Patents

Literature

64results about How to "Good hydrogen adjustment performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

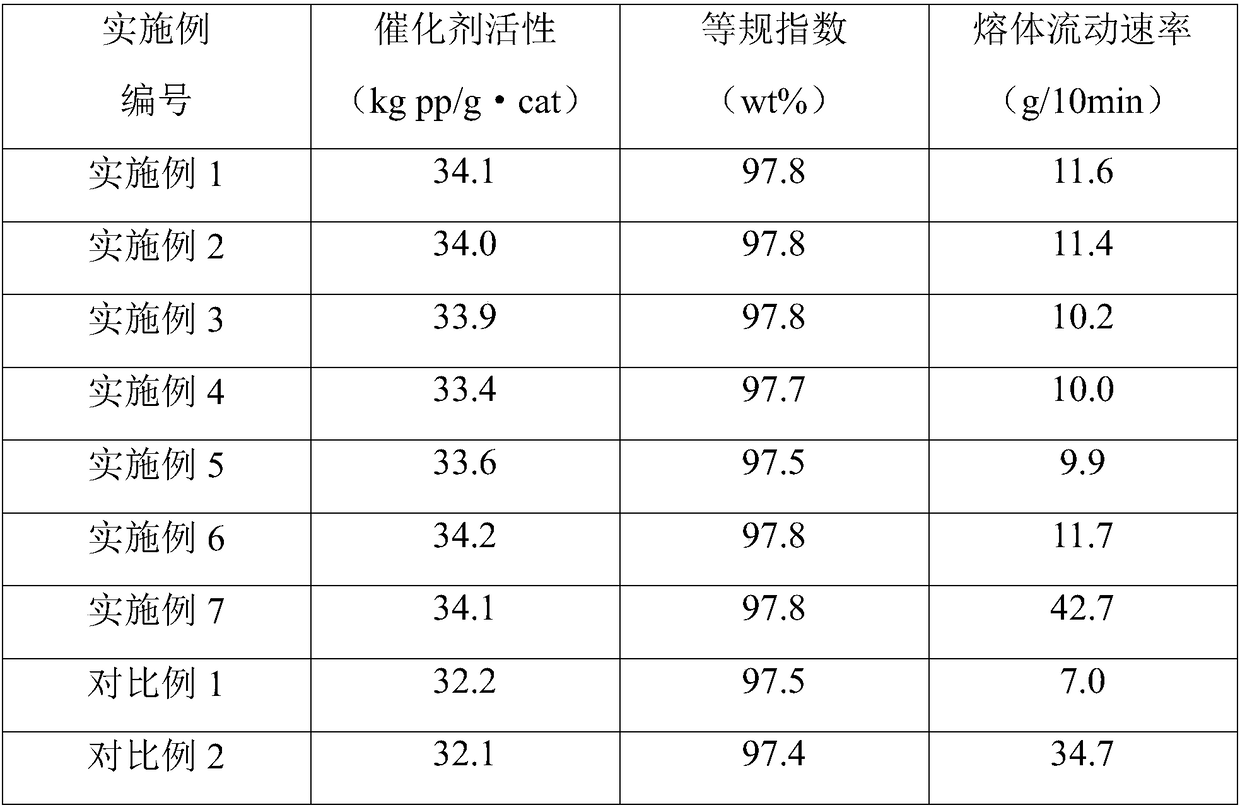

Catalyst, preparation method and application for olefin polymerization or copolymerization

This invention relates to a catalyst system which is used for alkenes polymerizing or copolymerization, it includes solid catalyst composition A that contains titanium and organic Aluminum compound B, silicoorganic compound C, in the composing process of catalyst composition A, use aldyl ester of aryl group mon-carboxylic acid and aldyl ester of fatty series or multielement carboxylic acid of aryl group for reasonable combination, among them aldyl ester of aryl group mon-carboxylic can play a role of assisting separating agent, it is useful to separate catalyst particle; Meanwhile it is used as electron donor, it also can load on the surface of catalytic agent together with compound of multielement carboxylic esters, improve the surface structure of catalytic agent, thus improve the catalyzing function of catalytic agent. This catalytic agent that is used for propylene polymerizing has high catalytic activity and anti- impurity function, particle appearance of catalytic agent is good, particles distribute narrowly, hydro-adjusting function of catalytic agent is good, it is useful for many polymerizing technology such as seriflux method, noumenon method and gas method, molecular weight distribution of polymer is narrow, particle appearance of polymer is good, fine grits is little; Its fine anti-impurity function can effectively reduce production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

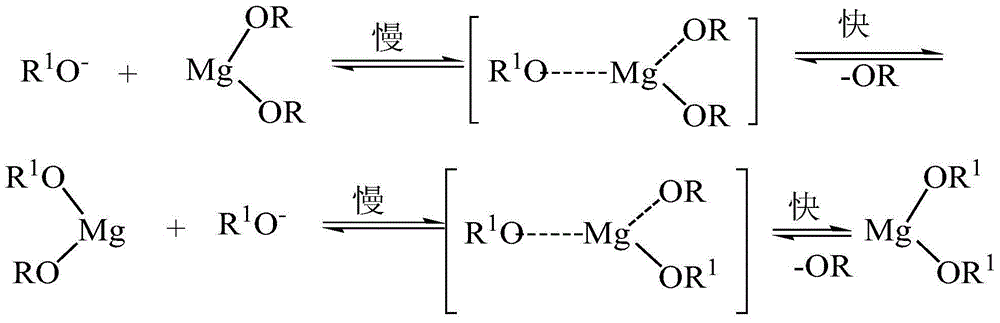

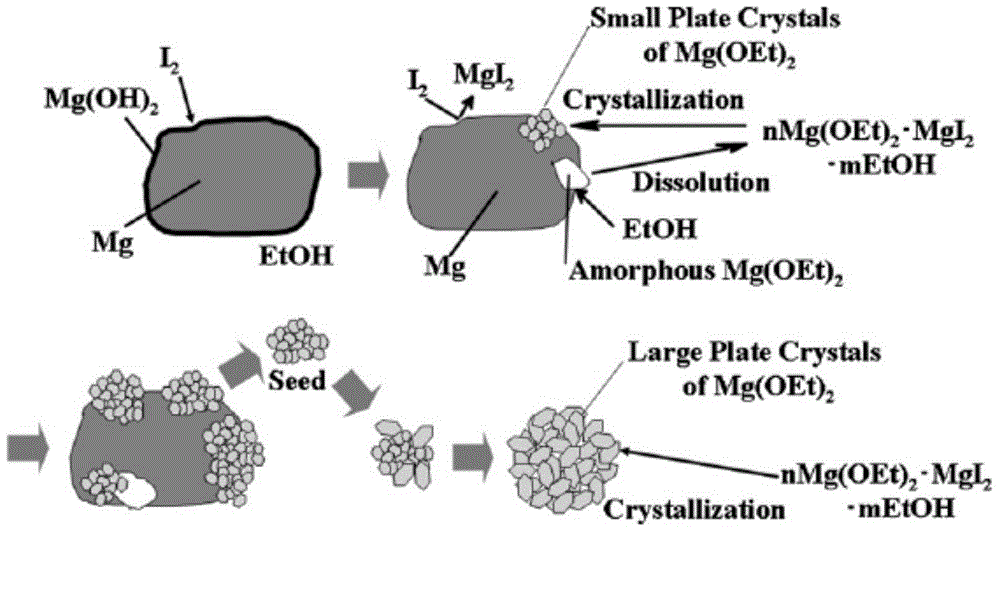

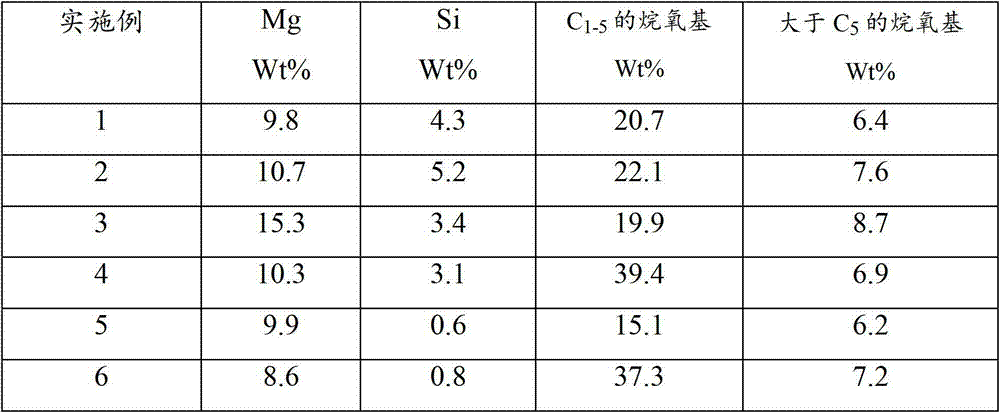

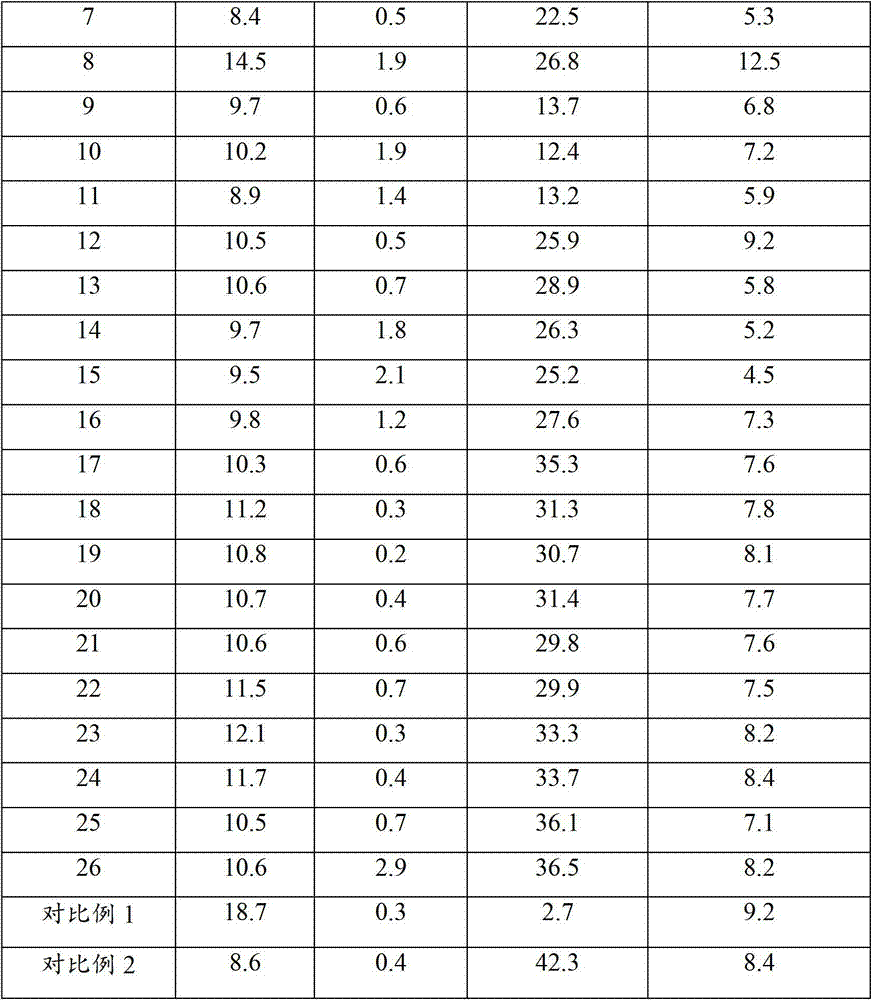

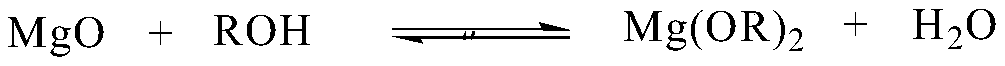

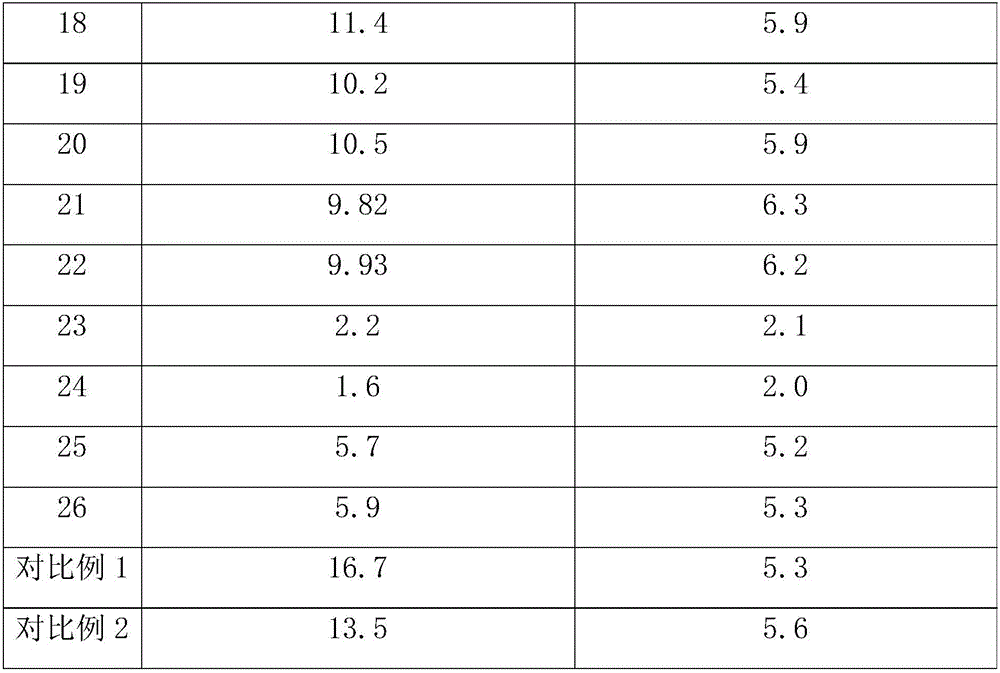

Preparation method and applications of alkoxyl magnesium carrier

The invention relates to a preparation method and applications of an alkoxyl magnesium carrier. The preparation method is used for preparing an olefin polymerization catalyst alkoxyl magnesium carrier. The alkoxyl magnesium carrier comprises the following components: magnesium powder, an initiator, a cross-linking agent, a unitary organic alcohol, a dispersing agent and a dispersing medium according to mole ratio of 1 to (0.00001-0.1) to (0.0001-0.5) to (2-100) to (0.05-50) to (1-100). The involved alkoxyl magnesium carrier is good in particle morphology, high in bulk density, and high in mechanical strength. A catalyst prepared by the carrier is used for preparing an olefin polymerization catalyst, the catalyst is high in activity, good in hydrogen regulation performance and good in copolymerization performance, and the polymer is low in the powder content, low in wax content, and good in particle morphology; the involved catalyst is used for ethylene homopolymerization, copolymerization of ethylene and alpha-olefin, or ethylene and polar alkene monomer, propylene homopolymerization, propylene and alpha-olefin copolymerization or propylene and polar alkene monomer copolymerization.

Owner:BEIJING UNIV OF CHEM TECH

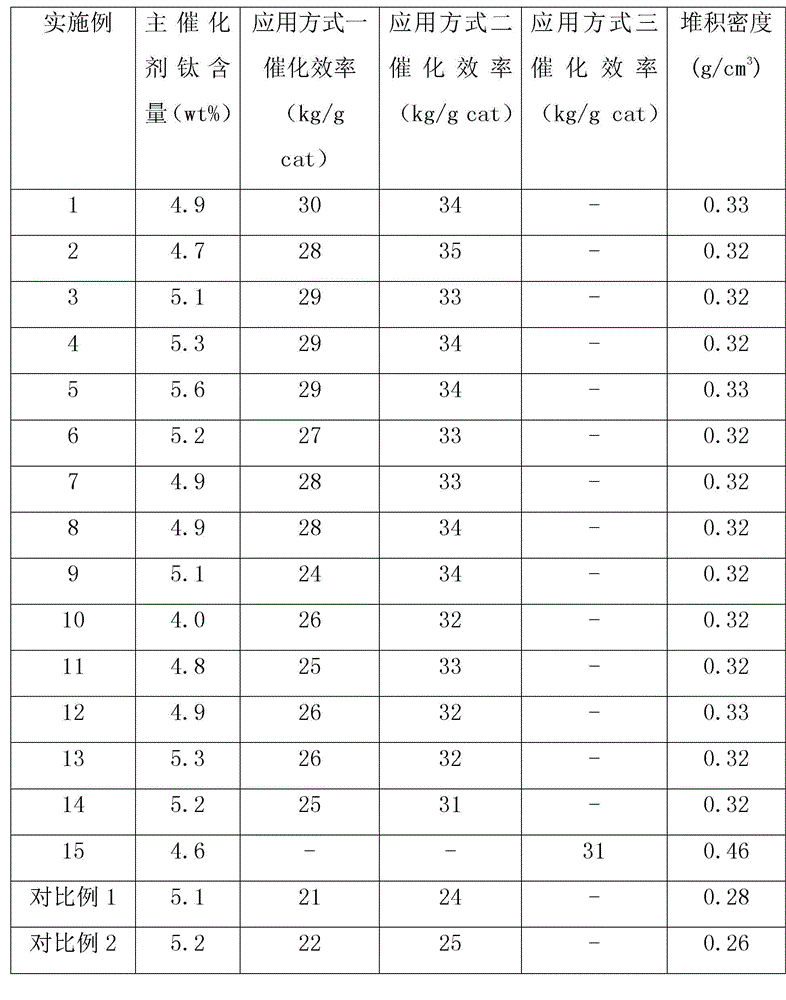

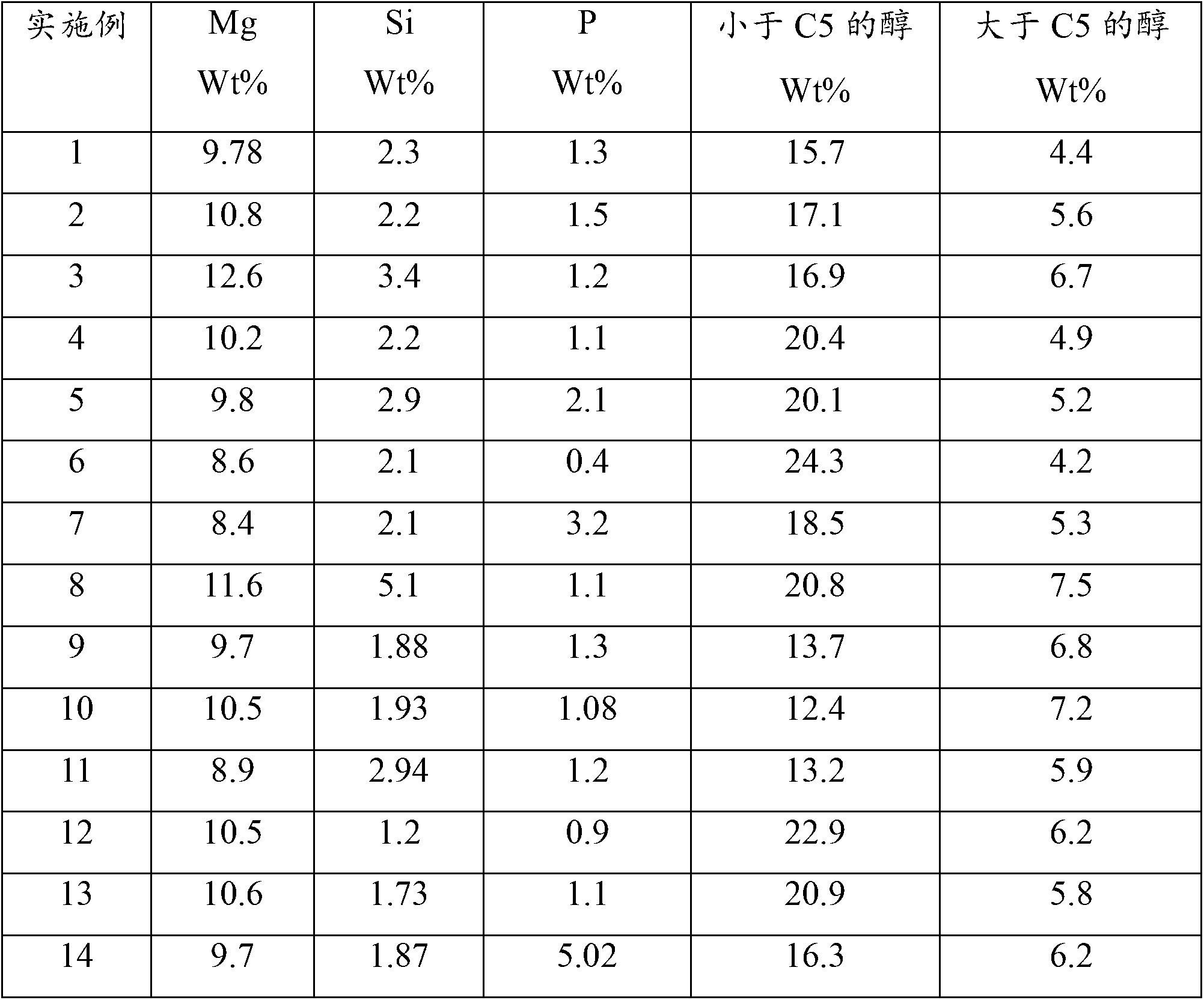

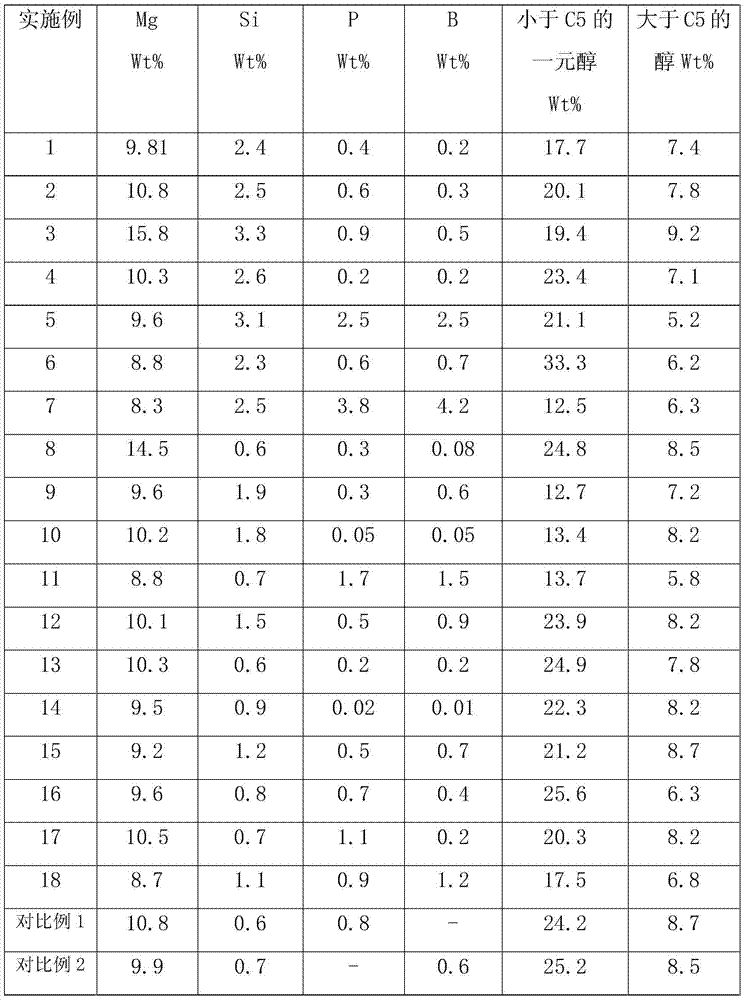

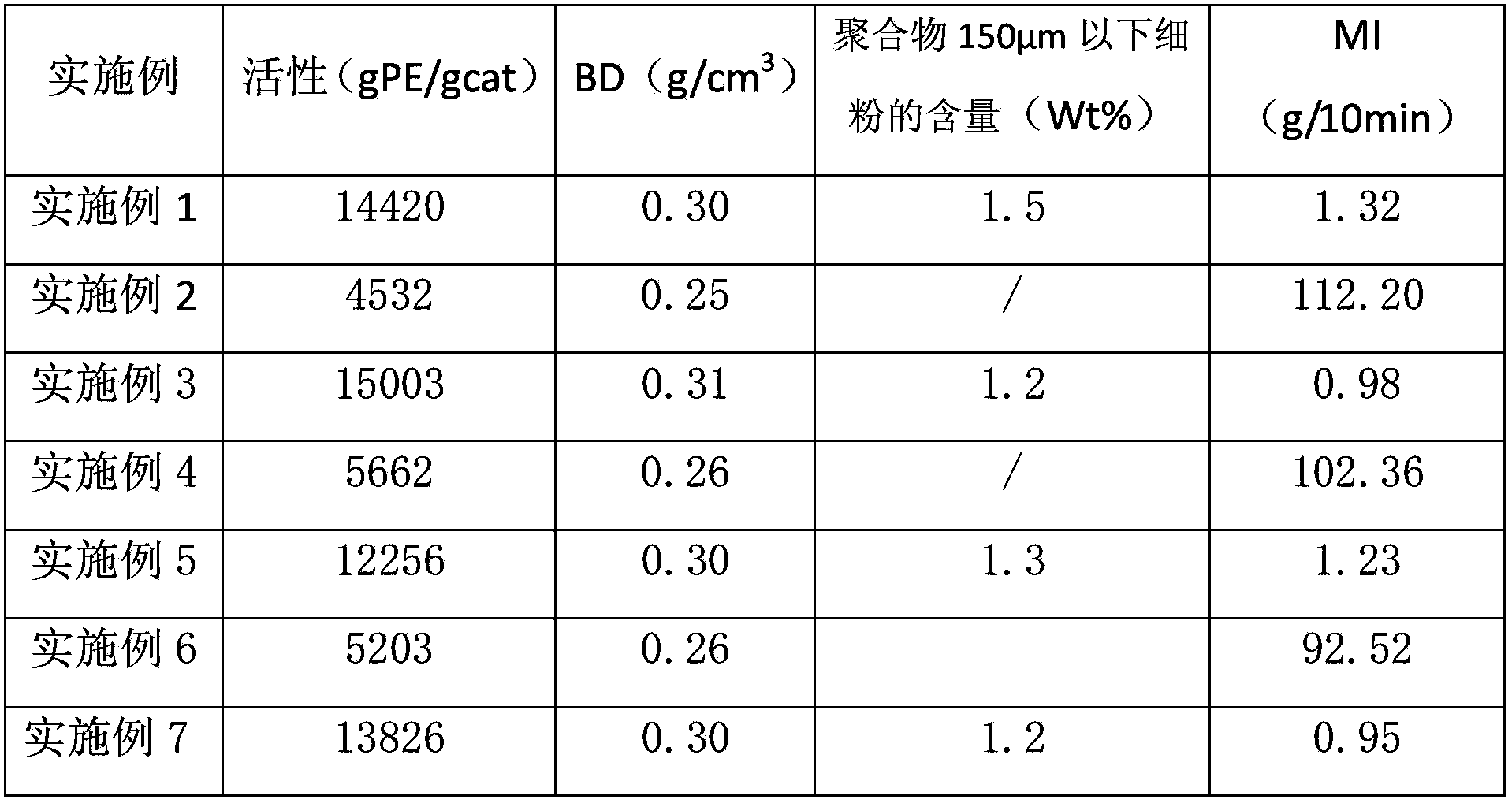

High-activity olefin polymerization catalyst, preparation method and application

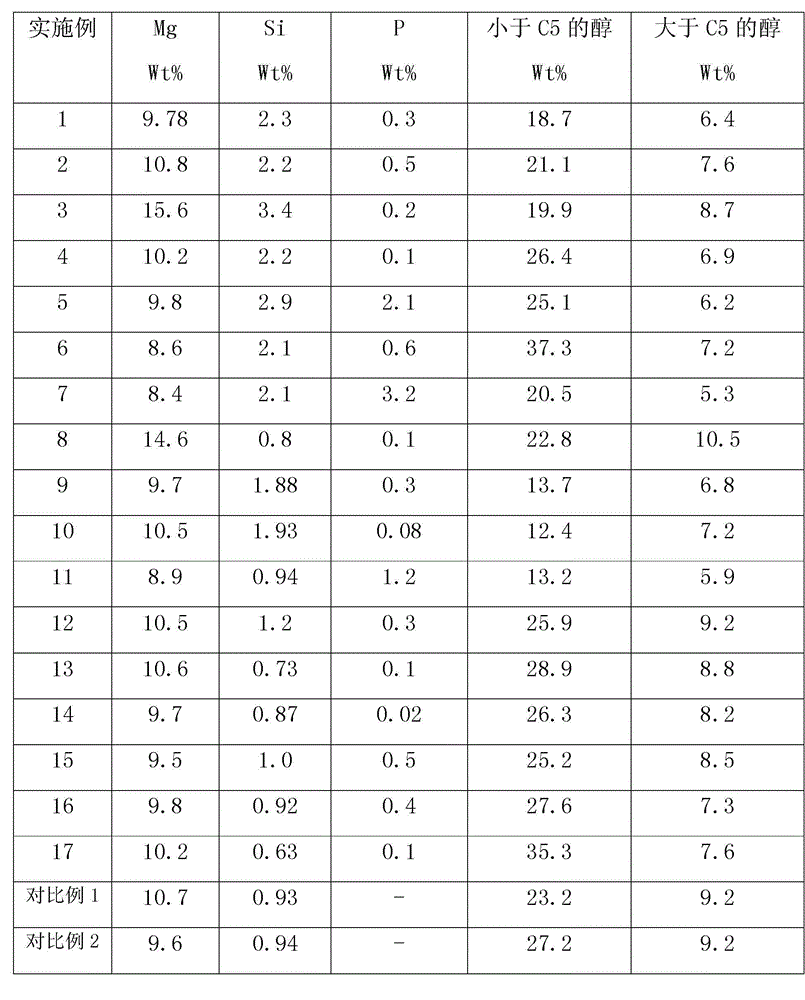

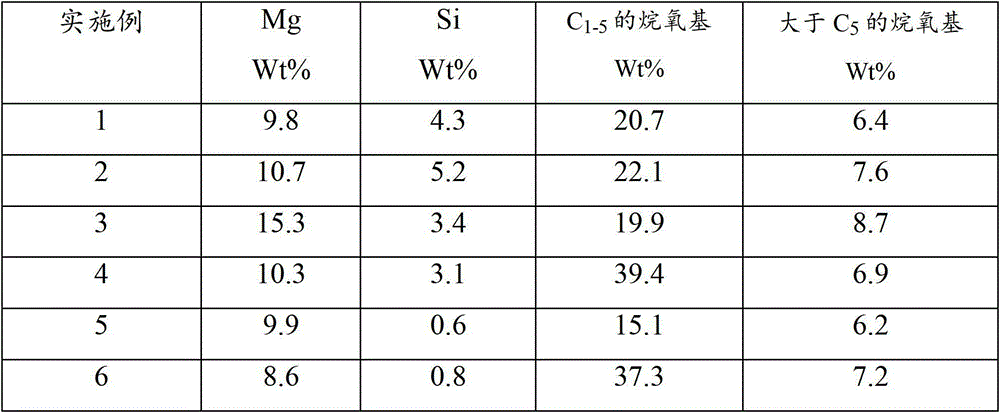

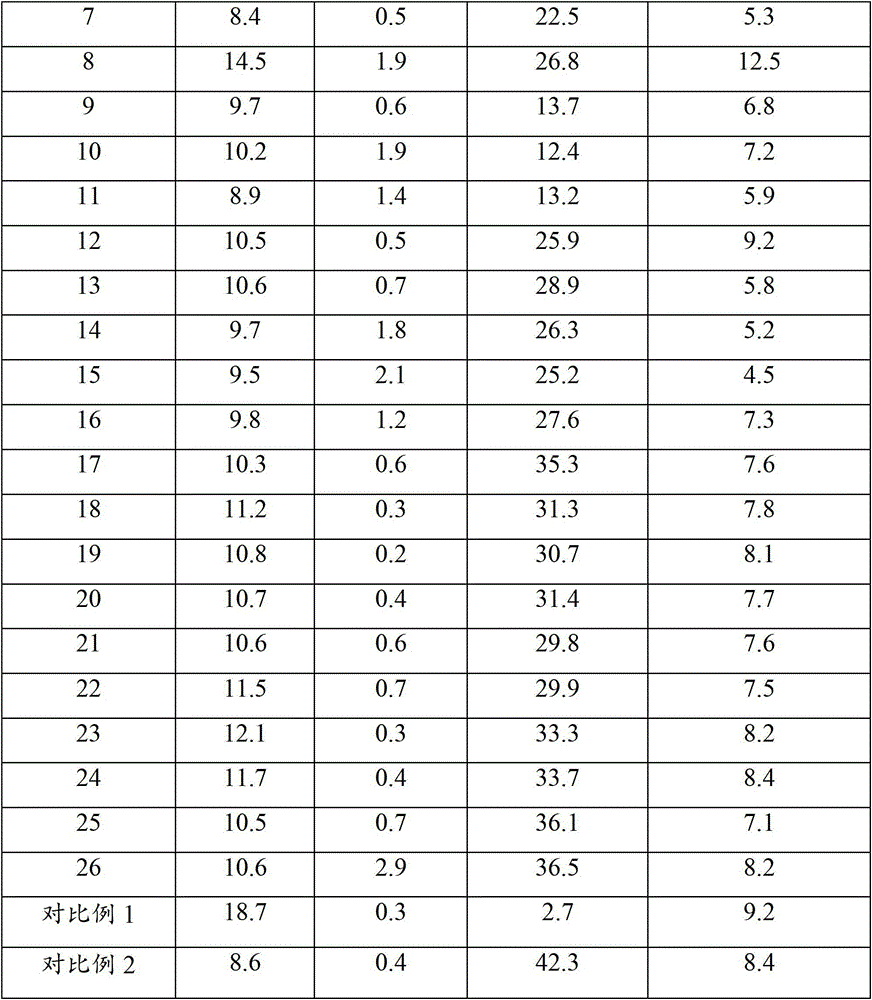

The invention relates to a high-activity olefin polymerization catalyst, a preparation method and an application and belongs to the field of olefin polymerization. The high-activity olefin polymerization catalyst is composed of a main catalyst and a cocatalyst and characterized in that the main catalyst is composed of a magnesium halide carrier, a transition metal halide, alcohol which is smaller than C5, alcohol which is larger than C5, an organosilicon compound and an organic phosphorus compound; the mole ratio of the magnesium halide carrier, the transition metal halide, the alcohol which is smaller than C5, the alcohol which is larger than C5, the organosilicon compound and the organic phosphorus compound is 1: (1-40): (0.01-5): (0.01-10): (0.01-10): (0.05-5); and the cocatalyst is an organic aluminum compound. Particles of the catalyst are good in shape, spherical and free from adhering to the wall of a container; and the catalyst is high in activity, good in hydrogen regulation performance and applicable to a slurry polymerization process, a loop polymerization process, a gas phase polymerization process or a combined polymerization process, and a melt flow rate (MFR) of polyethylene can be regulated within a range of 0.1g / 10min-600g / 10min.

Owner:BEIJING UNIV OF CHEM TECH

Olefin polymerization catalyst, and preparation method and application of catalyst

The invention provides a high-efficiency olefin polymerization catalyst, and a preparation method and an application of the catalyst. The olefin polymerization catalyst comprises a main catalyst and a cocatalyst, and is characterized in that the main catalyst comprises a magnesium halide carrier, transition metal halide, less than C5 alcohol, greater than C5 alcohol, an organic silicon compound, an organic phosphorus compound and a solid polyhydroxy substance. Solid particles of the catalyst are good in shape and spherical; the particles of the catalyst are not adhered to a wall of a container; the catalyst is high in activity and good in hydrogen regulation performance; a melt flow rate (MFR) of polyethylene can be regulated within 0.1g / 10min-600g / 10min; and the catalyst is suitable for a slurry method polymerization technology, a ring pipe polymerization technology, a gas phase method polymerization technology or a combination polymerization technology.

Owner:BEIJING UNIV OF CHEM TECH

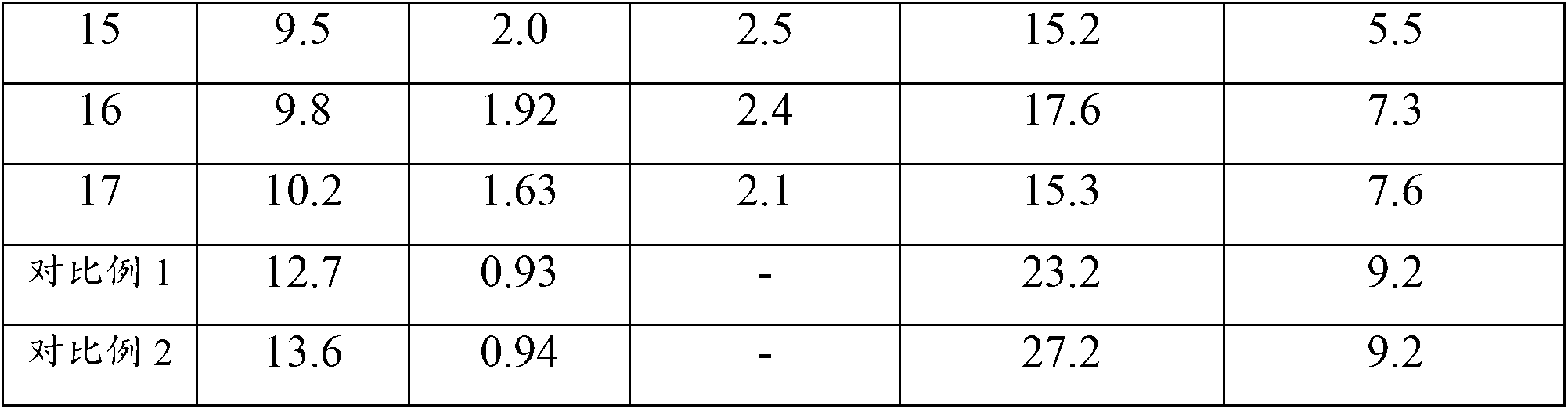

Olefin polymerization catalyst and preparation method and application thereof

InactiveCN103613690AParticles in good shapeGood hydrogen adjustment performancePolymer scienceGas phase

The invention relates to an efficient olefin polymerization catalyst and a preparation method and application thereof, belonging to the field of olefin polymerization. A main catalyst of the olefin polymerization catalyst is made from a magnesium halide support, a transition metal halide, monohydric alcohol with less than 5 carbon atoms, alcohol with more than 5 carbon atoms, an organosilicon compound, an organophosphorus compound and an organoboron compound, wherein the mole ratio of magnesium halide to the transition metal halide to monohydric alcohol with less than 5 carbon atoms to alcohol with more than 5 carbon atoms to the organosilicon compound to the organophosphorus compound to the organoboron compound is 1: (1-40): (0.01-5): (0.01-10): (0.01-10): (0.01-5): (0.01-5); a cocatalyst of the olefin polymerization catalyst is an organoaluminum compound. Particles of the catalyst disclosed by the invention are good in morphology, are spherical and are not adhered to the wall of a container; the catalyst is high in activity and good in hydrogen regulation performance, the melt index MFR (Melt Flow Rate) of polyethylene is adjustable in the range of 0.1g / 10min to 600g / 10min, and the bulk density of polyethylene particles is high, so that the catalyst is applicable to slurry-method polymerization, loop-tube polymerization, gas-phase method polymerization or combined polymerization processes.

Owner:BEIJING UNIV OF CHEM TECH

Olefin polymerization catalyst, and preparation method and application thereof

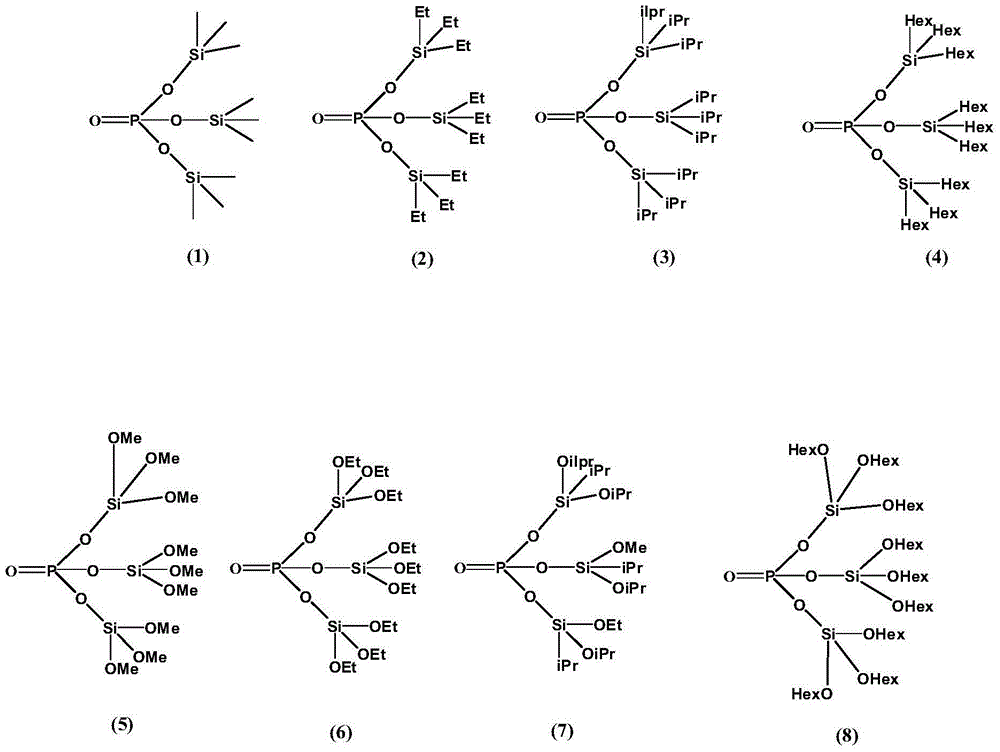

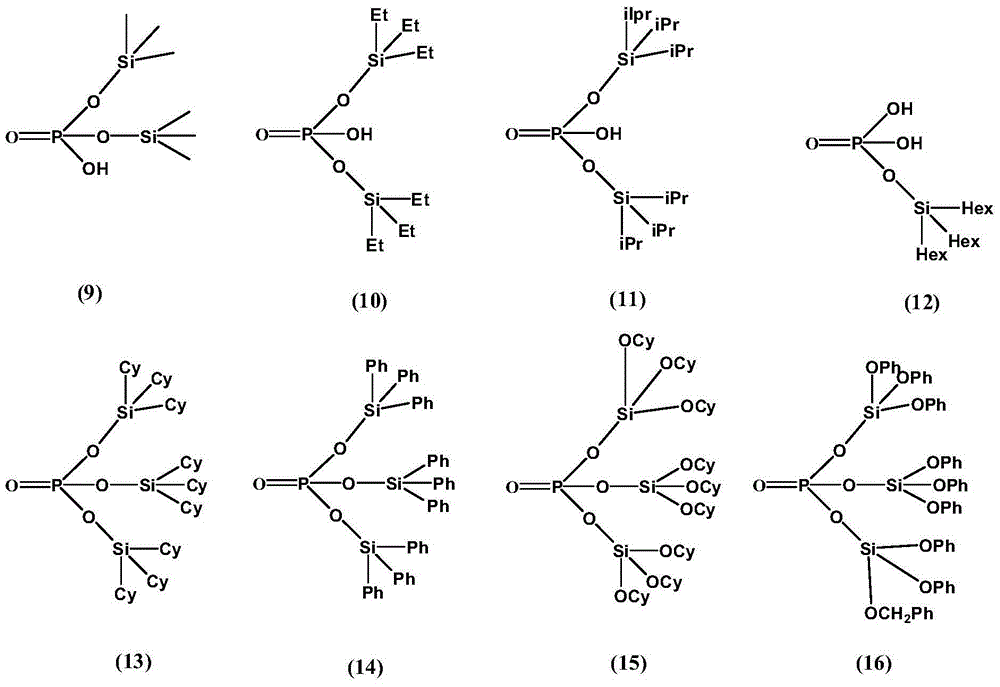

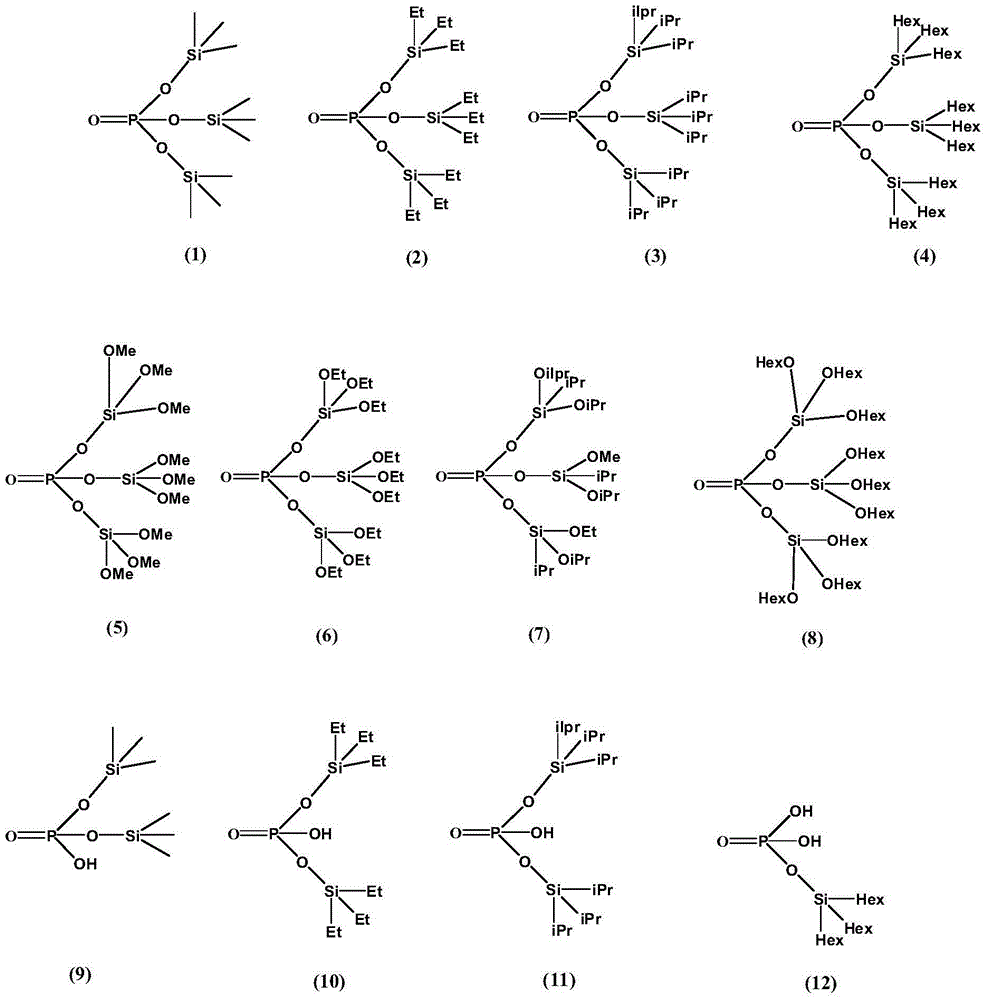

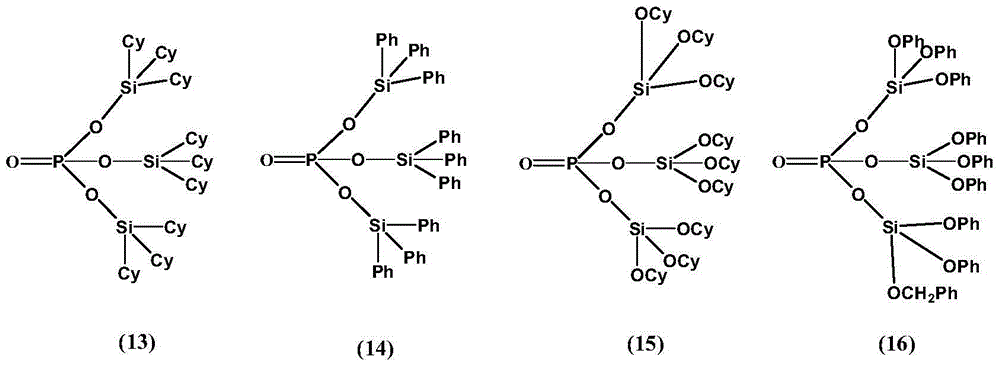

The invention provides an olefin polymerization catalyst. The catalyst is composed of a main catalyst and a cocatalyst, and the main catalyst is composed of a magnesium halide carrier, transition metal halide, C2-15 alcohol, an organo silicon compound and an alkyloxy organic phosphoric acid ether compound according to a molar ratio of 1:(1-40):(0.01-5):(0.01-10):(0.01-10); and the cocatalyst is an organic aluminum compound. The catalyst has the advantages of good particle form, high catalysis activity and good hydrogen regulation performance. The invention also provides a preparation method and an application of the olefin polymerization catalyst.

Owner:BEIJING UNIV OF CHEM TECH

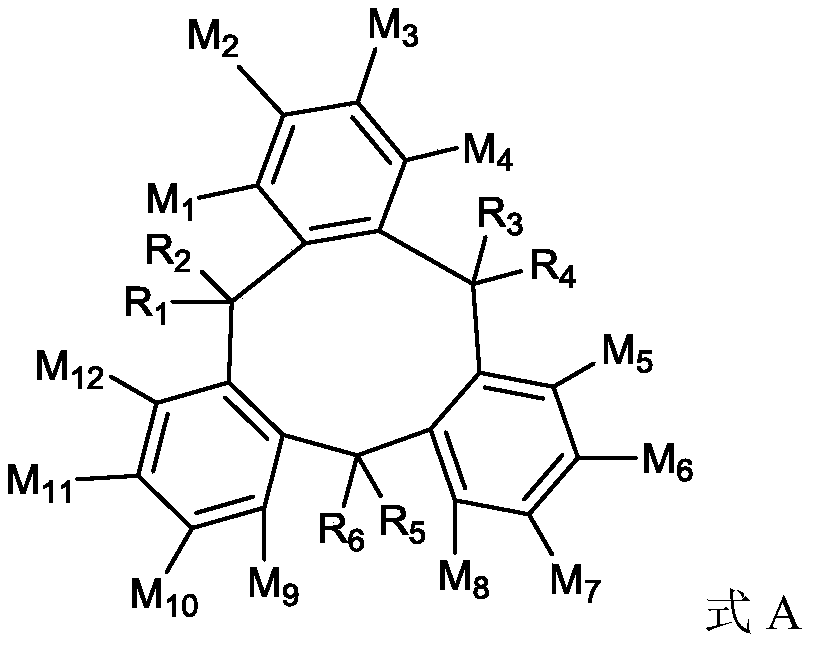

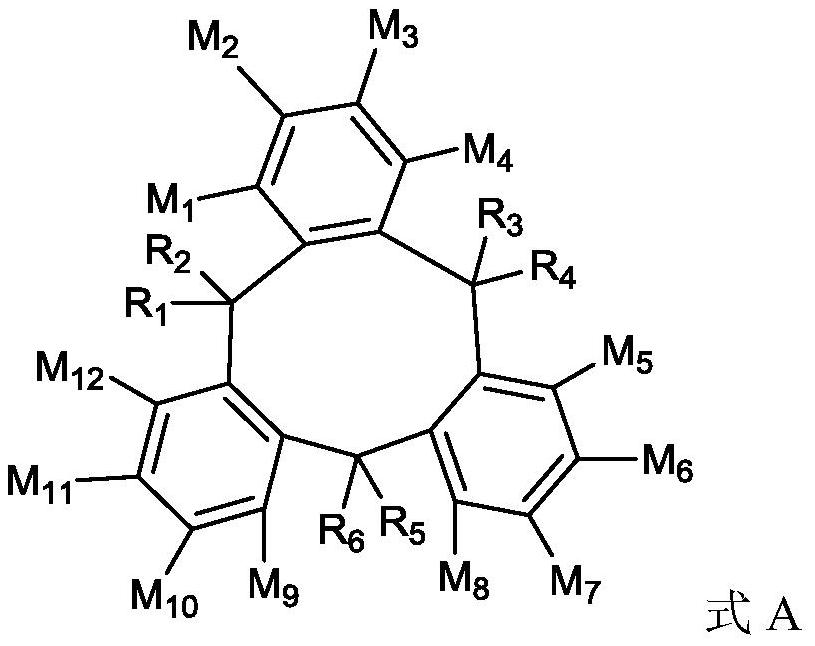

Main catalyst of olefin polymerization catalyst, preparation method thereof, and olefin polymerization catalyst

A main catalyst of an olefin polymerization catalyst comprises the following components: a magnesium compound carrier, transition metal halides, C2-C15 alcohols, and asteroid organic aza-ether compounds. The preparation method of the main catalyst comprises the following steps: (1) dispersing a magnesium compound carrier into an inert organic solvent, adding C2-C15 alcohols into the solvent, and stirring to dissolve the alcohols; (2) cooling the solution obtained in the step (1), and adding asteroid organic aza-ether compounds to carry out reactions; and (3) contacting the system obtained in the step (2) with transition metal halides at a temperature of -25 to 30 DEG C, after reactions, washing the reaction products by toluene or n-hexane, filtering to remove unreacted substances, and carrying out vacuum drying to obtain the main catalyst. An olefin polymerization catalyst comprises the abovementioned main catalyst and an auxiliary catalyst, which is one of trimethyl aluminum, triisobutyl aluminum, tri-n-hexyl aluminum, aluminum diethyl mono-chloride, and methyl aluminoxane (MAO).

Owner:PETROCHINA CO LTD

Alkene coordination polymerization catalyst as well as preparation method and application thereof

The invention provides an alkene coordination polymerization catalyst as well as a preparation method and an application thereof. The alkene coordination polymerization catalyst consists of a primary catalyst and an auxiliary catalyst, and is characterized in that the primary catalyst consists of a magnesium halide carrier, a transition metal halide, an ethanol with the carbon number of less than 5, an ethanol with the carbon number of greater than 5, an organosilicon compound and a polyhydroxy solid, wherein the mass ratio of the polyhydroxy solid to the magnesium halide carrier is (0.05-20):100. The catalyst solid particle is in a good shape of sphere, the catalyst is high in activity, the hydrogen regulation performance is favorable, and the melt index MFR of polyethylene can be regulated within 0.1g / 10min-600g / 10min. The alkene coordination polymerization catalyst is suitable for slurry-method polymerization process, gas-phase-method polymerization process or combination polymerization process.

Owner:BEIJING UNIV OF CHEM TECH

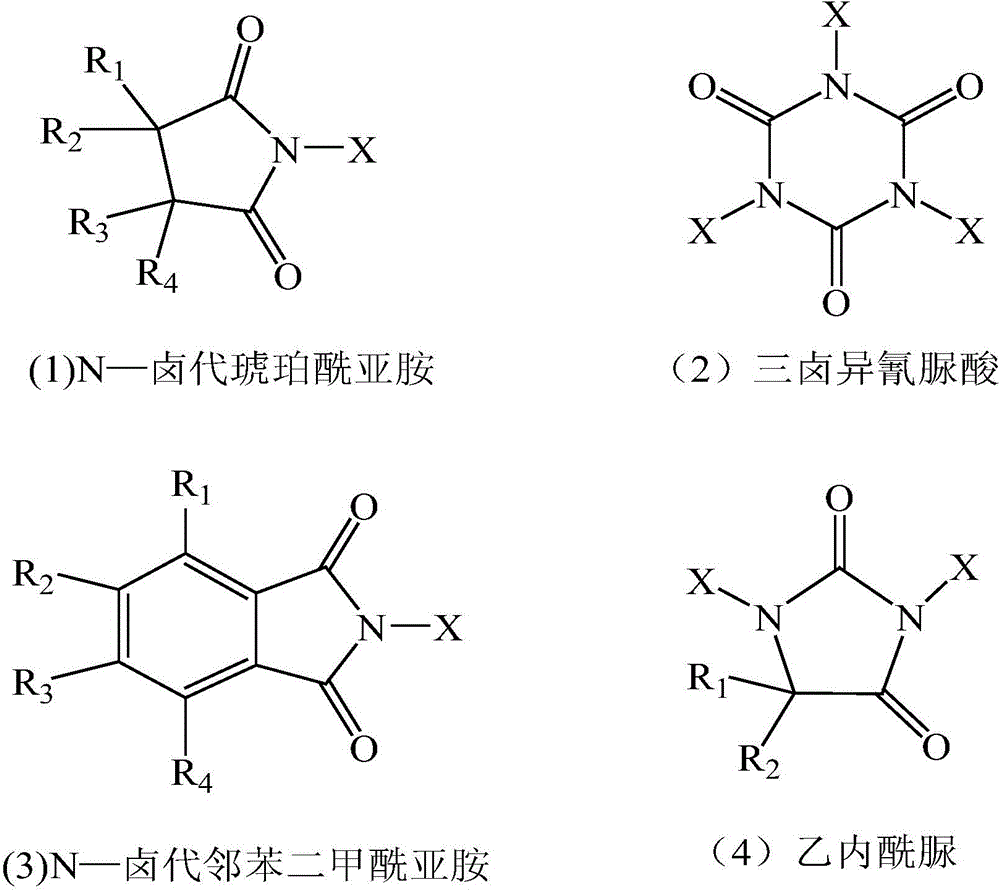

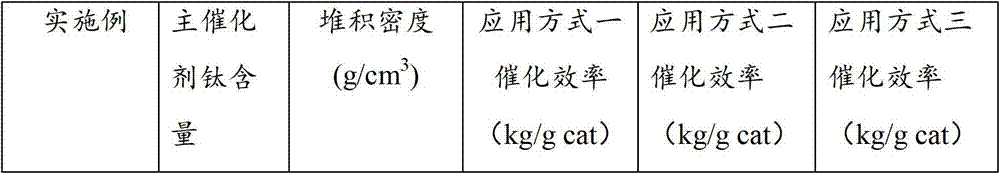

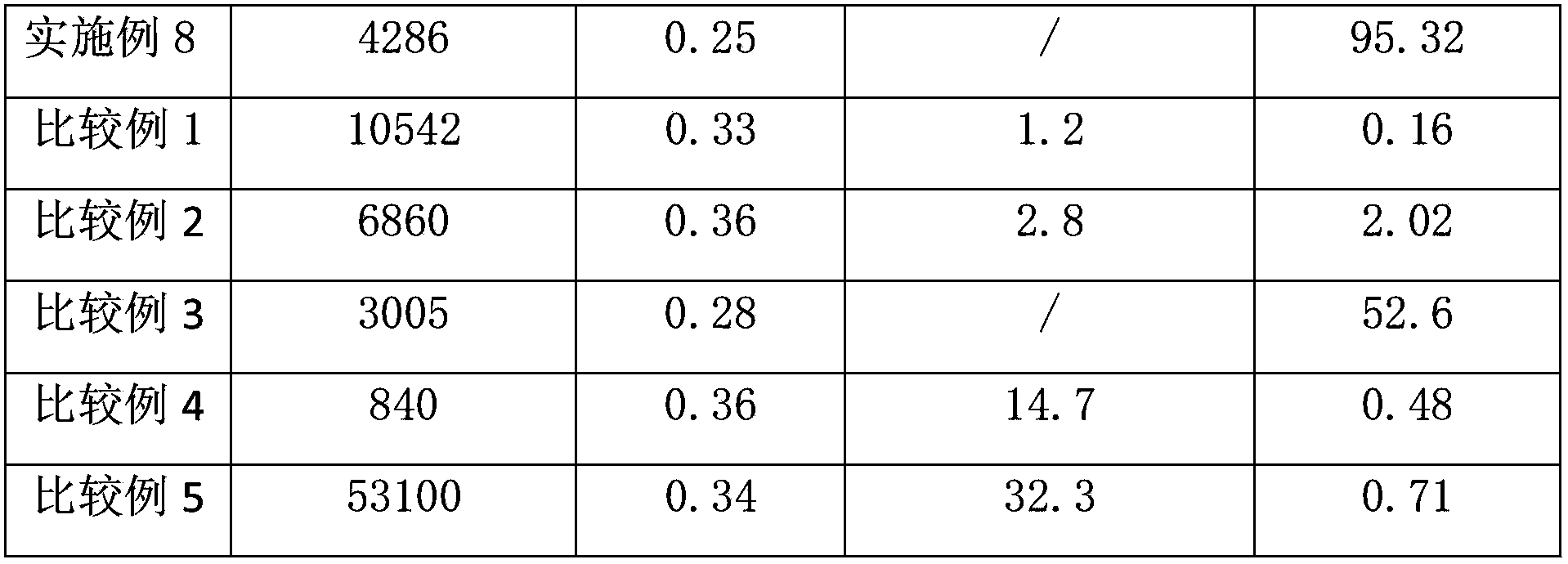

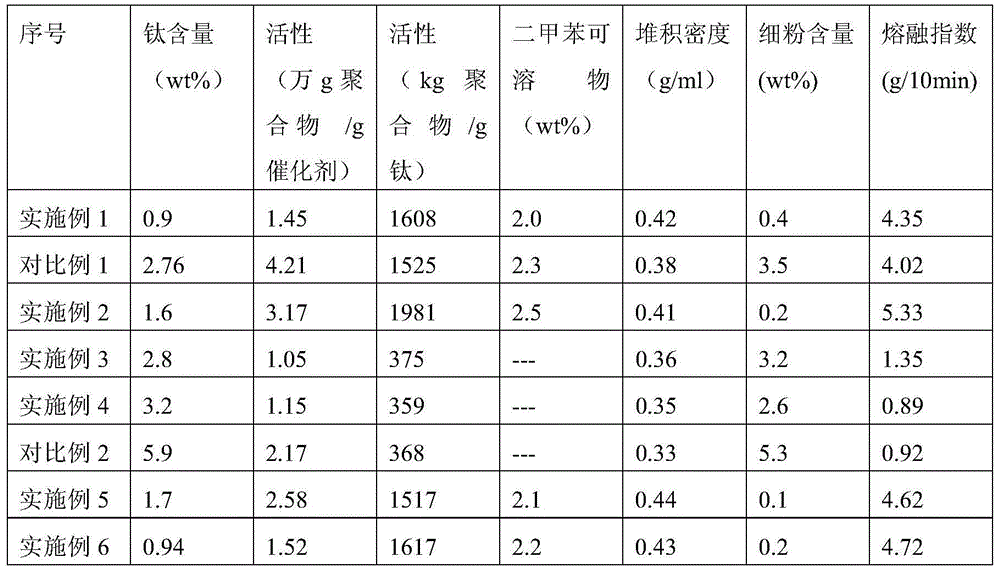

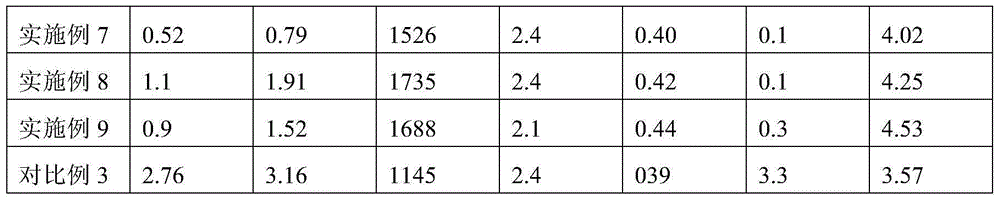

Catalyst ingredient used for ethylene polymerization, and catalyst thereof

The invention relates to a catalyst used for ethylene polymerization. The catalyst comprises following ingredients, A, a titanium-containing solid catalyst ingredient, and B, an organic aluminium compound. The titanium-containing solid catalyst ingredient is prepared by following steps: magnesium halide is dissolved in an organic epoxy compound and an organic phosphorous compound; an electron donor compound is added so as to obtain a uniform solution; a silica compound and a precipitation accessory ingredient are added; and an obtained mixture is mixed with a halide or a derivative of titanium so as to obtain the titanium-containing solid catalyst ingredient; general formula of the organic aluminium compound is AlRX<3-n>, wherein R is used for representing alkyl with 1 to 20 hydrogen or carbon atoms, X is used for representing halogen atom, and n is an integer, 0

Owner:CHINA PETROLEUM & CHEM CORP +1

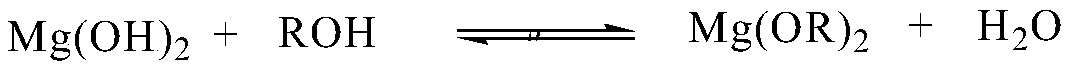

A catalyst component used for olefin polymerization, and a preparing method and applications thereof

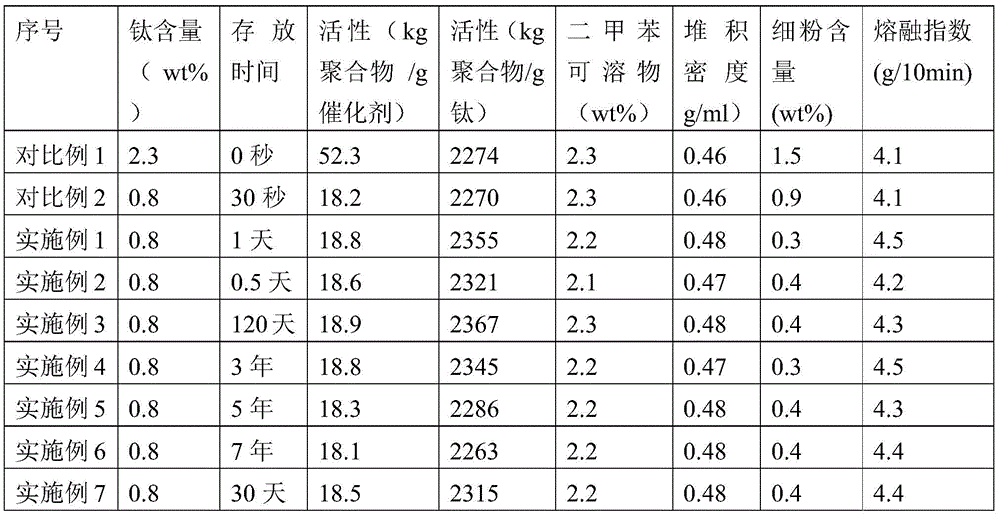

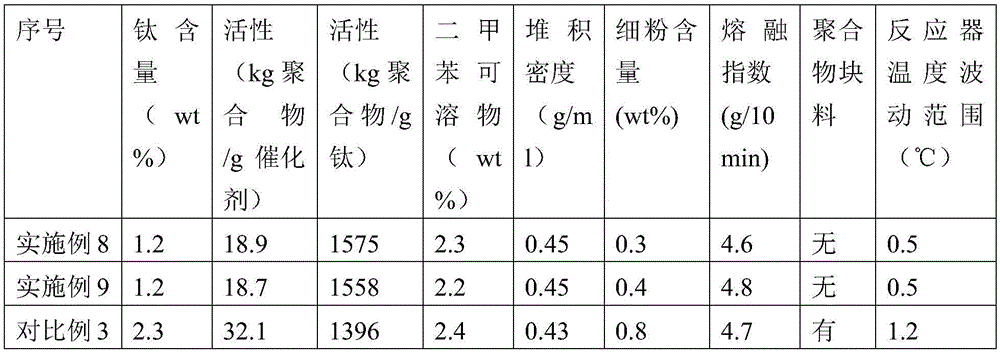

The invention provides a catalyst component for olefin polymerization. The catalyst component comprises Ti, Mg, halogen, at least one electron donor compound and 1-99% of an olefin polymer. The catalyst component is used for olefin polymerization and has characteristics of high activity, high accumulation density and low fine-powder content. The catalyst component is free of ageing influences during room-temperature storage. Polymer particles are not liable to break. The catalyst component is especially suitable for synthesis of in-reactor alloying polymers with high rubber contents.

Owner:RENQIU LIHE TECH LTD +1

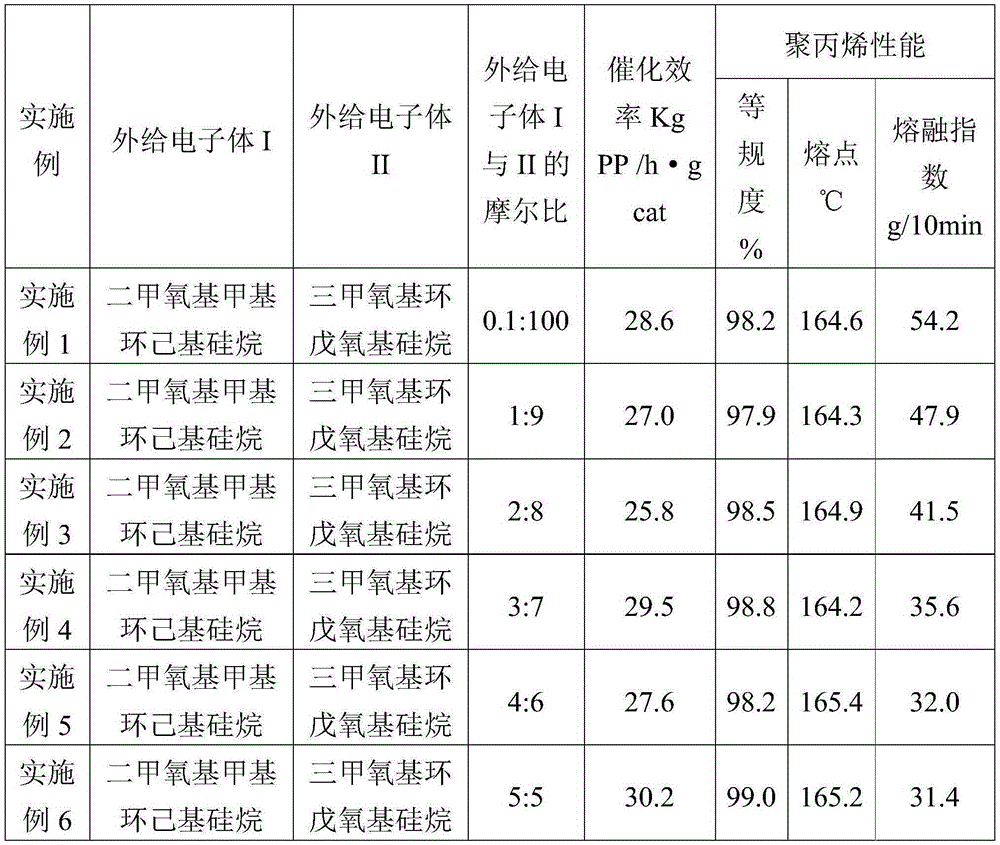

Propylene polymerization catalyst, preparation method and application thereof

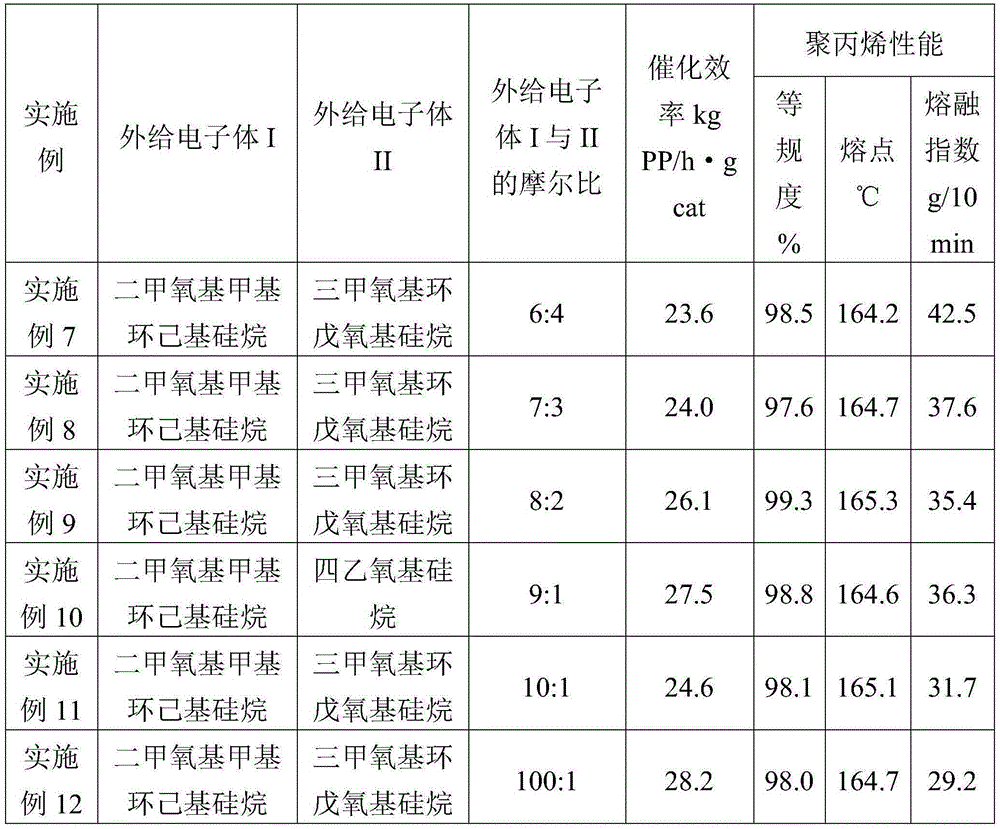

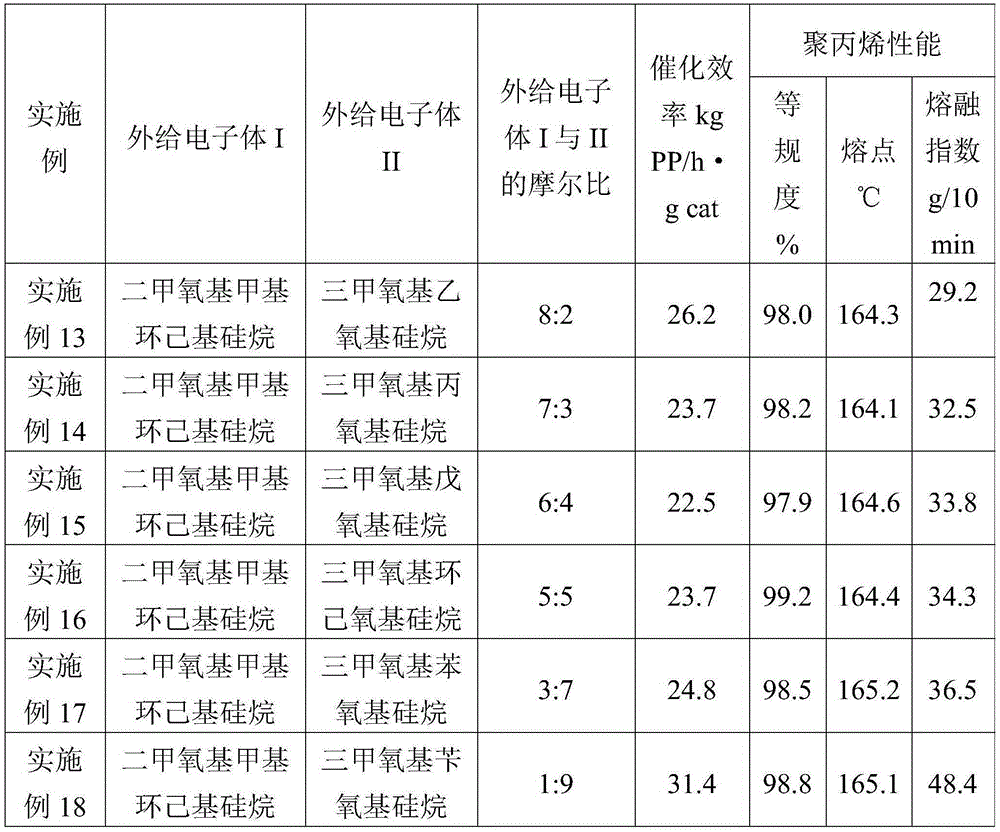

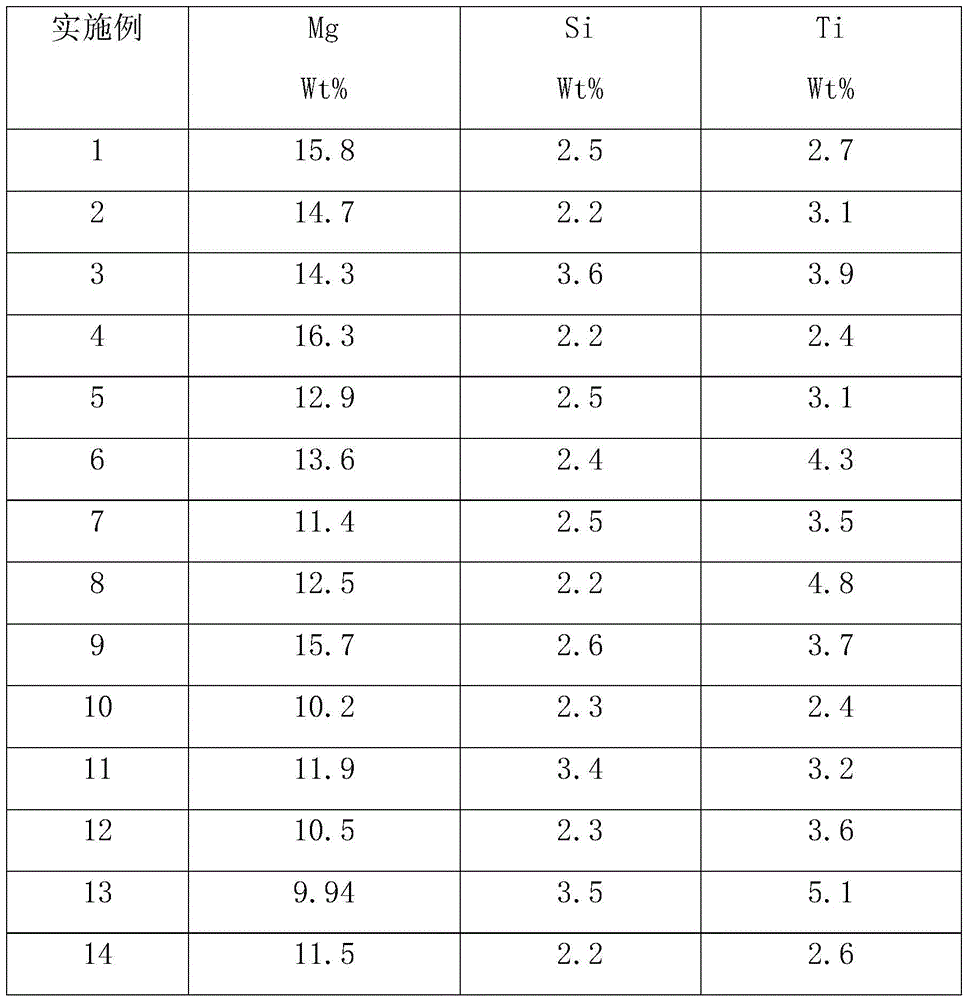

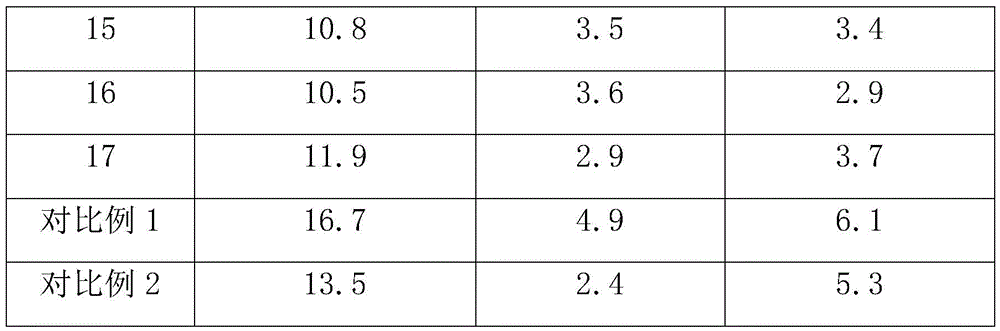

The invention discloses a propylene polymerization catalyst, a preparation method and application thereof. The catalyst comprises a main catalyst, a compound external electron donor and a cocatalyst, wherein the compound external electron donor comprises an external electron donor I and an external electron donor II with the molar ratio of 1:(0.01-100); the general formula of the external electron donor I is R1nSi(OR2)4-n or R3R4Si(OR5)2, and the general formula of the external electron donor II is (R6O)(R7O)Si(R8O)(R9O). The invention also discloses a preparation method of the main catalyst in the catalyst and the application thereof in propylene polymerization reaction and copolymerization reaction of propylene and C3-C20 alpha-olefin. The catalyst provided by the invention is high in catalytic activity, the propylene as a product obtained from catalysis has the characteristics of high isotacticity, high melt index and high melting point; the preparation method of the catalyst is simple and environmental-friendly and is applicable to processes of bulk polymerization, slurry polymerization, gaseous polymerization or combined polymerization of the propylene.

Owner:PETROCHINA CO LTD

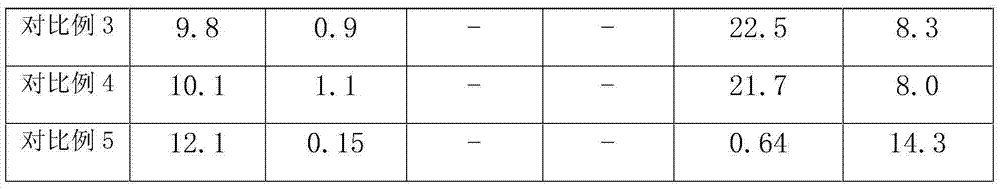

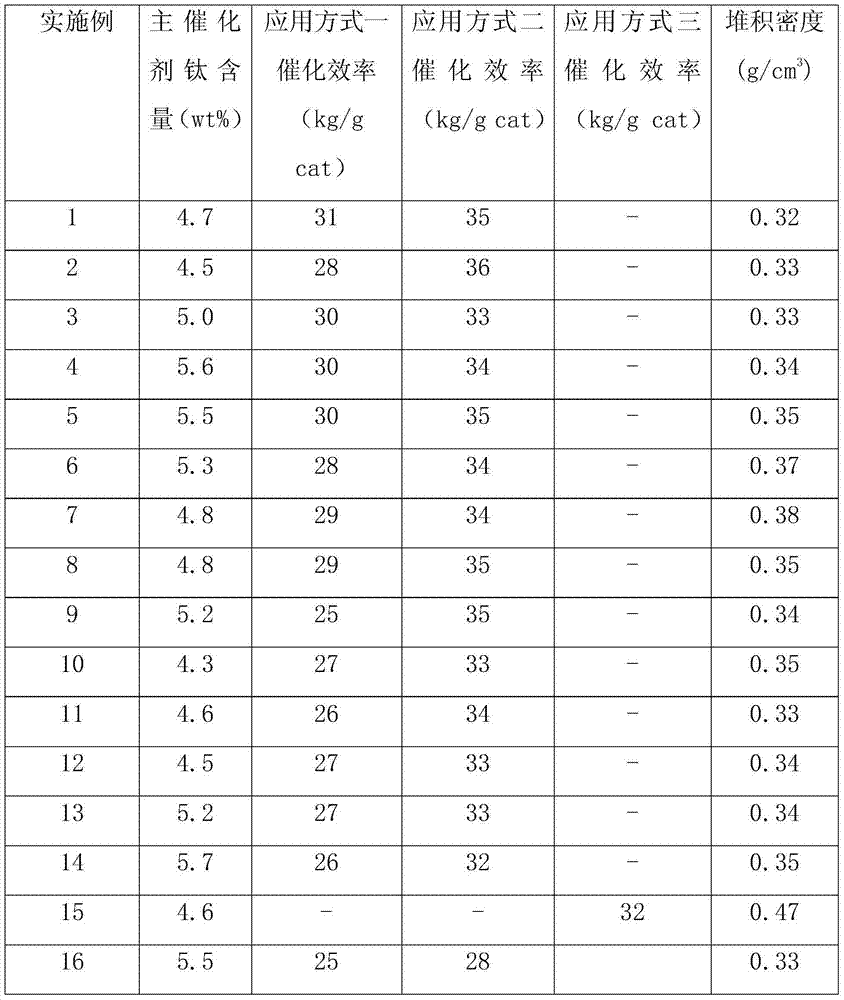

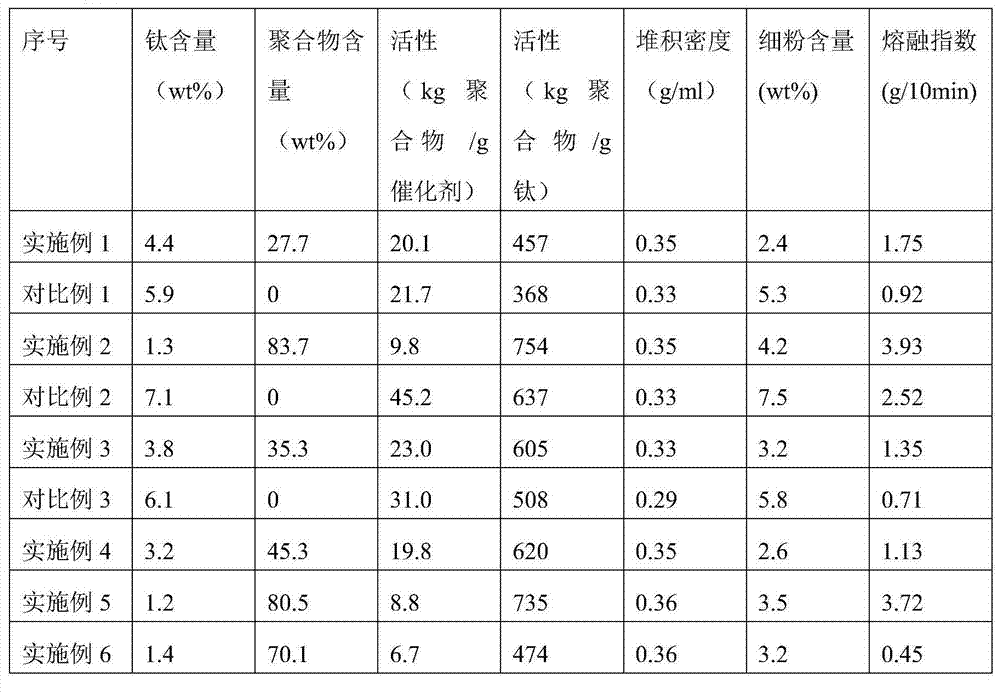

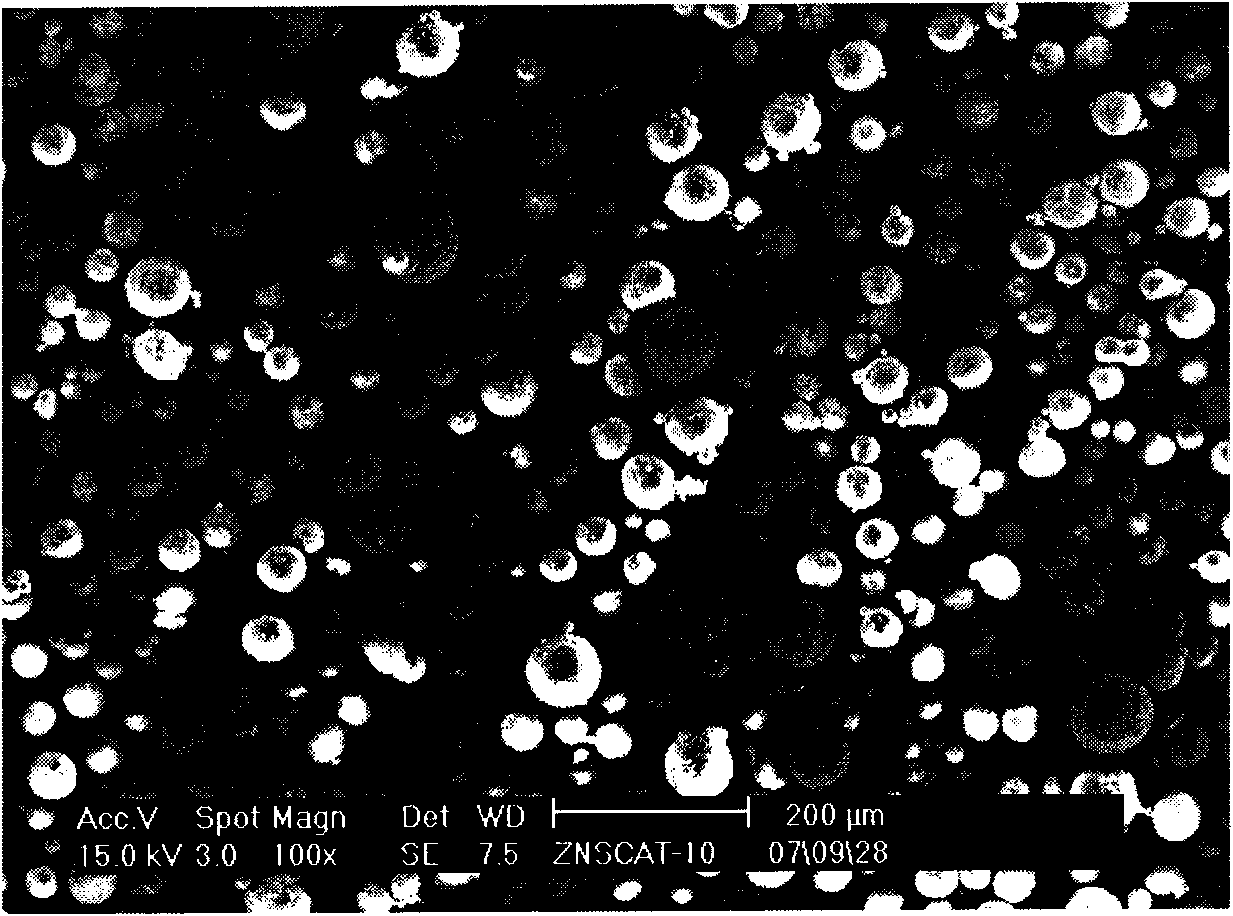

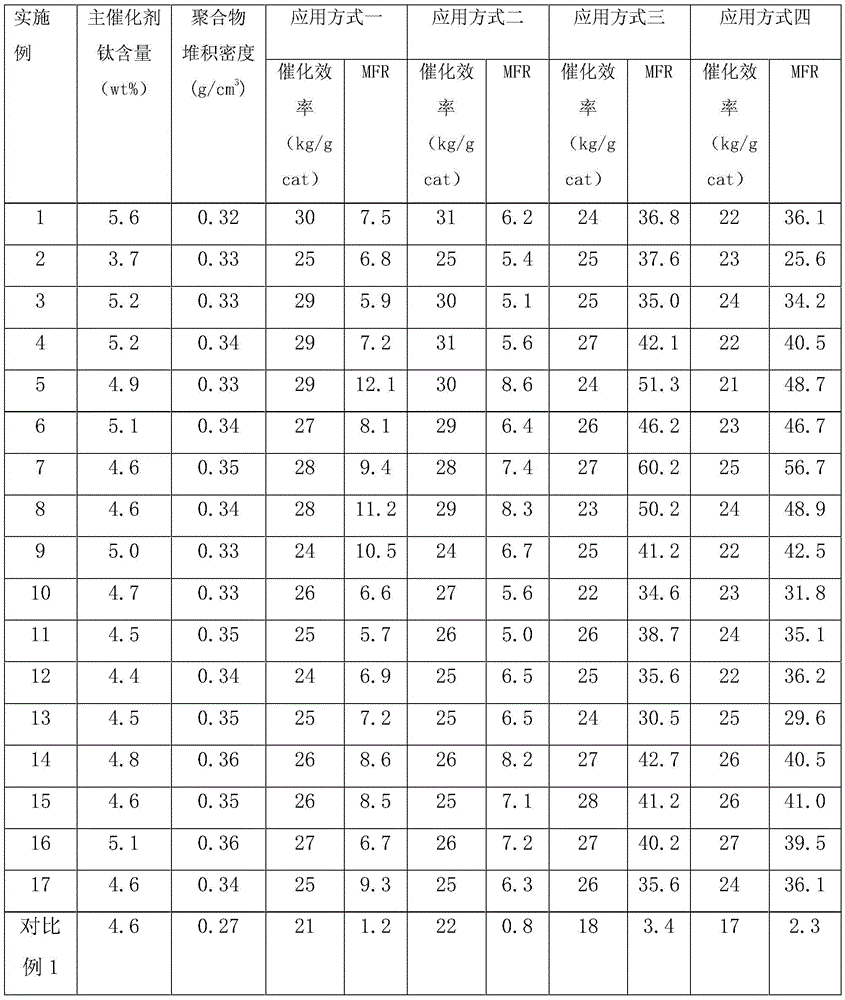

Preparation method and application of polyolefin-coated Ziegler-Natta catalyst

InactiveCN105542039AParticles in good shapeGood hydrogen adjustment performancePolymer sciencePolyolefin

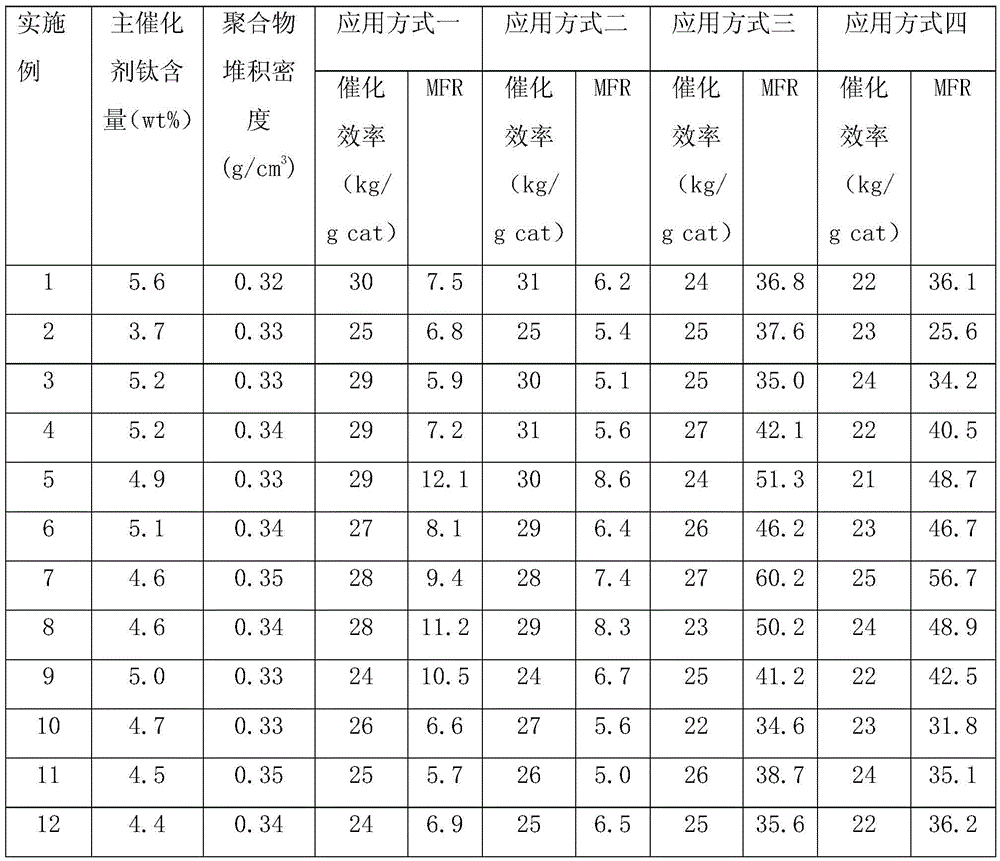

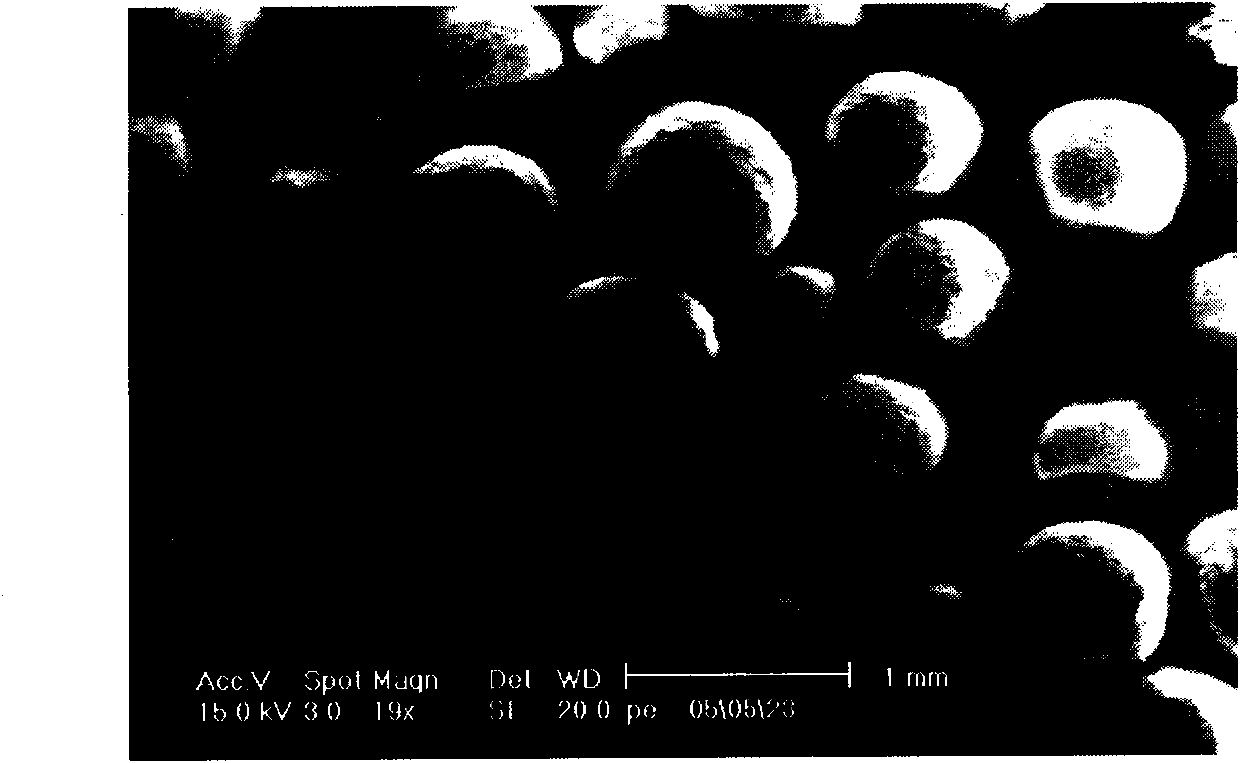

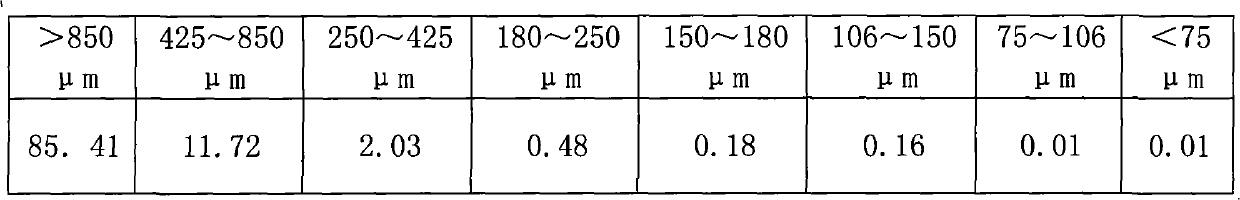

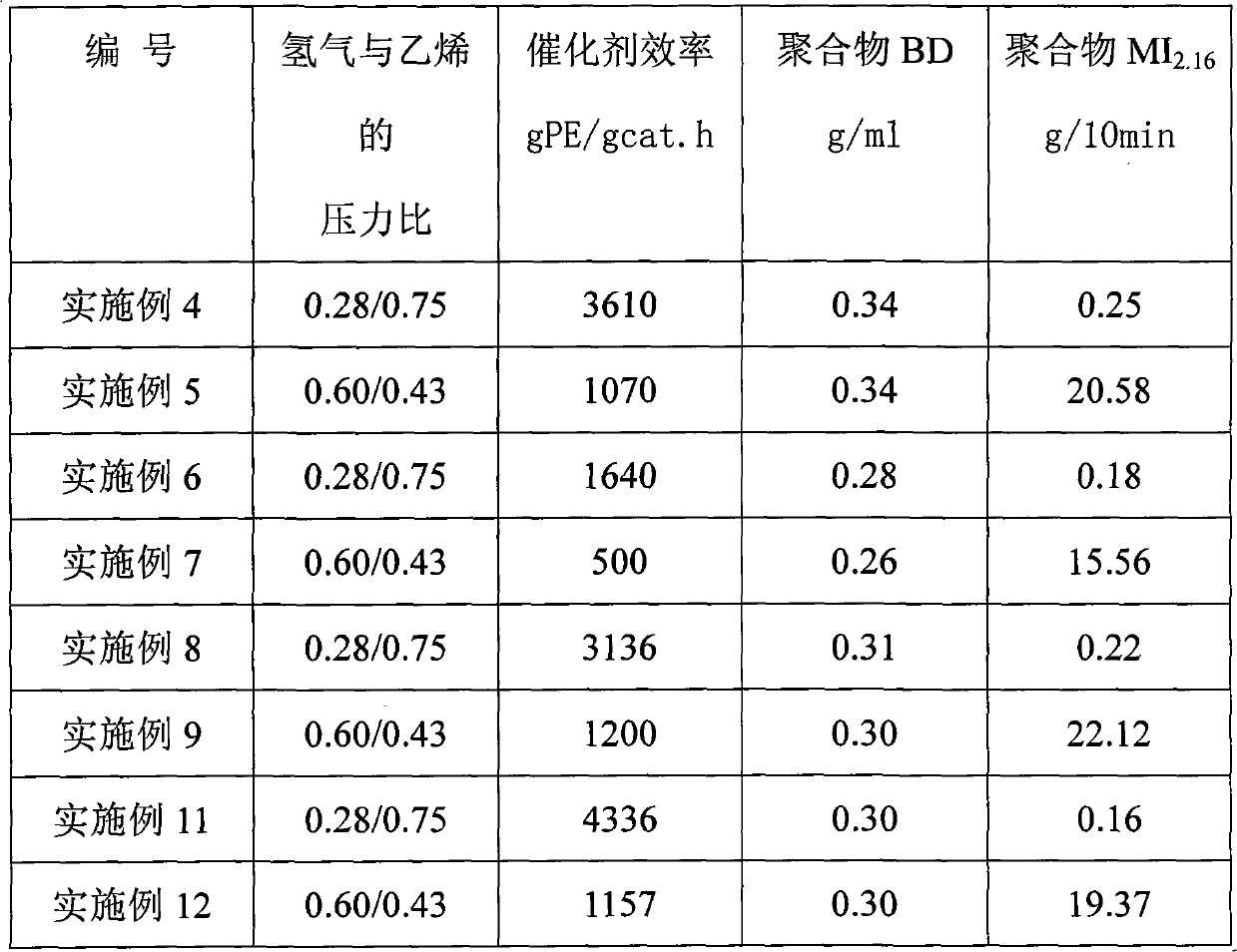

The invention provides a preparation method and application of a polyolefin-coated Ziegler-Natta, and belongs to the field of olefin coordination polymerization catalysts and olefin coordination polymerization. The method comprises the steps that a carrier is dispersed in inert organic solvent and makes contact with organic alcohol and a third component to form a mixture, and then the mixture makes contact with TiCl4; olefin monomers are activated by an activating agent for polymerization, and a polyolefin-coated Ziegler-Natta main catalyst is obtained. The stacking density of polyolefin can be obviously increased, static electricity of solid main catalyst particles can be eliminated, and the main catalyst particles and polyolefin particles do not stick to the container wall. The Ziegler-Natta catalyst is good in particle morphology and uniform in particle size distribution; the catalyst is excellent in hydrogen regulation performances, the melt flow rate (MFR) of polyethylene can be adjusted between 0.01 g / 10 min and 600 g / 10 min, and the stacking density of polyolefin ranges from 0.3 to 0.4; the catalyst is high in loading capacity and high in activity, the main catalyst particles and the polyolefin particles do not stick to the container wall, and the polymer is good in particle morphology, high in stacking density and less in fine powder; the preparation technology is simple, low in cost and less in environmental pollution.

Owner:BEIJING UNIV OF CHEM TECH

Olefin polymer-containing catalyst component and catalyst used for olefin polymerization

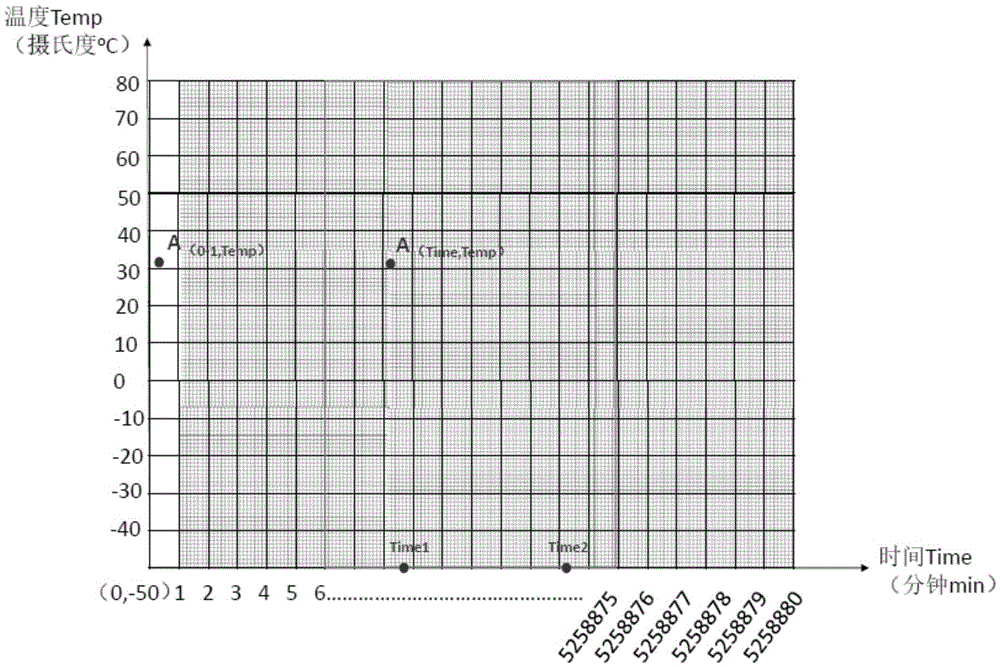

The invention discloses an olefin polymer-containing catalyst component used for olefin polymerization. The catalyst component is obtained by pre-polymerizing an olefin polymerization catalyst, an activator and olefin, and then storing offline, wherein the conditions of storing offline are as follows: the storage period is greater than 1 minute and less than 10 years, the storage temperature is -50 DEG C to 80 DEG C, A(Time, Temp) of the catalyst component is greater than or equal to A(0-1, Temp)*50%(g polymer / g reactive metal center), and when the fluctuation range of the storage temperature is within -10 DEG C to 10 DEG C, A(Time2, Temp) is greater than or equal to A(Time1, Temp)*50%(g polymer / g reactive metal center). The invention also discloses a catalyst used for olefin polymerization, comprising the olefin polymer-containing catalyst component, an aluminium compound and optionally, an external electron donor compound. When the catalyst component and the catalyst are applied in olefin polymerization, the problems of aggregation, caking and the like caused by catalyst particle breakage and local hot points can be avoided, and the fine powder content can be reduced.

Owner:RENQIU LIHE TECH LTD

Catalyst for olefin polymerization, and preparation method thereof, and catalyst composition for olefin polymerization, and applications thereof

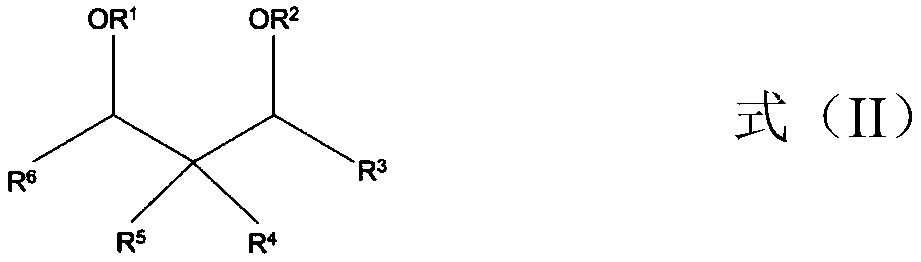

ActiveCN111019023AImprove structural strengthThe polymerization reaction is stableBulk chemical productionPolymer sciencePtru catalyst

The invention relates to the field of olefin polymerization catalysts, and discloses a catalyst for olefin polymerization, wherein the catalyst comprises a catalyst precursor and a polymer with a structural unit represented by a formula (IV), the catalyst precursor contains an alkoxy magnesium carrier represented by a formula (I), an electron donor compound represented by a formula (II), a titanium compound represented by a formula (III) and an organic aluminum compound represented by a formula (V), and the catalyst precursor is coated with the polymer with the structural unit represented by the formula (IV). According to the invention, the catalyst is uniform in particle size distribution; the catalyst component containing the catalyst has the characteristics of high activity and low finepowder content when applied to olefin polymerization, and further has characteristics of less activity attenuation under a normal-temperature storage condition, high isotacticity of a polymer, reduced fine powder content in polymer powder and high stacking density; and the formula (1) is Mg(OEt)2-m(OEHA)m, the formula (II) is defined in the specification, the formula (III) is TiXn(OR<7>)4-n, theformula (IV) is -CH2CHR<8>-, and the formula (V) is AlR<9>nY3-n.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alkoxy metal powder as well as preparation method and application thereof

InactiveCN110483247AGood hydrogen adjustment performanceHigh activityTitanium organic compoundsPreparation of metal alcoholatesIodidePotassium

The invention relates to a preparation method and an application of alkoxy metal powder, which are applied to preparation of an alkoxy metal carrier of an olefin polymerization catalyst. The alkoxy metal carrier comprises the following components: metal halide, sodium alcoholate or potassium alcoholate, or a solvent. The molar ratio of the components for preparing the alkoxy metal compound is as follows: metal halide: sodium alcoholate or potassium alcoholate = 1:(0.001-30); wherein the metal halide is a metal chloride, a metal bromide, a metal fluoride or a metal iodide; the metal is a main group metal, a sub-group metal or a VIII group metal. The catalyst prepared from the carrier is used for preparing an olefin polymerization catalyst, and has the advantages of high catalyst activity, good hydrogen regulation performance, good copolymerization performance, low polymer powder content, low wax content and good particle morphology; the catalyst is used for ethylene homopolymerization,ethylene and alpha-olefin copolymerization or ethylene and polar alkene monomer copolymerization, propylene homopolymerization, propylene and alpha-olefin copolymerization, or propylene and polar alkene monomer copolymerization.

Owner:北京国达恒泰科贸有限责任公司

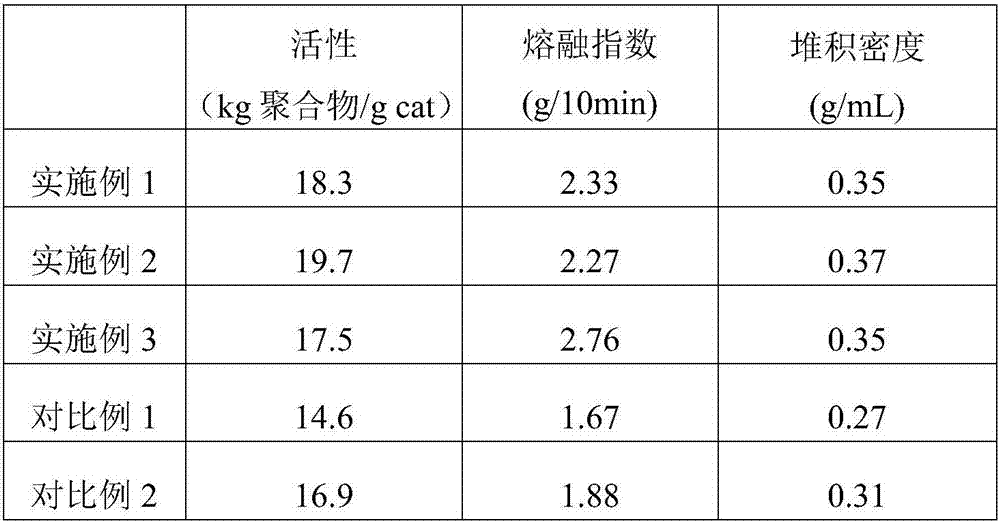

Catalyst component for vinyl polymerization and preparation method and application of catalyst component

The invention provides a catalyst component for vinyl polymerization. The catalyst component comprises Ti, Mg, halogens and 1-99% of olefin polymers. The catalyst component for vinyl polymerization not only has the characteristics of high activity, high bulk density, low breaking rate of polymeric particles and low fine powder content, but also has good hydrogen regulating performance.

Owner:RENQIU LIHE TECH LTD

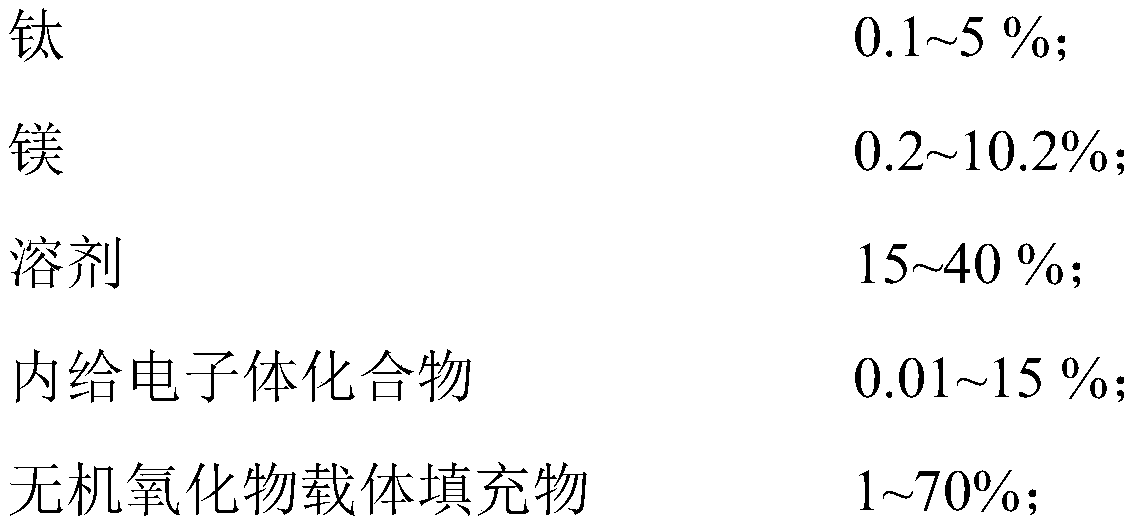

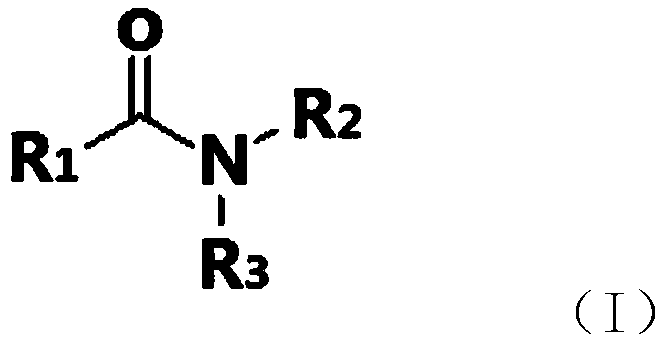

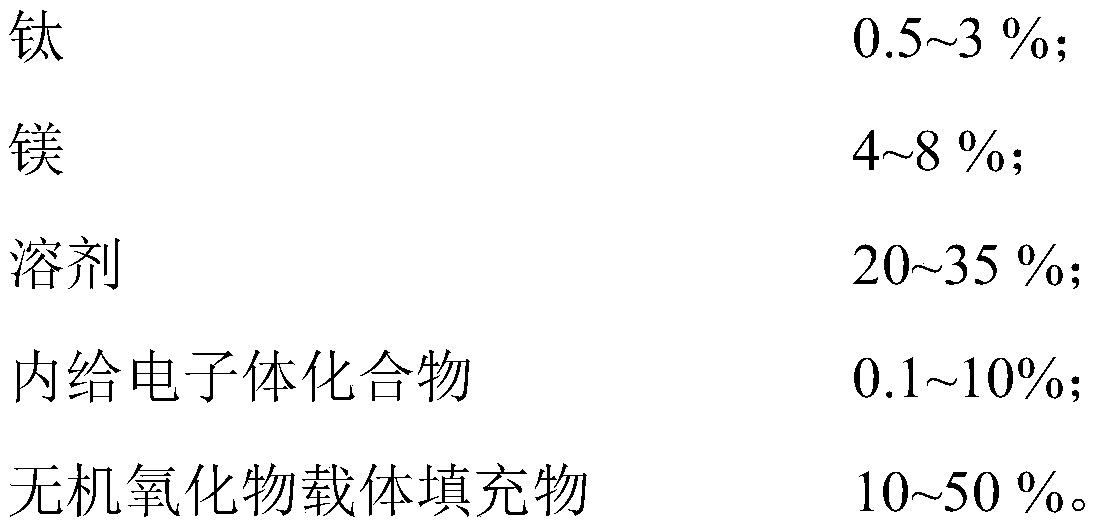

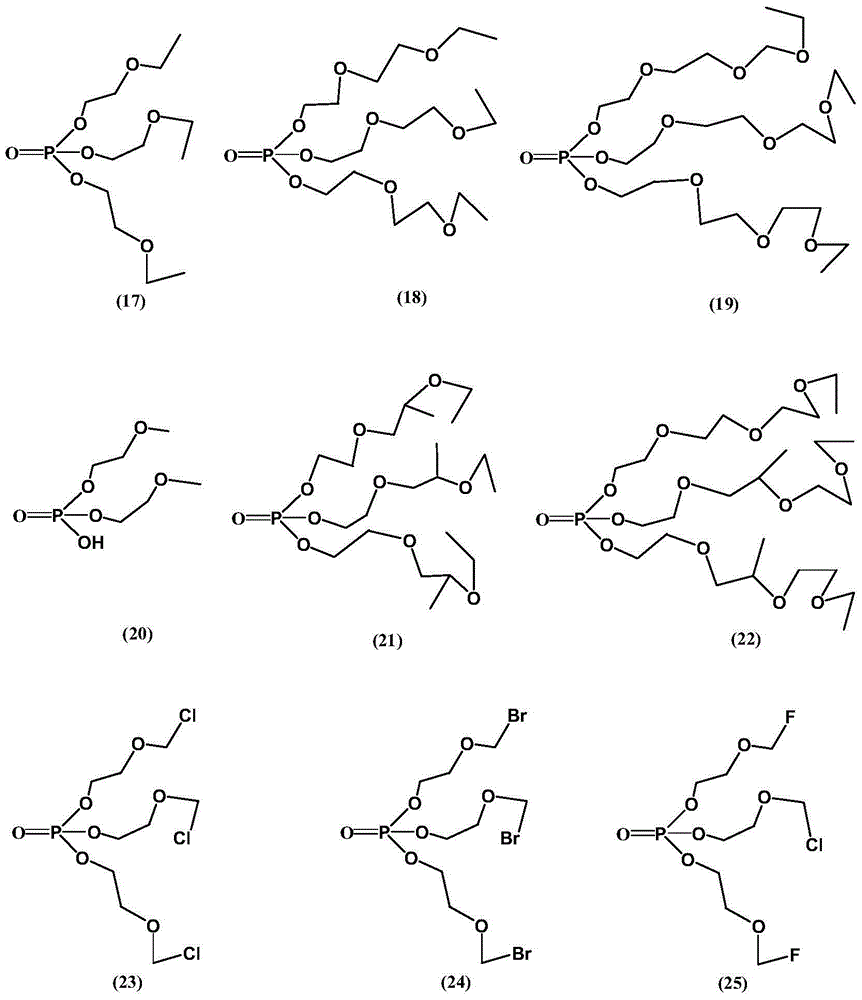

Catalyst component for olefin polymerization, preparation method, catalyst and application thereof

The invention discloses a catalyst component for olefin polymerization, a preparation method of the catalyst component, a catalyst and application of the catalyst. The catalyst component comprises, byweight, 0.1 to 5 percent of titanium, 0.2 to 10.2 percent of magnesium, 15 to 40 percent of a solvent, 0.01 to 15 percent of an internal electron donor compound and 1 to 70 percent of an inorganic oxide carrier filler. The catalyst provided by the invention is prepared by a spray drying method, and the obtained catalyst component particles have low solvent content. The catalyst is used for catalyzing ethylene polymerization, and has the advantages of high catalyst activity, good hydrogen regulation performance, high polymer powder bulk density and low polymer powder fine powder content.

Owner:CHINA PETROLEUM & CHEM CORP +1

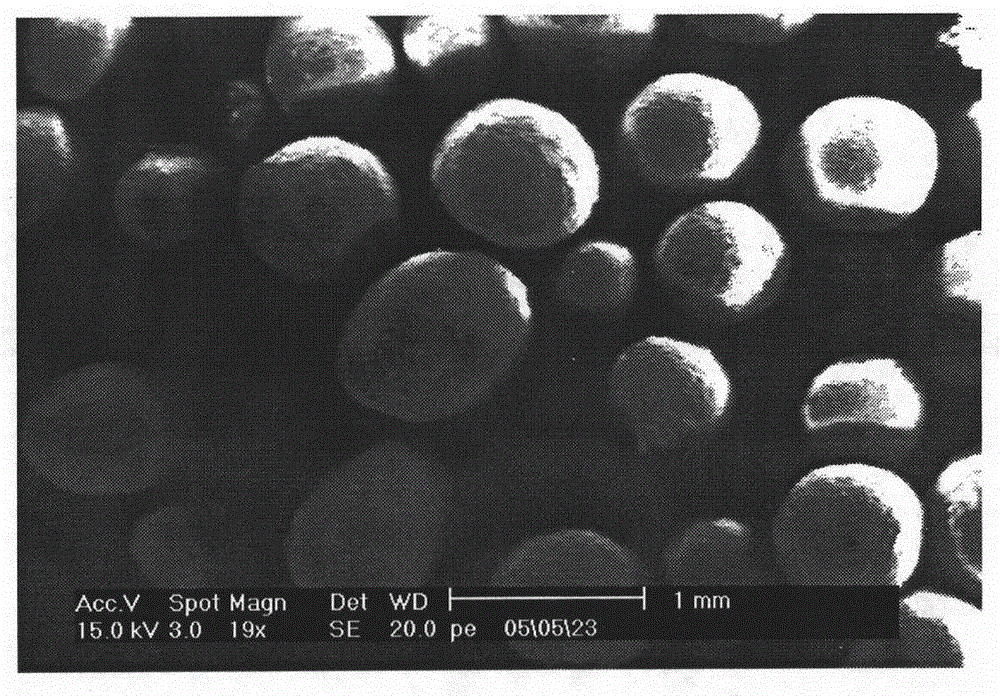

Preparation method of catalyst component for polymerization of vinyl and catalyst for polymerization of vinyl

ActiveCN102050897AEasy to prepareThe preparation method is simple and controllableTitanium tetrachlorideCorrosion

The invention relates to a preparation method of catalyst components for polymerization of vinyl and a catalyst for the polymerization of vinyl. The method comprises the following steps: carrying out proper physical modification on a magnesium compound at a certain temperature; and then directly loading active components such as titanium tetrachloride and the like on the magnesium compound so as to prepare the catalyst suitable for the slurry polymerization and gas phase polymerization of vinyl. The catalyst prepared by the method has good hydrogen-regulating sensitivity in the process of catalyzing the polymerization of vinyl, the catalyst particle is strong and has small possibility of breaking, a particle form is good and is of a sphere shape, and the prepared catalyst has the characteristic of higher catalysis activity; and the preparation method is simple and easy to operate, and has small possibilities of generating serious corrosion on a device, and causing serious influence on environment; and the prepared polymer particle is of a sphere shape, and the fine powder is less.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alkene coordination polymerization catalyst as well as preparation method and application thereof

The invention provides an alkene coordination polymerization catalyst as well as a preparation method and an application thereof. The alkene coordination polymerization catalyst consists of a primary catalyst and an auxiliary catalyst, and is characterized in that the primary catalyst consists of a magnesium halide carrier, a transition metal halide, an ethanol with the carbon number of less than 5, an ethanol with the carbon number of greater than 5, an organosilicon compound and a polyhydroxy solid, wherein the mass ratio of the polyhydroxy solid to the magnesium halide carrier is (0.05-20):100. The catalyst solid particle is in a good shape of sphere, the catalyst is high in activity, the hydrogen regulation performance is favorable, and the melt index MFR of polyethylene can be regulated within 0.1g / 10min-600g / 10min. The alkene coordination polymerization catalyst is suitable for slurry-method polymerization process, gas-phase-method polymerization process or combination polymerization process.

Owner:BEIJING UNIV OF CHEM TECH

Catalyst component preparation method and catalyst for vinyl polymerization

ActiveCN102020732AEasy to prepareThe preparation method is simple and controllablePolymer scienceHydrogen

The invention relates to a catalyst component preparation method and a catalyst for vinyl polymerization. The method comprises the following step of: after proper chemical modification is performed on a magnesiumhalide alcoholic compound at a certain temperature, directly loading active ingredients such as titanium tetrachloride and the like to prepare the catalyst which can be applied to vinyl slurry polymerization and gas-phase polymerization. The method is simple and is easy to control. When catalyzing vinyl polymerization, the catalyst prepared by the method has high hydrogen regulation sensitivity; catalyst particles are compact, are difficult to crush, have good shapes, are spherical and have relatively high catalytic activity; and the obtained polymer particles are spherical and have a small amount of fine powder.

Owner:CHINA PETROLEUM & CHEM CORP +1

Olefin efficient polymerization catalyst, and preparation method and application thereof

The invention provides an olefin efficient polymerization catalyst. The catalyst is composed of a main catalyst and a cocatalyst, the main catalyst is composed of an alkyloxy magnesium carrier, transition metal halide and an alkyloxy organic phosphoric acid ether compound according to a molar ratio of 1:(1-40):(0.01-10); and the cocatalyst is an organic aluminum compound. The catalyst has the advantages of good particle form, high catalysis activity and good hydrogen regulation performance. The invention also provides a preparation method and an application of the olefin efficient polymerization catalyst.

Owner:BEIJING UNIV OF CHEM TECH

Load type Ziegler-Natta catalyst, preparation method and application

The invention provides a load type Ziegler-Natta catalyst and a preparation method. The main catalyst load type Ziegler-Natta catalyst is prepared from a carrier, transition metallic halide, C2-20 alcohol, organic acid and an ionic compound with the molar ratio of 1:(3-50):(0.01-20):(0.01-20):(0.01-20). The catalyst is excellent in hydrogen regulation performance, high in load amount and high in activity, and main catalyst particles and polyolefin particles are not attached to a container wall. The polymer is good in particle morphology, high in stacking density and small in fine powder amount. The catalyst is applicable to slurry polymerization technology, ring pipe polymerization technology, gas phase polymerization technology or combination polymerization process. The preparation process of the main catalyst is simple, low in cost, low in equipment requirement, small in energy consumption and small in environmental pollution.

Owner:BEIJING UNIV OF CHEM TECH

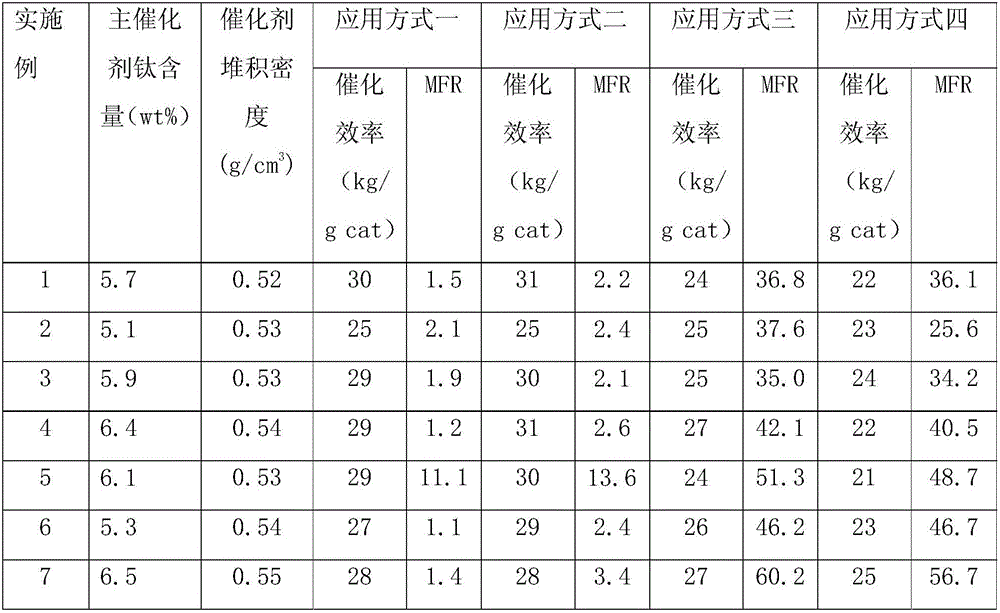

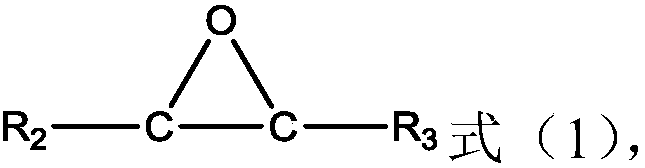

Catalyst component for olefin polymerization, preparation method of catalyst component, catalyst for olefin polymerization and olefin polymerization method

ActiveCN109400775AGood hydrogen adjustment performanceGood lookingResponse sensitivityElectron donor

The invention relates to the field of olefin polymerization and discloses a catalyst component for olefin polymerization, a preparation method of the catalyst component, a catalyst for olefin polymerization and an olefin polymerization method. The method comprises the following steps: (1) magnesium halide with the general formula of MgXY and an alcohol compound with the general formula of R1OH aremixed and emulsified, obtained emulsion is subjected to a contact reaction with an ethylene oxide compound shown as formula (I) in the description, and solid-liquid separation is performed, wherein Xis halogen, Y is halogen, C1-C14 alkyl, C6-C14 aryl, C1-C14 alkoxy or C6-C14 aryloxy; R1 is C1-C8 alkyl or C1-C8 naphthenic group; R2 and R3 are hydrogen, C1-C5 alkyl or haloalkyl independently; (2)a solid phase obtained by solid-liquid separation is directly mixed with an inert solvent without washing, and temperature of the obtained mixture is adjusted to subzero 50 DEG C-10 DEG C; (3) the mixture obtained in step (2) is subjected to a contact reaction with a titanium compound and an optional internal electron donor compound. The prepared catalyst component has high catalytic activity andbetter hydrogen response sensitivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

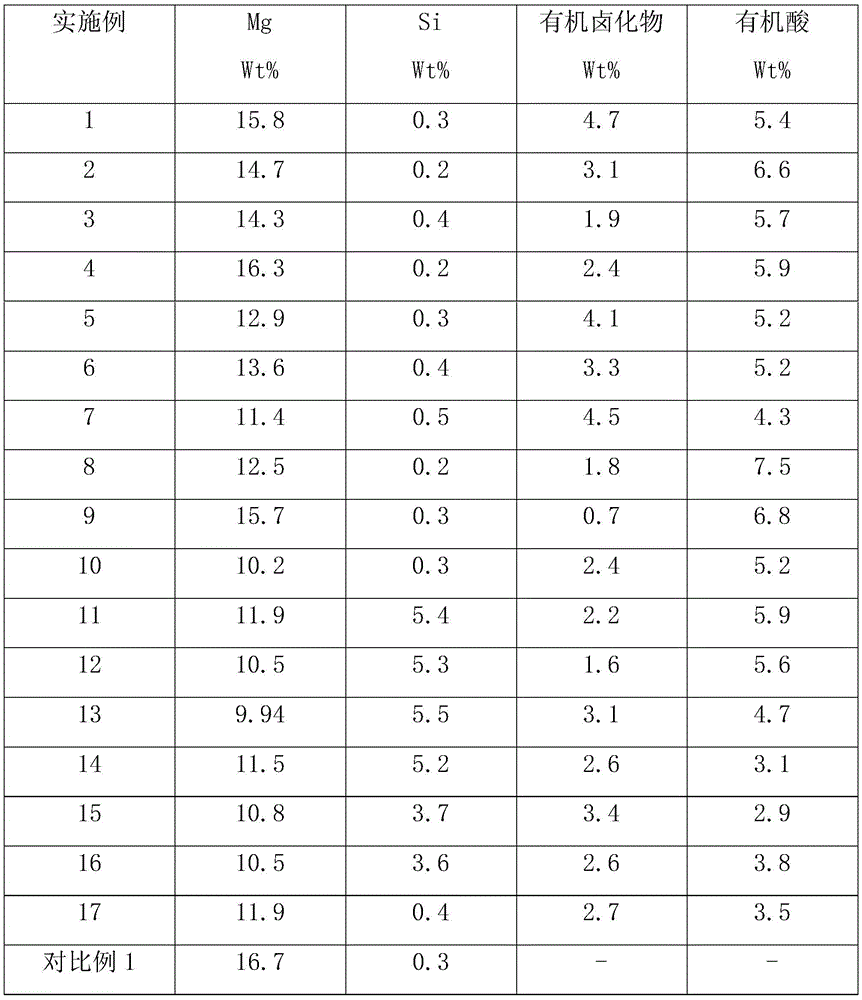

Olefin coordination polymerization catalyst and preparation method thereof

The invention relates to an olefin coordination polymerization catalyst component and a catalyst, belonging to the fields of olefin polymerization catalysts and olefin polymerization. The olefin polymerization catalyst is composed of a main catalyst and a cocatalyst. The catalyst is characterized in that the main catalyst is composed of the following components in parts by mole: 1 part of magnesium halide carrier, 5-40 parts of transition metal halide, 0.05-10 parts of C1-C20 organic alcohol, 0.001-3 parts of C1-C30 organic halide, 0.001-3 parts of C2-C30 organic acid and 0.01-10 parts of organic silicon compound; and the cocatalyst is an organic aluminum compound. The catalyst has the advantages of favorable particle shape (spherical), high bulk density and favorable flowability; and the catalyst has high activity, favorable hydrogen regulation property, favorable polyolefin particle shape (spherical) and high bulk density, and is suitable for slurry-process polymerization techniques, gas-phase polymerization techniques or combined polymerization techniques.

Owner:BEIJING UNIV OF CHEM TECH

Catalyst component for olefin polymerization and preparation method and catalyst thereof

ActiveCN107880187AGood hydrogen adjustment performanceGood particle shape and distributionOlefin polymerizationMagnesium

The invention provides a catalyst component for olefin polymerization and a preparation method and a catalyst thereof. The catalyst component contains a reaction product of at least one organic magnesium compound, at least one titanium-containing compound, at least one hydroxyl-containing compound, at least one fluorine-containing and phosphorus-containing compound and at least one additive, wherein the additive is a polybutadiene block polymethyl methacrylate block polymer. The catalyst provided by the invention not only has a good hydrogen regulating property, but also has good particle shape and distribution, so that the catalyst is more favorably used in polymerization process devices such as gas phase and slurry.

Owner:CHINA PETROLEUM & CHEM CORP +1

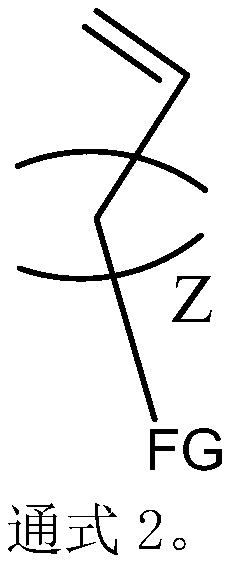

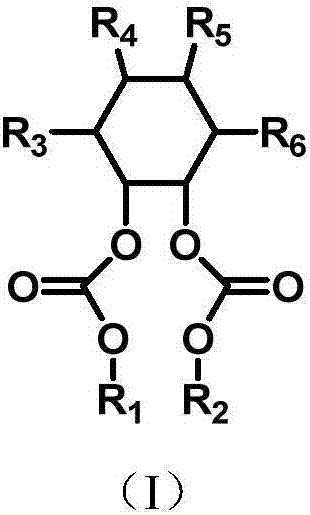

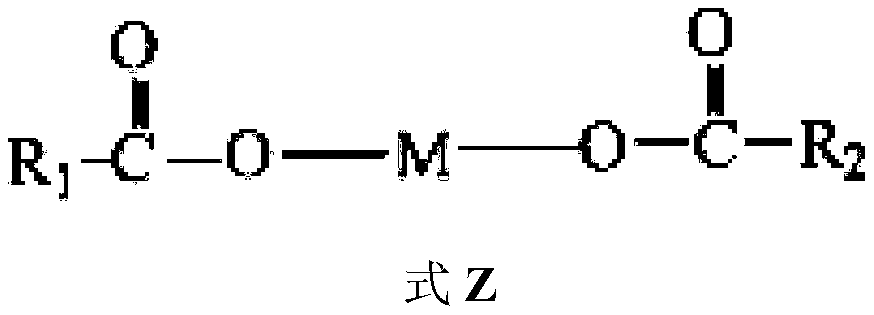

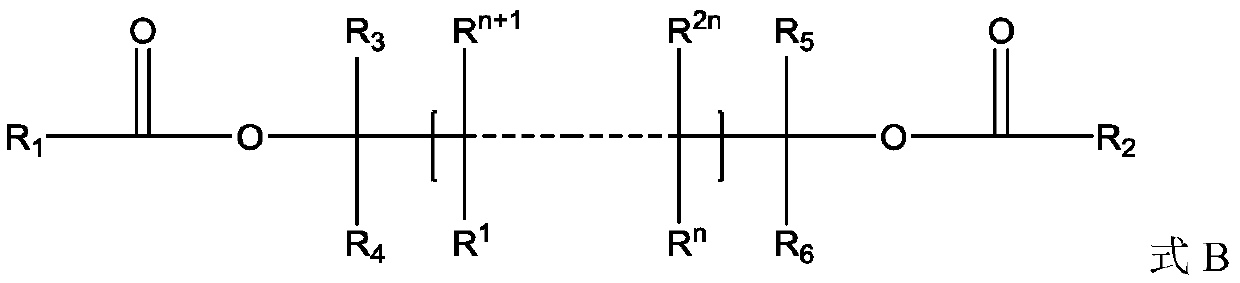

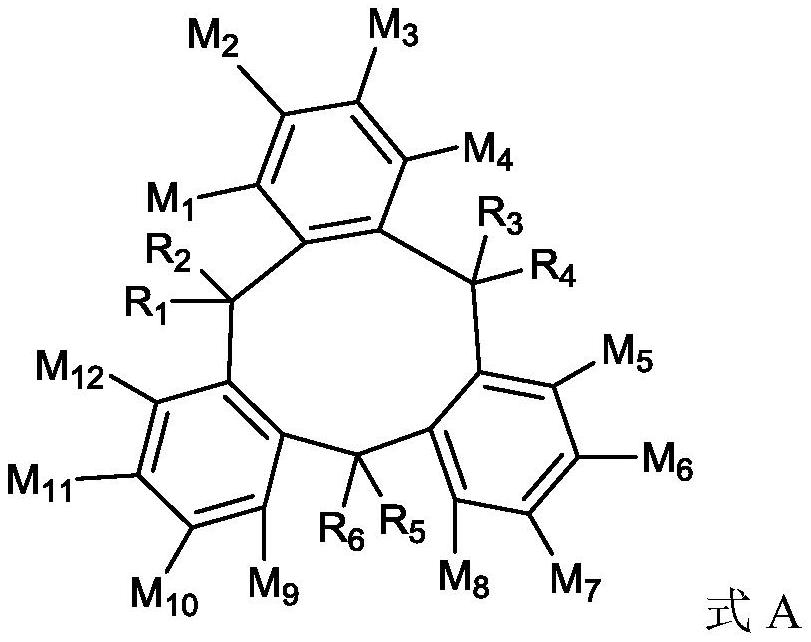

Catalyst component and catalyst system for olefin polymerization and application thereof

ActiveCN107344977AGood hydrogen adjustment performanceSuitable polymerization activityHalogenOlefin polymerization

The invention relates to a catalyst component and a catalyst system for olefin polymerization and an application thereof. The catalyst component provided by the invention consists of titanium, magnesium, halogen, and internal electron donor, wherein the internal electron donor comprises 1,2-cyclohexyl dicarbonate ester compound shown as formula (I). The catalyst component and the catalyst system comprising same provided by the invention are applicable to the development of polyolefin, particularly polypropylene, resin. (img file='DDA0000982187580000011.TIF' wi='309' he='517' / ).

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst component for olefin polymerization and preparation method and catalyst thereof

ActiveCN107880184AGood hydrogen adjustment performanceGood particle shape and distributionOlefin polymerizationMagnesium

The invention provides a catalyst component for olefin polymerization and a preparation method and a catalyst thereof. The catalyst component contains a reaction product of at least one organic magnesium compound, at least one titanium-containing compound, at least one hydroxyl-containing compound, at least one fluorine-containing organic aluminum compound and at least one additive, wherein the additive is a polybutadiene block polymethyl methacrylate block polymer. The catalyst provided by the invention not only has a good hydrogen regulating property, but also has good particle shape and distribution, so that the catalyst is more favorably used in polymerization process devices such as gas phase and slurry.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of solid catalyst component for olefin polymerization, olefin polymerization catalyst and application thereof

The invention relates to a preparation method of a solid catalyst component for olefin polymerization, an olefin polymerization catalyst and application of the olefin polymerization catalyst. The preparation method comprises the following steps: 1)dissolving magnesium halide in a solvent system, preferably a solvent system comprising an organic epoxy compound, an organic phosphorus compound and aninert diluent, to form a solution; and 2)contacting the solution obtained in the step 1)with a precipitation aid and a titanium compound to produce a mixture containing solid precipitates. Accordingto the preparation method provided by the invention, a novel catalyst with excellent particle morphology and comprehensive properties can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of solid catalyst component for olefin polymerization and olefin polymerization catalyst and use thereof

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst component preparation method and catalyst for vinyl polymerization

ActiveCN102020732BEasy to prepareThe preparation method is simple and controllablePtru catalystTitanium tetrachloride

The invention relates to a catalyst component preparation method and a catalyst for vinyl polymerization. The method comprises the following step of: after proper chemical modification is performed on a magnesiumhalide alcoholic compound at a certain temperature, directly loading active ingredients such as titanium tetrachloride and the like to prepare the catalyst which can be applied to vinyl slurry polymerization and gas-phase polymerization. The method is simple and is easy to control. When catalyzing vinyl polymerization, the catalyst prepared by the method has high hydrogen regulation sensitivity; catalyst particles are compact, are difficult to crush, have good shapes, are spherical and have relatively high catalytic activity; and the obtained polymer particles are spherical and have a small amount of fine powder.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com