Square particle benzoxazine molding plastic

A technology of benzoxazine and molding compound, applied in the field of molding compound, can solve problems such as environmental pollution and endanger human health, and achieve the effects of environmental protection, high flame retardancy and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Benzoxazine resin 20%; chopped fiber 60%; titanium dioxide 2%; curing accelerator 1%; wollastonite 12.5%; thermoplastic polyurethane elastomer rubber 3%; stearic acid 1%; wax 0.5%.

Embodiment 2

[0014] Benzoxazine Resin 30%; Chopped Fiber 50%; Titanium Dioxide 3%; Curing Accelerator 2%; Wollastonite 8%; Thermoplastic Polyurethane Elastomer Rubber 4%; Stearic Acid 2%; Wax 1%.

Embodiment 3

[0016] Benzoxazine resin 40%; chopped fiber 30%; titanium dioxide 5%; curing accelerator 3%; wollastonite 12%; thermoplastic polyurethane elastomer rubber 5%; stearic acid 3%; wax 2%.

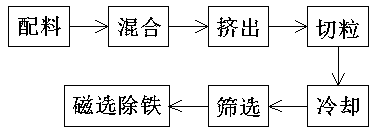

[0017] Such as figure 1 As shown, mix the components of the above examples 1, 2, and 3 evenly, knead them with a screw extruder, cut them into square particles with a pelletizer, and sieve out the fine powder after air cooling, and then remove iron to obtain finished product. The products made in Examples 1, 2, and 3 were prepared as sample strips according to GB / T1404-2008 powdered phenolic molding compound, and after the post-curing test, the test data were obtained in the following table:

[0018] Test items

[0019] During the curing process, because no small molecules are released, the mold shrinkage rate is small and the yield is high; the product is baked in an oven at 240°C for 2 hours, no abnormal deformation is seen, and the heat resistance is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com