Nixing pottery rapid manufacturing process suitable for dry pressing molding

A technology of dry pressing molding and manufacturing technology, which is applied in the field of Nixing pottery processing, which can solve the problems of uneven density of the formed green body, high energy consumption of green body drying, and large friction force of the green body, so as to achieve uniform density, reduce distortion and cracking , time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

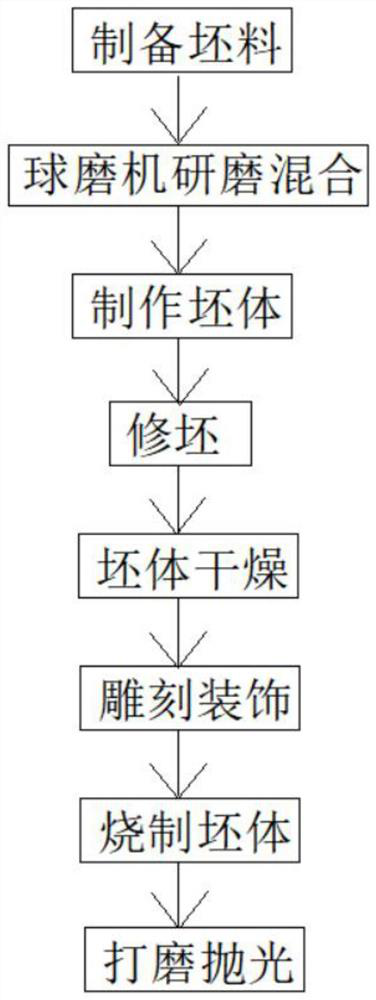

[0025] see figure 1 , a kind of embodiment that the present invention provides: a kind of Nixing pottery rapid production process suitable for dry pressing molding, comprises the following steps:

[0026] Step 1: Prepare blanks: the blanks are made of the following raw materials in parts by weight: 40 parts of Dongni, 40 parts of Xini, 15 parts of kaolin, and 5 parts of silicon carbide particles, and mix and pulverize the blanks to obtain clay powder ;

[0027] Step 2: put the pottery clay powder in step 1 into a ball mill together with water for grinding and mixing, and obtain a powder with a moisture content of 15%;

[0028] Step 3: Make the green body, pass the powder in step 2 through a 100-mesh sieve, enter the sedimentation tank, and let it stand for 2 hours. After the mud settles, drain the upper layer of clear water, and then dehydrate the mud through a filter press to make mud Strips, and finally the mud strips are made into various types of green bodies;

[0029] ...

Embodiment 2

[0039] see figure 1 , an embodiment provided by the present invention: a rapid manufacturing process of Nixing pottery suitable for dry pressing, comprising the following steps:

[0040] Step 1: Prepare the blank: the blank is made of the following raw materials in parts by weight: 50 parts of Dongni, 20 parts of Xini, 20 parts of kaolin, and 10 parts of silicon carbide particles. Mix and pulverize the blank to obtain clay powder ;

[0041] Step 2: put the pottery clay powder in step 1 into a ball mill with water to grind and mix, and obtain a powder with a moisture content of 20%;

[0042] Step 3: Make the body, pass the powder in step 2 through a 100-mesh sieve, enter the sedimentation tank, and let it stand for 3 hours. After the mud settles, drain the upper layer of clear water, and then dehydrate the mud through a filter press to make mud Strips, and finally the mud strips are made into various types of green bodies;

[0043] Step 4: Trim the blank, trim the blank to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com