Preparation method and application of superhigh-molecular weight polyolefin catalyst

A technology of polyolefin catalyst and main catalyst, which is applied in the fields of olefin polymerization catalyst and olefin polymerization, and can solve problems such as poor reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

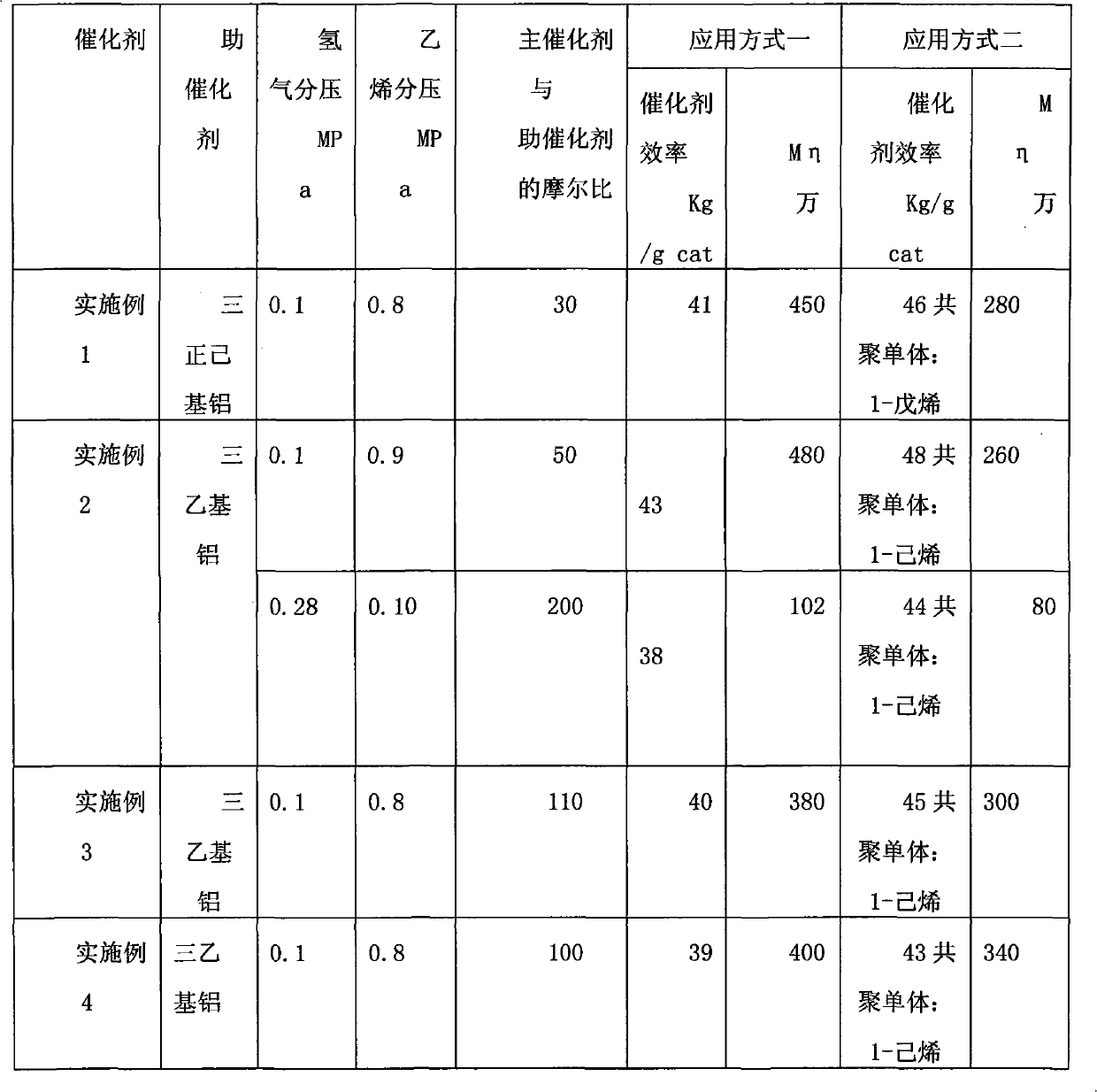

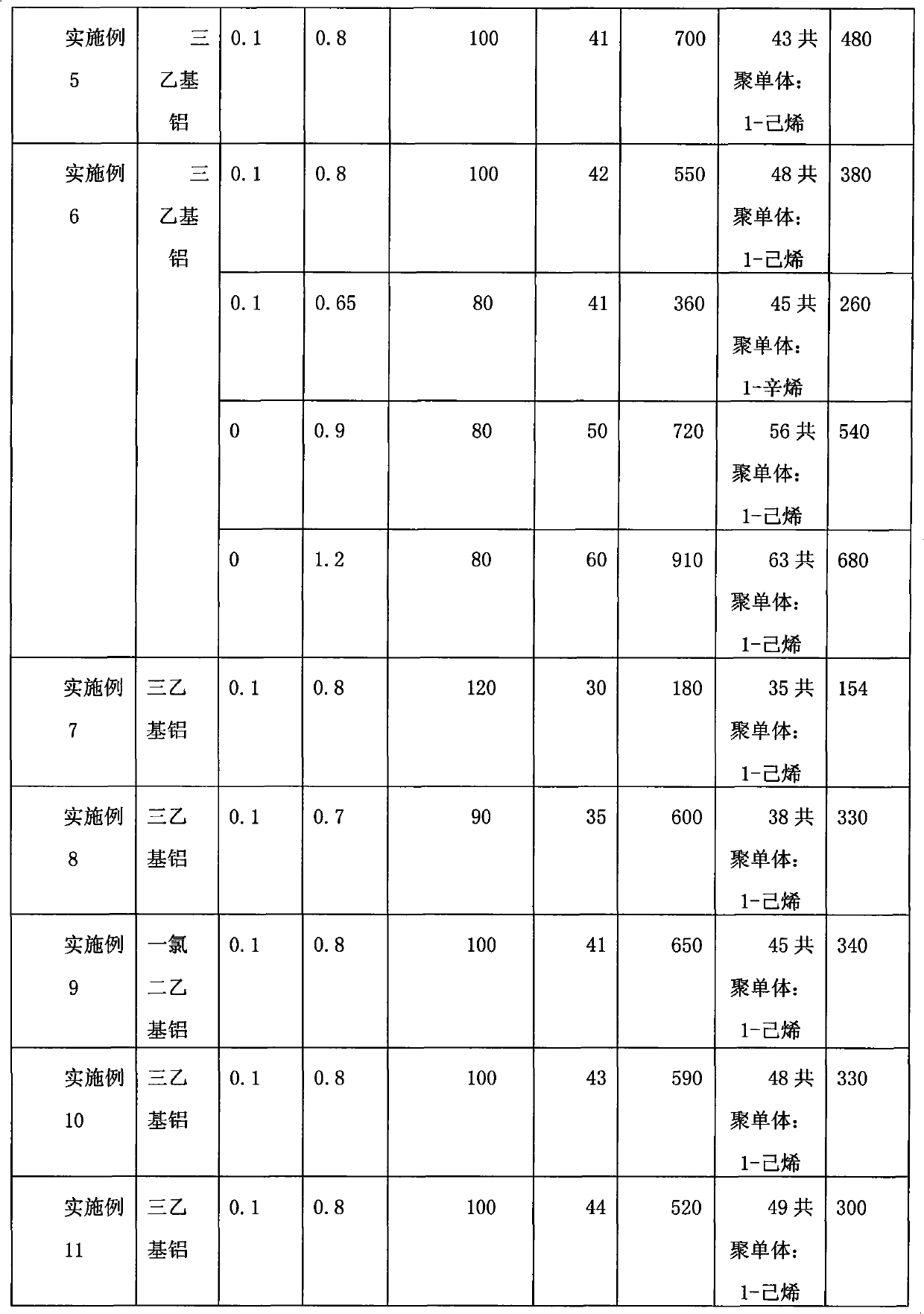

Examples

Embodiment 1

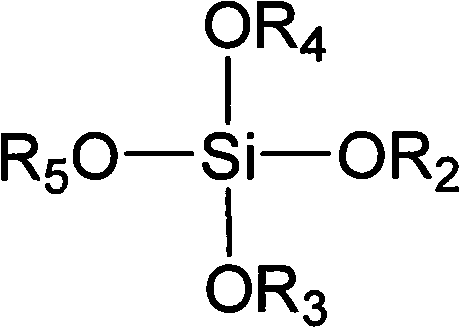

[0045] In a reactor that has been fully replaced by nitrogen, add activated SiO calcined at 400 ° C 2 1g, 50ml of toluene, stir, control the temperature at about -20°C, add 5ml of n-butyllithium (2.0M hexane solution) dropwise, and react at about 10°C for 1 hour after the dropwise addition; raise the temperature to 40°C and then react for 2 Hour. Reduce to room temperature and filter, wash twice with toluene (40 ml each time), and wash twice with n-hexane (40 ml each time). Add 50 ml of n-hexane, cool down to -25°C, add 1 g of dimethyldiethoxy silicon, dropwise add 25 ml of titanium tetrachloride, and react for 1 hour, then slowly (within 4 hours) heat up to 70°C for reaction 2 Hour, stop stirring, leave standstill suspension, layering, extract supernatant liquid, hexane washes four times (each 40 milliliters), vacuum-drying, obtains good fluidity, narrow particle size distribution, spherical procatalyst, The Ti content is 4.5 wt%.

Embodiment 2

[0047] In the reactor that has been fully replaced by nitrogen, add SiO activated by calcination at 500 °C 2 1g, 50ml of toluene, stir, control the temperature at about -30°C, add 0.5g of sodium n-tert-butoxide, react at about 0°C for 1 hour after the dropwise addition; raise the temperature to 50°C for another 3 hours. Reduce to room temperature and filter, wash twice with tetrahydrofuran (40 ml each time), and wash twice with n-hexane (40 ml each time). Add 60 ml of n-hexane, cool down to -10°C, add 15g of tetraethoxy silicon, dropwise add 20 ml of titanium tetrachloride, react for 1 hour, slowly (within 4 hours) raise the temperature to 70°C for 2 hours, stop Stir, leave standstill suspension, layering, extract supernatant liquid, hexane washes four times (each 40 milliliters), vacuum-drying, obtains fluidity good, narrow particle size distribution, spherical procatalyst, Ti content is 4.8 wt%.

Embodiment 3

[0049] In a reactor that has been fully replaced by nitrogen, add activated SiO calcined at 600°C 2 1g, 50ml of tetrahydrofuran, stir, control the temperature at about 20°C, add 0.8g of potassium ethoxide, react at about 20°C for 1 hour after the dropwise addition; raise the temperature to 50°C for another 3 hours. Reduce to room temperature and filter, wash twice with tetrahydrofuran (40 ml each time), and wash twice with n-hexane (40 ml each time). Add 60 ml of n-hexane, cool down to -10°C, add 20 g of diethoxyisopropoxy tert-butoxy silicon, dropwise add 50 ml of titanium tetrachloride, react for 1 hour, then slowly (within 4 hours) heat up React at 70°C for 2 hours, stop stirring, let the suspension stand, separate layers, extract the supernatant, wash with hexane four times (40 ml each time), and dry in vacuo to obtain a liquid with good fluidity, narrow particle size distribution, and The spherical procatalyst has a Ti content of 5.2 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com