Catalyst component for vinyl polymerization and preparation method and application of catalyst component

An ethylene polymerization and catalyst technology, applied in the field of polyethylene catalysts, can solve the problems of decreased catalyst activity, long synthesis process of catalyst components, low efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

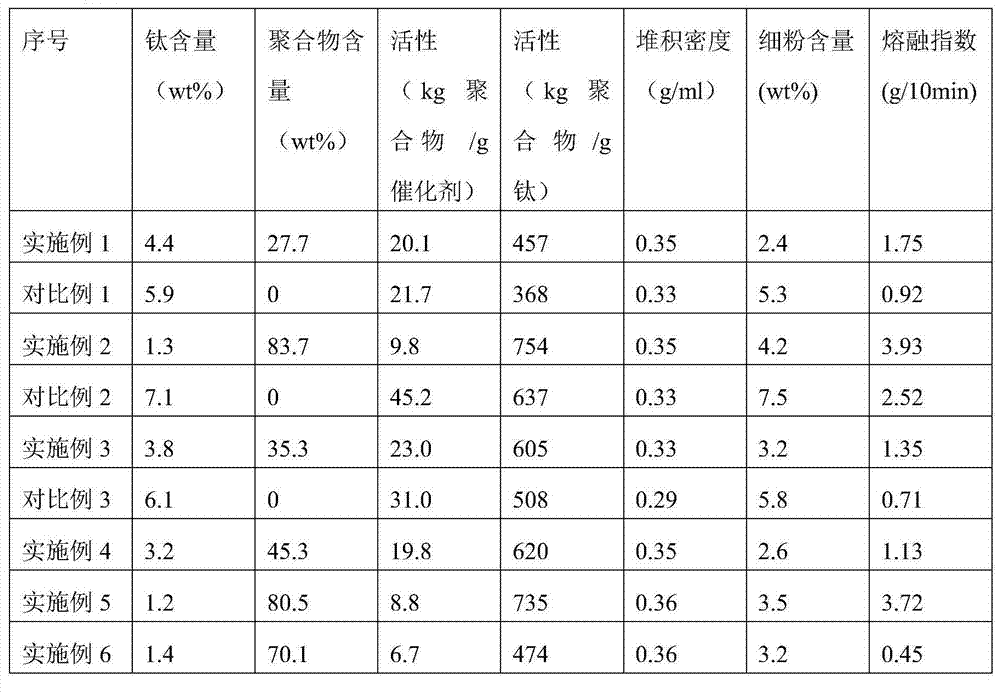

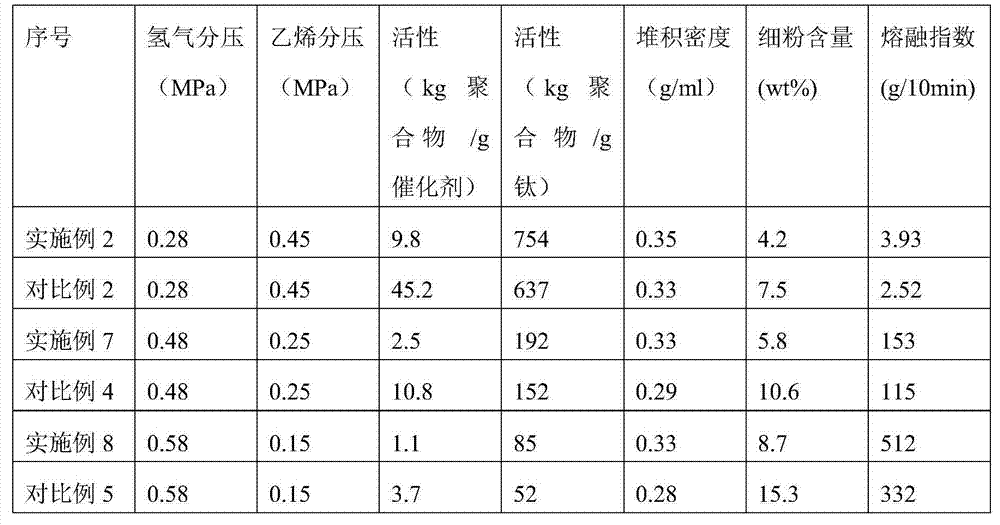

Examples

Embodiment 1

[0074] 1. Preparation of catalyst components:

[0075] In a 500ml stirred 5-neck flask fully replaced by nitrogen, add 10g of diethoxymagnesium and 80mL of toluene to prepare a suspension, then maintain 0°C and add 20mL of titanium tetrachloride dropwise, and then slowly raise the temperature to 110°C The temperature was kept constant for 2 hours, and then the liquid was press-filtered to remove the liquid, and the obtained solid was washed three times with 100 mL of toluene at 90°C. Then, a mixed solution of 20 ml of titanium tetrachloride and 80 ml of toluene was added and stirred at 110° C. for 1 hour, and the liquid was filtered off. The obtained solid was washed 5 times with 100 mL of hexane at 60° C., and the liquid was filtered off. Add 300mL of n-hexane into the flask, add 4ml of 0.5mol / L triethylaluminum hexane solution, control the temperature at 5°C, and keep the temperature constant for 5 minutes; feed ethylene gas through a mass flow meter, and control the feedin...

Embodiment 2

[0084] 1. Preparation of catalyst components:

[0085] Add 4.76g of anhydrous magnesium chloride, 28.1ml of decane and 16.3g of isooctyl alcohol into a 100ml three-necked flask with stirring fully replaced by nitrogen, heat to 130°C, and react for 3 hours to form a uniform solution. The above solution was cooled to 50°C, 3.1 g of tetraethoxy silicon was added, and stirred for 2 hours. The above solution was cooled to room temperature, and then added dropwise to a 1 L three-necked flask with 200 mL of titanium tetrachloride kept at 0° C. within 1 hour. After the dropwise addition, the temperature was slowly raised to 110° C. and kept at a constant temperature for 2 hours. Then the liquid is press-filtered clean, the liquid is filtered off, and the obtained solid is washed twice at 110° C. with a decane solution of titanium tetrachloride with a volume fraction of 40%. °C wash twice. The obtained solid was washed twice with 150 mL of hexane at 60°C and twice at room temperatur...

Embodiment 3

[0094] 1. Preparation of catalyst components:

[0095] In a 500ml stirred 5-neck flask fully replaced by nitrogen, add 4.0g of anhydrous magnesium chloride, 50mL of toluene, 4.0ml of epichlorohydrin, 4.0ml of tributyl phosphate, and 6.4ml of ethanol in sequence, and heat up to 70 ℃, when the solid is completely dissolved to form a homogeneous solution, react for another 1 hour. The solution was cooled to -5°C, 40 mL of titanium tetrachloride was slowly added dropwise, and then 3 g of tetraethoxy silicon was added. Slowly raise the temperature to 80°C and keep the temperature for 2 hours, then press filter the liquid and remove the liquid. Then, a mixed solution of 20 ml of titanium tetrachloride and 80 ml of toluene was added and stirred at 110° C. for 1 hour, and the liquid was filtered off. The obtained solid was washed 5 times with 100 mL of hexane at 60° C., and the liquid was filtered off. Add 300mL of n-hexane into the flask, add 2ml of 0.5mol / L tri-n-hexylaluminum he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com