Alkene coordination polymerization catalyst as well as preparation method and application thereof

A technology of coordination polymerization and catalyst, applied in the field of olefin polymerization catalyst and olefin polymerization, can solve problems such as poor hydrogen regulation performance of catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

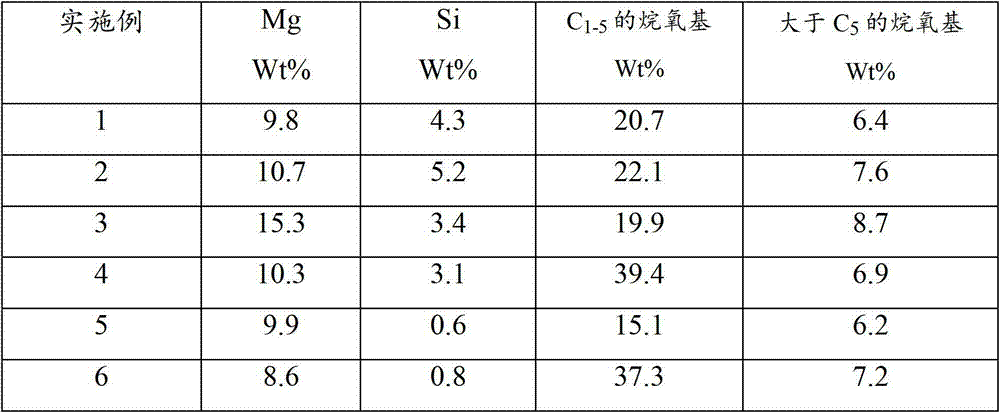

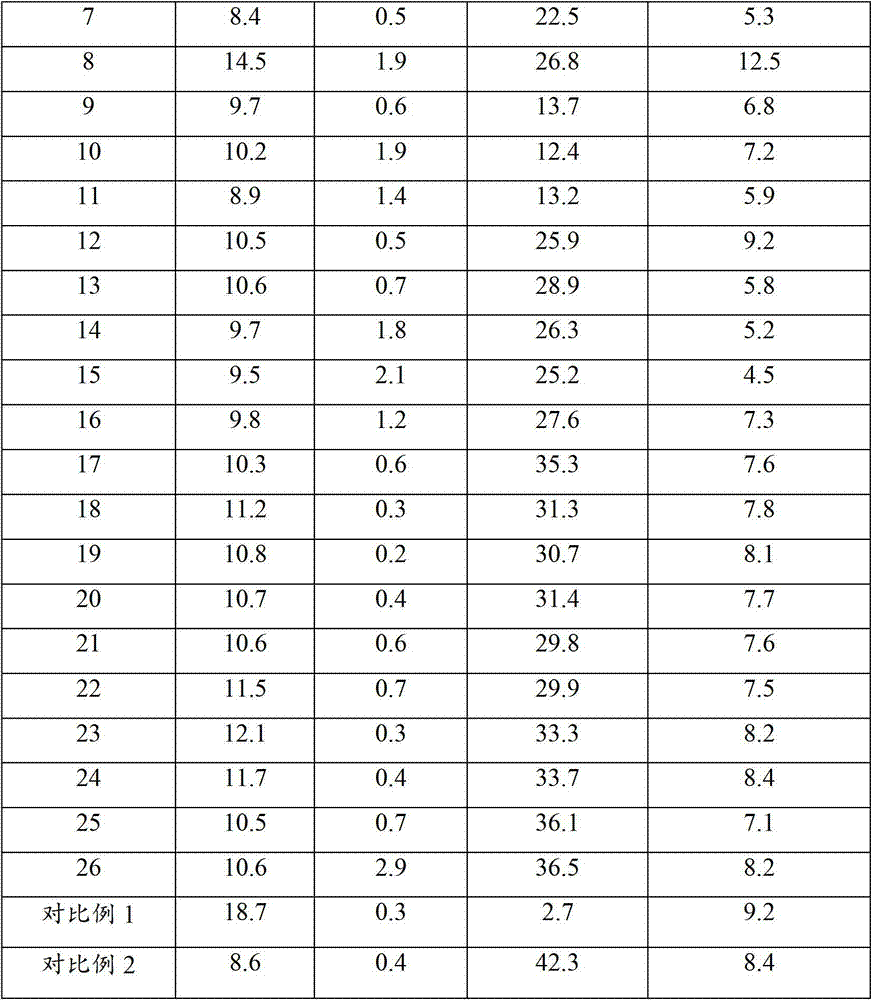

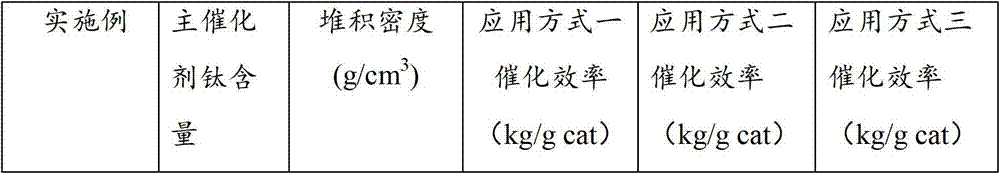

Examples

Embodiment 1

[0038] Add 1g of magnesium dichloride, 20ml of n-decane, 0.2ml of ethanol, and 6.5ml of isooctyl alcohol into the reactor fully replaced by nitrogen, stir and heat up to 120°C, react for 2h, and the solid is completely dissolved to form a uniform solution. Cool down to 50°C, add 5ml of tetraethoxysilane, and react for 2h. Lower the system to -15°C, add 30ml of titanium tetrachloride dropwise, then add 0.01g of fructose, react for 1h, raise the temperature to 110°C for another 2h. Stop stirring, let stand, separate layers, filter, wash with hexane four times (30 ml each time), and vacuum-dry at 70°C for 2 hours to obtain a spherical powdery solid procatalyst with good fluidity, uniform particle size distribution.

Embodiment 2

[0040]Add 1g of magnesium dichloride, 30ml of n-decane, 0.25ml of ethanol, and 7ml of isooctyl alcohol into the reactor fully replaced by nitrogen, stir and heat up to 120°C, react for 2h, and the solid dissolves completely to form a uniform solution. Cool down to 60°C, add 0.5ml of tetraethoxysilane, and react for 2h. Lower the system to -10°C, add dropwise 20ml of titanium tetrachloride, and then add 0.2 g of tetrahydroxyoctasiloxane, react for 1 hour, then raise the temperature to 100°C for another 3 hours. Stop stirring, let stand, separate layers, filter, and wash twice with hexane (30 ml each time). Add 20ml of n-decane to the reactor at 10°C, dropwise add 40ml of titanium tetrachloride, react for 1h, raise the temperature to 65°C and react for another 2h. Stop stirring, let stand, separate layers, filter, wash with hexane four times (30 ml each time), and vacuum-dry at 60° C. for 3 hours to obtain a spherical powdery solid procatalyst with good fluidity and uniform par...

Embodiment 3

[0042] Add 1g of magnesium dichloride, 20ml of n-decane, 0.2ml of ethanol, and 8ml of isooctyl alcohol into the reactor fully replaced by nitrogen, stir and heat up to 100°C, react for 2h, and the solid dissolves completely to form a uniform solution. Cool down to 50°C, add 2ml of tetraethoxysilane, and react for 2h. Lower the system to -15°C, add 15ml of titanium tetrachloride dropwise, and then add 0.2 g of tetrahydroxy POSS, react for 1 hour, raise the temperature to 65°C, and react for another 2 hours. Stop stirring, stand still, separate layers, filter, wash twice with hexane (30 ml each time), dry in vacuum at 70°C for 2 hours, add 20ml of n-decane to the reactor at 0°C, add dropwise 25ml of tetrachloride TiO, reacted for 1h, and raised the temperature to 65°C for 2h. Stop stirring, let stand, separate layers, filter, wash with hexane four times (30 ml each time), and vacuum dry at 50°C for 4 hours to obtain a spherical powdery solid procatalyst with good fluidity and u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com