Preparation methods for olefin polymerization catalyst component and corresponding catalyst

A technology for olefin polymerization and catalysts, which is applied in the field of rapid preparation of olefin polymerization catalyst components, and can solve the problems of reducing the content of catalyst fine powder, polymer fine powder content, equipment pipeline blockage, and shortening the dissolution time of carrier magnesium halide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

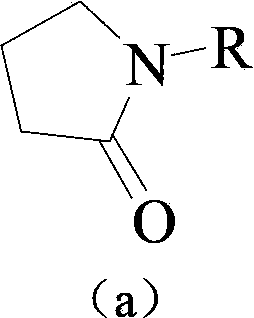

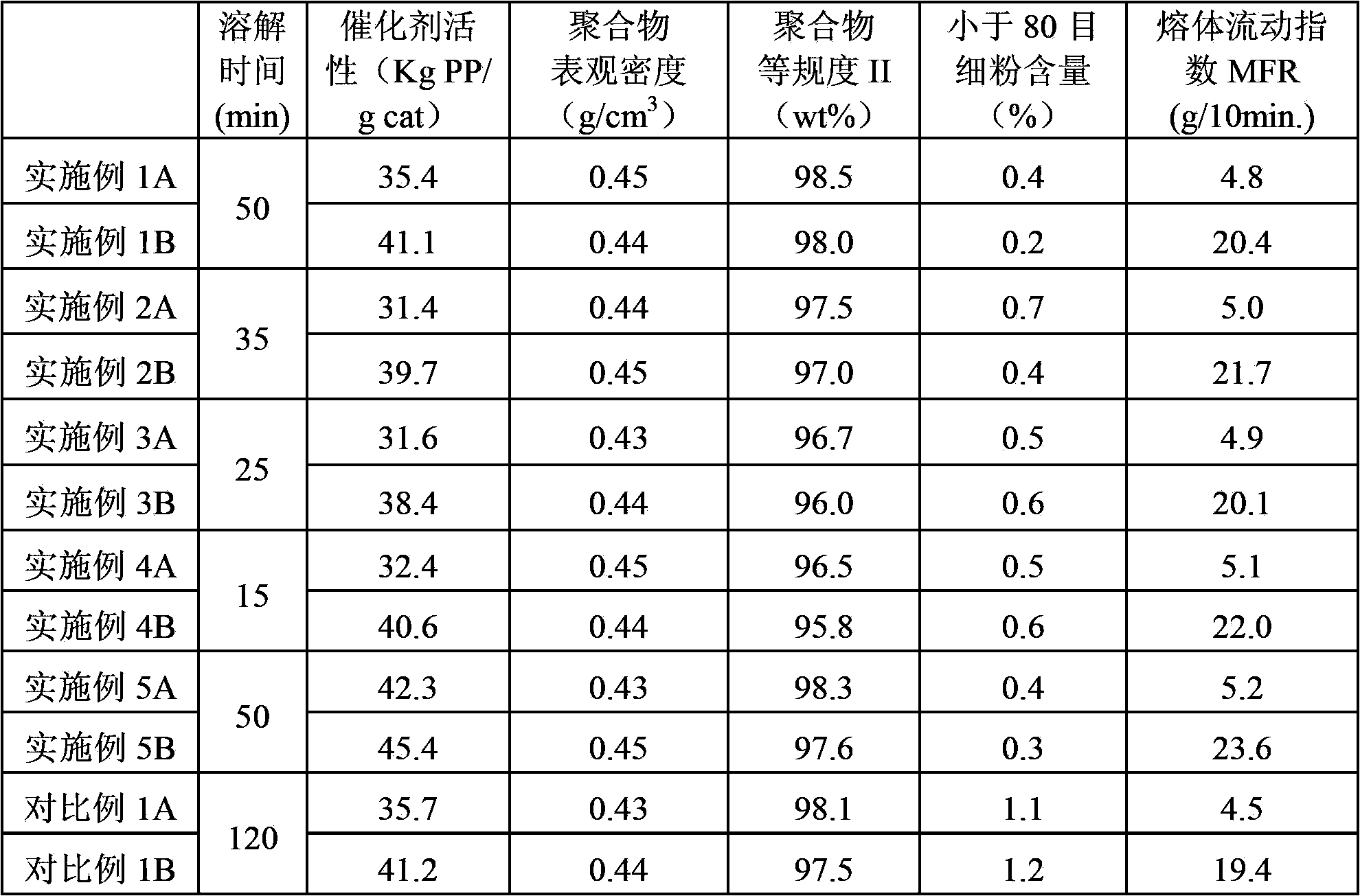

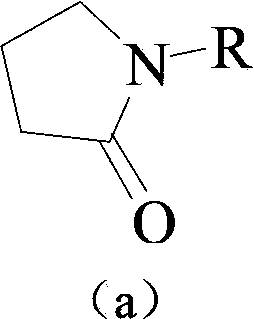

[0039] Preparation of olefin polymerization catalyst components: In an atmospheric pressure reactor repeatedly replaced by high-purity nitrogen, 4.8 grams of anhydrous magnesium chloride, 70 milliliters of toluene, 4.0 milliliters of epichlorohydrin, 12.5 milliliters of tributyl phosphate and 0.2 milliliters of N-Methylpyrrolidone, at a temperature of 60°C, react for 50 minutes to completely dissolve the carrier, add 1.4 grams of phthalic anhydride (co-eluting agent) and 30 ml of toluene, continue the reaction for one hour, and cool to -28 ℃, add 56 ml of titanium tetrachloride dropwise (the dropping rate is 1 ml / min), gradually raise the temperature to 85 °C (the heating rate is 5 °C / min), and add 1.1 ml of di-n-butyl phthalate at 80 °C (DNBP, internal electron donor), keep the temperature for one hour, filter, wash the solid twice with toluene, then add 48 ml of titanium tetrachloride and 72 ml of toluene, keep the temperature at 110°C for 0.5 hours and filter, repeat this op...

Embodiment 1B

[0041] The catalyst component is used to catalyze the polymerization of propylene (Example 1B): only change "1 liter of hydrogen under standard state" in Example 1A to "4 liters of hydrogen under standard state", and the rest are the same as in Example 1A.

Embodiment 2

[0043] Preparation of olefin polymerization catalyst components: the experimental conditions were basically the same as those in Example 1, except that the amount of N-methylpyrrolidone was changed to 0.5 ml, and the reaction time at 60° C. was changed to 35 minutes. In the prepared olefin polymerization catalyst component, by weight, the titanium content is 2.2%, the DNBP content is 12.50%, the magnesium content is 19%, the chlorine content is 64%, and the phosphorus content is 0.19%.

[0044] The catalyst component is used to catalyze the polymerization of propylene (Example 2A): the experimental conditions are basically the same as in Example 1A, except that the catalyst component prepared in Example 2 is used instead, and the specific results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com