Ethylene-alpha-olefin copolymerization catalyst and preparation and applications thereof

A technology of olefin copolymerization and catalyst, which is applied in the field of olefin polymerization catalysts, can solve the problems of failure to realize the copolymerization of ethylene and 1-hexene, difficult separation of catalyst solids, uneven distribution of 1-hexene, etc., and achieve low cost, good shape, The effect of less polymer fine powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

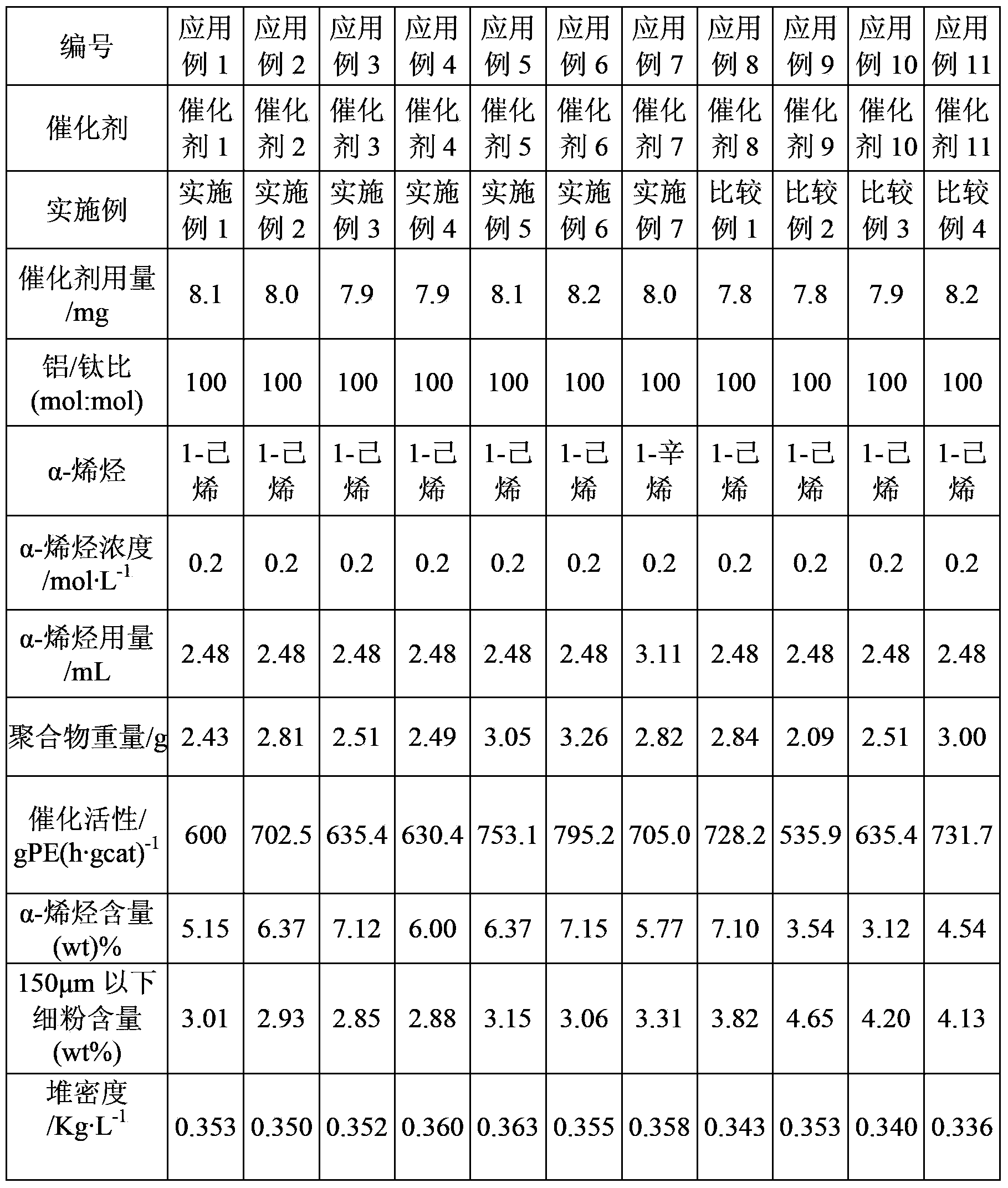

Examples

Embodiment 1

[0041] This embodiment provides a catalyst for the copolymerization of ethylene and α-olefin, which is prepared by the following steps:

[0042] (1) Add 1 g of anhydrous magnesium chloride, 30 ml of n-hexane and 3.75 ml of isobutanol into a three-neck flask replaced by argon, stir and heat to 70° C., and react for 3 hours to obtain a suspension.

[0043] (2) Add 0.10 ml of tributyl phosphate to the suspension, stir and react at 70° C. for 1.5 hours, then add 0.2 ml of tetraethoxysilane, and stir and react at 70° C. for 1.5 hours.

[0044] (3) Cool down to room temperature and slowly add 20 ml of titanium tetrachloride dropwise for 90 minutes; gradually raise the temperature to 70°C for 2 hours; then stir and react for 2 hours.

[0045] (4) Hydraulically filter the supernatant, add 25 ml of n-hexane, heat up to 70° C., add 0.20 ml of tetrahydrofuran, and stir for 1.5 hours.

[0046] (5) Then add 20 ml of titanium tetrachloride and react for 2 hours. After the reaction, it was...

Embodiment 2

[0049] The preparation method of the present embodiment ethylene and α-olefin copolymerization catalyst is the same as embodiment 1, the difference is:

[0050] The amount of isobutanol in step (1) is 4.3 milliliters.

[0051] In step (2), diethyl succinate was used instead of tributyl phosphate, and the amount used was 0.10 ml; hexyltrimethoxysilane was used instead of tetraethoxysilane, and the amount used was 0.25 ml.

[0052] In the step (3), the amount of titanium tetrachloride is 30 milliliters, the time for dropping is 2 hours, and the reaction time is 1 hour.

[0053] In step (4), the amount of tetrahydrofuran used is 0.35 milliliters, and the reaction time is 2 hours.

[0054] In the step (5), the consumption of titanium tetrachloride is 22 milliliters, and the reaction time is 3 hours.

[0055] The titanium content of the prepared solid catalyst 2 was 4.04wt%.

Embodiment 3

[0057] This embodiment provides a catalyst for the copolymerization of ethylene and α-olefin, the preparation method of which is the same as that of Example 1, except that:

[0058] The amount of isobutanol used in step (1) is 2.20 milliliters.

[0059] The amount of tributyl phosphate in step (2) is 0.20 ml; the amount of tetraethoxysilane is replaced by 3-chloropropyltriethoxysilane, and the amount is 0.22 ml.

[0060] In the step (3), the amount of titanium tetrachloride used is 16 milliliters, the dropwise addition time is 2 hours, and the reaction time is 1 hour.

[0061] In step (4), tetrahydrofuran was replaced with 2,2-dimethylpropane, and the dosage was 0.15 ml.

[0062] In the step (5), the consumption of titanium tetrachloride is 16 milliliters.

[0063] The titanium content of the prepared solid catalyst 3 was 4.10wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com