Patents

Literature

124results about How to "Less fine powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

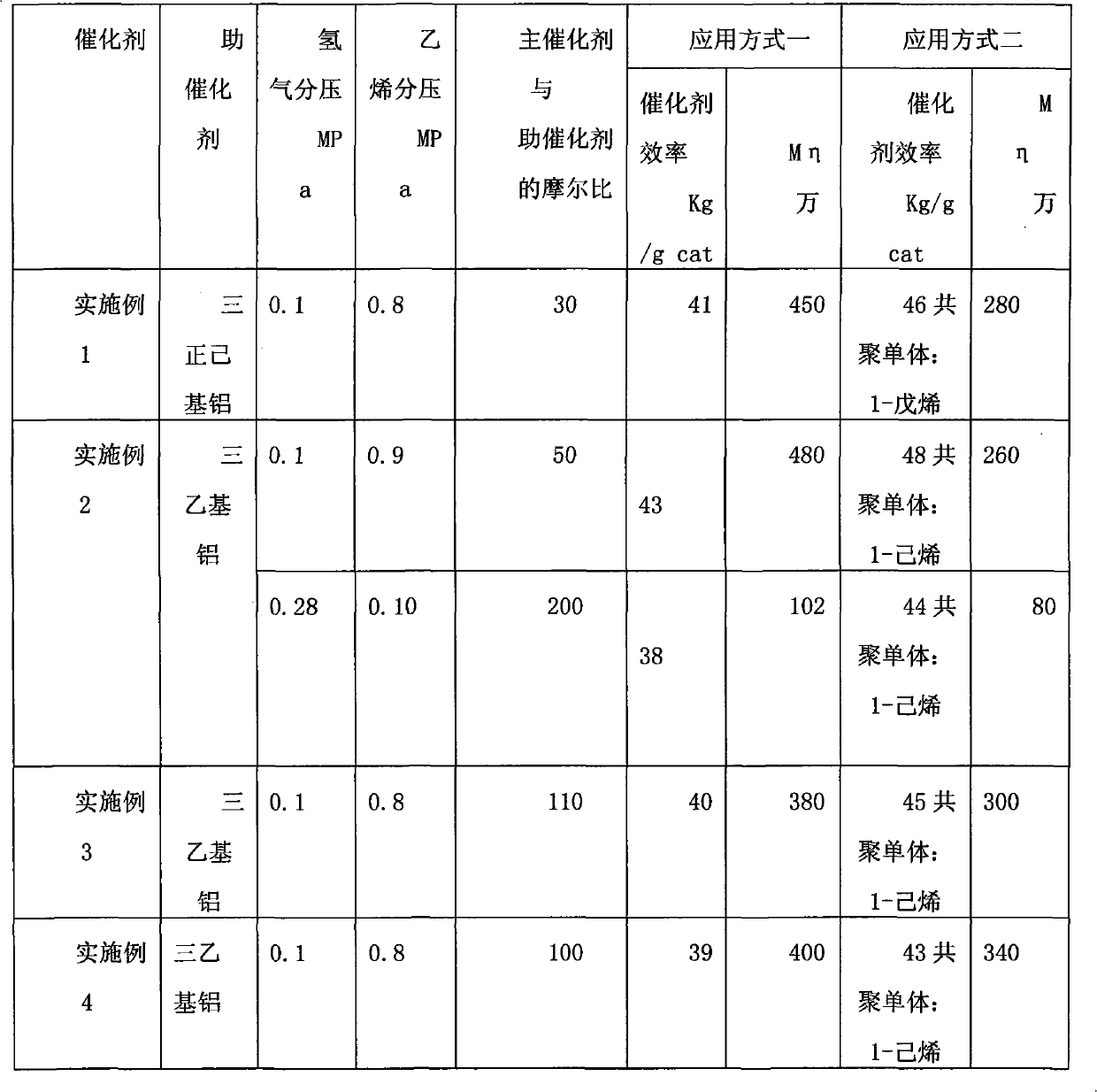

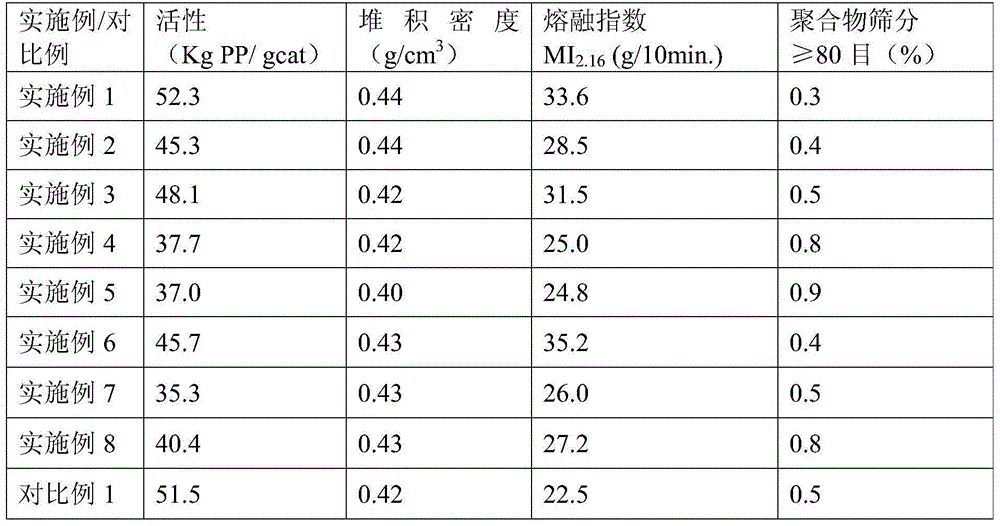

Catalyst used for olefine polymerization or copolymerization, its preparation method and application

A catalyst for the polymerization or copdymerization of olefin is composed of Ti-contained solid component A, organoaluminium compound B and organosilicon compound C. Said A is prepared through dissolving magnesium halide in the mixture of organic epoxy compound, organophosphorus compound and inertial diluent, adding educing agent and magnesium halide or its derivatives to educe out Mg / Ti contained deposit, and carrying a surface modifier, a titanium halide or derivative and an electronic doner. It can be used for the polymerization of propene or copolymerization of propene-ethene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Magnesium halide alcohol adduct and preparation method and application thereof

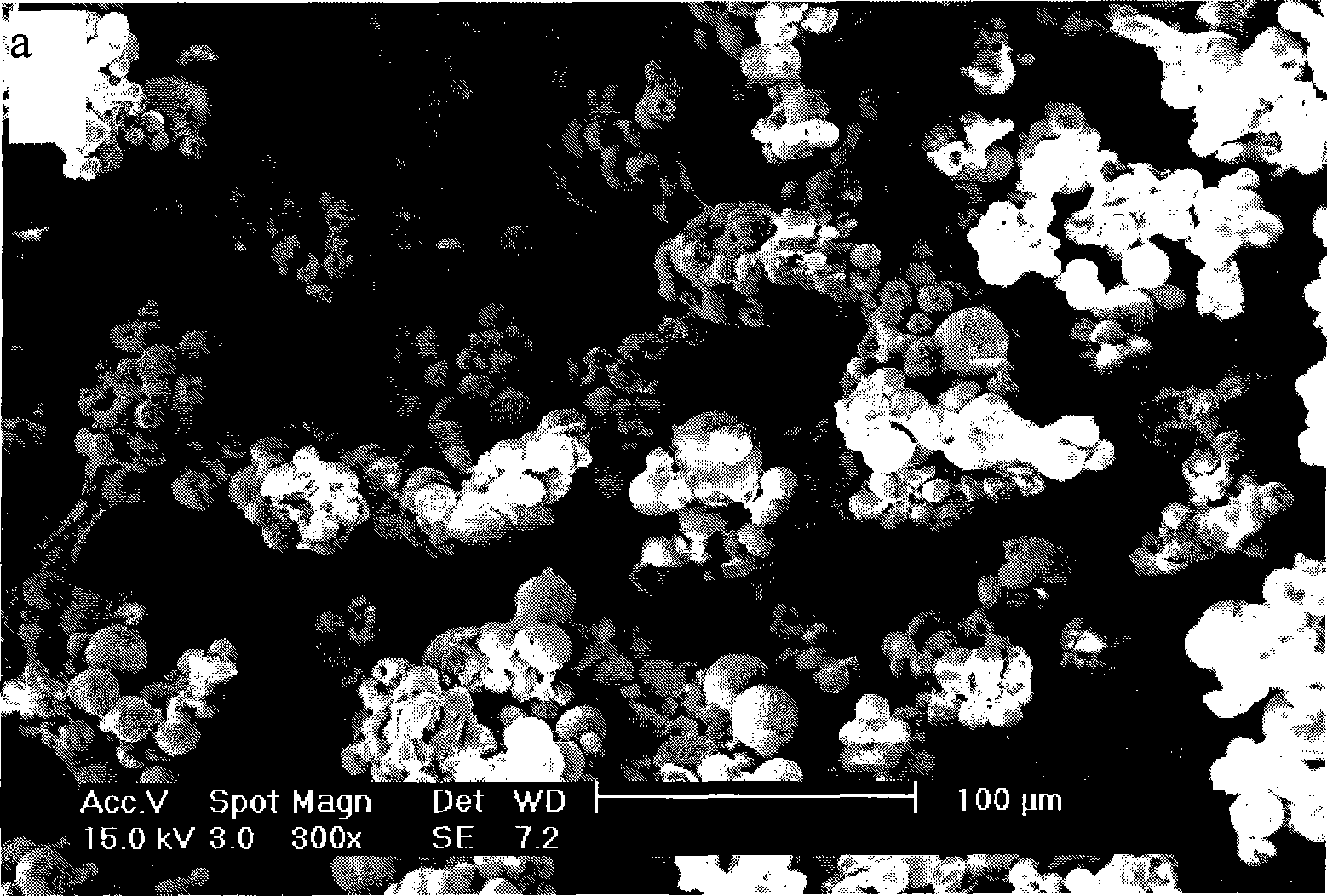

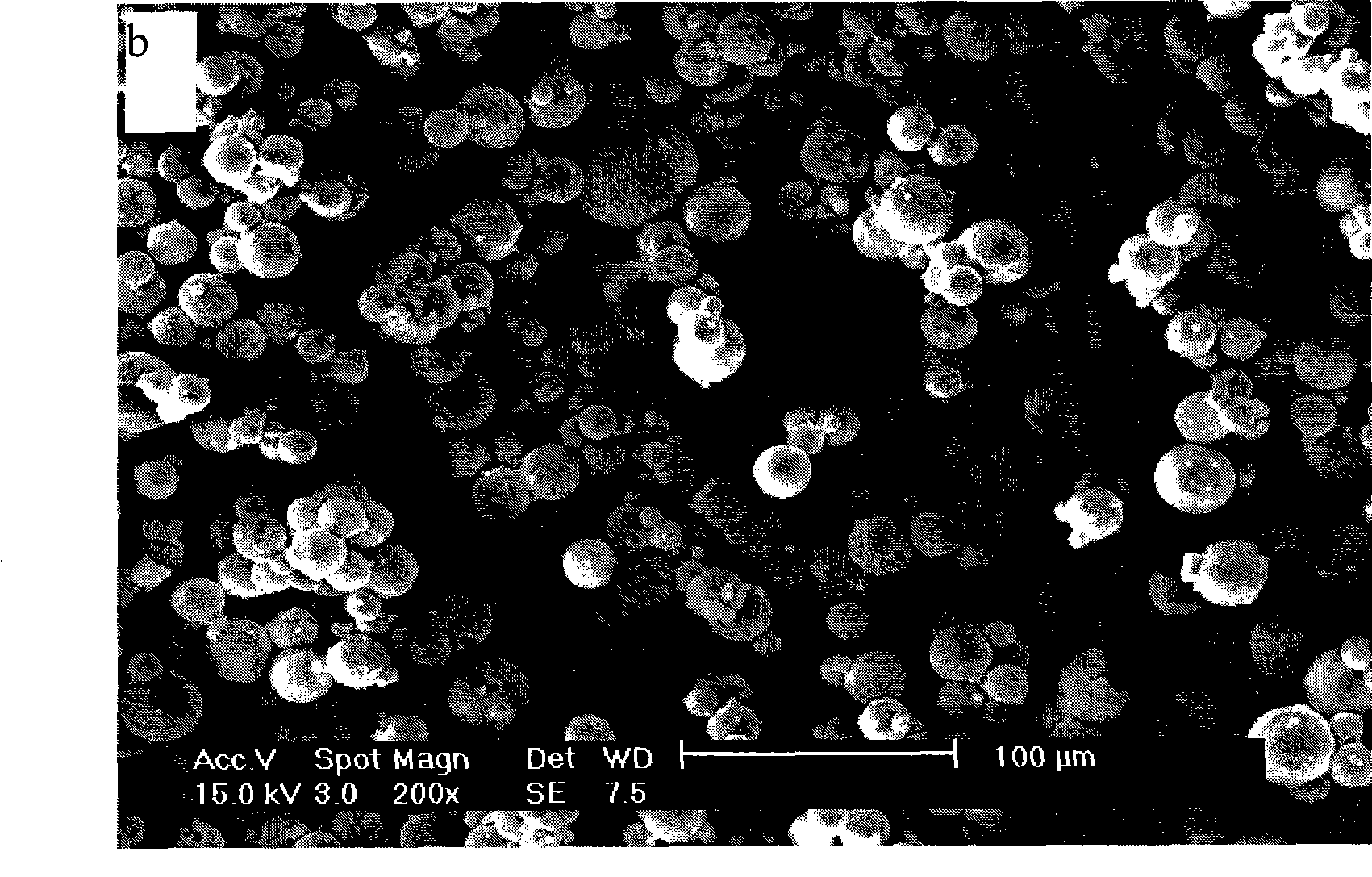

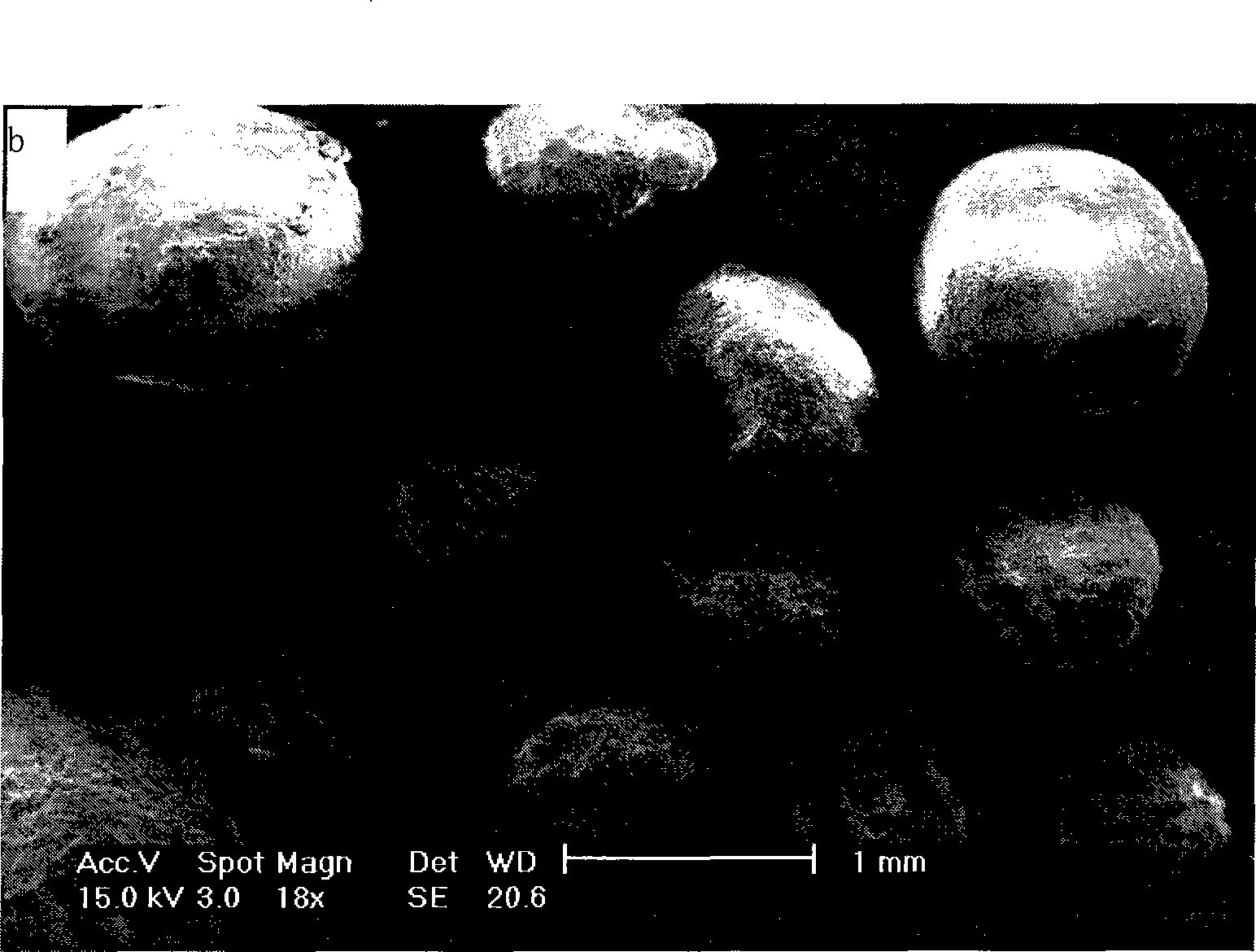

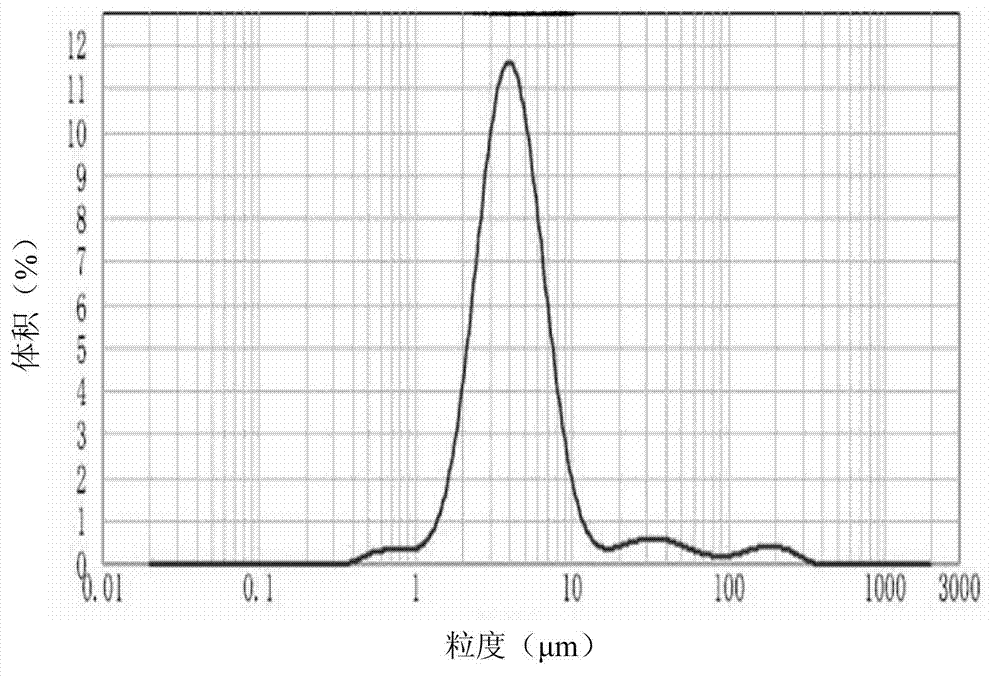

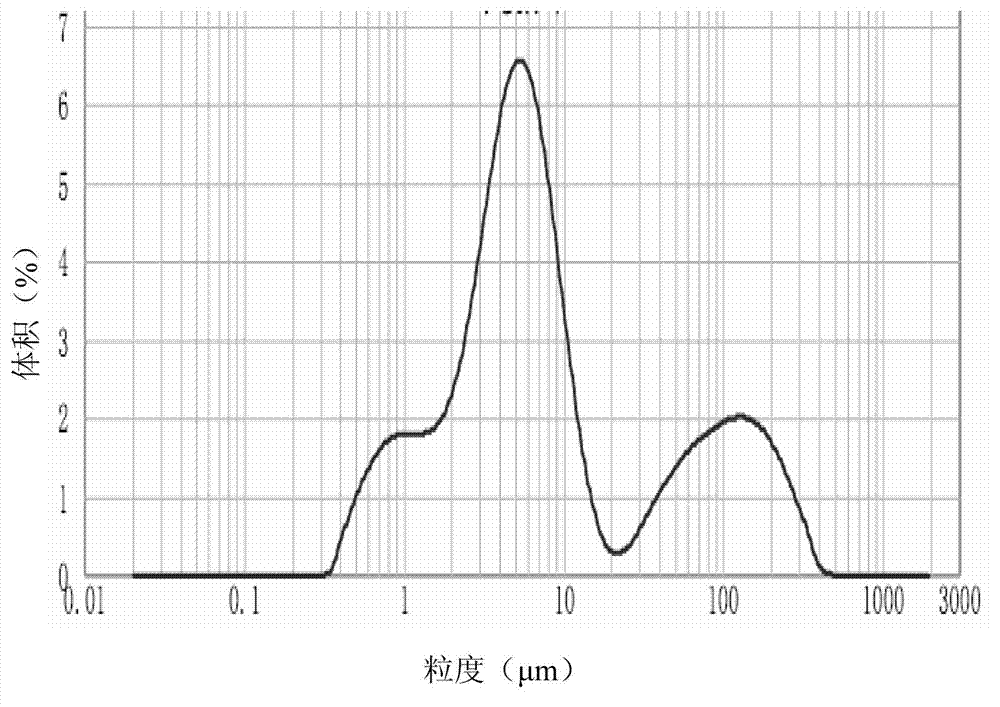

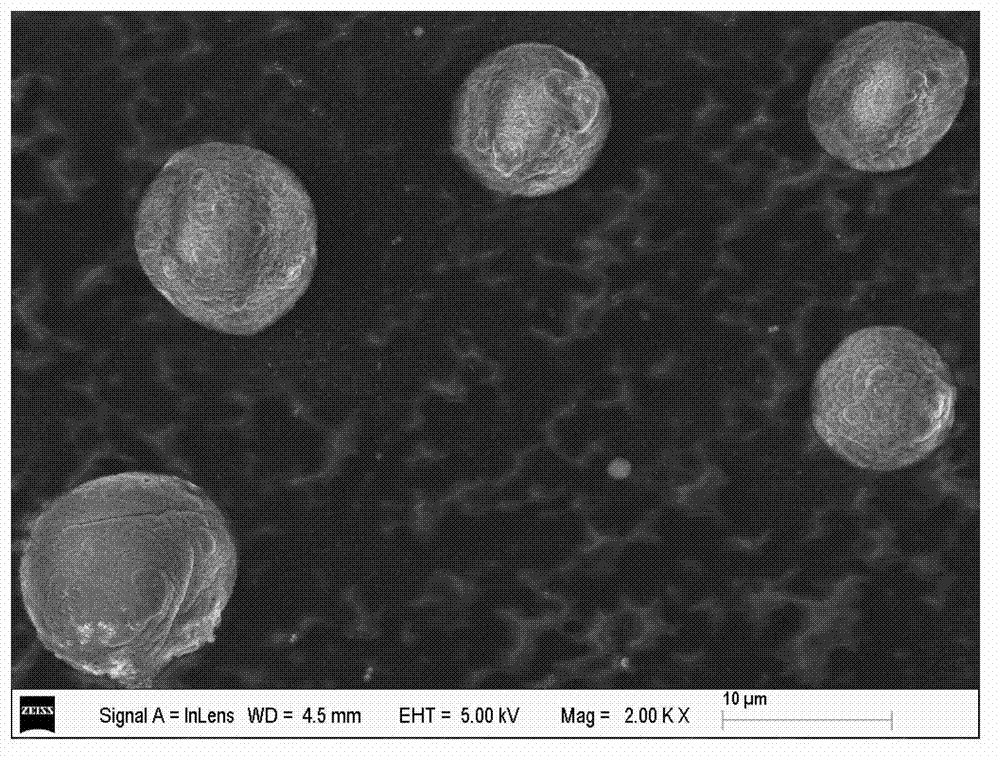

The invention relates to a catalyst component used for olefin polymerization, specially for propylene polymerization or copolymerization, in particular to a novel spherical alcohol adduct containing ternary components of magnesium halide, alcohol and polyether as well as the application of the alcohol adduct in the preparation of olefin polymerization catalyst. When the catalyst prepared by taking the alcohol adduct as a carrier is used for olefin polymerization, especially for propylene polymerization, better polymerization activity, good polymer grain forms and less fine powders are shown. The invention is used in the field of petrochemical industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst, preparation method and application for olefin polymerization or copolymerization

This invention relates to a catalyst system which is used for alkenes polymerizing or copolymerization, it includes solid catalyst composition A that contains titanium and organic Aluminum compound B, silicoorganic compound C, in the composing process of catalyst composition A, use aldyl ester of aryl group mon-carboxylic acid and aldyl ester of fatty series or multielement carboxylic acid of aryl group for reasonable combination, among them aldyl ester of aryl group mon-carboxylic can play a role of assisting separating agent, it is useful to separate catalyst particle; Meanwhile it is used as electron donor, it also can load on the surface of catalytic agent together with compound of multielement carboxylic esters, improve the surface structure of catalytic agent, thus improve the catalyzing function of catalytic agent. This catalytic agent that is used for propylene polymerizing has high catalytic activity and anti- impurity function, particle appearance of catalytic agent is good, particles distribute narrowly, hydro-adjusting function of catalytic agent is good, it is useful for many polymerizing technology such as seriflux method, noumenon method and gas method, molecular weight distribution of polymer is narrow, particle appearance of polymer is good, fine grits is little; Its fine anti-impurity function can effectively reduce production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

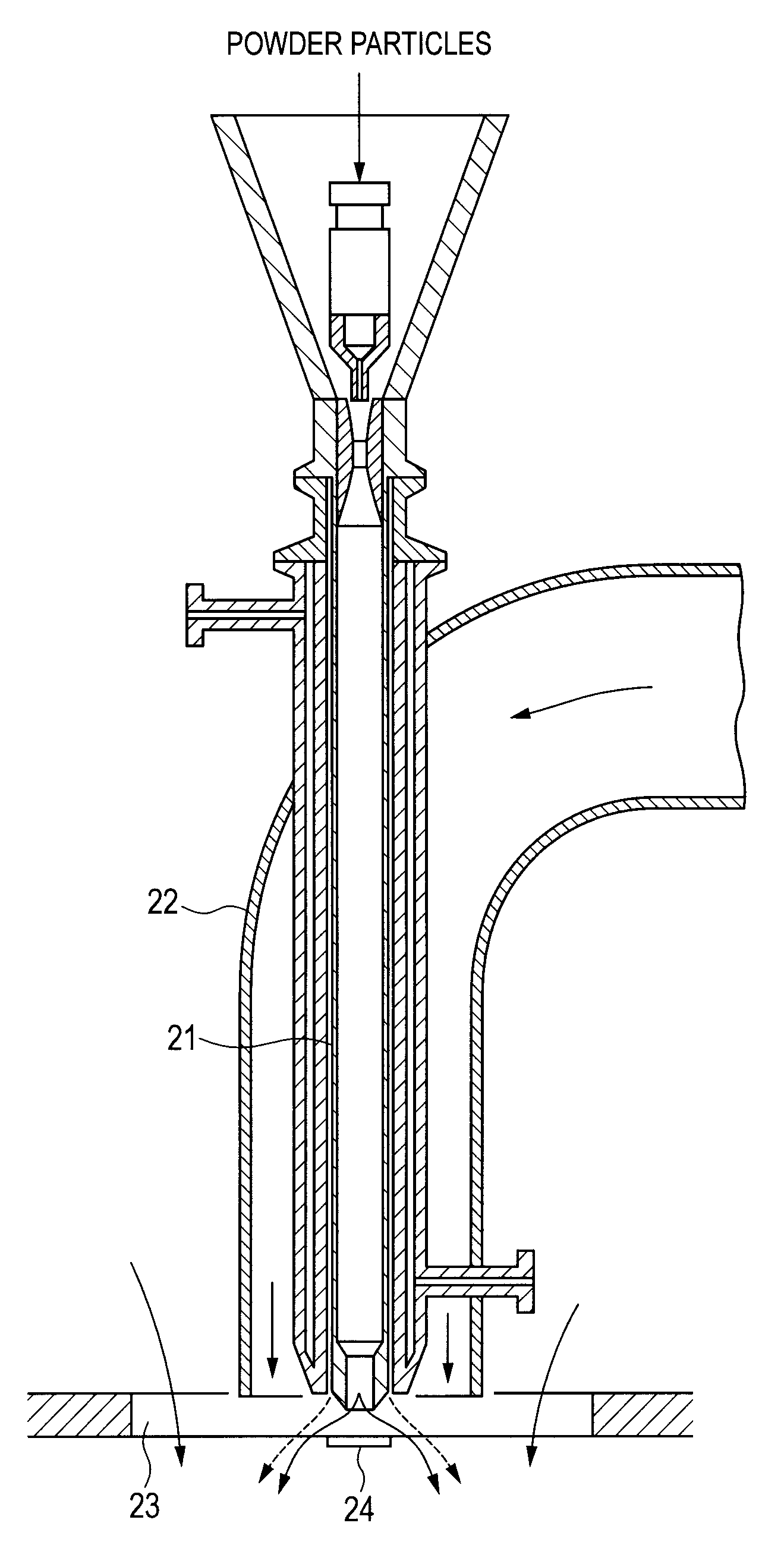

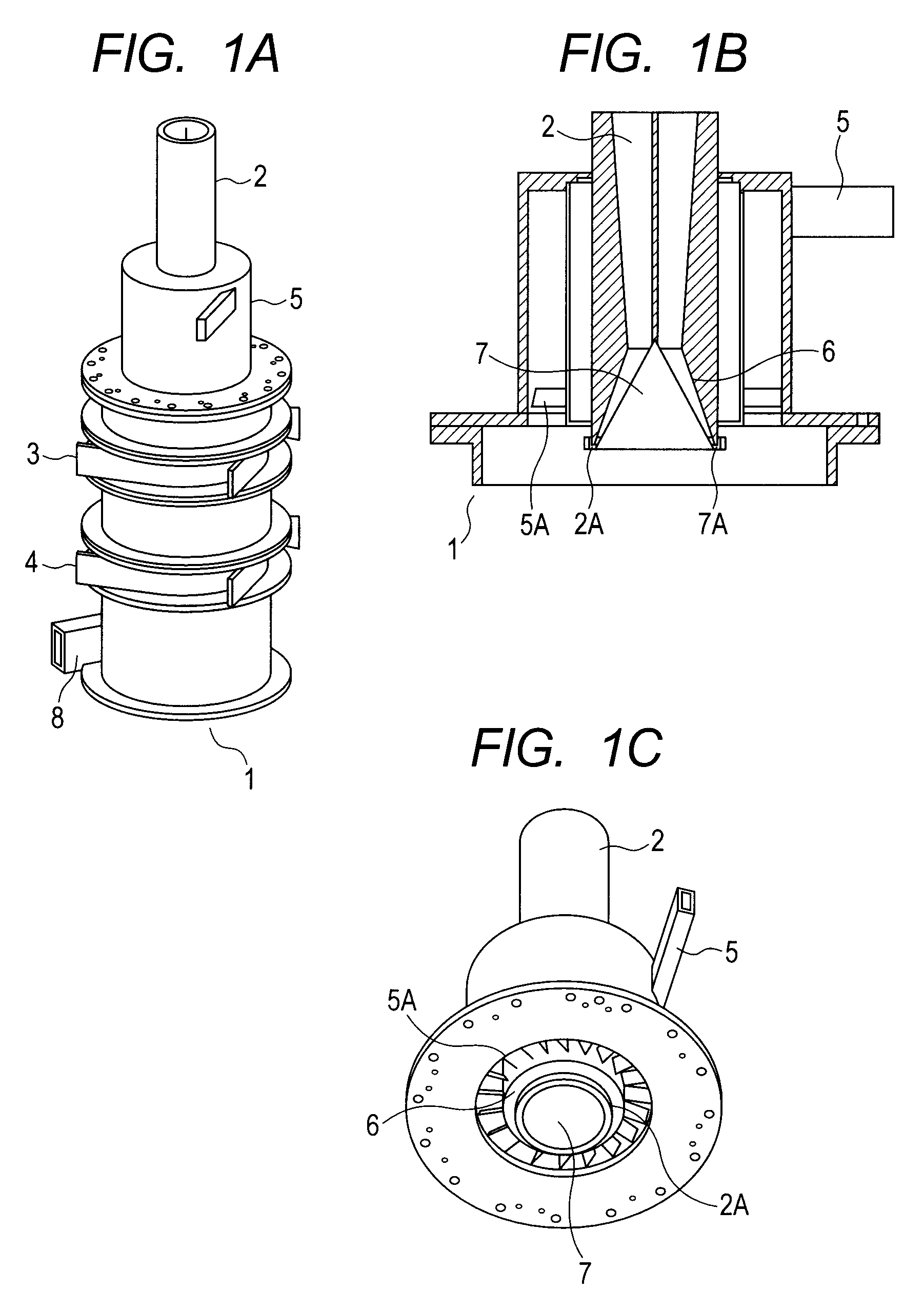

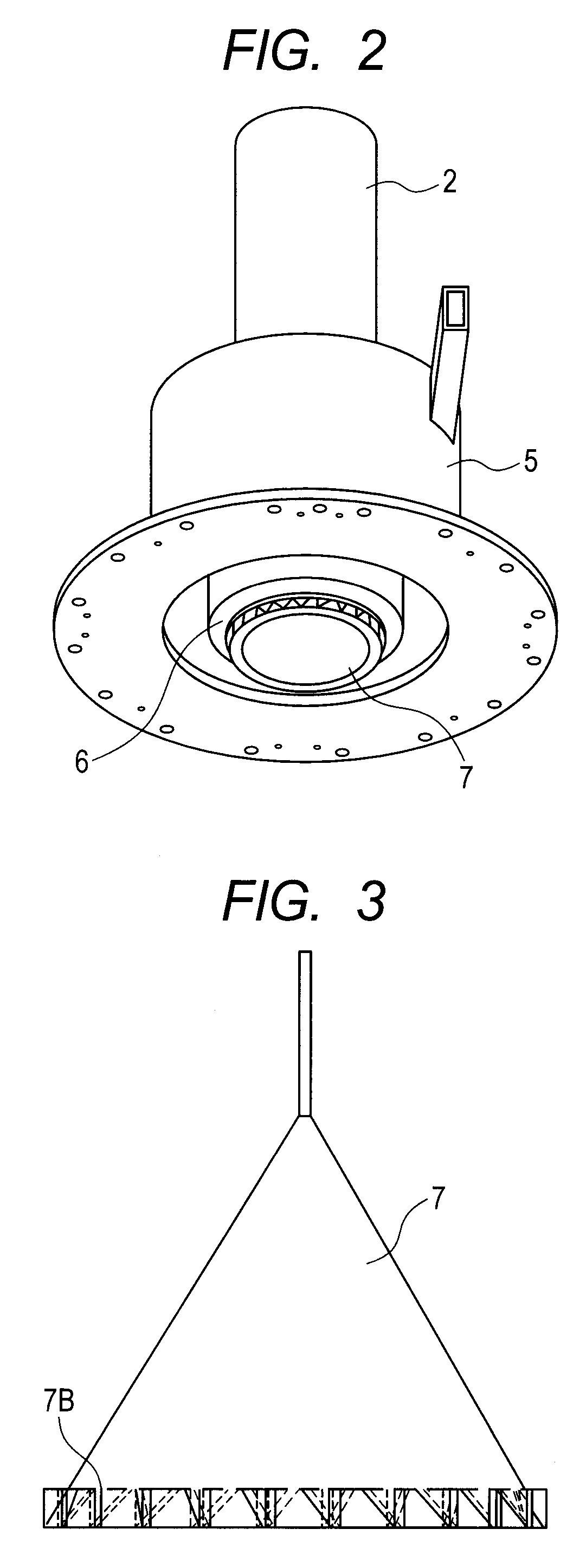

Heat treatment apparatus and method for manufacturing toner

InactiveUS9075328B2Suppress coarseningLess fine powderDrying solid materials with heatDrying gas arrangementsCoarse particleHeat treated

Owner:CANON KK

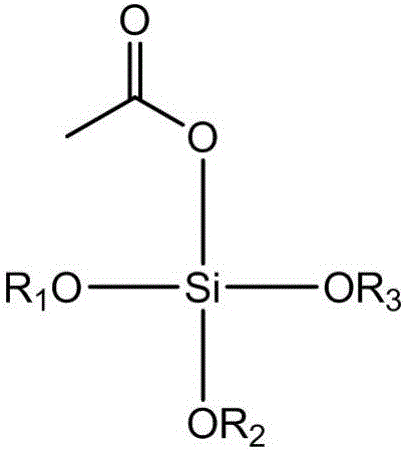

Olefin polymerization catalyst as well as preparation method and application thereof

The invention relates to an olefin polymerization catalyst as well as a preparation method and application of the olefin polymerization catalyst. The olefin polymerization catalyst comprises a primary catalyst and a promoter catalyst, wherein the primary catalyst comprises magnesium halide, transition metal halide, organic alcoholate, phosphate ester compound, epoxy haloalkane compound, organo-siloxane compound and organic alcohol ether compound; and the promoter catalyst comprises one or several kinds of the combination of organoaluminum compound. The preparation method of the olefin polymerization catalyst comprises the steps as follows: dispersing the magnesium halide into an organic solvent; sequentially adding the organic alcoholate, the phosphate ester compound and the epoxy haloalkane compound; heating and agitating to dissolve; then sequentially adding the organo-siloxane compound and the organic alcohol ether compound; and dropping the transition metal halide to obtain the primary catalyst, wherein the primary catalyst and the promoter catalyst are individually stored, and combined when in use. According to the olefin polymerization catalyst provided by the invention, the primary spherical catalyst and the promoter spherical catalyst are combined when in use, thus, high catalytic activity is achieved.

Owner:PETROCHINA CO LTD +1

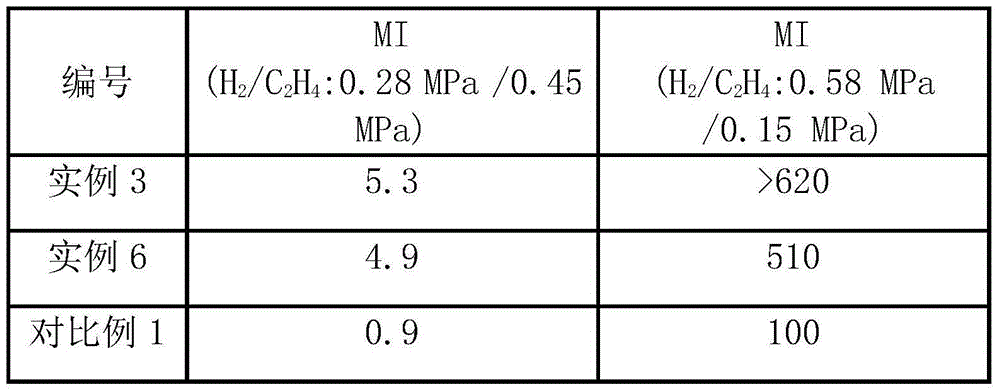

Catalyst for ethene polymerization or multipolymer, preparing method thereof

A catalyst for polymerization or copolymerization of ethylene is prepared through dissolving magnesium halide in organic epoxy compound, organic phosphorus compound or inertial diluent, adding alkane educing aid, porous inertial carrier and halide of Ti, and educing. It is possible to add alcohol compound and / or electron donor. Its advantages are high activity and copolymerizing performance, and high sensitivity to hydrogen regulation.

Owner:CHINA PETROLEUM & CHEM CORP +1

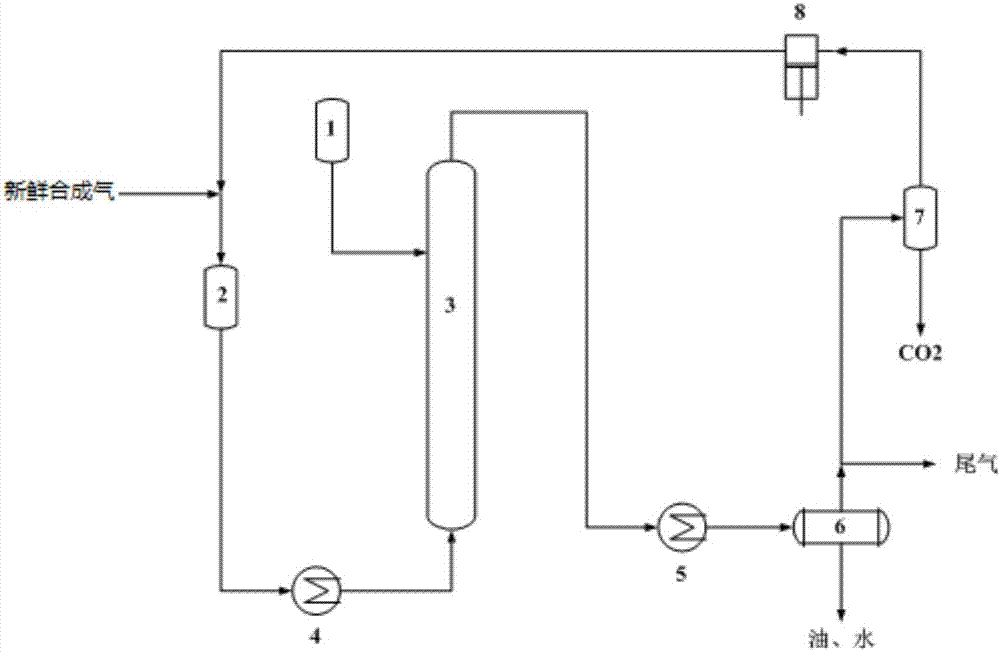

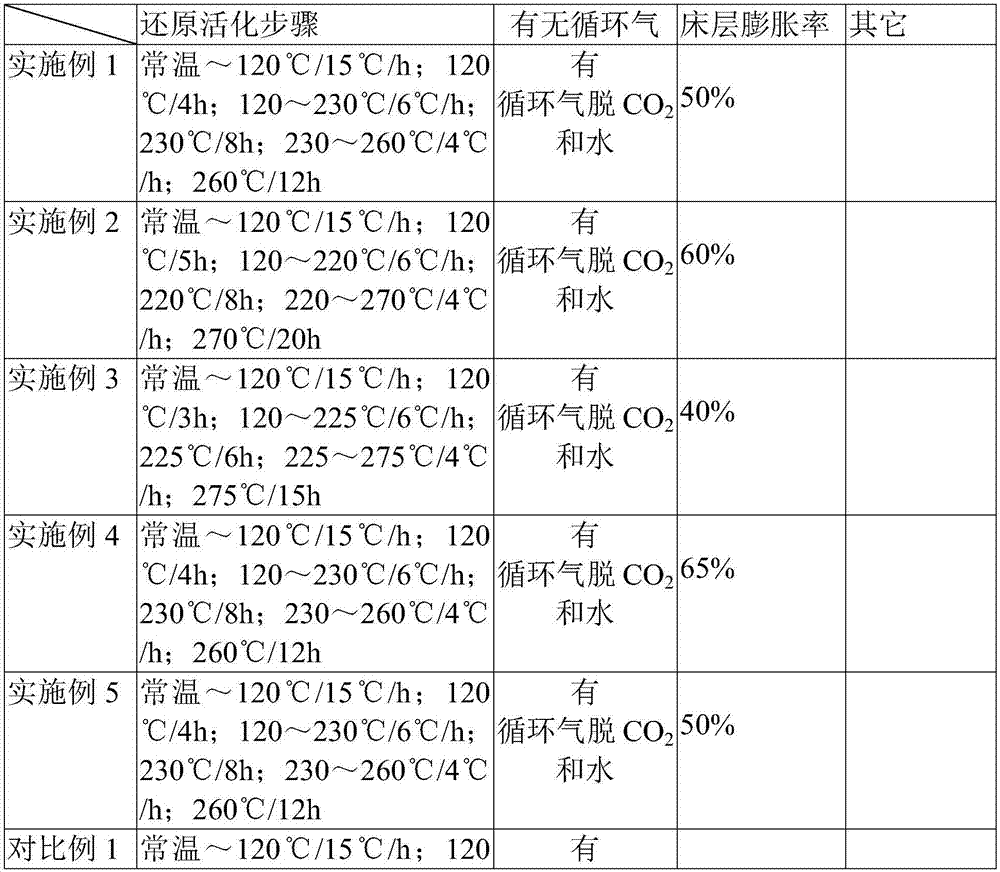

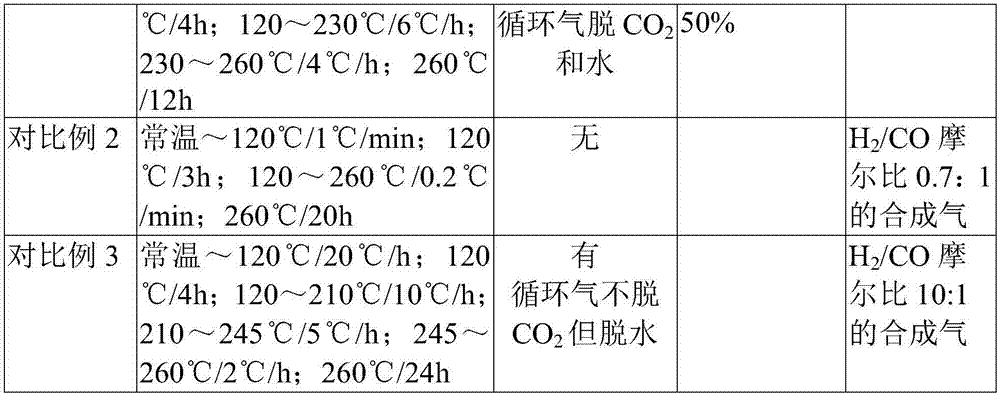

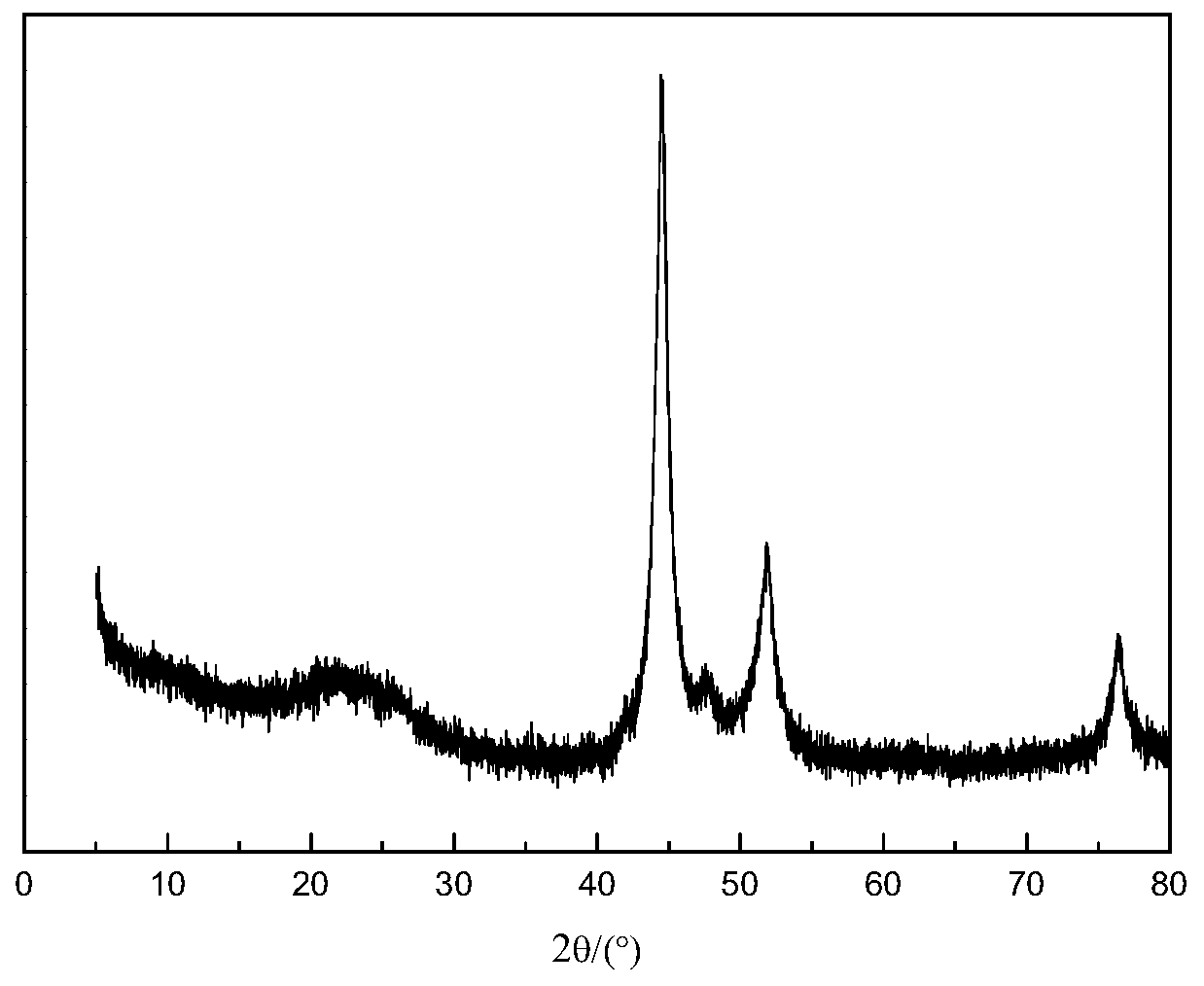

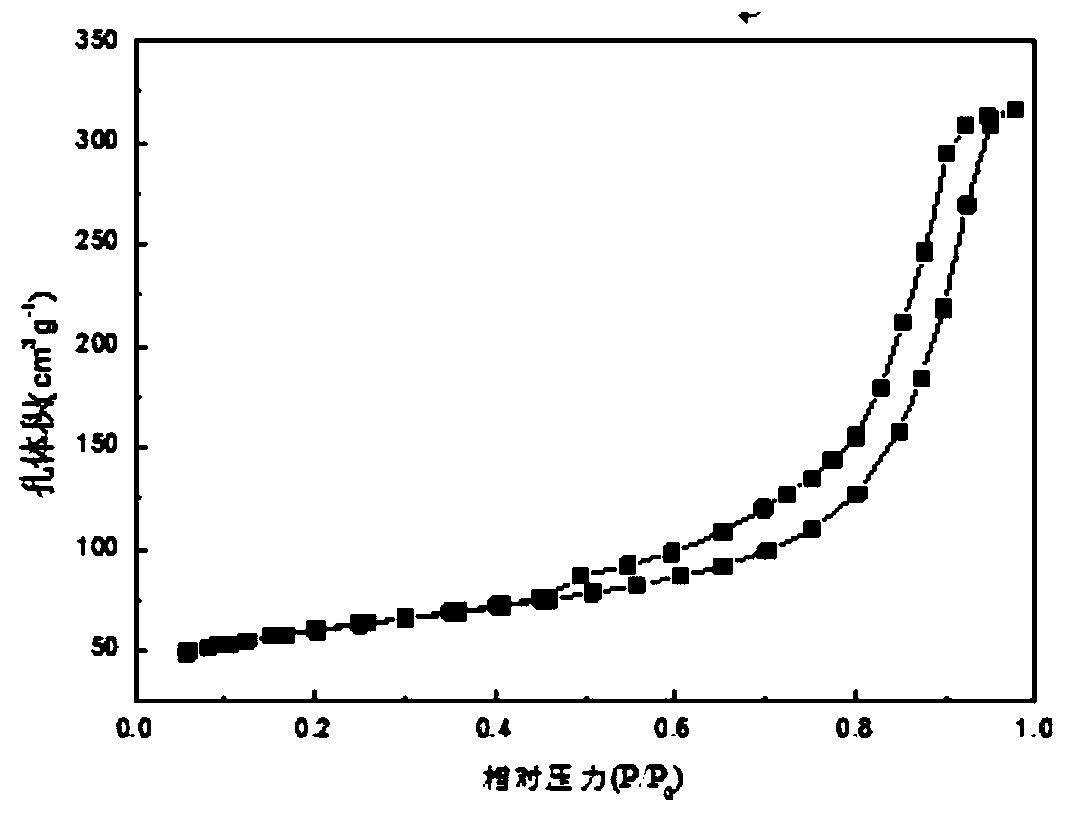

Reduction method for a Fischer-Tropsch synthesis iron-based catalyst

ActiveCN107149948AHigh activityLow selectivityCatalyst activation/preparationLiquid hydrocarbon mixture productionFluidized bedRoom temperature

The present invention relates to the field of Fischer-Tropsch synthesis iron-based catalyst reduction, and discloses a reduction method for a Fischer-Tropsch synthesis iron-based catalyst. The reduction method comprises: in the presence of a reducing gas, carrying out programmed heating reduction on Fischer-Tropsch synthesis iron-based catalyst particles in a fixed fluidized bed reactor, wherein the programmed heating reduction comprises that the heating rate is 10-20 DEG C / h and constant temperature treatment is performed for 2-8 h at a temperature of 120 DEG C when the temperature is from room temperature to 120 DEG C, the heating rate is 5-10 DEG C / h and constant temperature treatment is performed for 3-10 h at a temperature of 220-230 DEG C when the temperature is from 120 DEG C to (220-230) DEG C, and the heating rate is 3-5 DEG C / h and constant temperature treatment is performed for 10-30 h at a temperature of 260-280 DEG C when the temperature is from (220-230) DEG C to (260-280) DEG C. With the reduction method of the present invention, the Fischer-Tropsch synthesis iron-based catalyst can be smoothly subjected to the reduction reaction so as to reduce the influence on the water and the catalyst strength, and with the application of the reduced catalyst in the Fischer-Tropsch synthesis, the advantages of no breaking, high catalyst activity, low CO2 selectivity and low low-carbon hydrocarbon selectivity can be provided.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Catalyst in use for polymerization or combined polymerization of ethylene, preparation and application

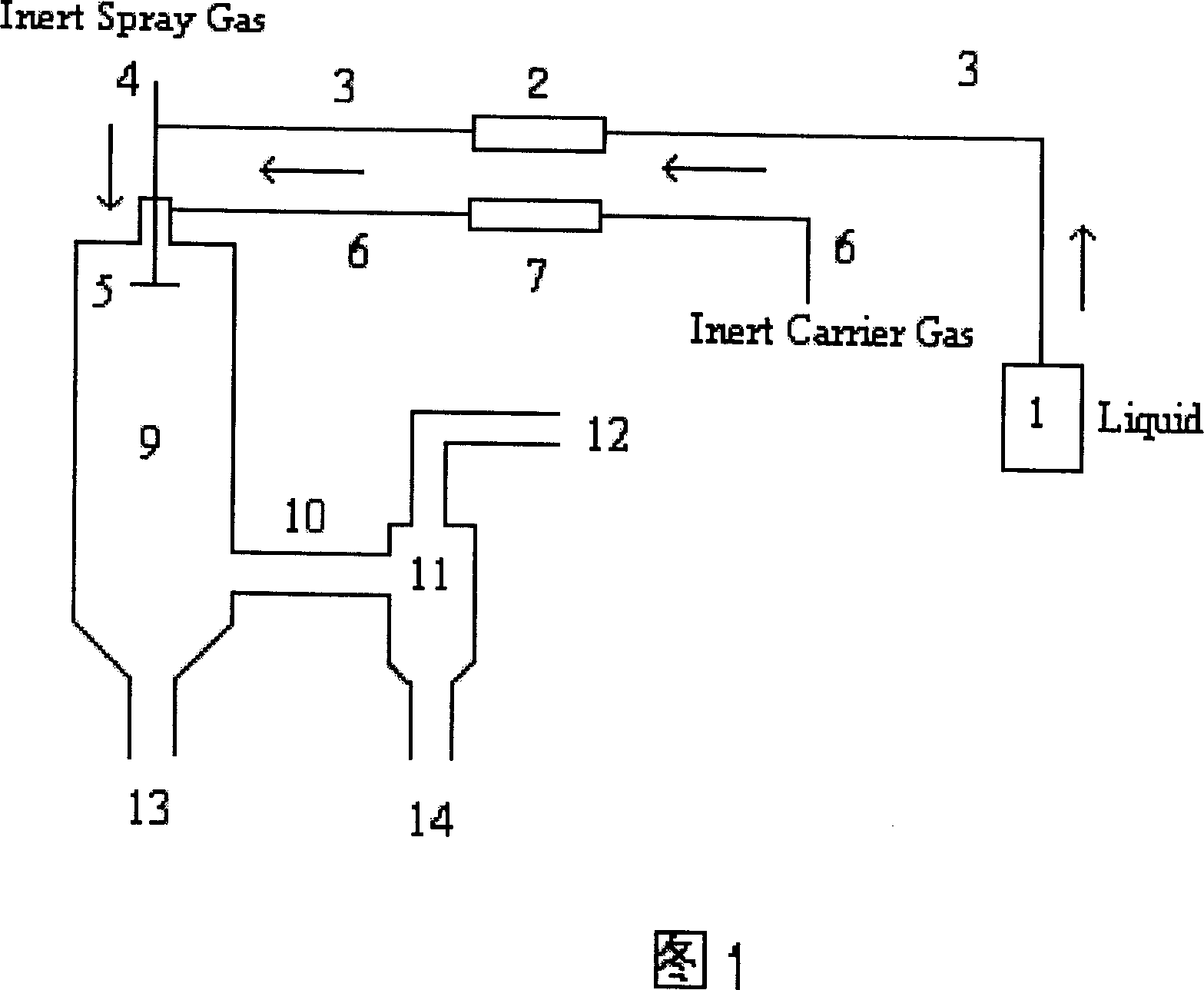

This invention provides a catalyst for ethylene polymerization or copolymerization and its synthesis. The catalyst comprises magnesium halide / inorganic matter composite carrier prepared by spray drying. This invention also provides the method for preparing the magnesium halide / inorganic matter composite carrier and the method for synthesizing the catalyst by using the composite carrier. The obtained catalyst has such advantages as high catalytic activity, no breakage of catalyst particles, and narrow particle size distribution. The polymer has such advantages as good particle morphology, little fine powder and high packing density.

Owner:CHINA PETROLEUM & CHEM CORP +1

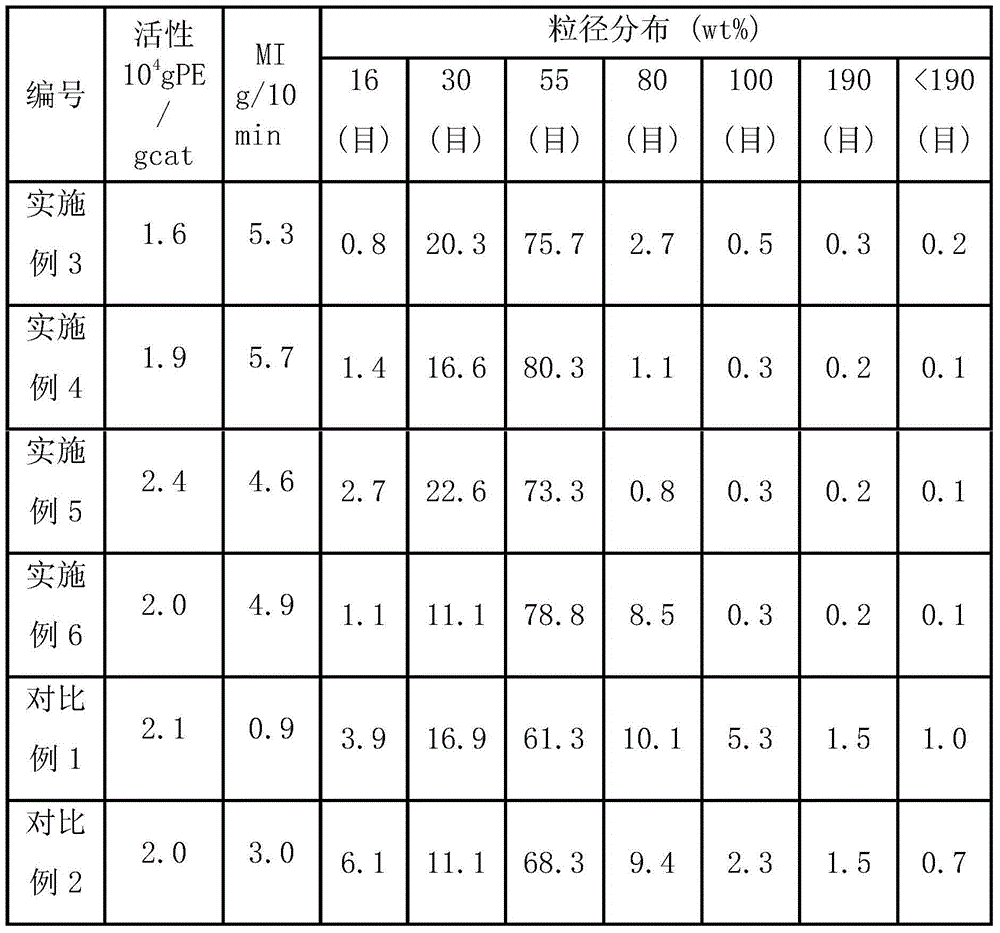

Ethylene in-situ copolymerization catalyst system

ActiveCN102336855ARaise the active release temperatureGood compatibilityPolymer scienceIn situ polymerization

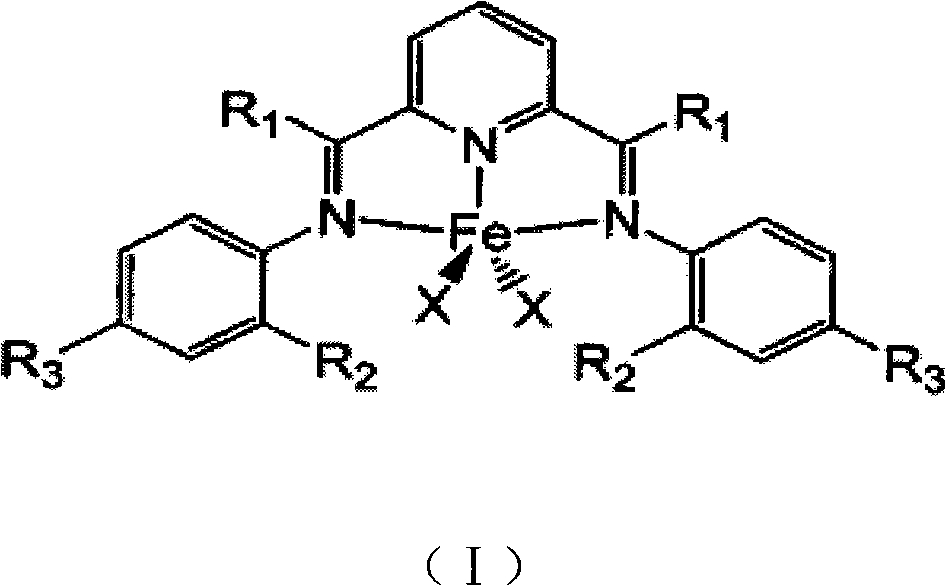

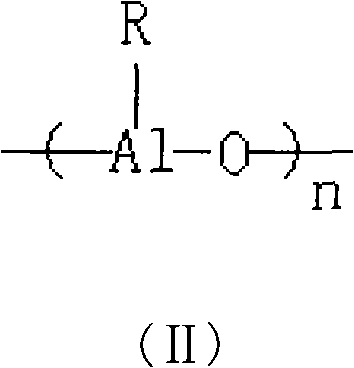

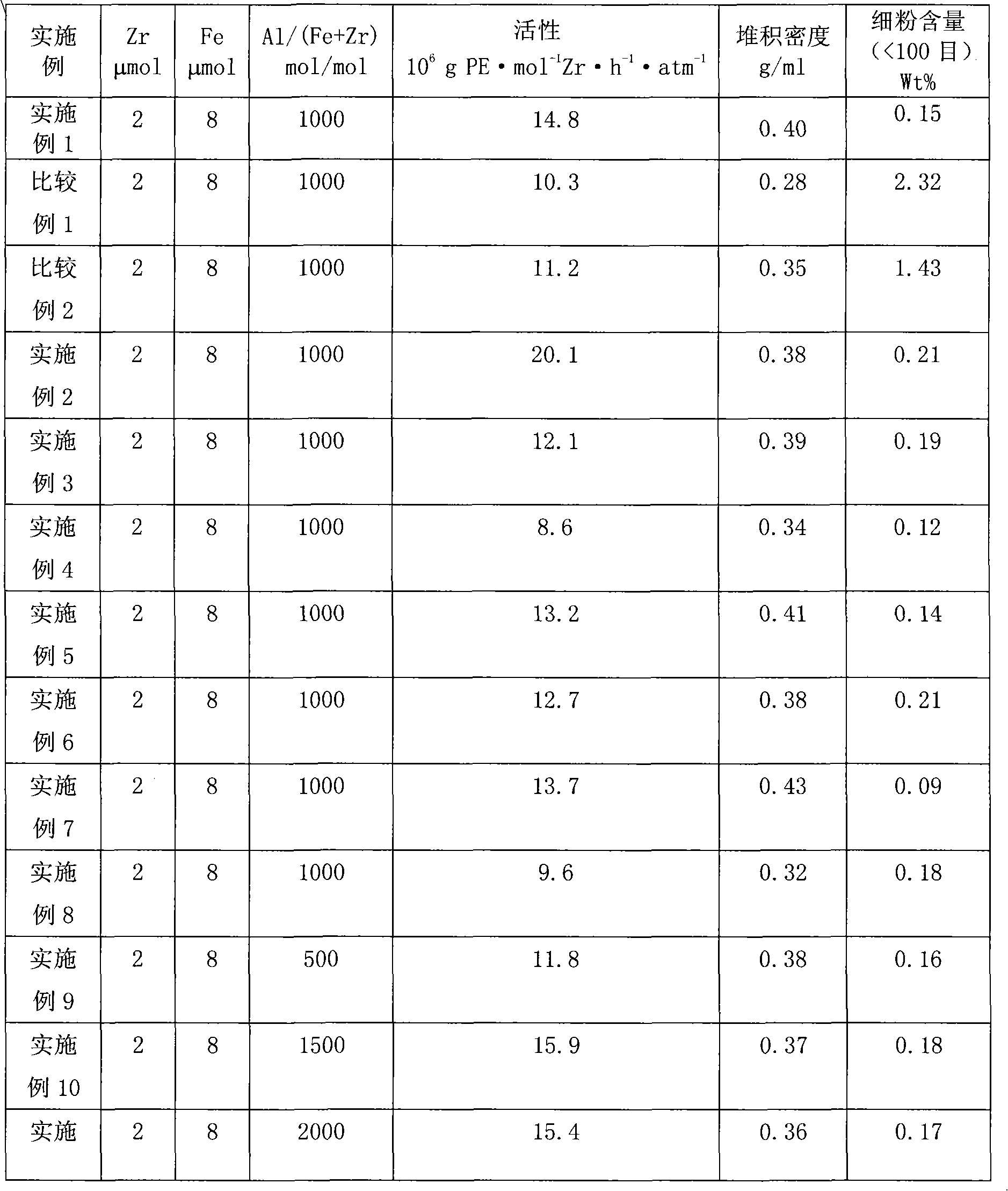

The invention discloses an ethylene in-situ copolymerization catalyst system mainly composed of an MgCl2-SiO2 loaded oligomerization catalyst, a spherical MgCl2-SiO2 loaded copolymerization catalyst and alkylaluminoxane. The spherical MgCl2-SiO2 carrier has a particle size of 10-30 micrometers, and MgCl2 and SiO2 are in a mass ratio of 0.5:1-20:1. The oligomerization catalyst is an alpha-diimino pyridine iron complex, while the copolymerization catalyst is a metallocene complex with Zr as the central atom, and the oligomerization and copolymerization catalysts are in a mole ratio of 1:8-100:1. For the oligomerization catalyst, in each gram of the solid catalyst, the content of metal Fe is 1-100 micromoles. For the copolymerization catalyst, in each gram of the solid catalyst, the content of metal Zr is 1-100 micromoles. And in the oligomerization and copolymerization catalysts, in each gram of the solid catalysts, the content of Al is 0.01-0.3g. The catalyst system of the invention overcomes a lot of problems brought by application of single carrier loading or a homogeneous catalyst in prior art, and can realize ethylene in-situ polymerization at a temperature of 50-90DEG C. With high catalyst activity, the catalyst system provided in the invention can obtain a polymer with high bulk density and less fine powder, thus being suitable for application in gas phase polymerization and slurry polymerization.

Owner:PETROCHINA CO LTD

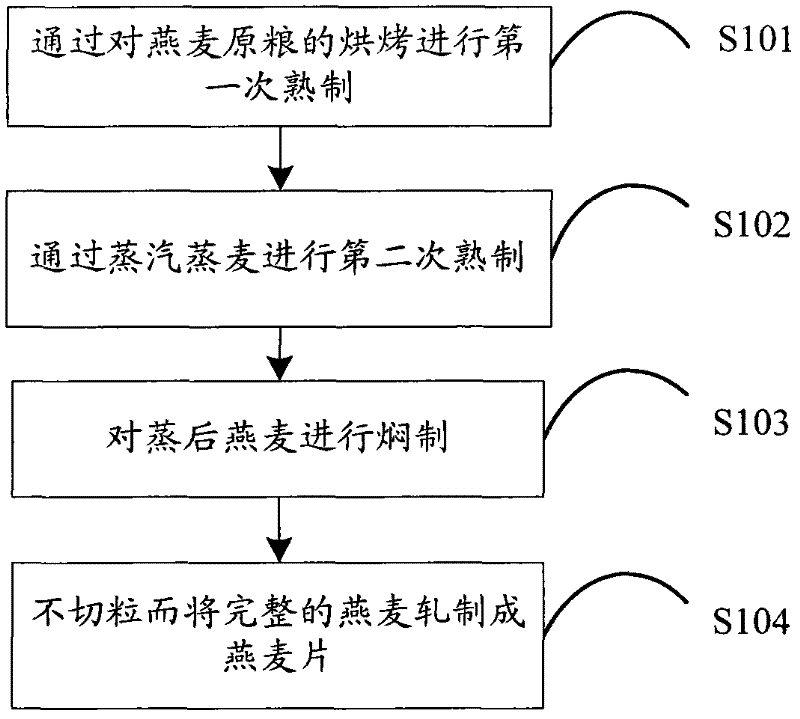

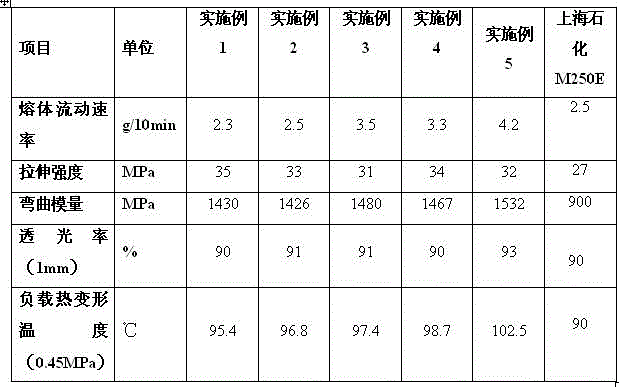

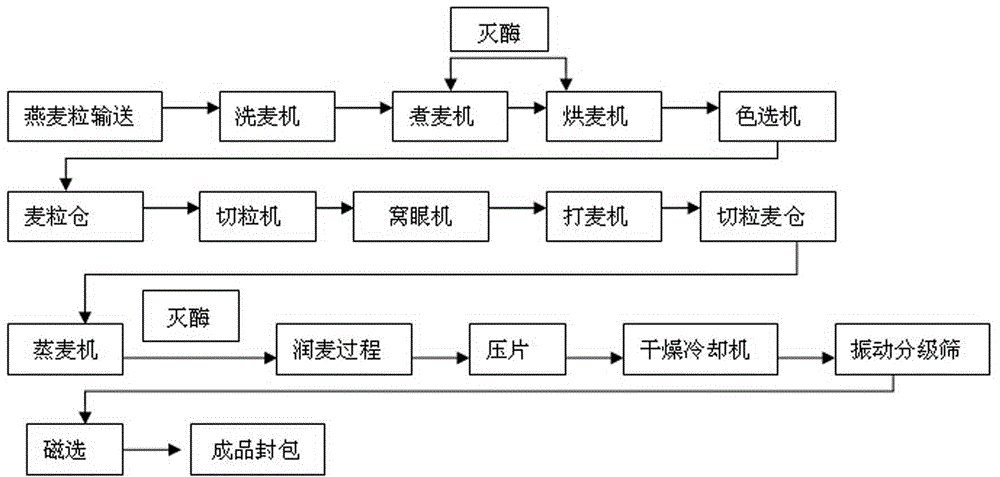

A kind of cooking method of oatmeal

The invention is applicable to the field of food processing, and provides an oatmeal cooking method; the method comprises the following steps: baking oat raw grains to perform first cooking; steaming oat by steam to perform second cooking; braising the steamed oat; rolling complete oat grains into oatmeal without grain cutting. According to the invention, while the oat grains is cooked, various enzymes in oat are passivated at high temperatures for several times in procedures such as oat baking, oat steaming, and oat braising; the product is guaranteed not to generate spoilage phenomenon under normal environment; the oatmeal is subject to third cooking during brewing; the oatmeal processed by the 'three cooking' processes has dense and lasting flavor, milk white soup, gloss, and high viscosity; and the oatmeal is chewy, is not sticky to teeth, and has smooth mouthfeel; the invention simultaneously adopts big-sheet rolling technology without grain cutting, and thus the prepared oatmeal has a complete shape, less fragments or fine powder, and good sensory quality.

Owner:INNER MONGOLIA SAIBAO OAT FOOD

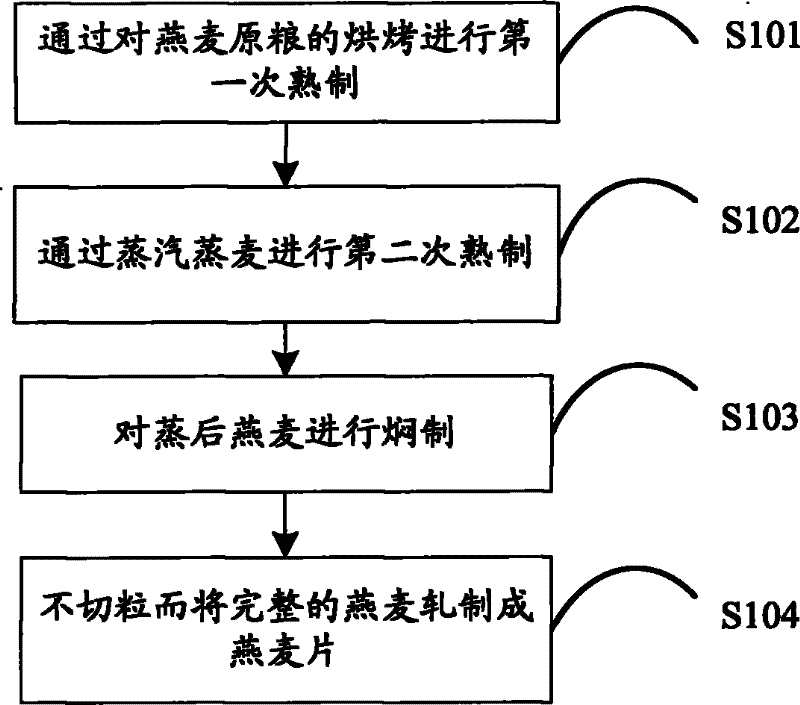

Preparation method for polypropylene material special for transparent sheet

The invention relates to a preparation method for a polypropylene material special for a transparent sheet. The preparation method comprises the following steps: (1) adding a propylene monomer, a Ziegler-Natta catalyst, an organic aluminum compound and an organic silicone compound to a first liquid-phase reactor for reacting; (2) charging products obtained at the step (1) into a second liquid-phase reactor for reacting; (3) charging products obtained at the step (2) into a first gas-phase fluidized bed reactor for reacting; (4) charging products obtained at the step (3) into a second gas-phase fluidized bed reactor for reacting to obtain polypropylene; (5) pelleting obtained polypropylene at the step (4), adding a compound adjuvant system at the same time, and then discharging to obtain the polypropylene material special for the transparent sheet. The prepared polypropylene resin special for the high-transparency sheet has high rigidity (the flexural modulus is no less than 1400 MPa) and high heat resistance on the premise of keeping the certain toughness.

Owner:CHINA PETROLEUM & CHEM CORP +1

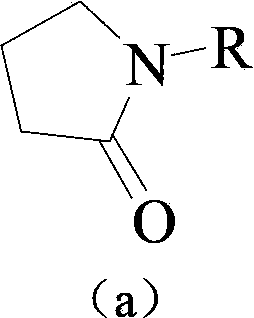

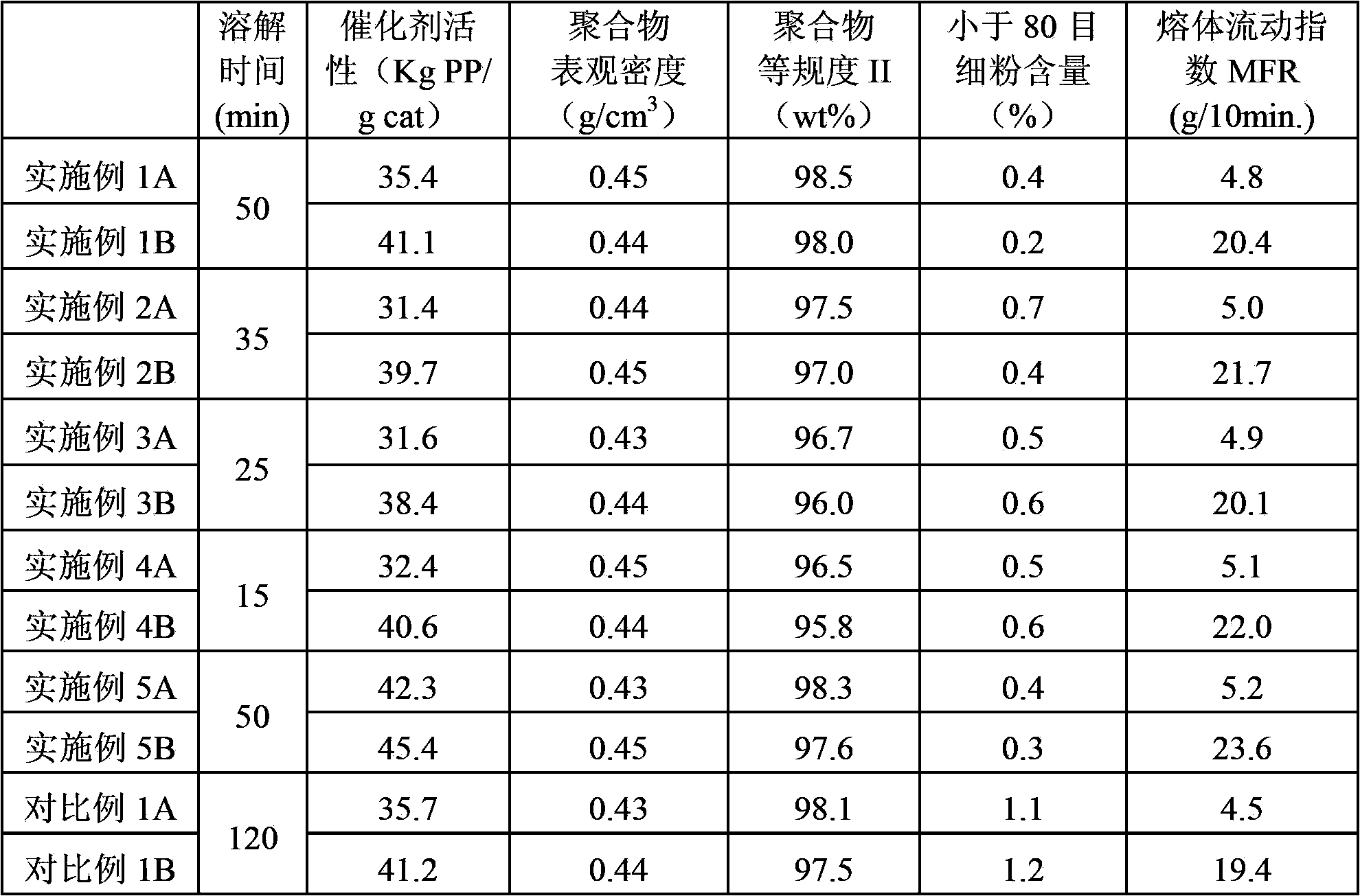

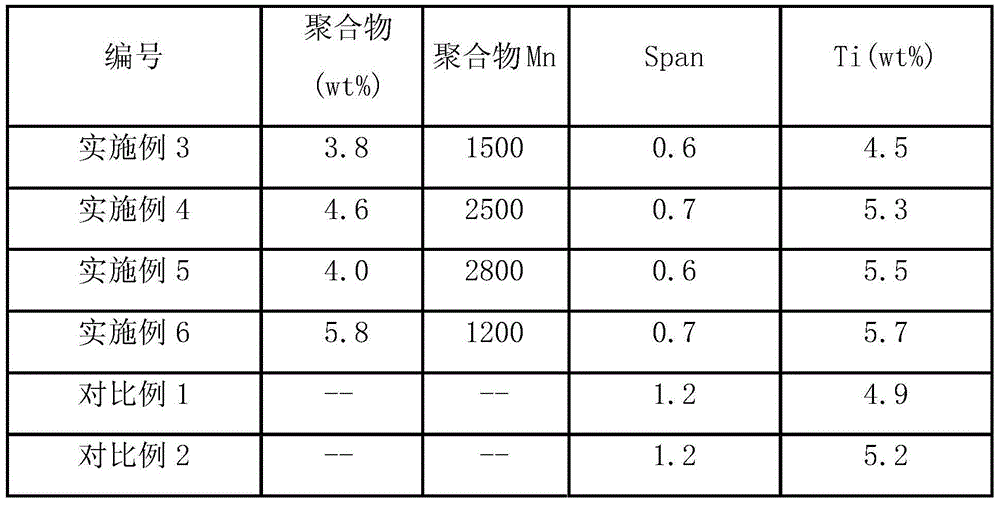

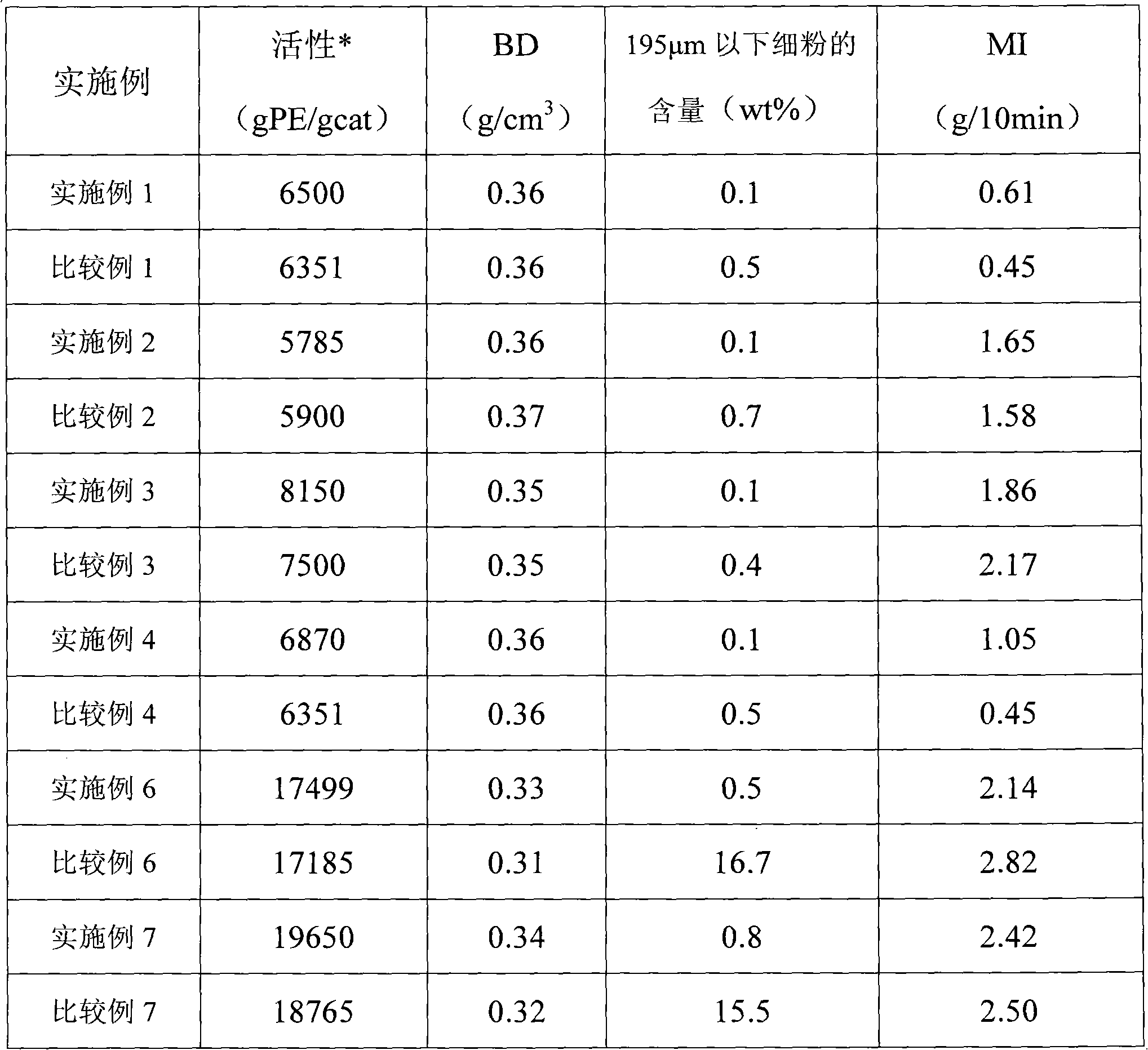

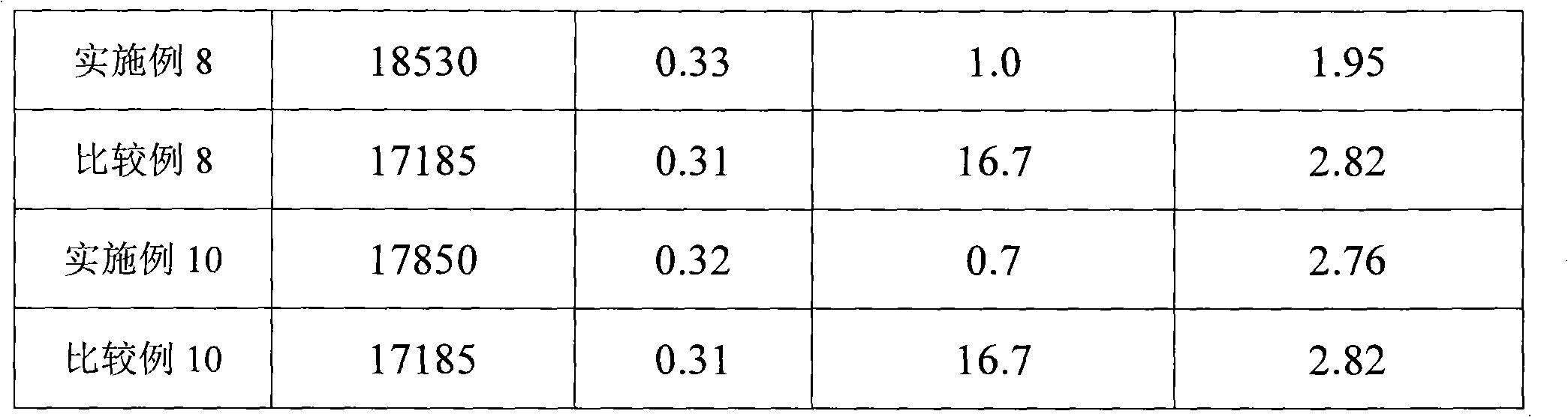

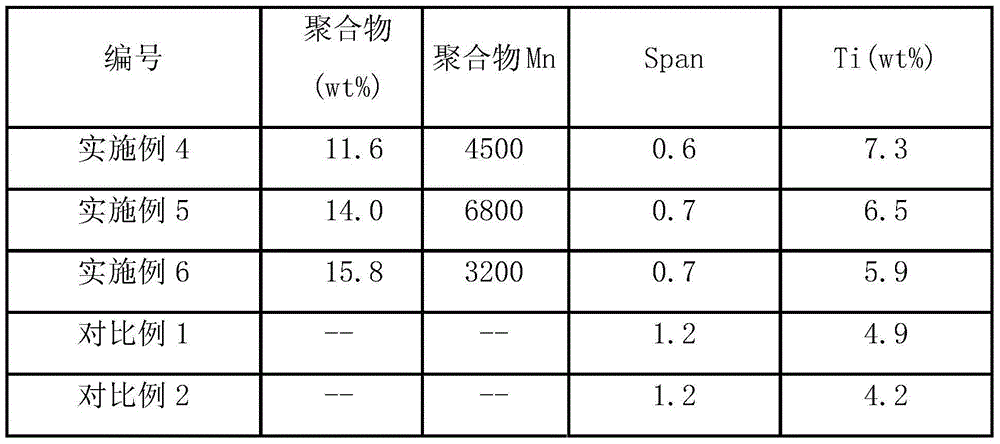

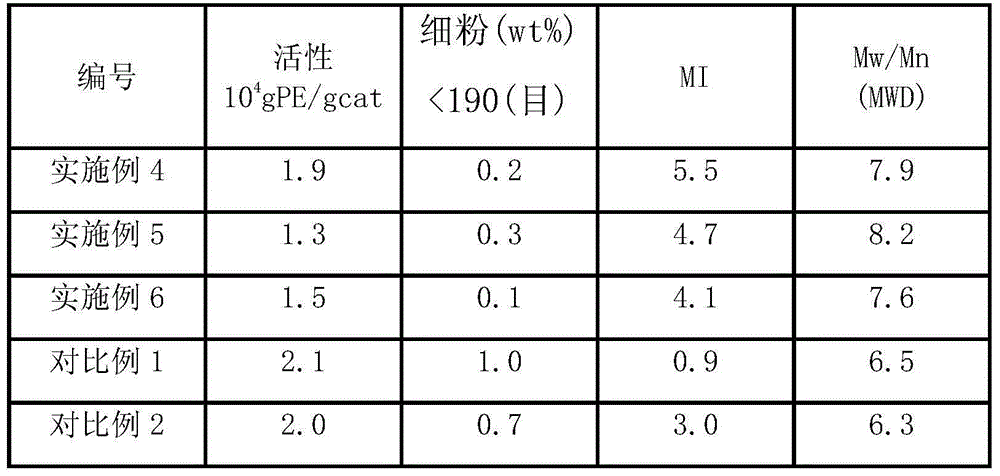

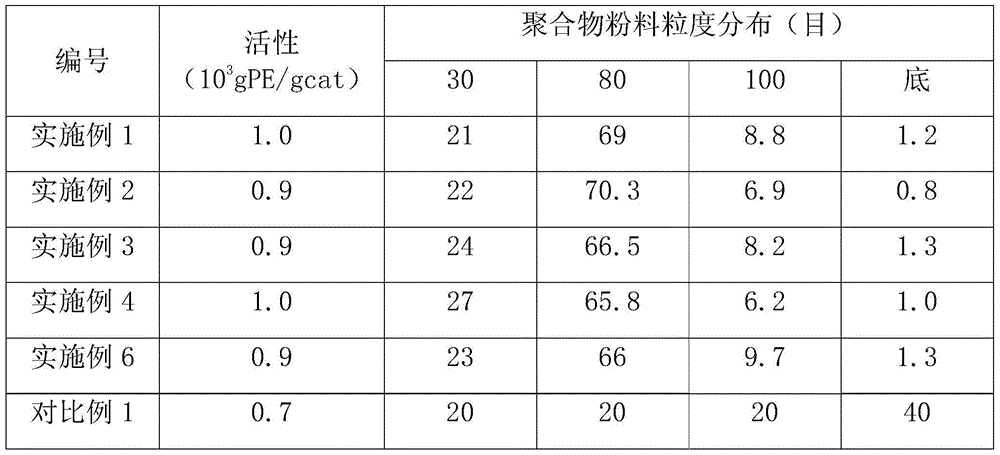

Preparation methods for olefin polymerization catalyst component and corresponding catalyst

The invention provides a preparation method for an olefin polymerization catalyst component. The preparation method comprises the steps: contacting a magnesium compound, an organophosphorus compound, a pyrrolidone compound and an organic epoxy compound in a solvent to form a uniform solution; in the presence of a precipitation aiding agent, contacting the uniform solution with a titanium compound to obtain a mixture; and then contacting the obtained mixture with an internal electron donor compound, and carrying out a reaction to obtain the olefin polymerization catalyst component, wherein at least one of the magnesium compound and the titanium compound is a halogen-containing compound. According to the preparation method, the addition of the pyrrolidone compound can effectively shorten the preparation time of the catalyst component, improve the particle morphology of a catalyst and greatly reduce the fine powder content of the polymer; and at the same time, after addition of the pyrrolidone compound, the catalyst activity can be basically maintained or improved, the apparent density of the polymer is relatively high, and the degree of isotacticity and the polymer melt flow index still maintain original relatively good performance of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Carrier for ethylene polymerization catalyst and catalyst of carrier

ActiveCN105482003ANarrow particle size distributionConcentrated particle size distributionDouble bondMagnesium

The invention provides a carrier for an ethylene polymerization catalyst and a catalyst of the carrier. The carrier comprises reactants of the following components: magnesium chloride / gallic acid derivatives / epoxy compounds with carbon-carbon double bonds / alcohol compounds / radical initiators. A mixed solution of the components is initiated by the radical initiators in the process of warming, and the carbon-carbon double bonds in a system can generate a polyreaction, so that the carrier with narrow particle size distribution and doped with polymers can be separated out. The polyethylene catalyst prepared through the carrier not only has the characteristic of narrow particle size distribution but also is high in hydrogen adjustment sensibility; the particle size distribution of obtained polymeric powder materials is particularly intensive, and less fine powder is generated.

Owner:CHINA PETROLEUM & CHEM CORP +1

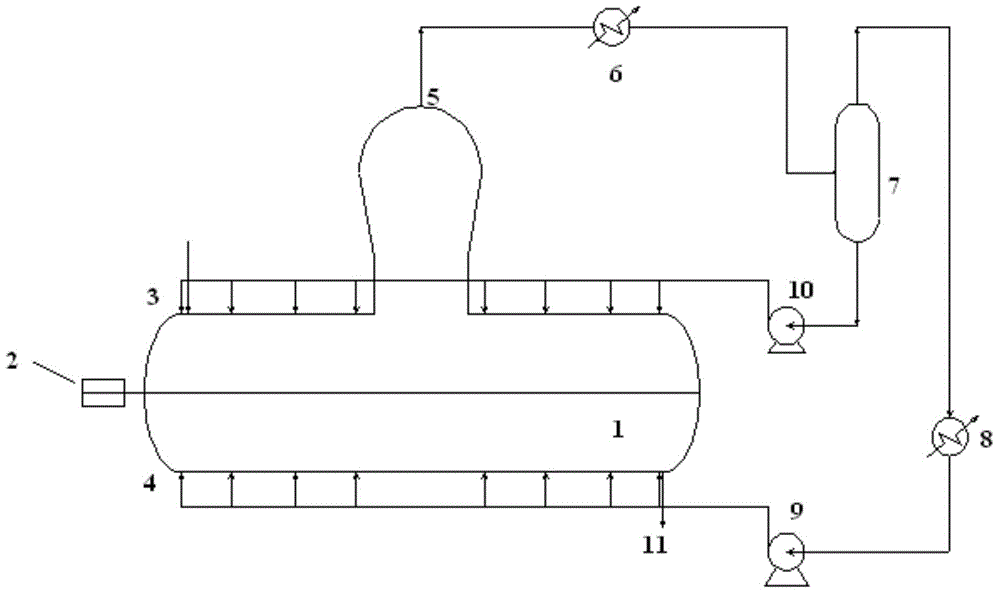

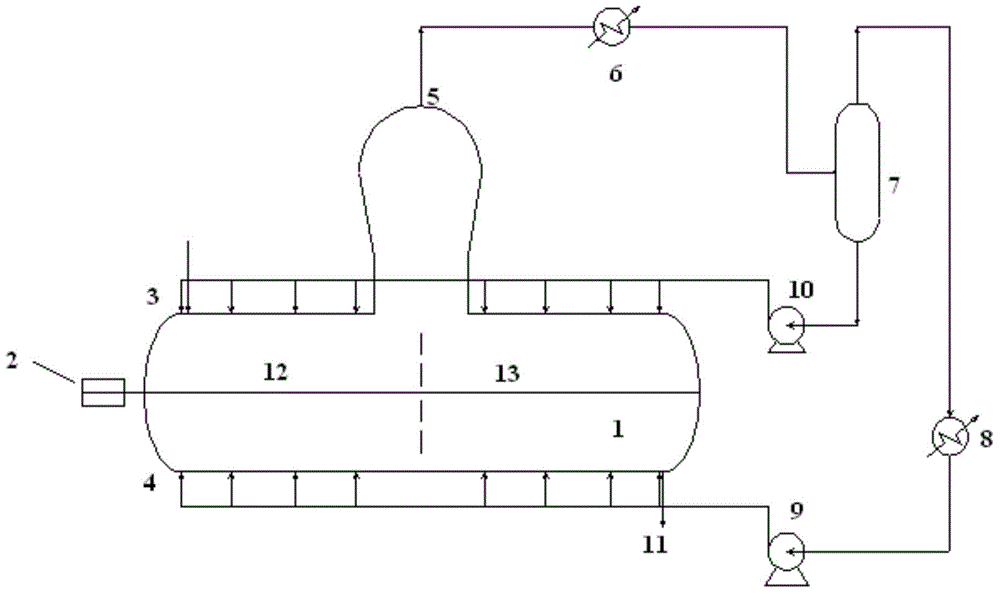

Preparation method for anti-impact polypropylene

The invention relates to a preparation method for anti-impact polypropylene. The anti-impact polypropylene is prepared from propylene and ethylene through polymerization in the presence of a Ziegler-Natta catalyst, and the preparation method comprises the following concrete steps: carrying out propylene homopolymerization in the presence of a solid catalyst component containing titanium, an aluminum alkyl compound and a first external electron donor; then adding a second external electron donor; and carrying out copolymerization of propylene and ethylene. The first external electron donor and the second external electron donor are selected from organosilicon compounds as shown in a general formula R'R''<q>Si(OR'' ')<4-p-q>, p+q of the first external electron donor is an integer in a range of 2 to 3, and p+q of the second external electron donor is an integer in a range of 0 to 1. The method provided by the invention can improve the reactivity ratio of ethylene; and in particular, through arrangement of a high temperature polymerization area during ethylene-propylene copolymerization, heat removing capability of a circulation gas heat exchanger can be improved, and running load of a condensation / cooling device can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method and application of superhigh-molecular weight polyolefin catalyst

The invention relates to a preparation method and application of a superhigh-molecular weight polyolefin catalyst, belonging to the field of olefin polymerization catalysts and olefin polymerization. The preparation method of the catalyst comprises the following steps of: dispersing a carrier in an organic solvent; adding organic lithium or a Grignard reagent and the like in the obtained dispersed solution at -40 DEG C to 30 DEG C, reacting for 0.5-3 hours at -20 DEG C to 30 DEG C after addition, and then raising the temperature to 30-100 DEG C for reacting for 0.5-5 hours to obtain a mixture; filtering and washing the mixture to remove the redundant organic lithium or Grignard reagent; reacting the mixture with a titanium-halogen compound in the organic solvent for 0.5-3 hours at -30 DEG C to 30 DEG C, and then raising the temperature to 30-100 DEG C for reacting for 1-5 hours; and filtering and washing the mixture to remove the redundant titanium-halogen compound and then drying to obtain a main catalyst. The main catalyst prepared in the method has the advantages of favorable particle form, high load capacity, high activity and no drop from the carrier and is suitable for a slurry polymerization process, a gas-phase polymerization process or a combined polymerization process; and the viscosity-average molecular weight of a polymer can be regulated within 800-10000 thousands.

Owner:BEIJING UNIV OF CHEM TECH

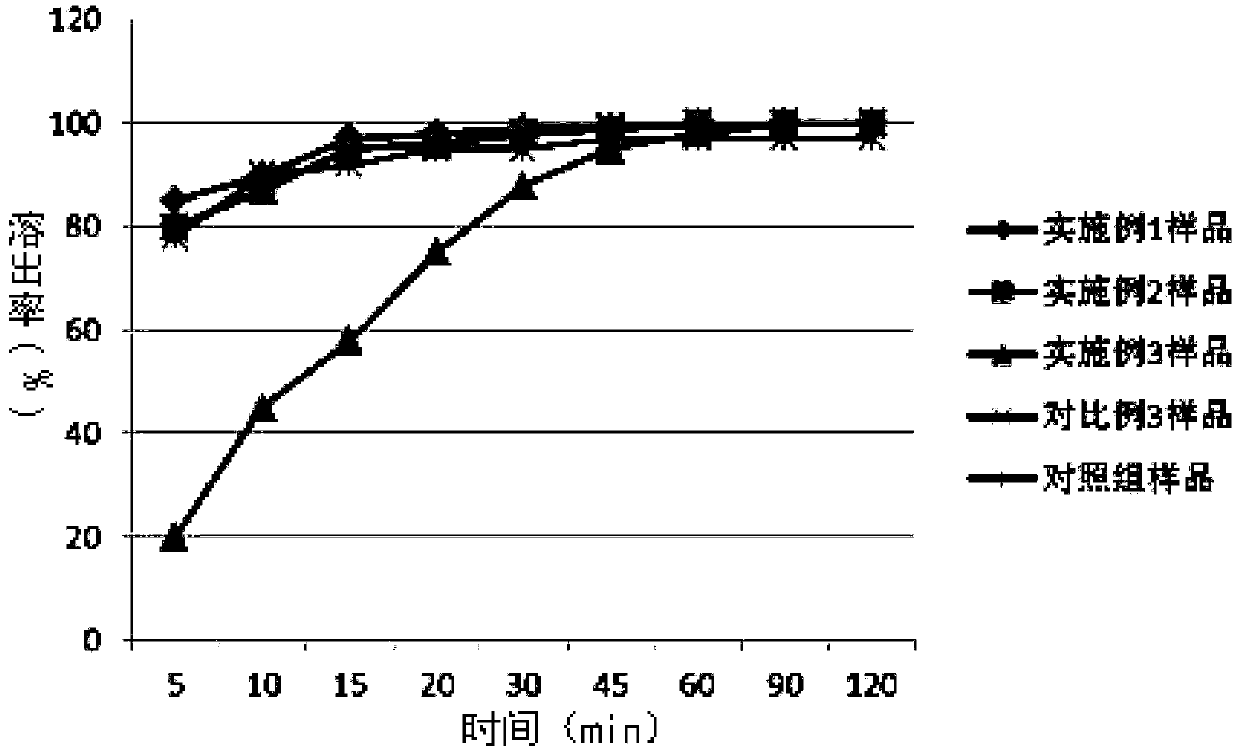

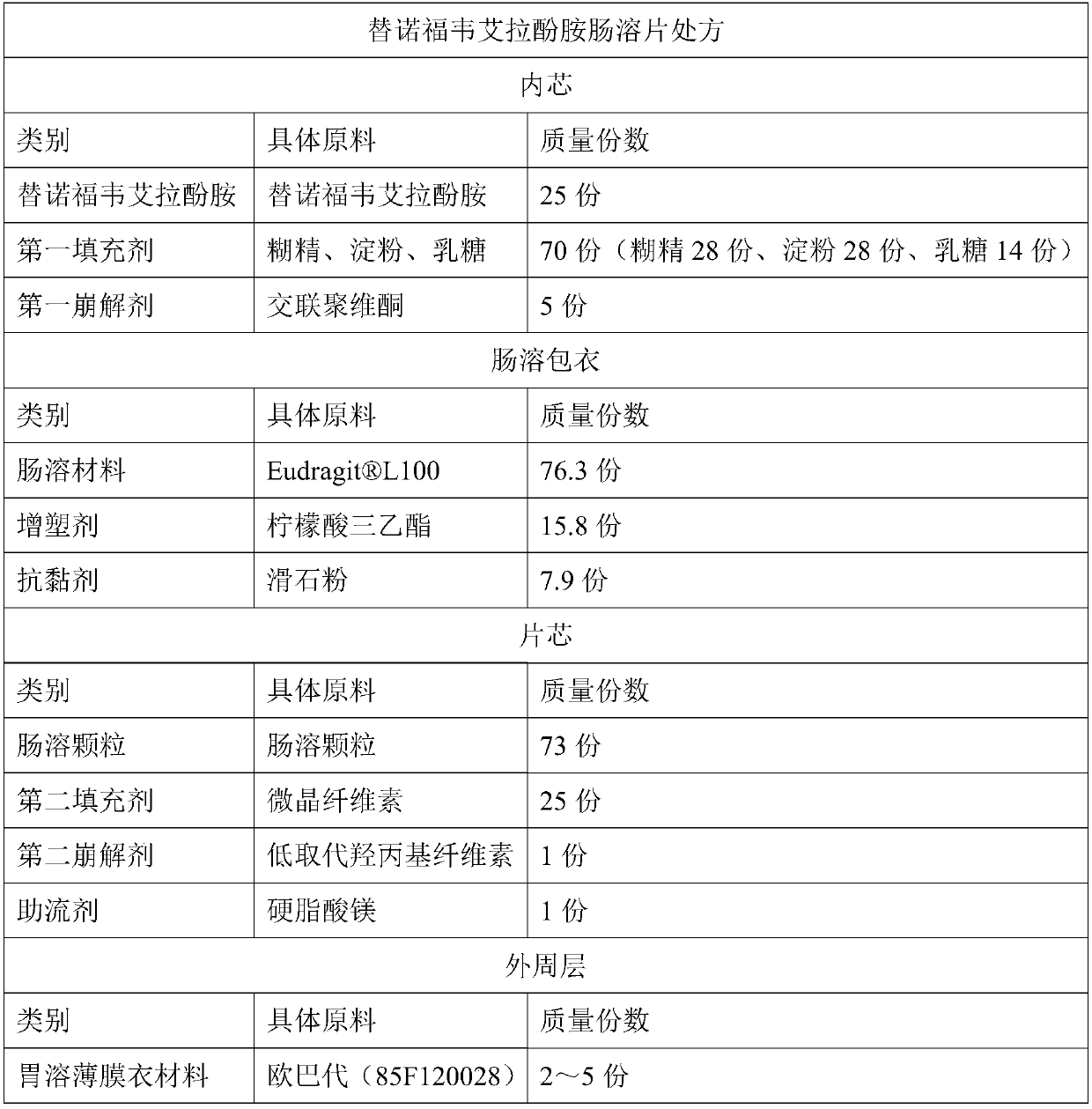

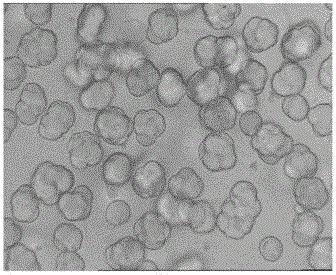

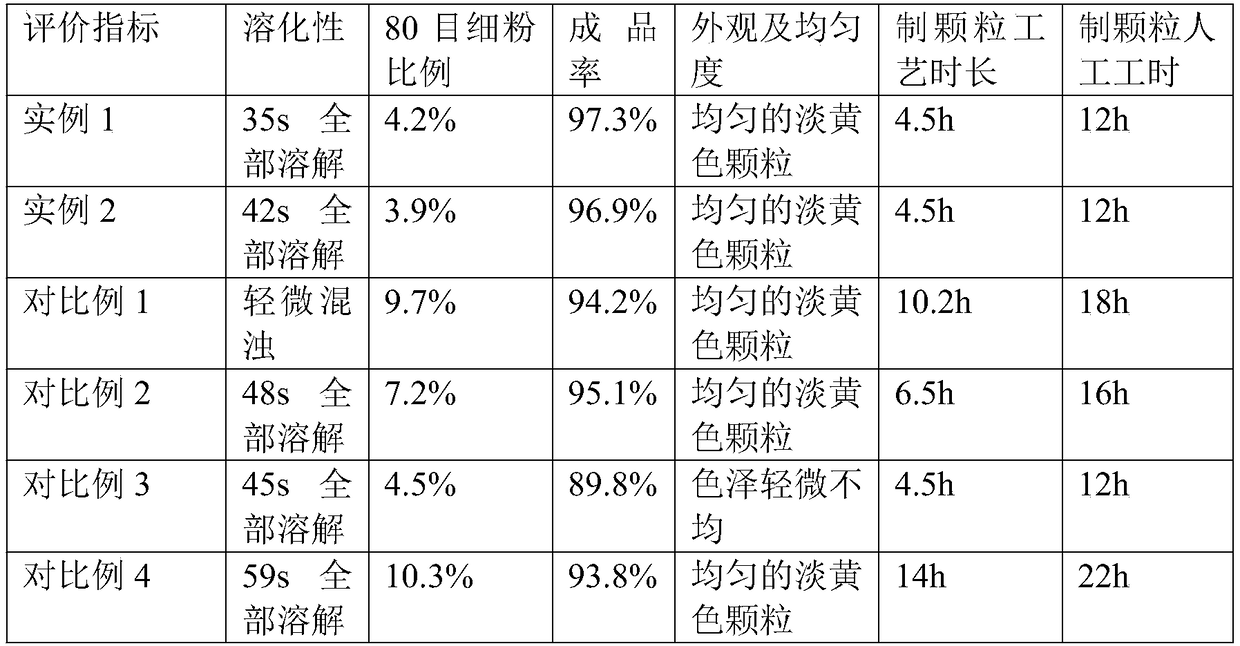

Tenofovir alafenamide enteric-coated tablet and preparation method thereof

ActiveCN109568284AFlexible way of takingImprove securityOrganic active ingredientsDigestive systemMulti unitCoated tablets

The invention discloses a tenofovir alafenamide enteric-coated tablet and a preparation method thereof. The enteric-coated tablet comprises a tablet core and a peripheral layer, wherein the tablet core contains enteric particles, a second filler, a second disintegrating agent and a glidant; the enteric particles contain an inner core and an enteric coating; and the inner core contains tenofouvir alafenamide, a first filler and a first disintegrating agent. The tenofovir alafenamide enteric-coated tablet is prepared by the preparation method successfully, and the limitation that the tablet mustbe taken with food is broken; and the bioavailability and the efficacy can not be affected by the type and amount of the food, and the safety and effectiveness of medication are improved through theenteric-coated tablet. The enteric-coated tablet is prepared by the process of enteric-coated multi-unit granule tabletting, so that the tablet is uniformly distributed after being taken orally, and the stimulation to the gastrointestinal tract caused by the excessive local concentration of drug is avoided. At the same time, the problems of poor compressibility of the tenofovir alafenamide, much fine powder from dry granulation, and uneven subsequent enteric-coated coating are overcame through the tenofovir alafenamide enteric-coated tablet. The preparation process is simple and the preparation conditions are controllable.

Owner:中润药业有限公司

Olefin polymerization catalyst, preparation method of olefin polymerization catalyst and olefin polymerization method

The invention relates to an olefin polymerization catalyst. The olefin polymerization catalyst is prepared from A, a magnesium compound, B, a titanium compound, C, an organophosphorus compound, D, an organic epoxy compound, E, an organosilicon compound and F, an organic alcohol ether compound. At least one of the magnesium compound and the titanium compound is a halogen-containing compound. The olefin polymerization catalyst does not contain a phthalic acid ester compound. The invention also provides a preparation method of the olefin polymerization catalyst and an olefin polymerization method using the olefin polymerization catalyst. The olefin polymerization catalyst is used for olefin polymerization and has good hydrogen regulation sensibility. A polymer prepared through the olefin polymerization catalyst contains less fine powder and has high bulk density.

Owner:CHINA PETROLEUM & CHEM CORP +1

Square particle benzoxazine molding plastic

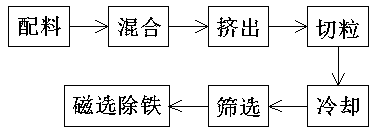

The invention relates to square particle benzoxazine molding plastic. The square particle benzoxazine molding plastic is prepared from the following components by weight percent: 20 to 40 percent of benxoxazine resin, 30 to 60 percent of chopped fibers, 1 to 5 percent of titanium dioxide, 1 to 3 percent of curing accelerant, 1 to 5 percent of thermoplastic polyurethane elastomer rubber, 1 to 3 percent of stearic acid, 0.5 to 2 percent of wax and the balance of wollastonite; and the components are prepared, mixed, extruded, diced, cooled, screened and magnetically selected so as to remove iron,thus obtaining a square finished product. By adopting the formula, the curing shrinkage is small, the mechanical properties are excellent, the flame retardant performance is high, the heat stabilityis high, less fine powder exists, the rate of finished products is increased, and the environment of a molding workshop is protected.

Owner:广西信和新合成材料有限公司

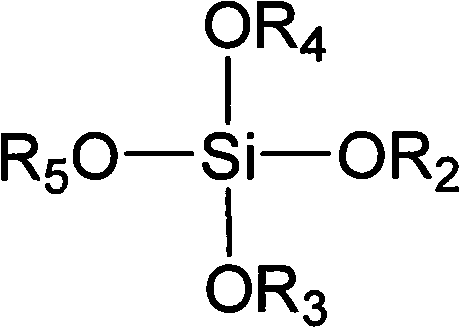

Prepolymerization catalyst for olefin polymerization and preparation method thereof

The invention provides a prepolymerization catalyst for olefin polymerization and a preparation method thereof. The prepolymerization catalyst is highly active during the polymerization. At the prepolymerization stage, beside the pressure and the hydrogen additional proportion, the prepolymerization temperature, varieties of alkylaluminium, the additional proportion of the alkylaluminium and the additional speed of a monomer are also controlled, thus the prepolymerization seriflux concentration of the catalyst can reach 10g / 100ml, the particles of the prepolymerization catalyst do not agglomerate and adhere to walls. The finally generated polymerization powders do not agglomerate, the content of the fine powders is reduced obviously, the bulk density is high, and the liquidity is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

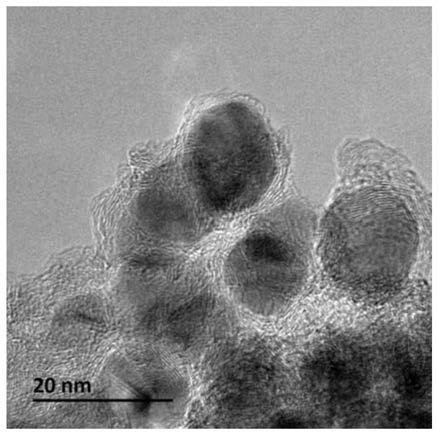

Carbon-coated transition metal nano composite material as well as preparation method and application thereof

InactiveCN111468118AImprove mass transfer efficiencyRich mesostructureGas treatmentOrganic compound preparationCarbon layerFixed bed

The invention provides a carbon-coated transition metal nano composite material, which comprises a carrier and a core-shell structure loaded on the carrier. The shell layer of the core-shell structureis an oxygen-containing graphitized carbon layer, and the inner core of the core-shell structure is transition metal nano particles. The core-shell structure is constructed by taking transition metals as an inner core and the transition metals are loaded on a carrier to form the nano composite material, so that the mass transfer efficiency and the strength of the nano composite material are improved, and the material has a good particle morphology and little fine powder and can be better applied to a fixed bed reactor. In addition, the nano composite material can also be a hierarchical pore structure material with rich mesopores or micro-pores and mesopores, and is beneficial to better play a role in more applications, especially in the application of the catalysis field.

Owner:CHINA PETROLEUM & CHEM CORP +1

Carrier for ethylene homopolymerization or copolymerization, and catalyst thereof

ActiveCN105622790ANarrow particle size distributionHigh sensitivity to hydrogen modulationEpoxyPolymer science

The present invention relates to a polymer doped carrier for an ethylene polymerization catalyst, an ethylene polymerization catalyst component prepared from the polymer doped carrier, a preparation method of the ethylene polymerization catalyst component, and a catalyst of the polymer doped carrier. According to the present invention, magnesium chloride / organic phosphorus compound / epoxy compound having a carbon-carbon double bond / alcohol compound can form a clear and transparent solution in an inert hydrocarbon solvent, and during the heating process of the solution, the epoxy compound having the carbon-carbon double bond in the system or the reaction product thereof and a subsequently-added free radical polymerization monomer are subjected to a copolymerization reaction so as to precipitate the polymer doped carrier; the polyethylene catalyst prepared from the carrier has characteristics of narrow particle size distribution, high hydrogen response, breaking resistance during the polymerization process, and less fine powder; and the obtained polyethylene powder material has the broad molecular weight distribution.

Owner:CHINA PETROLEUM & CHEM CORP +1

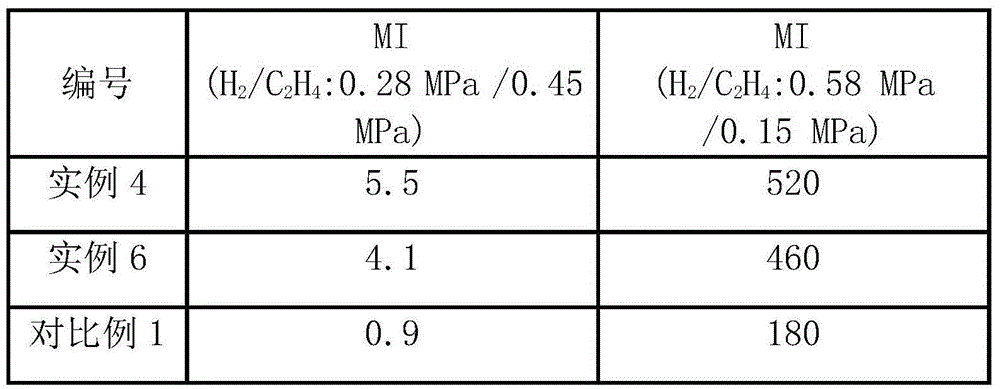

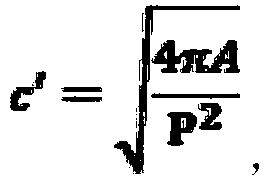

Solid catalyst component and catalyst for olefin polymerization

The invention provides a solid catalyst component and a catalyst for olefin polymerization. The solid catalyst component contains Mg, Ti, halogen, and optionally electron donor; and the C value of particles of the solid catalyst component is more than or equal to 0.7, and is an average degree of sphericity. The solid catalyst component and the catalyst have optimized particle forms; and the polymer product has good mobility, high bulk density, sticky prevention and few fine powder and bulks, and has the characteristics of good stability of polymerization production and high unit volume capacity of a reaction kettle.

Owner:RENQIU LIHE TECH LTD

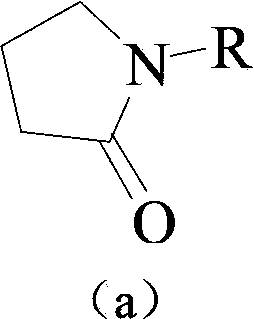

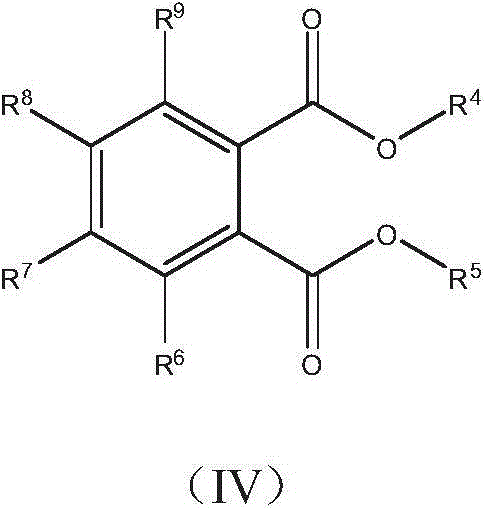

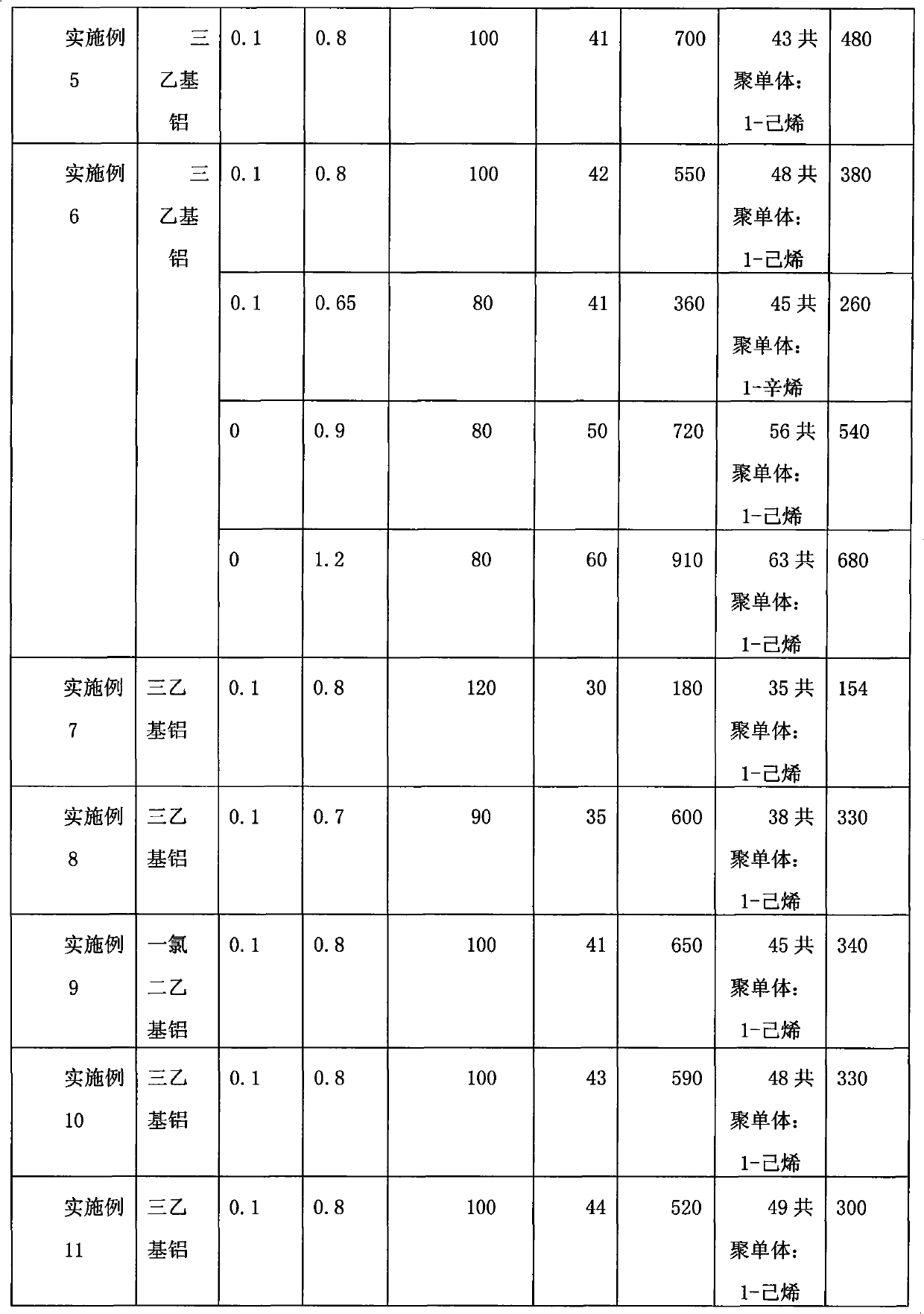

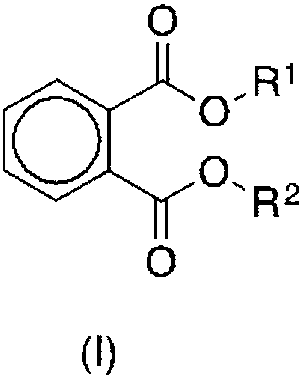

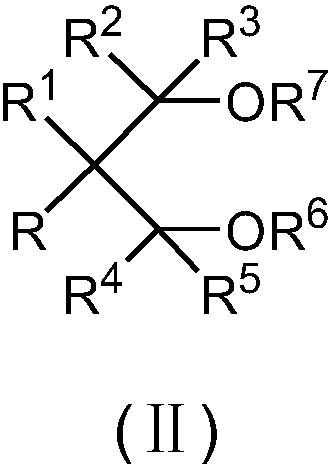

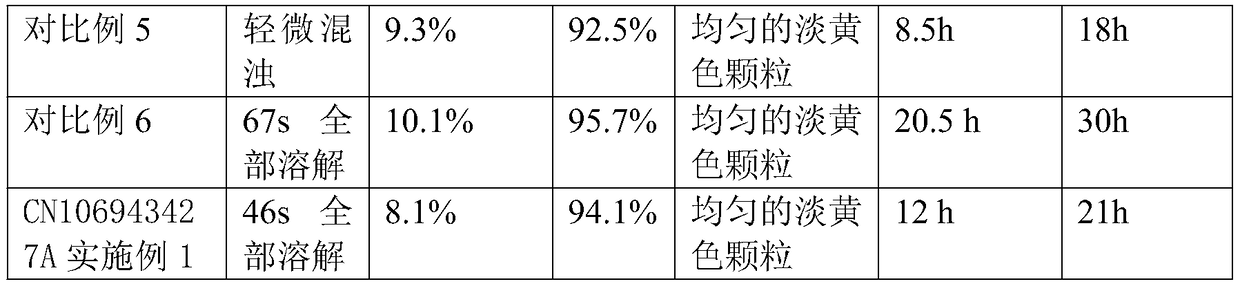

Preparation method of catalyst component for olefin polymerization

ActiveCN106608939AHigh catalytic activityGood orientationAcid anhydride formationOlefin polymerization

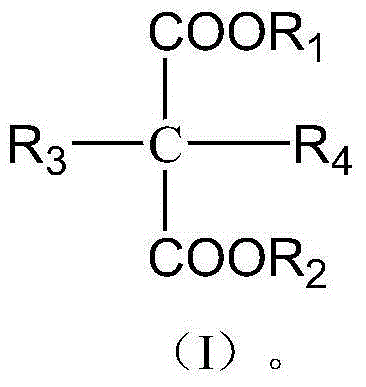

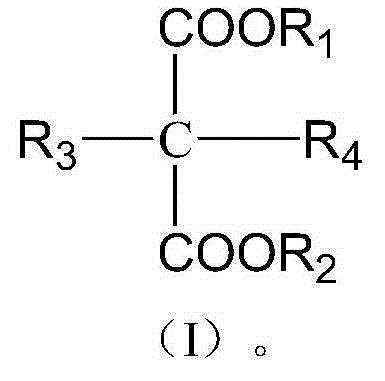

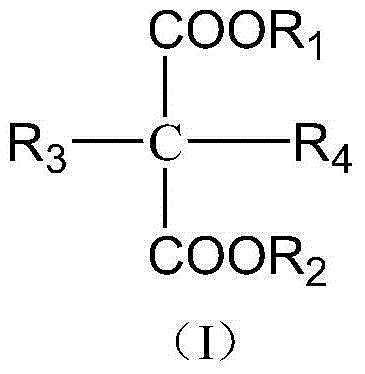

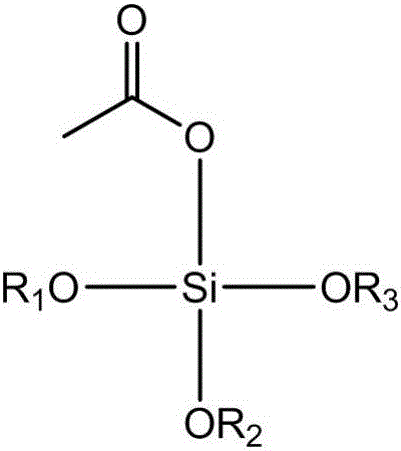

The invention relates to a preparation method of a catalyst component for olefin polymerization. In preparation of the catalyst component, a compound shown in the general formula (I) and an organic acid anhydride compound are used together as a precipitation aid so that a certain synergistic effect is obtained. The prepared catalyst has good fluidity, good particle morphology, uniform particle size distribution and excellent integrated performances. In a propylene polymerization reaction, the catalyst has high activity, a good orientation capacity and high isotacticity and is conducive to industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

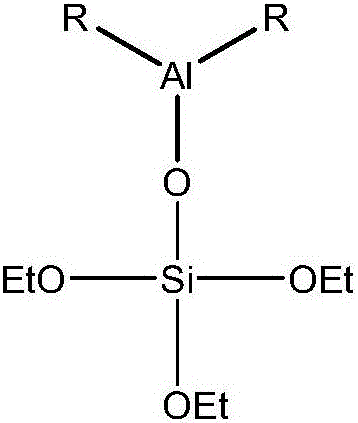

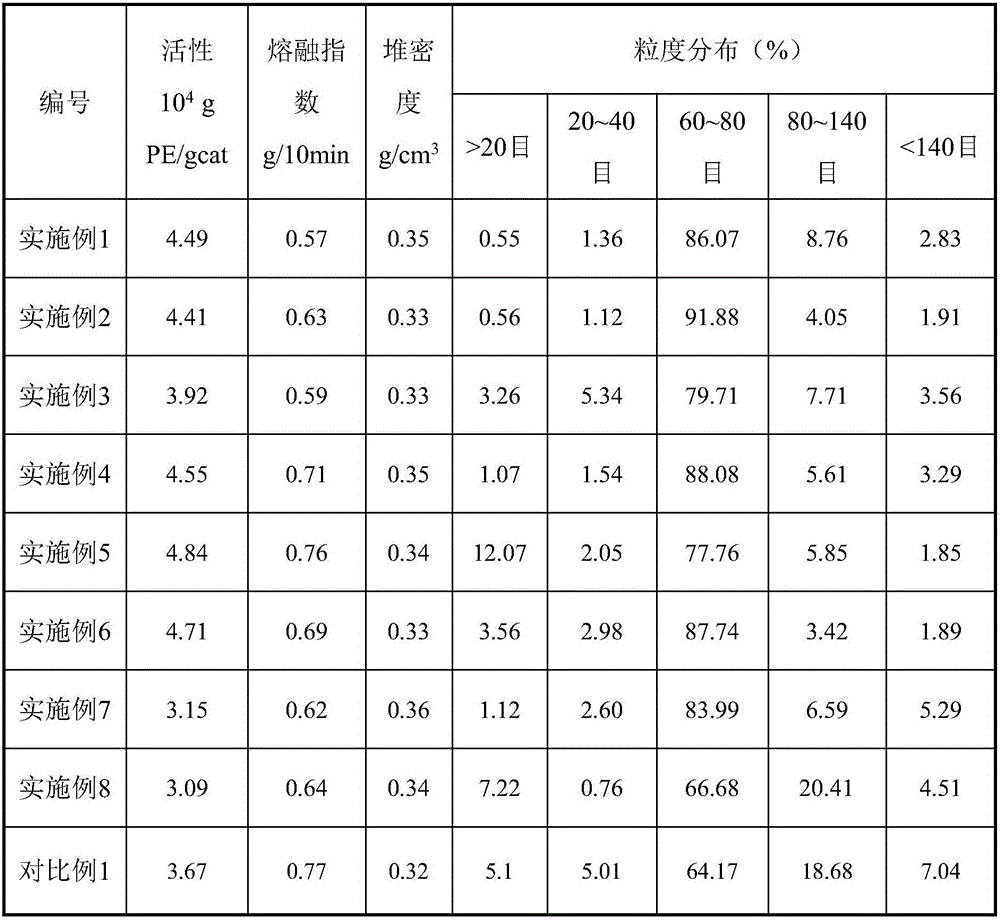

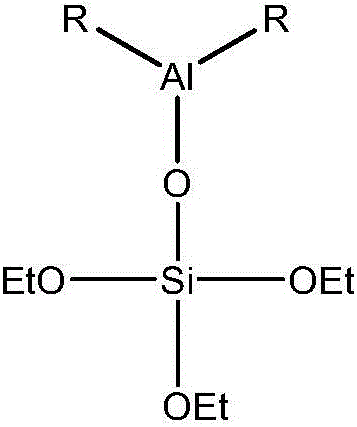

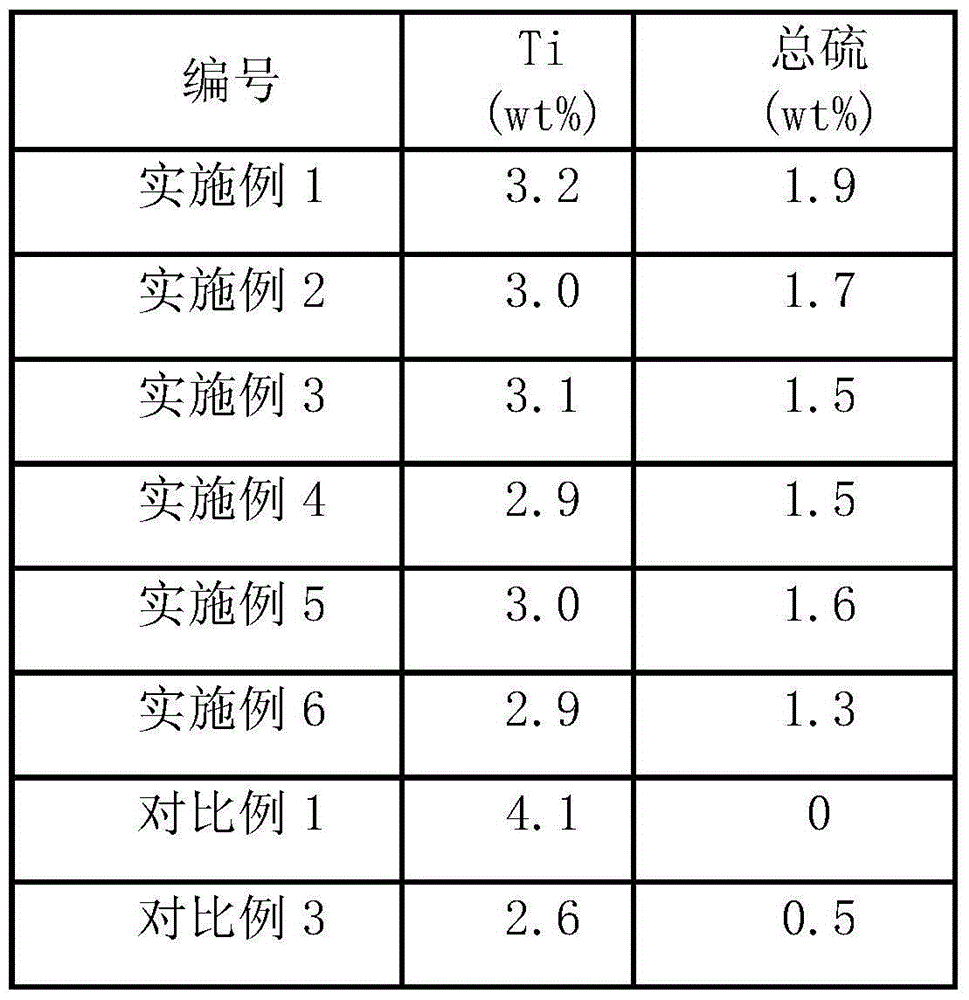

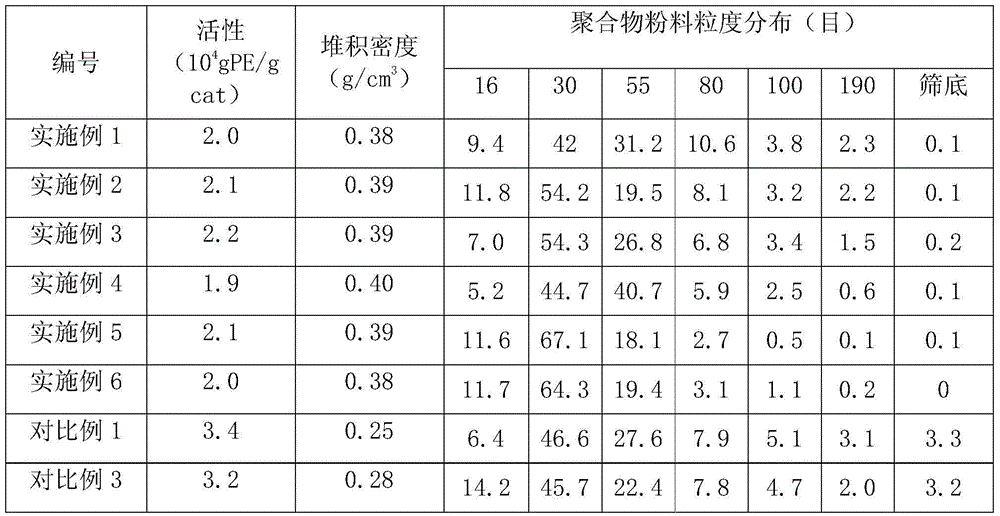

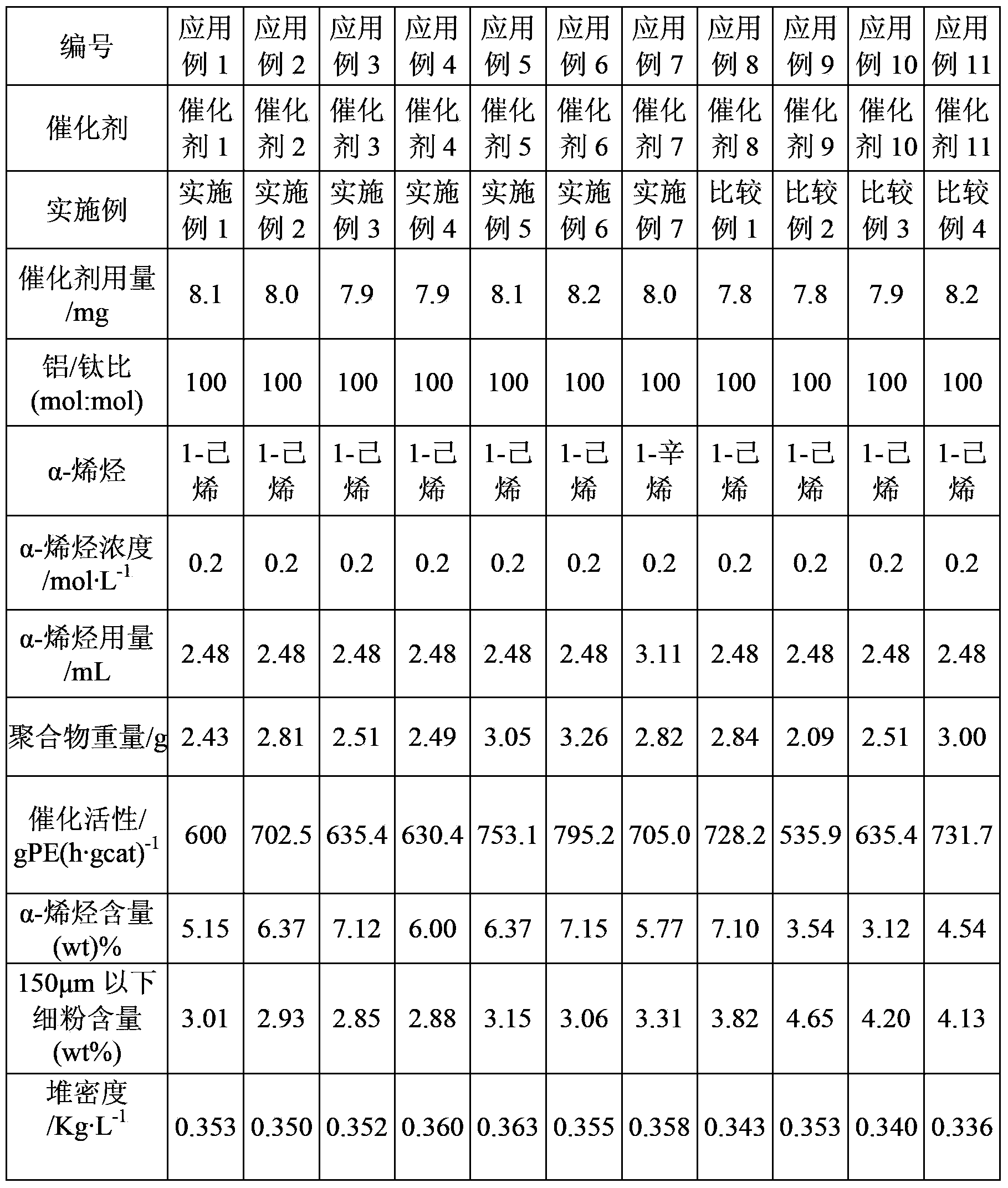

Electron donor of Ziegler-Natta catalyst and application of electron donor in vinyl polymerization

The invention relates to an electron donor of a Ziegler-Natta catalyst, a catalyst component comprising the electron donor and the catalyst. The electron donor adopts a Si-Al ester compound; the catalyst prepared from the Si-Al ester compound serving as the electron donor shows higher catalytic activity, better hydrogen response and better copolymerization performance when applied to vinyl polymerization and copolymerization, and can be used for catalyzing vinyl homopolymerization or production of high-performance polyolefin materials with high bulk density, narrow particle size distribution and small fine grain content through copolymerization of vinyl and other alpha-olefins.

Owner:TIANJIN UNIV OF SCI & TECH

Catalyst component used in ethylene polymerization reaction, catalyst and preparation method thereof

The invention discloses a catalyst component used in an ethylene polymerization reaction, a preparation method and a catalyst thereof, wherein the catalyst component includes: (1) a magnesium alcohol adduct; (2) a titanium compound; (3) a mercaptan compound; (4) a double-epoxy group compound and (5) a single-epoxy group compound. The catalyst has a polymerization activity being suitable for a gas-phase polymerization process of ethylene. An obtained polymer is high in stacking density and is low in fine powder content.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ethylene-alpha-olefin copolymerization catalyst and preparation and applications thereof

The invention relates to an ethylene-alpha-olefin copolymerization catalyst and preparation and applications thereof. The ethylene-alpha-olefin copolymerization catalyst is prepared through the steps of dissolving a magnesium compound in a hydrocarbon solvent, adding an alcohol solvent, and reacting for 2-4 hours under the condition of stirring at a temperature of 70-90 DEG C; then, adding an electron donor I, reacting for 1-2 hours under the condition of stirring, adding an electron donor II, and reacting for 1-2 hours under the condition of stirring; cooling to room temperature, dropwise adding a titanium compound, completing the dropwise adding in 1-2 hours, heating to 70-90 DEG C, and reacting for 1-3 hours under the condition of stirring; carrying out filter pressing on a reaction product so as to remove the solvent, adding a hydrocarbon solvent, stirring, heating to 70-90 DEG C, adding an electron donor III, and reacting for 1-2 hours under the condition of stirring; adding a titanium compound, and reacting for 1-3 hours under the condition of stirring; and filtering, washing and drying the obtained product. The catalytic activity of the catalyst for catalyzing the copolymerization of ethylene and long-chain alpha-olefin is high, so that a prepared copolymer is high in long-chain alpha-olefin insertion rate, high in bulk density, and less in fine powder.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A manufacturing method for oatmeal

The present invention discloses a manufacturing method for oatmeal. The method includes the following steps: cleaning and removing impurities in oats, washing, cooking, drying, granulating and steaming the oats in order, tempering the oats with 1-5% cellulase solution, and tableting and drying the oats. The tempering process accelerates the cell wall rupture of the oats, which makes intracellular substances of the oats sufficiently dissolved out, and improves nutritional ingredients and a health-care function of the oatmeal. The brewed oatmeal is strong and lasting in flavour, and customers can obviously feel a rich aroma which is pure natural; and soup is milky white, shiny and sticky in a greater degree, oatmeal porridge is chewy, but not sticky to teeth, and has a smooth taste. The produced oatmeal is oval and full in shape, uniform in size, less in piece and fine powder, and high in finished product rate.

Owner:金维他(福建)食品有限公司

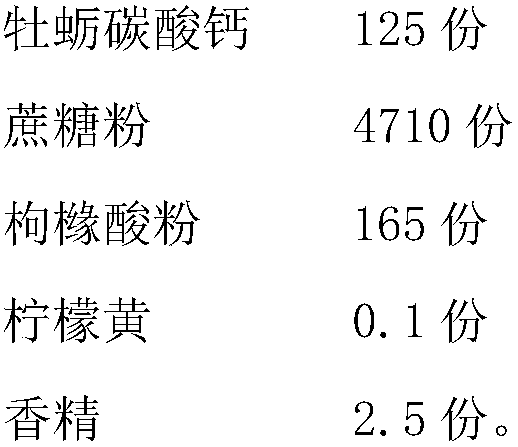

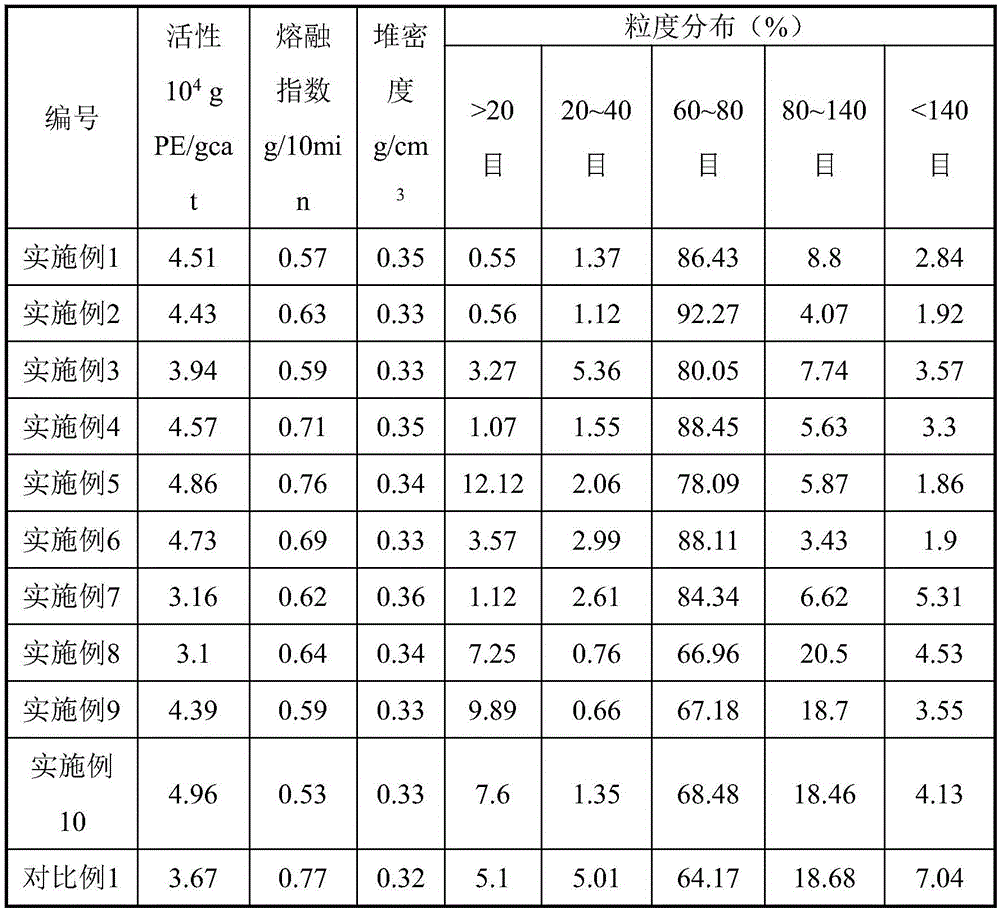

Method for preparing oyster calcium carbonate granules

ActiveCN109260220AImprove solubilityIncrease productionMetabolism disorderSkeletal disorderSucroseCitric acid

The invention discloses a preparation method of oyster calcium carbonate granules, which comprises stirring oyster calcium carbonate, sucrose powder and citric acid in a wet granulator, adding 20-30%ethanol solution is addd into a wet granulator to be stirred and cut to be granulate, and then is put into a one-step granulator to be resprayed with 20-30% ethanol solution to granule, making 80 meshfine powder quantity not exceed 5%, drying 5-10 min, sieve, spraying the atomize essence at an appropriate spray rate, mixing for 30 min, and finally packaging.

Owner:CHONGQING PHARSCIN PHARM CO LTD

Ethylene polymerization Ziegler-Natta catalyst electron donor, catalyst component, and catalyst

ActiveCN105859927AImproved particle size distributionHigh bulk densityPolyolefinZiegler–Natta catalyst

The invention relates to Ziegler-Natta catalyst electron donor, comprising a catalyst component of the electron donor and a catalyst of the electron donor. The electron donor is acetoxylsilane compound, the catalyst prepared with the acetoxylsilane compound as an electron donor shows high catalytic activity, good hydrogen modulation sensitivity and good copolymerizing performance when used in ethylene polymerization and copolymerization and can be used in homopolymerization of catalytic ethylene or copolymerization of ethylene with other Alpha-olefins to produce high-performance polyolefin material with high bulk density, narrow particle size distribution and low fine particle content.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation technology of roflumilast film-coated tablets

InactiveCN111643470AFriability meets requirementsGood granulationPharmaceutical non-active ingredientsRespiratory disorderAdhesiveMagnesium stearate

The invention relates to the technical field of tablet preparation, in particular to a preparation technology of roflumilast film-coated tablets. The preparation technology comprises the following steps of S1, micronizing roflumilast, and filtering starch, lactose and magnesium stearate through an 80-mesh sieve for later use; S2, dissolving hydroxypropyl methylcellulose into water to prepare aqueous solutions of different concentrations for later use; S3, mixing a mixture obtained by multiple equal incremental blending of 1 g of roflumilast and 15 g of starch with 398 g of lactose and remaining starch in the step S1; S4, adding an adhesive for granulation after mixing is ended; S5, preparing wet granules from prepared soft materials; S6, drying the wet granules obtained in the step S5; S7,carrying out granulation on the dried granules through a 20-mesh sieve; and S8, carrying out tableting by using a shallow concave mold with the diameter of 9 mm. When granulation is carried out by using the method, the granulation condition is good, the granules are uniform, the tablets are bright and clean, and the friability of tablet cores meets the requirements. Samples meeting the standard can be prepared through the method, the interbatch reproducibility is good, the samples are equivalent to originally commercially available products in quality, and production can be smoothly implemented through the preparation technology of a prescription.

Owner:山东希尔康泰药业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com