Preparation method for polypropylene material special for transparent sheet

A transparent sheet, polypropylene technology, applied in the field of polypropylene, to achieve the effect of high rigidity, high heat resistance, good rigidity and toughness balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

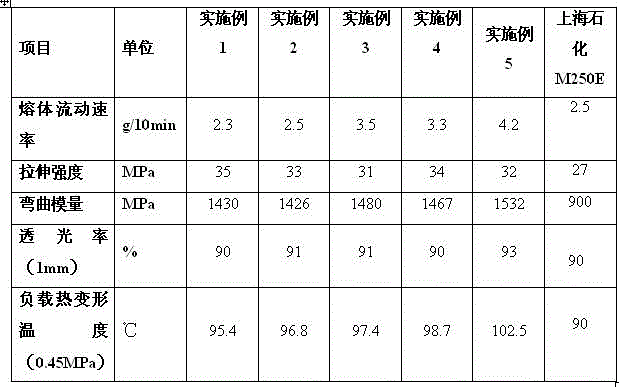

Examples

Embodiment 1

[0033] Add 100 parts of propylene monomer, 0.3 parts of TK catalyst, 0.3 parts of triethylaluminum and 0.1 parts of dimethyldimethoxysilane into the first liquid phase reactor for reaction, the reaction time is 0.5h, and the reaction temperature is 71°C , reaction pressure 2.9MPa, H 2 The mass ratio to propylene is controlled at 0.02‰; the obtained product then enters the second liquid phase reactor for reaction, closes the hydrogen feed valve, the reaction temperature is 65°C, the reaction pressure is 2.5MPa, and the reaction time is 0.8h. The obtained product continues to Enter the first gas-phase fluidized-bed reactor for reaction, the reaction temperature is 83°C, the reaction pressure is 1.8MPa, and the reaction time is 1.5h. The product obtained by the reaction in the first gas-phase fluidized-bed reactor enters the second gas-phase fluidized-bed reactor for reaction , the reaction temperature is 79°C, the reaction pressure is 1.2MPa, a small amount of hydrogen is added ...

Embodiment 2

[0040] Add 70 parts of propylene monomer, 0.2 part of ND catalyst, 0.3 part of triisobutylaluminum and 0.1 part of dimethyldimethoxysilane into the first liquid phase reactor for reaction, the reaction time is 1.0 h, and the reaction temperature is 75 ℃, reaction pressure 2.6MPa, H 2 The mass ratio to propylene is controlled at 0.03‰; the obtained product then enters the second liquid phase reactor for reaction, closes the hydrogen feed valve, the reaction temperature is 66°C, the reaction pressure is 2.5MPa, and the reaction time is 1.0h. The obtained product continues to Enter the first gas-phase fluidized-bed reactor for reaction, the reaction temperature is 80°C, the reaction pressure is 1.2MPa, and the reaction time is 1.0h. The product obtained by the reaction in the first gas-phase fluidized-bed reactor enters the second gas-phase fluidized-bed reactor for reaction , the reaction temperature is 85°C, the reaction pressure is 1.2MPa, a small amount of hydrogen is added a...

Embodiment 3

[0047] Add 90 parts of propylene monomer, 0.1 part of CDI catalyst, 0.2 part of NG catalyst, 0.1 part of triisobutylaluminum and 0.05 part of trimethylmethoxysilane into the first liquid phase reactor for reaction, and the reaction time is 0.8h , reaction temperature 68°C, reaction pressure 3.2MPa, H 2 The mass ratio to propylene is controlled at 0.02‰; the obtained product then enters the second liquid phase reactor for reaction, closes the hydrogen feed valve, the reaction temperature is 60°C, the reaction pressure is 3MPa, and the reaction time is 0.5h, and the obtained product continues to enter The first gas-phase fluidized-bed reactor reacts, the reaction temperature is 83°C, the reaction pressure is 1.8MPa, and the reaction time is 1.2h. The product obtained by the first gas-phase fluidized-bed reactor enters the second gas-phase fluidized-bed reactor for reaction. The reaction temperature is 81° C., the reaction pressure is 1.2 MPa, and a small amount of hydrogen is ap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com