A manufacturing method for oatmeal

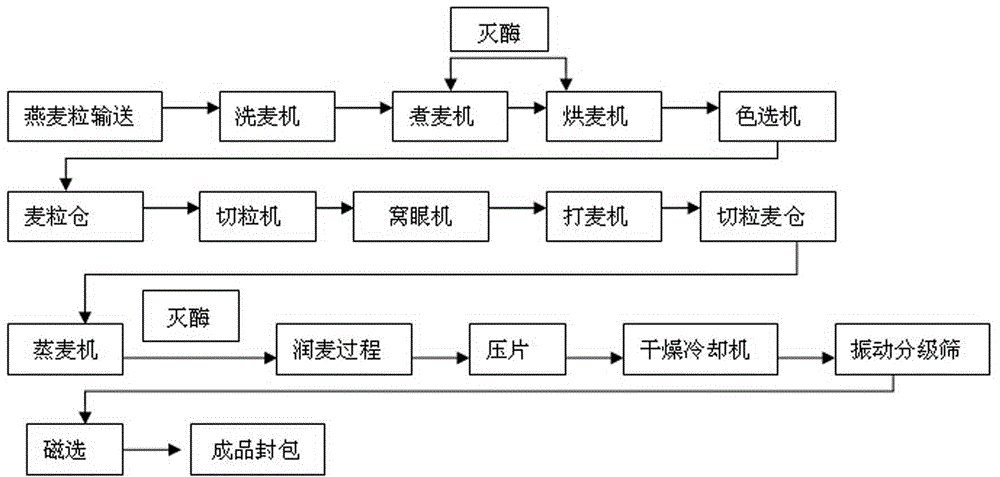

A production method and technology of oatmeal, which is applied in the field of food processing, can solve the problems of reduced food quality, non-lubrication, rough taste of oatmeal, etc., and achieve the effect of natural and pure flavor, less fragments and fine powder, and improved nutritional components and health care functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The preparation method of oatmeal comprises the following steps:

[0017] 1. Oat selection: feed the oats, and go through the rough selection of the primary selection machine to remove the impurities in the oats; the selection of the selection machine to remove the unqualified oat grains; the delivery of oat grains is between 700 and 900kg per hour between;

[0018] 2. Requirements for wheat washing: wash the transported oat grains with tap water. The cleaned wheat grains should not contain excessive water, and the water should be on the surface, with no water dripping down as the standard.

[0019] 3. Cooking wheat: Send the cleaned oat grains into the wheat cooking machine. The air pressure of the oat cooker is required to be between 0.4-0.5MPa, and the temperature of the oat grains cooked at the outlet of the oat cooker is between 100-130°C. The cooking time is 15-30min.

[0020] 4. Oat baking: The oat grains from the outlet of the oat cooking machine are sent to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com