A catalyst component used for olefin polymerization, and a preparing method and applications thereof

A technology of olefin polymerization and olefin polymer, applied in the field of polyolefin catalysts, can solve problems such as low efficiency, long pre-polymerization time, and decreased catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

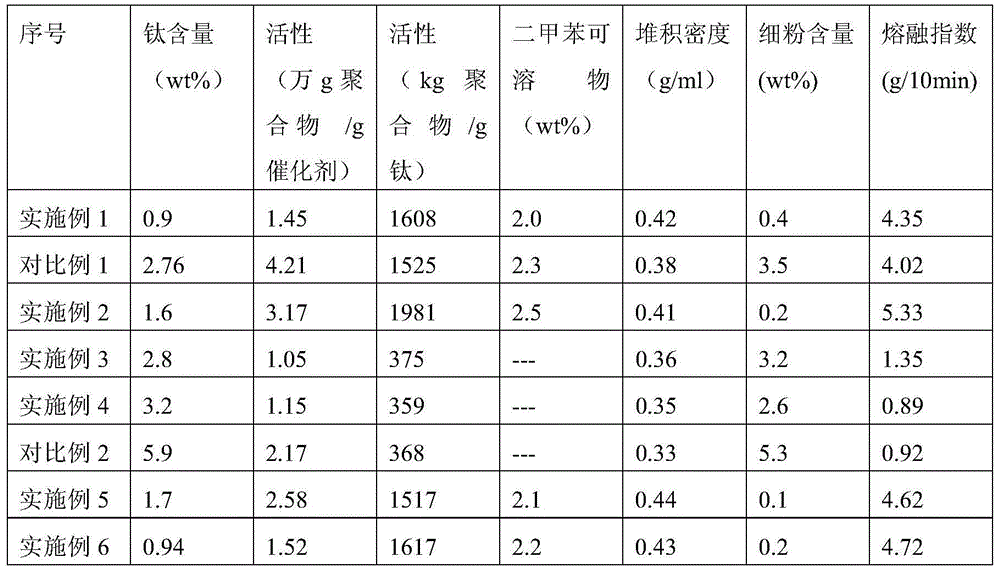

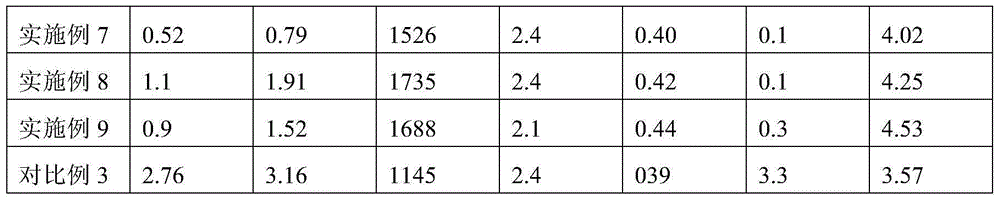

Examples

Embodiment 1

[0100] 1. Preparation of catalyst components:

[0101] In a 500ml stirred 5-neck flask fully replaced by nitrogen, add 10g of diethoxymagnesium and 80mL of toluene to prepare a suspension, then maintain 0°C and add 20mL of titanium tetrachloride dropwise, and then slowly raise the temperature to 80°C , add 3.6mL DNBP (dibutyl phthalate), then continue to heat up to 110°C for 2 hours at a constant temperature, then press filter the liquid, filter off the liquid, and wash the obtained solid three times with 100mL toluene at 90°C. Then, a mixed solution of 20 ml of titanium tetrachloride and 80 ml of toluene was added and stirred at 110° C. for 1 hour, and the liquid was filtered off. The obtained solid was washed 5 times with 100 mL of hexane at 60° C., and the liquid was filtered off. Add 300mL of n-hexane into the flask, add 4ml of 0.5mol / L triethylaluminum hexane solution, control the temperature at 5°C, and keep the temperature constant for 5 minutes; feed ethylene gas thro...

Embodiment 2

[0110] 1. Preparation of catalyst components:

[0111] In a 500ml stirred 5-neck flask fully replaced by nitrogen, add 10g of diethoxymagnesium and 80mL of toluene to prepare a suspension, then maintain 0°C and dropwise add 80mL of titanium tetrachloride, and slowly heat up to 80°C, add 3.6mL DIBP (diisobutyl phthalate), then continue to heat up to 120°C for 2 hours at a constant temperature, then press filter the liquid clean, filter off the liquid, and use 120mL of titanium tetrachloride to obtain the solid at 125 ℃ washing 3 times. The obtained solid was washed twice with 150 mL of hexane at 60°C and twice at room temperature. Add 300mL of n-hexane into the flask, add 8ml of 0.5mol / L triisobutylaluminum hexane solution, control the temperature at 18°C, and keep the temperature constant for 20 minutes; feed propylene gas through a mass flow meter, and control the feeding speed of propylene 20g / h, react for 60 minutes. The air intake was stopped, and nitrogen replacement w...

Embodiment 3

[0115] 1. Preparation of catalyst components:

[0116]In a 500ml stirred 5-neck flask fully replaced by nitrogen, add 10g of diethoxymagnesium and 80mL of toluene to prepare a suspension, then maintain 0°C and add 20mL of titanium tetrachloride dropwise, and then slowly raise the temperature to 110°C The temperature was kept constant for 2 hours, and then the liquid was press-filtered to remove the liquid, and the obtained solid was washed three times with 100 mL of toluene at 90°C. Then, a mixed solution of 20 ml of titanium tetrachloride and 80 ml of toluene was added and stirred at 110° C. for 1 hour, and the liquid was filtered off. The obtained solid was washed 5 times with 100 mL of hexane at 60° C., and the liquid was filtered off. Add 300mL of n-hexane into the flask, add 4ml of 0.5mol / L tri-n-hexylaluminum hexane solution, control the temperature at 5°C, and keep the temperature constant for 5 minutes; feed ethylene gas through a mass flow meter, and control the feed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com