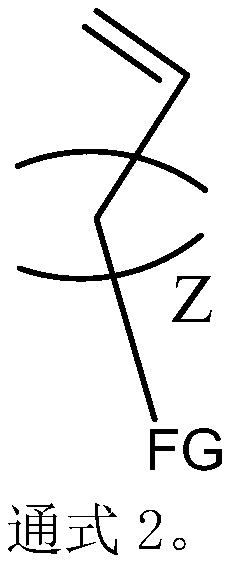

Alkoxy metal powder as well as preparation method and application thereof

A technology based on metal and alkoxide, which is applied in the field of metal alkoxide powder and preparation, and can solve the problems of heavy pollution and high energy consumption of metal magnesium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

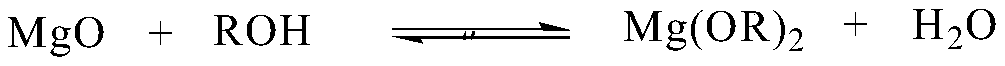

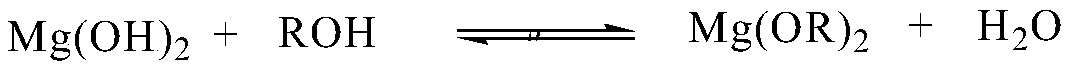

Method used

Image

Examples

Embodiment 1

[0068] In a reactor fully replaced with nitrogen, add 30 g of calcium dichloride and 100 mL of hexane at 25°C, stir for 0.5 hours, add 25 g of sodium ethoxide, stir, and the reaction temperature rises to 60°C, and react for 6 hours. Stop the reaction, lower the temperature to 30°C, filter, wash with hexane three times, and vacuum-dry at 50°C for 1 hour to obtain 33 g of calcium ethoxide powder, BD=0.39.

Embodiment 2

[0070] In the reactor fully replaced by nitrogen, add 45g of magnesium dichloride and 50mL of hexane at 5°C, stir for 1 hour, add 20g of sodium ethoxide, stir, the reaction temperature rises to 80°C, and react for 10 hours. Stop the reaction, lower the temperature to 25°C, filter, wash with hexane four times, and dry in vacuum at 40°C for 2 hours to obtain 48 grams of magnesium ethoxide powder, BD=0.40.

Embodiment 3

[0072] In a reactor fully replaced by nitrogen, add 40 g of aluminum trichloride and 80 mL of heptane at 35°C, stir for 6 hours, add 41 g of potassium ethoxide, stir, the reaction temperature rises to 120°C, and react for 35 hours. Stop the reaction, lower the temperature to 20°C, filter, wash with hexane four times, and vacuum-dry at 60°C for 1 hour to obtain 42 grams of aluminum ethoxide powder, BD=0.39.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com