Preparation method for anti-impact polypropylene

A polypropylene and propylene technology is applied in the field of preparation of impact-resistant polypropylene, which can solve the problems of reduced plant capacity, high cost of plant renovation, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0081] This preparation example is used to prepare the titanium-containing solid catalyst component in the catalyst.

[0082] After fully replacing the 16L pressure-resistant reactor with agitator with nitrogen, add 10L ethanol, 300mL 2-ethylhexanol, 11.2g iodine, 8g magnesium chloride and 640g magnesium powder into the reactor. While stirring, the system was refluxed until no more hydrogen was released. The reaction was stopped, and the product was washed with 3L of ethanol, filtered, and dried to obtain a dialkoxymagnesium carrier. The dialkoxymagnesium carrier D50=30.2um, Span=0.81, m=0.015. Take 650 g of the above-mentioned dialkoxymagnesium carrier and 3250 mL of toluene to prepare a suspension. In a 16L pressure-resistant reactor that has been repeatedly replaced by high-purity nitrogen, add 2600 mL of toluene and 3900 mL of titanium tetrachloride, raise the temperature to 80 ° C, then add the prepared suspension to the kettle, keep the temperature for 1 hour, and add ...

Embodiment 1

[0084] This example is used to illustrate that in the method for preparing impact polypropylene with high ethylene content, the use of external electron donor T-Donor can increase the reactivity ratio of ethylene.

[0085] 1) Raw materials

[0086] The titanium-containing solid catalyst component obtained in the preparation example is a main catalyst; Triethylaluminum is used as a cocatalyst; Dicyclopentyldimethoxysilane (D-Donor) is used as the first external electron donor; Tetraethylaluminum Oxysilane (T-Donor) is used as the second external electron donor; propylene, ethylene and hydrogen are of polymerization grade, which are used after removing water and oxygen, and hexane is used after being dehydrated.

[0087] 2) Test device

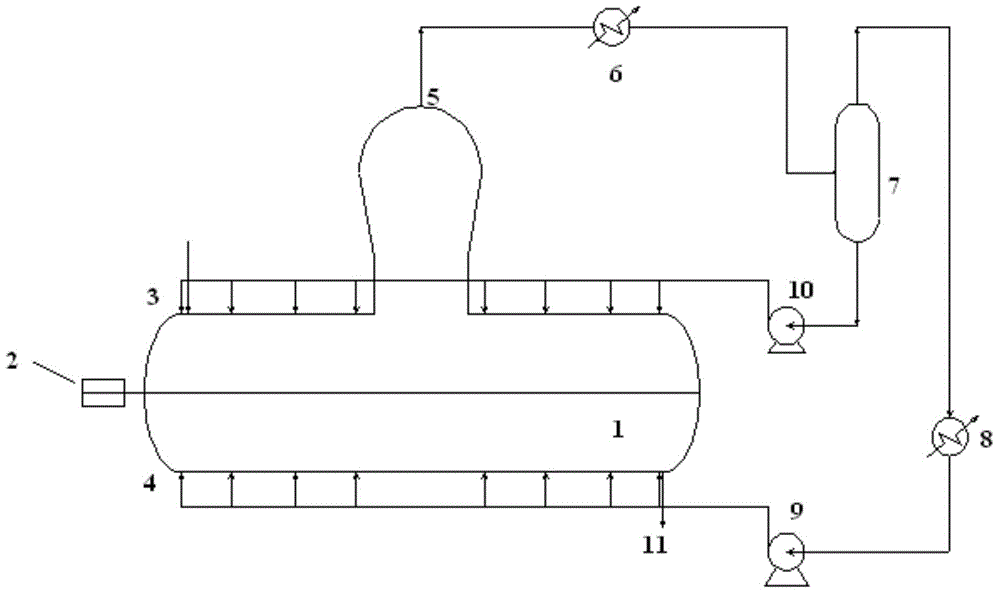

[0088] A polymerization process in which two horizontal tank gas phase reactors are connected in series is adopted, and the two horizontal tank gas phase reactors have the same structure and are respectively used as the first gas phase reactor ...

Embodiment 2

[0098] This example is used to illustrate that in the method for preparing impact polypropylene with high ethylene content, the load of cooling / condensing equipment can be reduced by adopting gas-phase multi-temperature zone technology.

[0099] 1) raw material, with embodiment 1.

[0100] 2) Test device, same as embodiment 1.

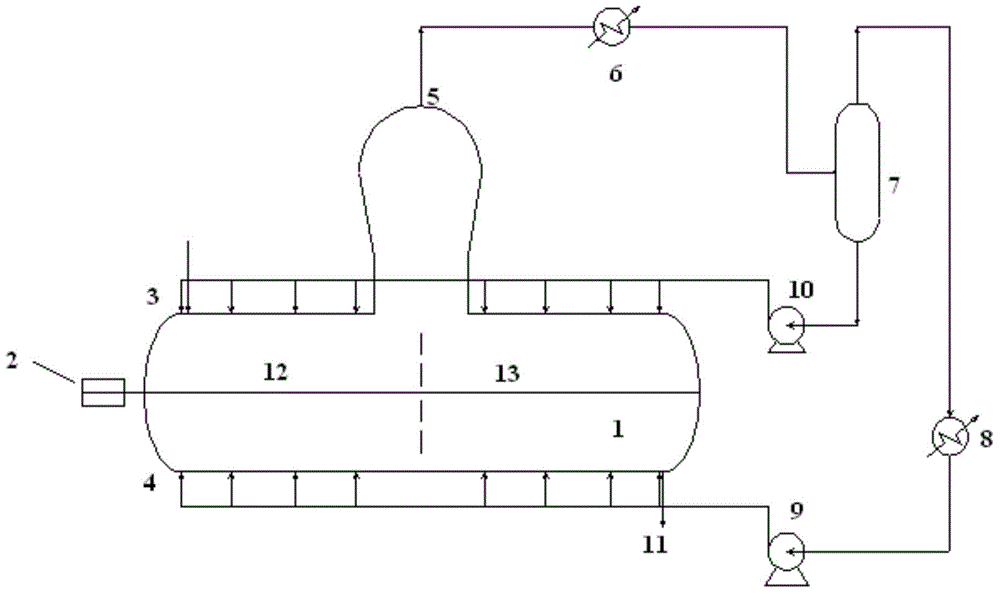

[0101] Among them, the second gas-phase horizontal reactor adopts gas-phase multi-temperature zone polymerization technology, such as figure 2 As shown: the first gas phase reaction zone 12 and the second gas phase reaction zone 13 are horizontally divided along the direction of the horizontal stirring shaft 2 of the horizontal tank, and different reaction zones have different reaction temperatures. The temperature of each reaction zone is independently adjusted by changing the flow rate of the quenching liquid sprayed in this zone or the size of the quenching liquid / circulation flow.

[0102] After the polymer powder and other streams are discharged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com