Olefin efficient polymerization catalyst, and preparation method and application thereof

A technology for olefin polymerization and catalyst, applied in the preparation of catalyst and catalyst field, can solve the problems of easy adhesion to the container wall and low catalyst activity, and achieve the effects of good particle shape, high catalyst activity and low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

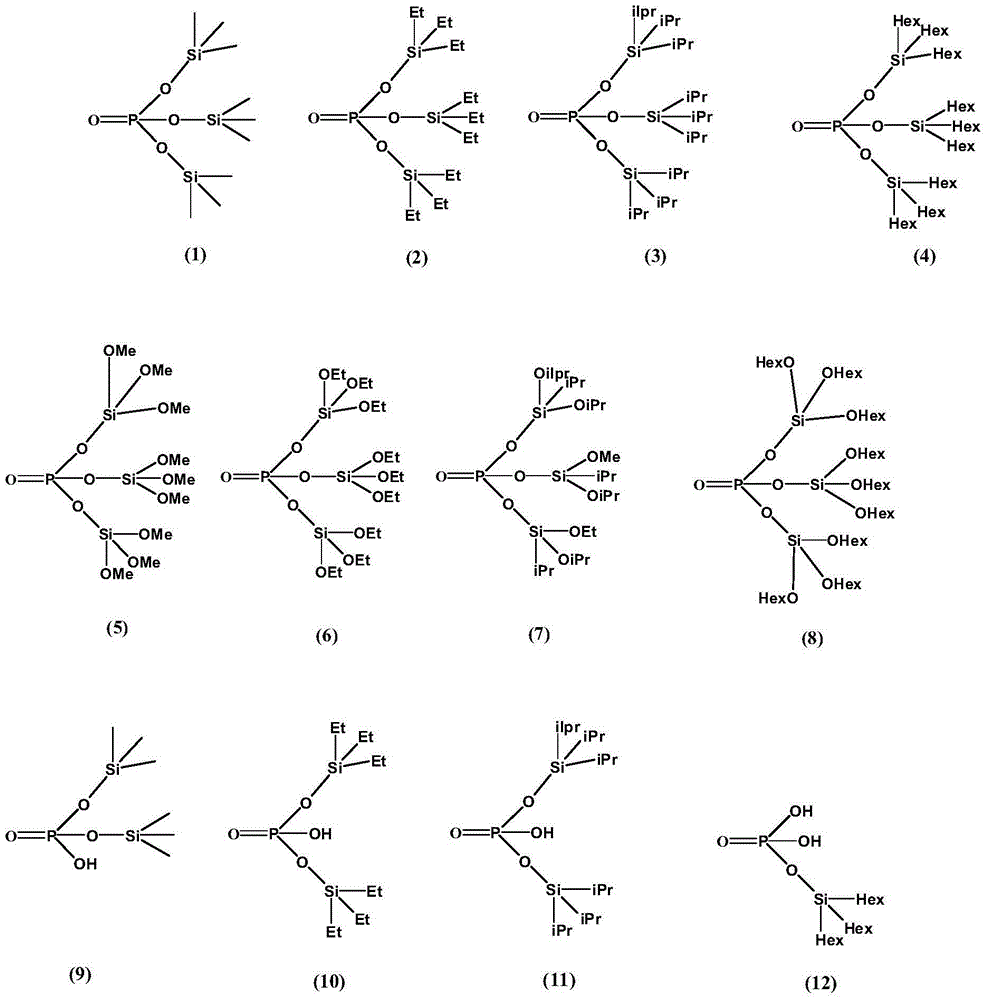

[0037] In the reactor fully replaced by nitrogen, add 1g of diethoxymagnesium, 20ml of n-decane, and 0.2g of alkoxy organic phosphate ether compound (1) conforming to the general formula (3), and stir to raise the temperature to 60°C , Reaction 2h. Lower the system to -15°C, add 30ml of titanium tetrachloride dropwise, react for 1h, then raise the temperature to 90°C for another 2h. Stop stirring, stand still, separate layers, filter, wash with hexane four times (30 ml each time), and vacuum dry at 70°C for 2 hours to obtain a spherical powder with good fluidity, non-stick container wall, uniform particle size distribution solid catalyst.

Embodiment 2

[0039] In the reactor fully replaced by nitrogen, 1g of diethoxymagnesium, 30ml of n-hexane, and 0.3g of alkoxy organic phosphate ether compound (2) conforming to the general formula (3) were sequentially added, and the temperature was raised to 70°C with stirring. Reaction 3h. Lower the system to -10°C, add 40ml of titanium tetrachloride dropwise, react for 2h, raise the temperature to 80°C and react for another 3h. Stop stirring, stand still, separate layers, filter, wash with hexane four times (30 ml each time), and dry in vacuum at 60°C for 2 hours to obtain a spherical powder with good fluidity, non-stick container wall, uniform particle size distribution solid catalyst.

Embodiment 3

[0041] In the reactor fully replaced by nitrogen, add 1g of diethoxymagnesium, 40ml of n-heptane, and 0.1g of alkoxy organic phosphate ether compound (3) conforming to the general formula (3) in sequence, and stir to raise the temperature to 80°C , Reaction 2h. Lower the system to -5°C, add 20ml of titanium tetrachloride dropwise, react for 3h, then raise the temperature to 100°C for another 2h. Stop stirring, stand still, separate layers, filter, wash with hexane four times (30 ml each time), and dry in vacuum at 80°C for 2 hours to obtain a spherical powder with good fluidity, non-stick container wall, uniform particle size distribution solid catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com