Electron donor of Ziegler-Natta catalyst and application of electron donor in vinyl polymerization

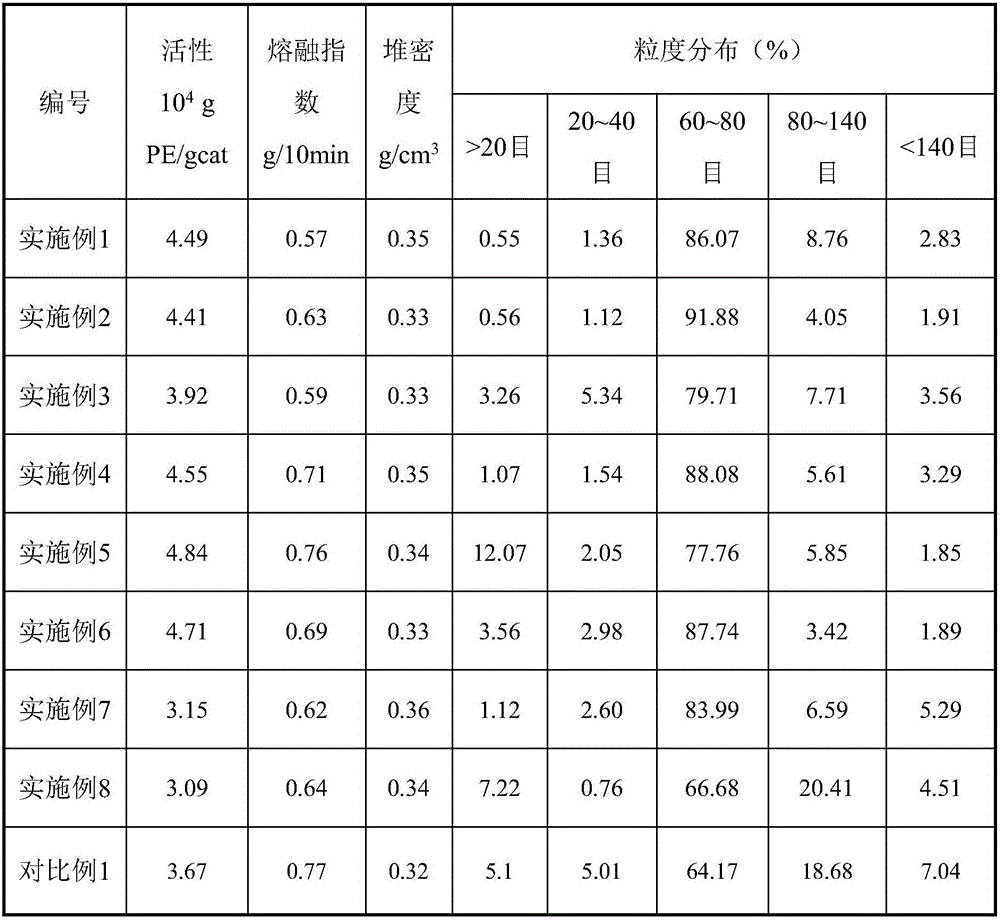

An electron donor and catalyst technology, applied in the field of ethylene polymerization catalysis, can solve the problems of high price, limited application, etc., and achieve the effects of low production cost, less fine powder of polymer products, good hydrogen-adjusted sensitivity performance and copolymerization performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

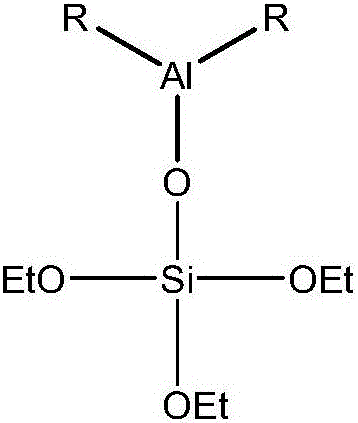

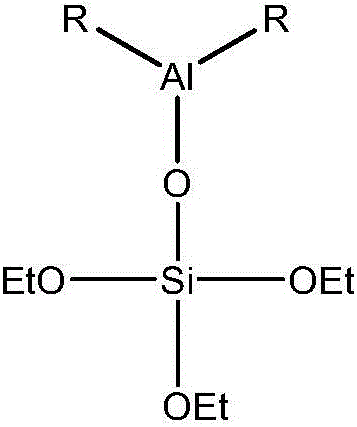

[0034] Put 4.76 g (50 mmol) of anhydrous MgCl 2 , 75 milliliters of decane and 16.3 grams (125 mmol) of isooctyl alcohol were heated to 125° C., and reacted at a constant temperature for 3 hours to obtain a homogeneous and transparent solution. To this solution was added 15 mmol of di-t-butoxytriethoxysilaluminate and stirred at 50° C. for 2 hours to dissolve di-t-butoxytriethoxysilaluminate in the solution. The homogeneous solution obtained above was cooled to room temperature, and then added dropwise to 150 mL of TiCl with stirring at -10 °C within 1 hour. 4 middle. After dropping, the temperature of the mixture was maintained at -10°C for 1 hour, then the temperature was raised to 120°C at a certain rate of temperature increase under stirring, and the temperature was maintained for 2 hours. After 2 hours of reaction, the resulting solid was separated by hot filtration. The solid catalyst is fully washed with decane and hexane respectively until no precipitated titanium c...

Embodiment 2

[0038] Put 4.76 g (50 mmol) of anhydrous MgCl 2 , 75 milliliters of decane and 16.3 grams (125 mmol) of isooctyl alcohol were heated to 125° C., and reacted at a constant temperature for 3 hours to obtain a homogeneous solution. To this solution was added 15 mmol of diisopropoxytriethoxysilaluminate and stirred at 50°C for 2 hours to dissolve diisopropoxytriethoxysilaluminate in the solution. All the homogeneous solutions obtained above were cooled to room temperature, and then added dropwise to 200 mL of TiCl maintained at -15 °C within 1 hour while stirring 4 middle. After completion of the dropwise addition, the temperature of the mixture was maintained at -15°C for 1 hour, then raised to 120°C over 4 hours with stirring, and maintained at this temperature for 2 hours. After 2 hours of reaction, the resulting solid was separated by hot filtration. The solid catalyst is fully washed with decane and hexane respectively until no precipitated titanium compound can be detecte...

Embodiment 3

[0042] 4.76 g (50 mmol) of anhydrous magnesium chloride, 75 ml of decane and 16.3 g (125 mmol) of isooctyl alcohol were heated to 125° C. and reacted at constant temperature for 3 hours to obtain a homogeneous solution. To this solution was added 15 mmol of diethoxytriethoxysilaluminate and stirred at 50°C for 2 hours to dissolve diethoxytriethoxysilaluminate in the solution. All the homogeneous solutions obtained above were cooled to room temperature, and then added dropwise to 150 mL of TiCl with stirring at 0 °C within 1 hour 4 middle. After completion of the dropwise addition, the temperature of the mixture was maintained at 0°C for 1 hour, then raised to 120°C over 2 hours with stirring, and maintained at this temperature for 2 hours. After 2 hours of reaction, the resulting solid was separated by hot filtration. The solid catalyst is fully washed with decane and hexane respectively until no precipitated titanium compound can be detected in the cleaning liquid, and a so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com