Preparation method of lithium iron phosphate/lithium vanadium phosphate composite material

A technology of lithium vanadium phosphate and lithium iron phosphate, which is applied in the field of electrochemical power supply material preparation, can solve problems such as difficulty in meeting industrialized large-scale preparation, uneven heating of bulk materials, and ascorbic acid consumption, and is easy to realize industrialized scale production. , regular particle morphology, excellent abnormal temperature and low temperature electrochemical performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

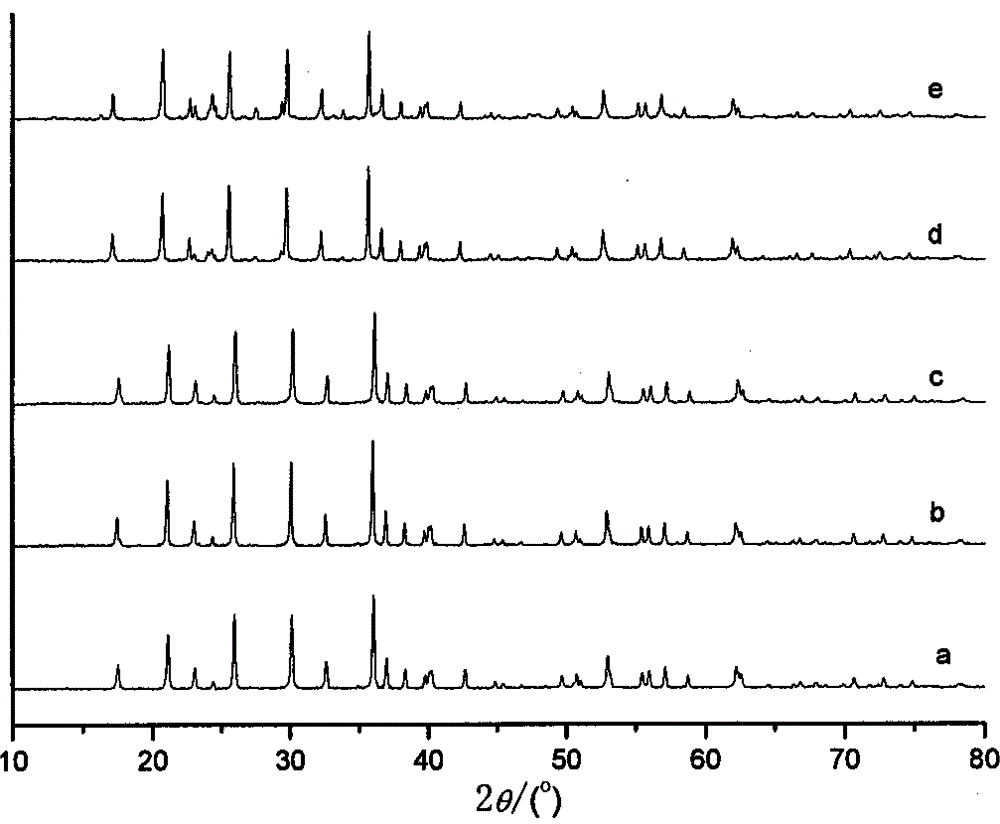

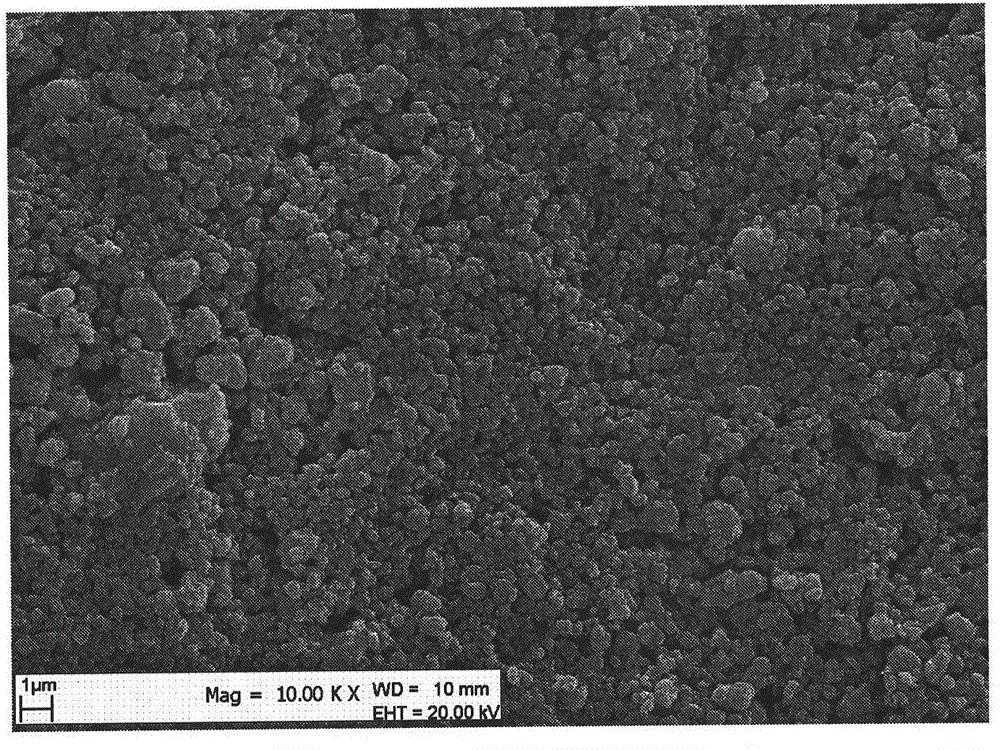

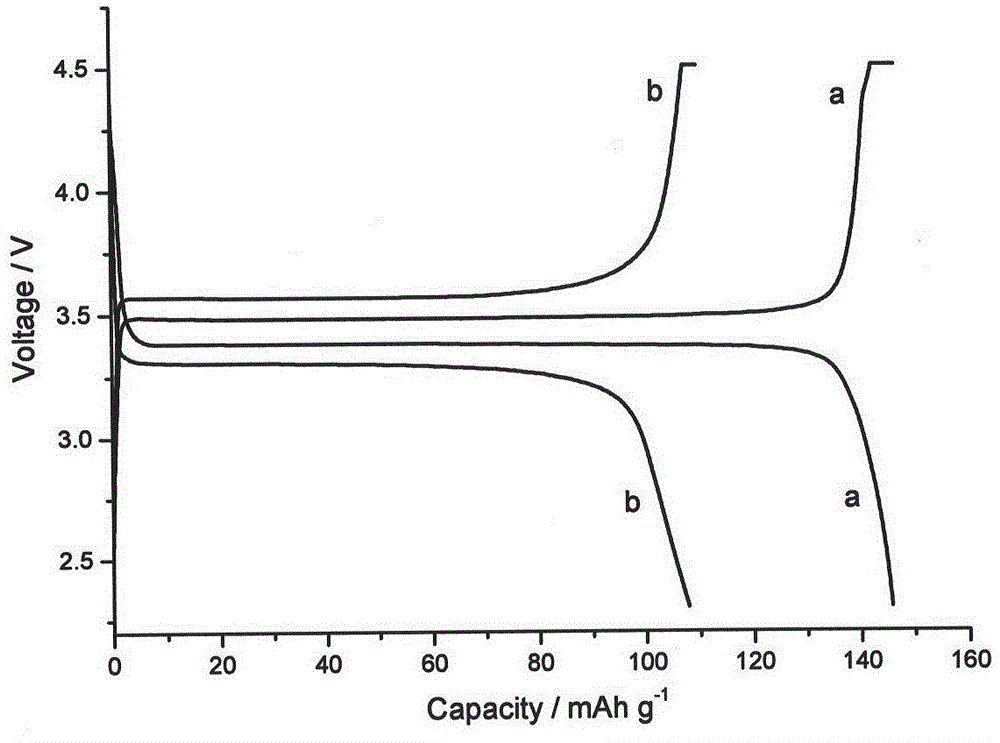

Image

Examples

Embodiment 1

[0031] a. Molar ratio Fe:V:Li:P:H 2 C 2 o 4 =50:2:53:53:27 Weigh iron phosphate, vanadium pentoxide, lithium carbonate, ammonium dihydrogen phosphate and oxalic acid (raw material purity is 99.9%), fully mix, grind in agate mortar, grind time 3h;

[0032] b. Heat-treat the powder in step a under a protective gas nitrogen atmosphere with an air flow rate of 0.2 L / min, raise the temperature at a heating rate of 5°C / min, bake at a temperature of 300°C for 5 hours, and then heat it at a temperature of 1°C / min. Speed down to room temperature;

[0033] c. Add carbon source glucose with a mass fraction of 5% to the powder obtained in step b (the mass fraction of carbon in the composite material after decomposition is 1.6%-2.4%), and grind for 1 hour;

[0034] d. Press-molding the powder in step c, and heat-treating it under the protective gas nitrogen atmosphere, the molding pressure is 10MPa, the airflow speed is 0.2L / min, the heating rate is 5°C / min, and the temperature is 65...

Embodiment 2

[0037] a. Molar ratio Fe:V:Li:P:H 2 C 2 o 4 =40:2:43:43:22 Weigh iron phosphate, vanadium pentoxide, lithium carbonate, ammonium dihydrogen phosphate and oxalic acid (purity of raw material is 99.9%), mix well, grind in agate mortar, grinding time 5h ;

[0038] b. Heat-treat the powder in step a under the protective gas argon atmosphere, the air flow rate is 0.4L / min, the temperature is raised at a heating rate of 7°C / min, and the temperature is roasted at 330°C for 8 hours, and then the temperature is 3°C / min cooling down to room temperature;

[0039] c. Add carbon source sucrose with a mass fraction of 20% to the powder obtained in step b (the mass fraction of carbon in the composite material after decomposition is 6.7%-10%), and grind for 1-4 hours;

[0040] d. Press-molding the powder in step c, heat treatment under the protective gas argon atmosphere, the molding pressure is 15MPa, the air flow rate is 0.4L / min, the temperature is raised at a heating rate of 7°C / min, ...

Embodiment 3

[0043] a. Molar ratio Fe:V:Li:P:H 2 C 2 o 4 =40:2:43:43:22 Weigh iron phosphate, vanadium pentoxide, lithium hydroxide, ammonium dihydrogen phosphate and oxalic acid (raw material purity is 99.9%), mix well, grind in agate mortar, grind time 5.5 hours;

[0044] b. Heat-treat the powder in step a under the protective gas argon atmosphere, the air flow rate is 0.5L / min, the temperature is raised at a heating rate of 8°C / min, and the temperature is roasted at 350°C for 10 hours, and then the temperature is 5°C / min cooling down to room temperature;

[0045] c. Add 15% carbon source glucose (the mass fraction of carbon in the composite material after decomposition is 4.8%-7.2%) to the powder obtained in step b, and grind for 1-4 hours;

[0046] d. Press-molding the powder in step c, heat-treating it under the protective gas argon atmosphere, the molding pressure is 20MPa, the airflow velocity is 0.5L / min, the temperature is raised at a heating rate of 8°C / min, and then roasted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com