Magnesium halide alcohol adduct and preparation method and application thereof

A technology of magnesium halide alcohol compound and polyether compound, which is applied in the field of olefin polymerization, especially in the field of propylene polymerization or copolymerization catalyst components, can solve the problems such as difficulty in forming spherical particles of particle size, easy stickiness, and reduction in fine powder content. , to achieve the effect of good particle shape, less fine powder and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

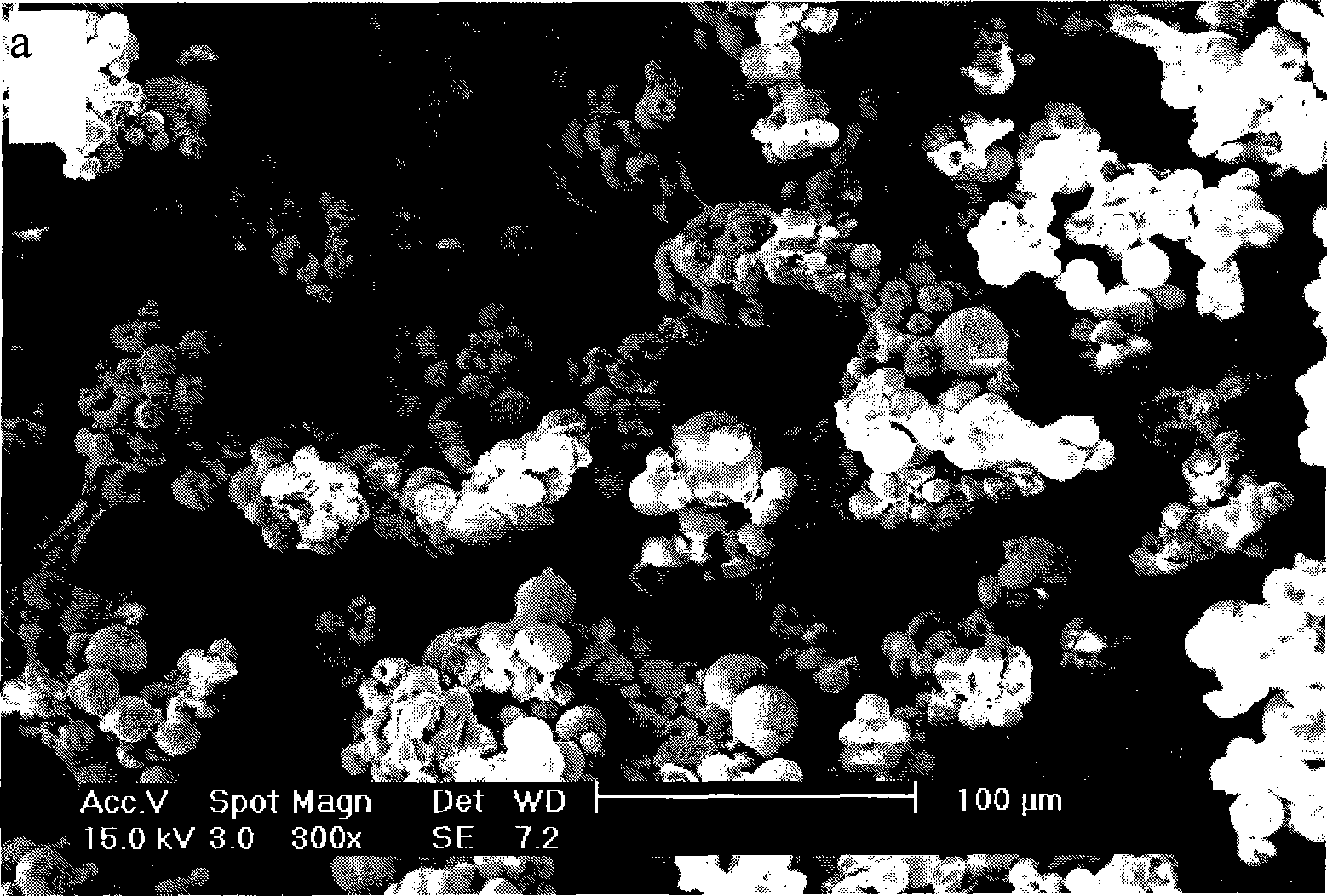

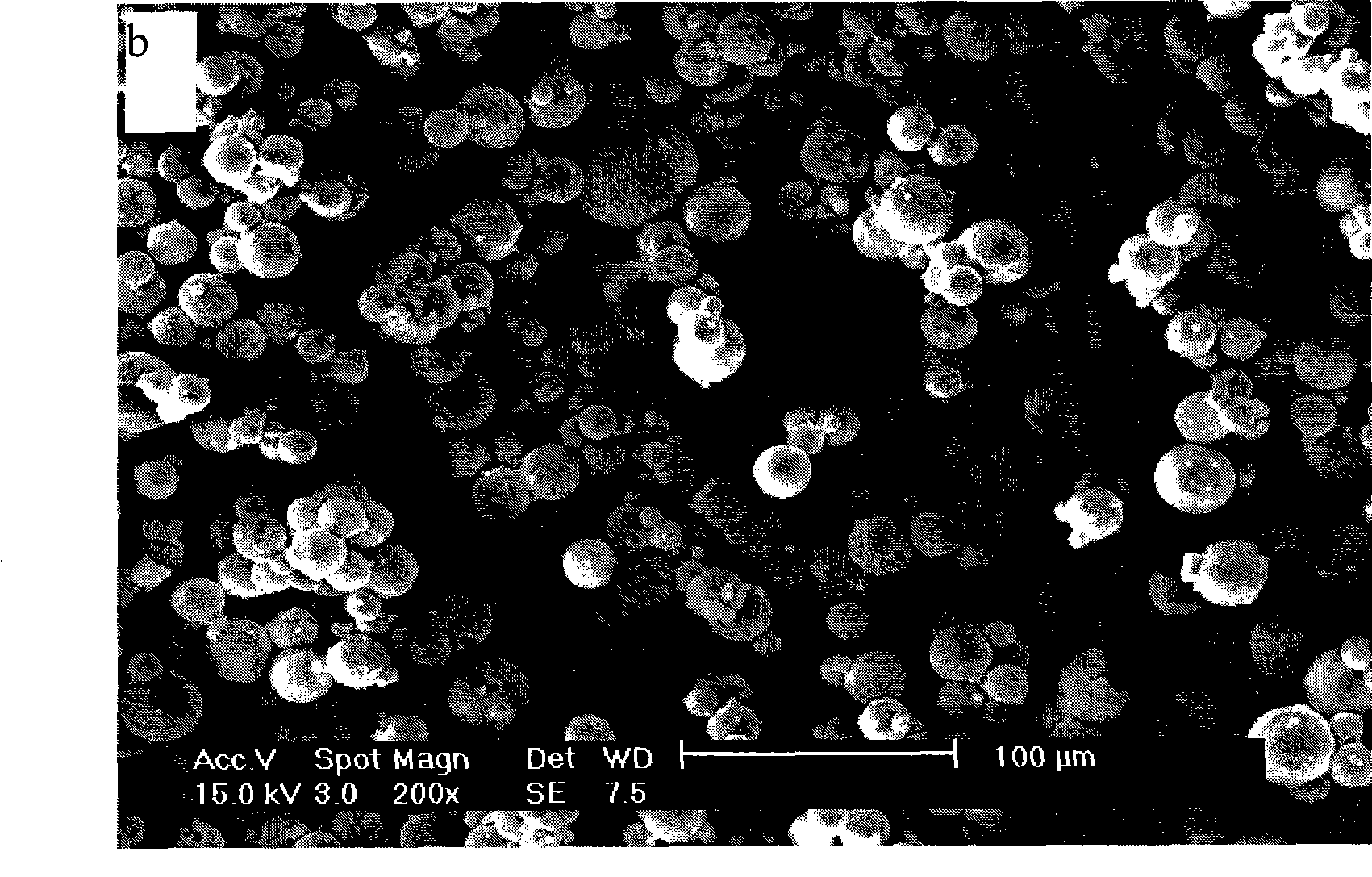

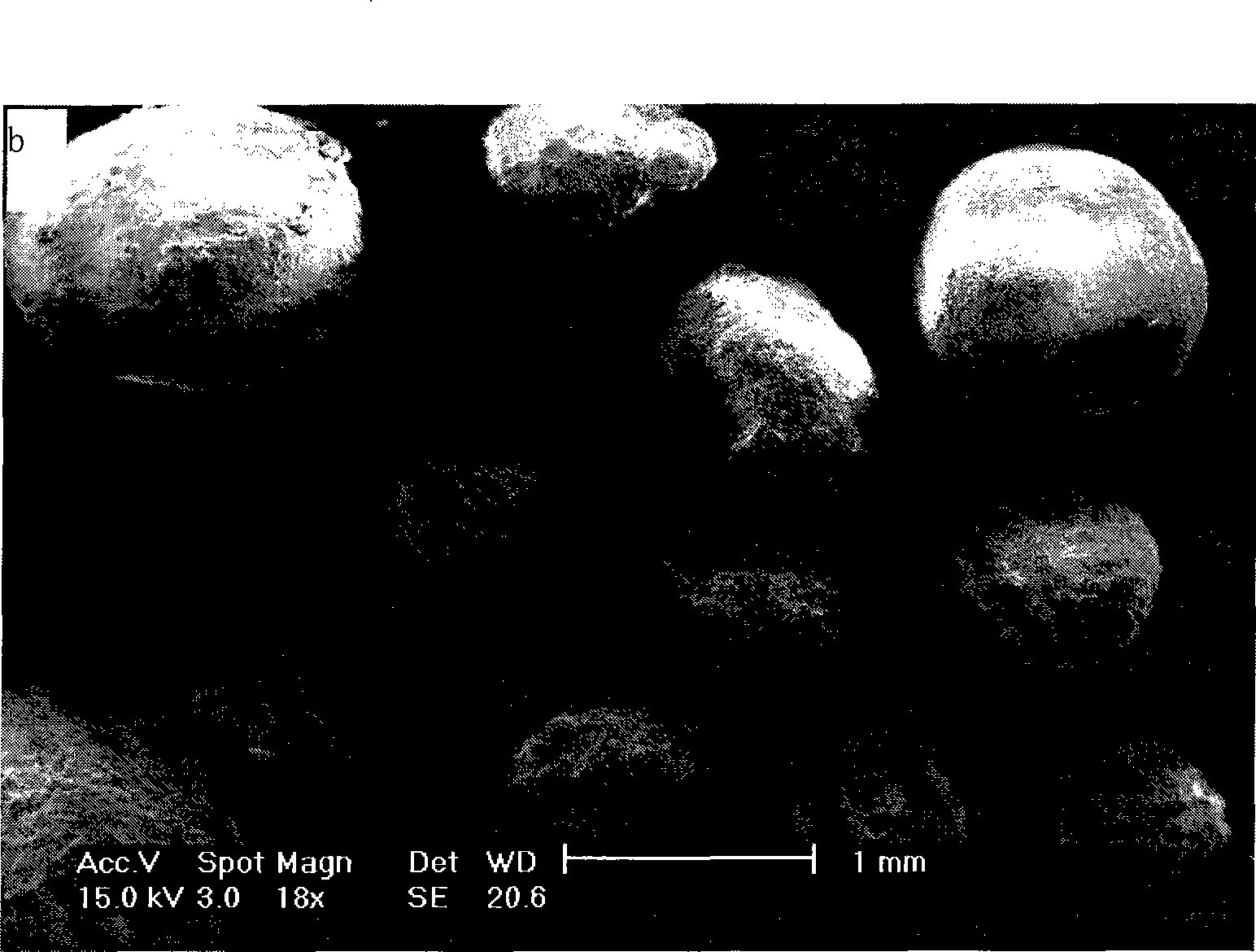

[0049] Preparation of the carrier:

[0050] In a 500mL pressure-resistant reactor, sequentially add 250ml of silicone oil, 15g of magnesium chloride, 26ml of ethanol and 0.3g of polypropylene alcohol (PPG). Suction filtration and washing with hexane three times, and vacuum drying to obtain a spherical carrier referred to as Sp-p for short.

[0051] Catalyst preparation:

[0052] Into a 300 mL glass reaction bottle, add 100 ml of titanium tetrachloride and hexane, cool to -20°C, add 8 grams of the above-mentioned spherical carrier, and heat up to 110°C. During the heating process, 1.5 ml of diisobutyl phthalate was added, the liquid was filtered off, washed twice with titanium tetrachloride, washed three times with hexane, and dried in vacuo. The catalyst prepared by Sp-p carrier is called SpC-p for short.

[0053] Propylene polymerization:

[0054] The liquid-phase bulk polymerization of propylene was carried out in a 5L stainless steel autoclave. Under nitrogen protectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com