Solid catalyst component and catalyst for olefin polymerization

A solid catalyst and olefin polymerization technology, applied in the field of polyolefin catalysts, can solve problems such as increased investment modification, chain parking of pre-polymerization reactors, and agglomeration of pre-polymerization reactors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] In a four-neck flask equipped with a stirrer, install a reflux condenser and connect an accumulative gas meter to the reflux condenser. After the entire reaction device is fully replaced by nitrogen, add 70.8mL of absolute ethanol and 1.26g of iodine to the container. , to dissolve it. Add 6g of magnesium powder into it, heat up to the reflux temperature of ethanol under stirring conditions, and add 40mL of absolute ethanol and 5g of magnesium powder every 15 minutes from the reflux, a total of 5 times. About 1 to 2 hours after the completion of the fifth addition, the liquid viscosity began to rise sharply. At this time, add 259 mL of ethanol to the reaction system and continue the reaction until the reaction ends and no hydrogen is generated. The entire reaction time is about 6 hours. After filtration and drying, a diethoxymagnesium support was obtained.

[0083] Add 960 mL of toluene to the above-mentioned diethoxymagnesium carrier, start stirring and cool down to 0...

Embodiment 2

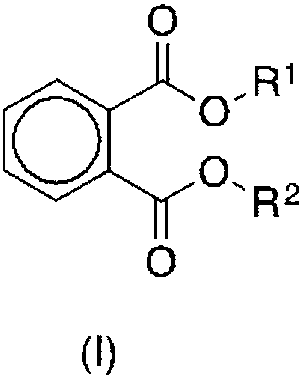

[0085] The preparation steps of the catalyst component are the same as in Example 1, except that 30 mL of absolute ethanol and 4 g of magnesium powder are added successively every 30 minutes from the reflux; 35 mL of absolute ethanol and 4.5 g of magnesium powder; 40 mL of absolute ethanol and magnesium powder 5g; absolute ethanol 45mL, magnesium powder 5.5g; absolute ethanol 50mL, magnesium powder 6g. And replace di-n-butyl phthalate with equimolar 9,9-bismethoxymethylfluorene.

Embodiment 3

[0087] The preparation steps of the catalyst component are the same as in Example 1, except that 30 mL of absolute ethanol and 4 g of magnesium powder are added successively every 20 minutes from the reflux; 35 mL of absolute ethanol and 4.5 g of magnesium powder; 40 mL of absolute ethanol and magnesium powder 5g; absolute ethanol 45mL, magnesium powder 5.5g; absolute ethanol 50mL, magnesium powder 6g; absolute ethanol 55mL, magnesium powder 6.5g; absolute ethanol 60mL, magnesium powder 7g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com