Catalyst component for olefin polymerization, preparation method of catalyst component, catalyst for olefin polymerization and olefin polymerization method

A technology of olefin polymerization and catalyst, which is applied in the field of olefin polymerization, can solve problems such as the complexity of the catalyst process, and achieve good economic benefits, improved morphology, and good hydrogen adjustment performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

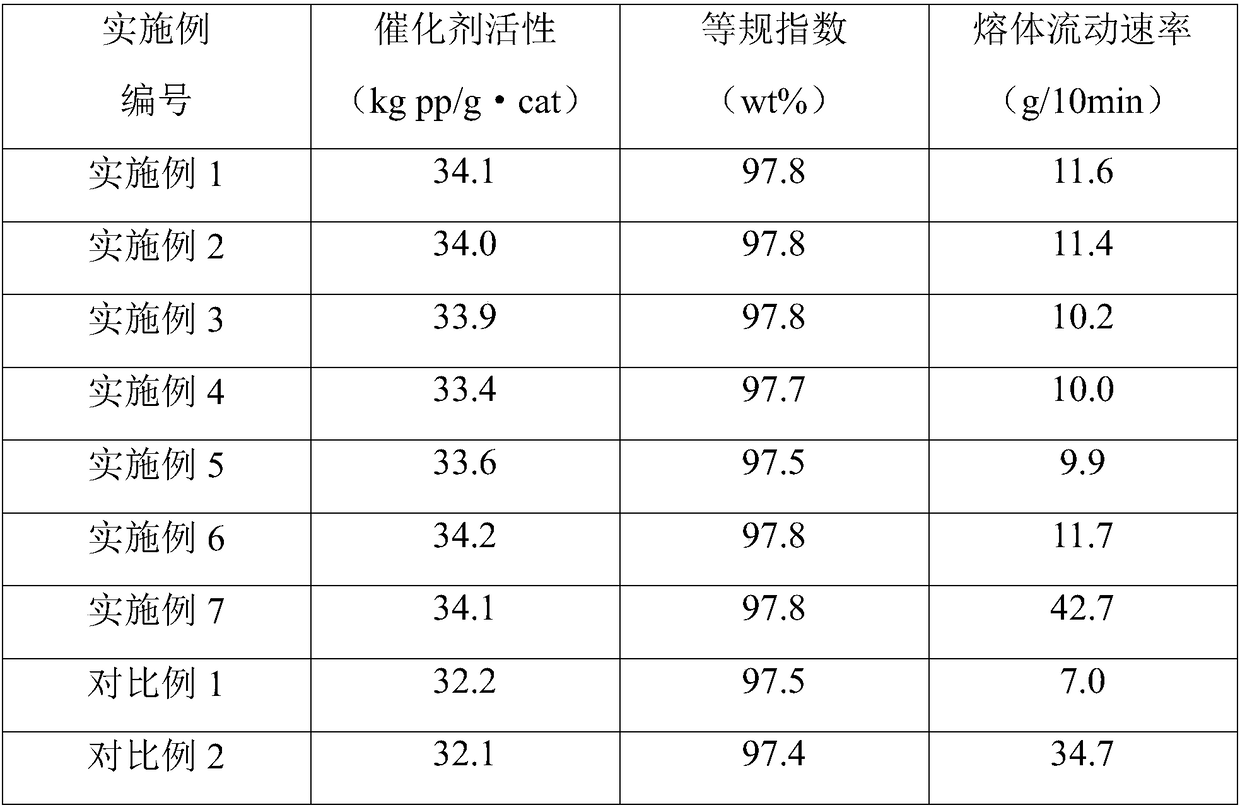

Examples

preparation example Construction

[0020] One aspect of the present invention provides a method for preparing a catalyst component for olefin polymerization, wherein the preparation method comprises:

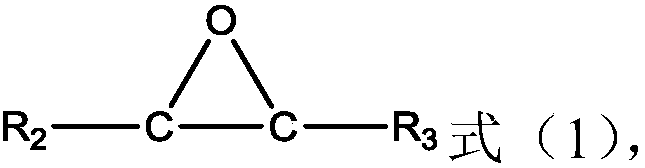

[0021] (1) the general formula is the magnesium halide of MgXY and the general formula is R 1 The alcohol compound of OH is mixed and emulsified, and the obtained emulsion is contacted and reacted with the oxirane compound shown in formula (1), and then solid-liquid separation is carried out;

[0022]

[0023] Wherein, in the general formula MgXY, X is halogen, Y is halogen, C 1 -C 14 Alkyl, C 6 -C 14 Aryl, C 1 -C 14 alkoxy or C 6 -C 14 The aryloxy group; general formula R 1 OH, R 1 for C 1 -C 8 Alkyl or C 3 -C 8 Cycloalkyl; formula (1), R 2 and R 3 each independently hydrogen, C 1 -C 5 Alkyl or haloalkyl;

[0024] (2) The solid phase obtained by solid-liquid separation is directly mixed with an inert solvent without washing, and the temperature of the resulting mixture is adjusted to -50°C t...

preparation example 1

[0064]In a 0.6L reactor, add 0.08mol magnesium chloride and 0.96mol ethanol, raise the temperature to 80°C under stirring, and react at constant temperature for 2 hours. Add 0.48mol (38ml) of epichlorohydrin, and press filter after half an hour of reaction. After the press filter product is directly mixed with 200mL hexane, cool down to -30°C, add 150mL (1.35mol) of titanium tetrachloride, and Stir at -30°C for 30min, then slowly heat up to 110°C, add 1.5mL of diisobutyl phthalate during the temperature rise, maintain at 110°C for 30min, then filter off the liquid. The obtained solid was washed twice with titanium tetrachloride and three times with hexane, and dried to obtain catalyst component C1 for olefin polymerization.

[0065] The catalyst component C1 for olefin polymerization was observed by an optical microscope, and it was not substantially broken.

preparation example 2

[0067] In a 0.6L reactor, add 0.08mol magnesium chloride and 1.6mol ethanol, raise the temperature to 90°C under stirring, and react at constant temperature for 3 hours. Add 0.32 mol of epichlorohydrin, react for half an hour, press filter, mix the press filter product with 100mL hexane directly, cool down to -20°C, add 145mL of titanium tetrachloride, and stir at -20°C for 30min, Then began to slowly raise the temperature to 120°C, and added 1.3mL of diisobutyl phthalate during the heating process, maintained at 120°C for 40min, and then filtered off the liquid. The obtained solid was washed twice with titanium tetrachloride and three times with hexane, and dried to obtain catalyst component C2 for olefin polymerization.

[0068] The catalyst component C2 for olefin polymerization was observed with an optical microscope, and it was not substantially broken.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com