Olefin polymer-containing catalyst component and catalyst used for olefin polymerization

An olefin polymer and olefin polymerization technology, which is applied in the field of polyolefin catalysts, can solve problems such as large temperature fluctuations, high fine powder content, polymer agglomeration, etc., and achieve the advantages of increasing particle strength, good hydrogen adjustment performance, and maintaining polymerization activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

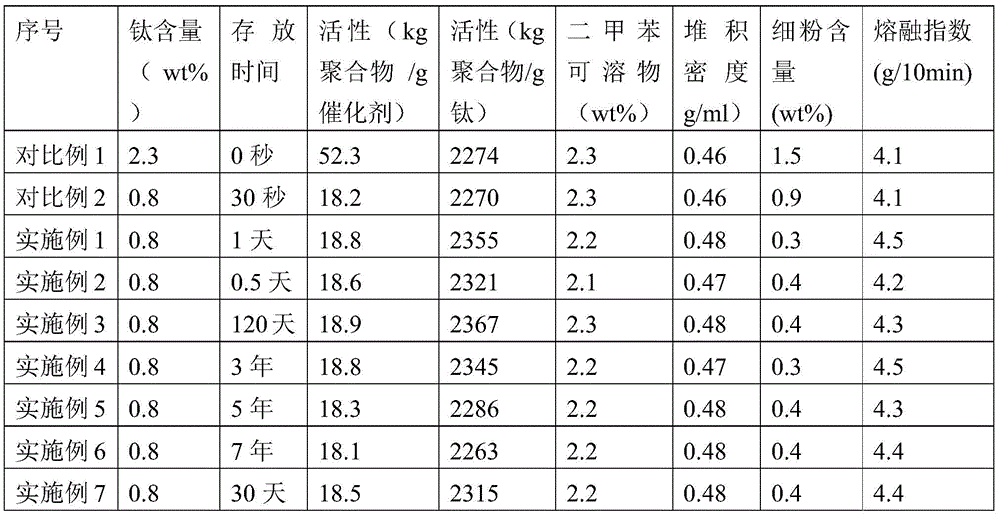

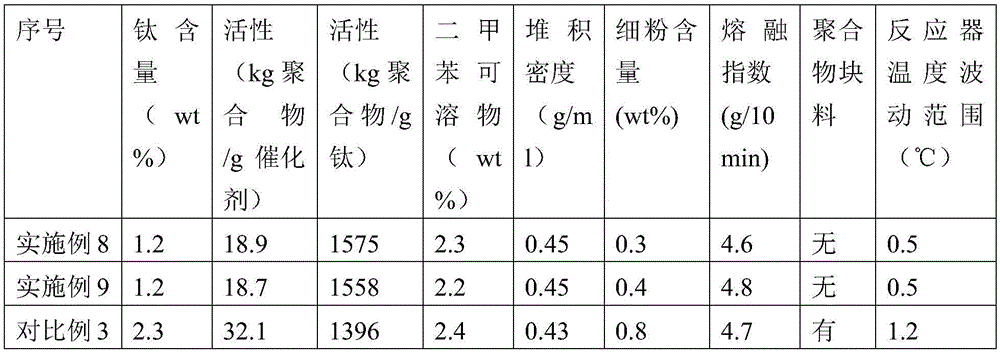

Examples

Embodiment approach

[0036] According to an exemplary embodiment of the present invention, the olefin polymerization catalyst includes at least one of a Ziegler-Natta solid catalyst, a metallocene catalyst, and a non-metallocene catalyst. Specific catalysts in the above-mentioned several types of catalysts can be adjusted, improved, evaluated and screened by common technical means known in the art, so as to select catalysts satisfying the above-mentioned conditions for use in the preparation of olefin polymerization of the present invention. In the present invention, the olefin polymer catalyst is preferably a Ziegler-Natta solid catalyst.

[0037] According to an exemplary embodiment of the present invention, the activator is an alkylaluminum compound or an oxygen-containing organoaluminum compound, such as a trialkylaluminum compound and / or methylaluminoxane, modified methylaluminoxane, and the like. Specifically, the activator includes, but is not limited to: triethylaluminum, triisobutylalumin...

Embodiment 1

[0062] 1. Preparation of catalyst components

[0063] In a 500ml 5-necked flask with stirring fully replaced by nitrogen, add 300mL of normal hexane, 20ml of 0.5mol / L triisobutylaluminum hexane solution, 10g of the catalyst prepared in Comparative Example 1, and control the temperature at 5 ℃, constant temperature for 5 minutes; feed propylene through a mass flow meter, control the feeding rate of propylene to 20 g / h, and react for 60 minutes. Stop entering propylene, wash with n-hexane, filter, and vacuum-dry to obtain 27.8 g of solid, the analyzed titanium content is 0.8 (wt) %, and the polymer content is 64.0 (wt) %. The catalyst was stored in the form of dry powder at room temperature under the protection of nitrogen, and the storage time was recorded.

[0064] 2. Propylene polymerization

[0065] Catalysts were used for polymerization evaluation after storage at room temperature for 24 hours. After the 5L stainless steel reactor was fully replaced by nitrogen, 5 mL of ...

Embodiment 2

[0069] The only difference between using the catalyst component prepared in Example 1 and the polymerization conditions in Example 1 is that the catalyst component was placed at room temperature for 12 hours. The analysis results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com