Preparation method for salinomycin sodium fine granular formulation

A salinomycin sodium and micro-particle technology, applied in the directions of additional food elements, animal feed molding or processing, animal feed, etc., can solve problems such as unfavorable production costs and product quality, affecting the health of operators, and easily generating dust. , to avoid insufficient or excessive intake of food, which is beneficial to mixing and uniform feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

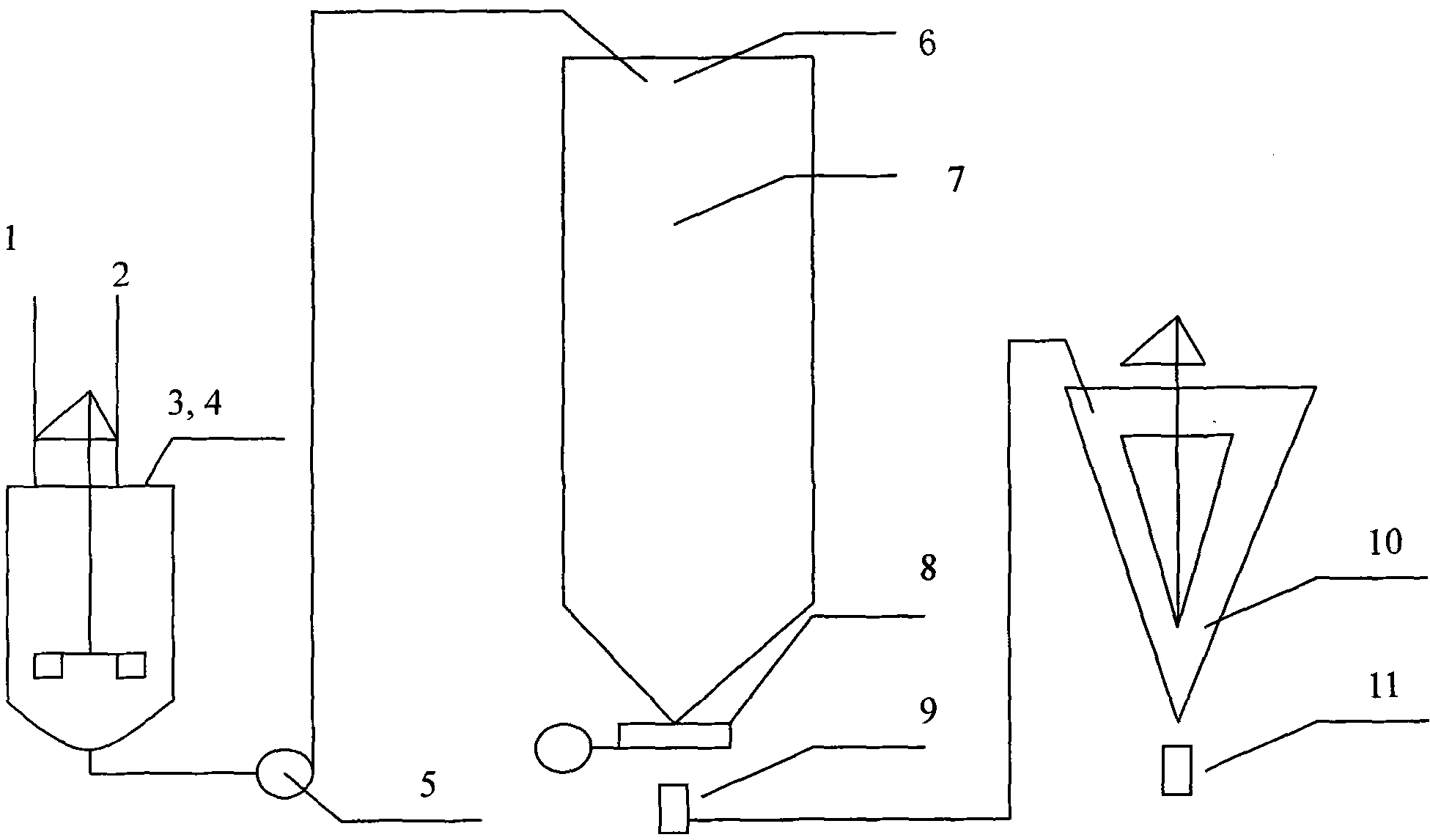

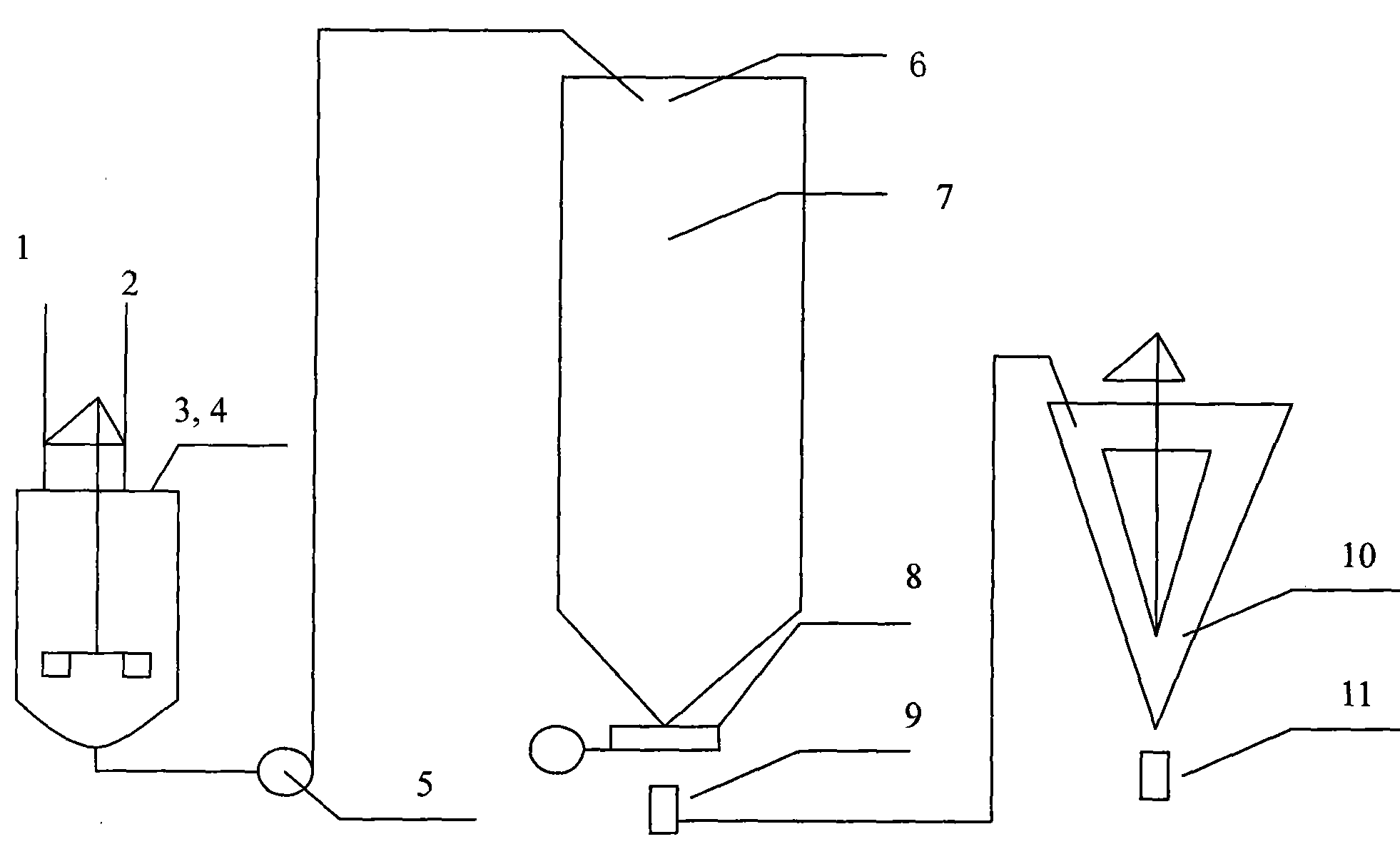

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1. The total amount of salinomycin and the content of dry matter in the fermented liquid are 13%wt.

[0025] The titer of salinomycin fermentation broth is 65000 μg / mL, take 200L, add 65Kg calcium carbonate, 0.4Kg hydroxymethyl cellulose, add caustic soda to adjust pH, measure pH while adding, adjust to pH7.5 and stop adding alkali. The feed liquid is pressurized by the screw pump and enters the spray gun. The nozzle of the spray gun adopts a 1.8mm aperture spray piece. The liquid droplets exchange water with the hot air flowing upstream and quickly dry into tiny particles. The particles enter the vibrating screen and collect the middle layer to obtain salt. 98Kg semi-finished product of mycin sodium microparticles. Tested content: 121 μg / mg, particle size: 100% passed No. 2 drug sieve, 12% passed No. 5 drug sieve.

[0026] After sieving, the semi-finished product of salinomycin sodium microparticles is sent to a powder mixer, and mixed with semi-finished pr...

Embodiment 2

[0028] After the fermentation, the titer of the salinomycin fermentation broth was 70000 μg / mL, 200 L was taken, 70 Kg calcium carbonate, 0.4 Kg hydroxymethyl cellulose were added, and caustic soda was added to adjust the pH to 7.4 to stop adding alkali. Spray drying is the same as in Example 1 to obtain 103Kg of semi-finished product. Tested content: 122 μg / mg, particle size: 100% passed No. 2 drug sieve, 13% passed No. 5 drug sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com