Press the liquid mixture into 300ml of methyl silicone oil preheated to 125°C, stir at high speed (1600rpm) for dispersing and emulsifying for 30min.

[0049] 3. Introduce the emulsified product into 2L hexane solution pre-cooled to -35°C, and after rapid cooling, disperse into small droplets of MgCl 2 After the alcoholate melt is cooled and solidified, it becomes spherical particles. The liquid was removed by filtration, the solid was washed 5 times with 300 ml of hexane, and vacuum-dried at 30° C. for 1 hour to obtain a solid carrier of magnesium chloride alcoholate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com