Preparation method and applications of alkoxyl magnesium carrier

A technology of alkoxymagnesium carrier and magnesium powder, which is applied in the field of preparation of alkoxymagnesium carrier, and can solve the problems of high polymer fine powder content, low mechanical strength, poor shape of carrier particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

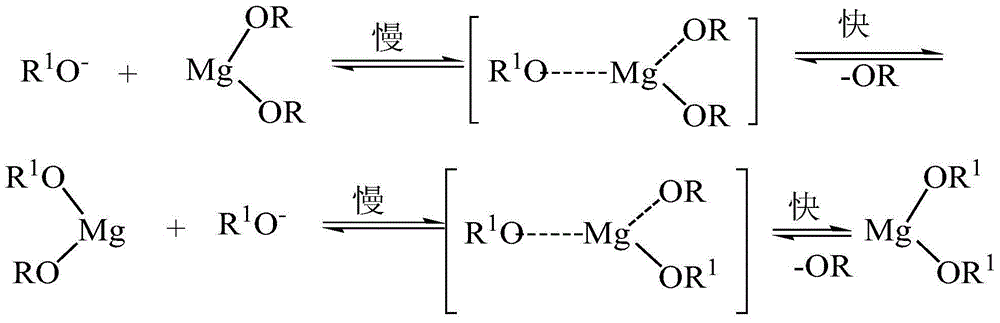

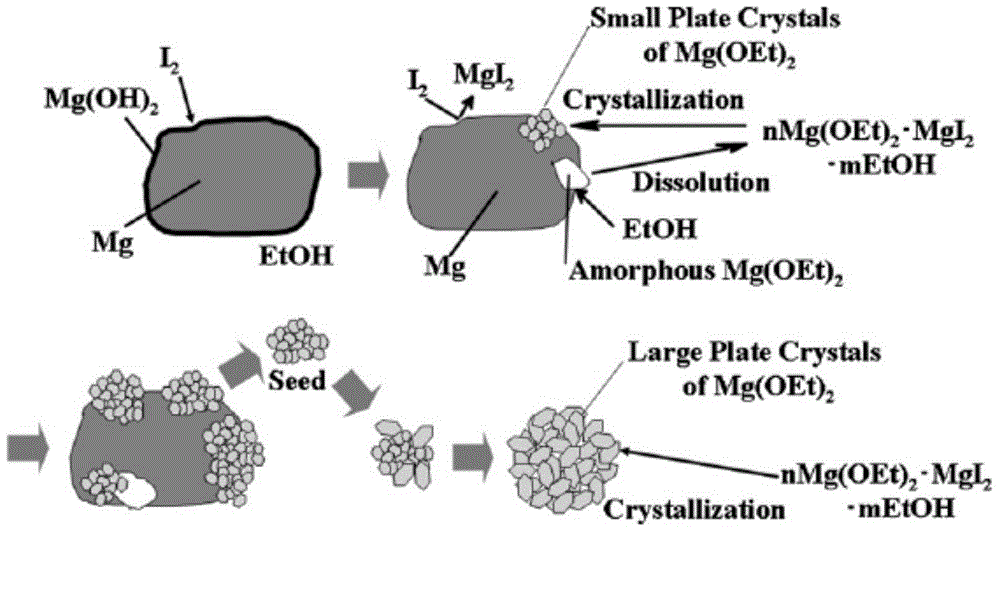

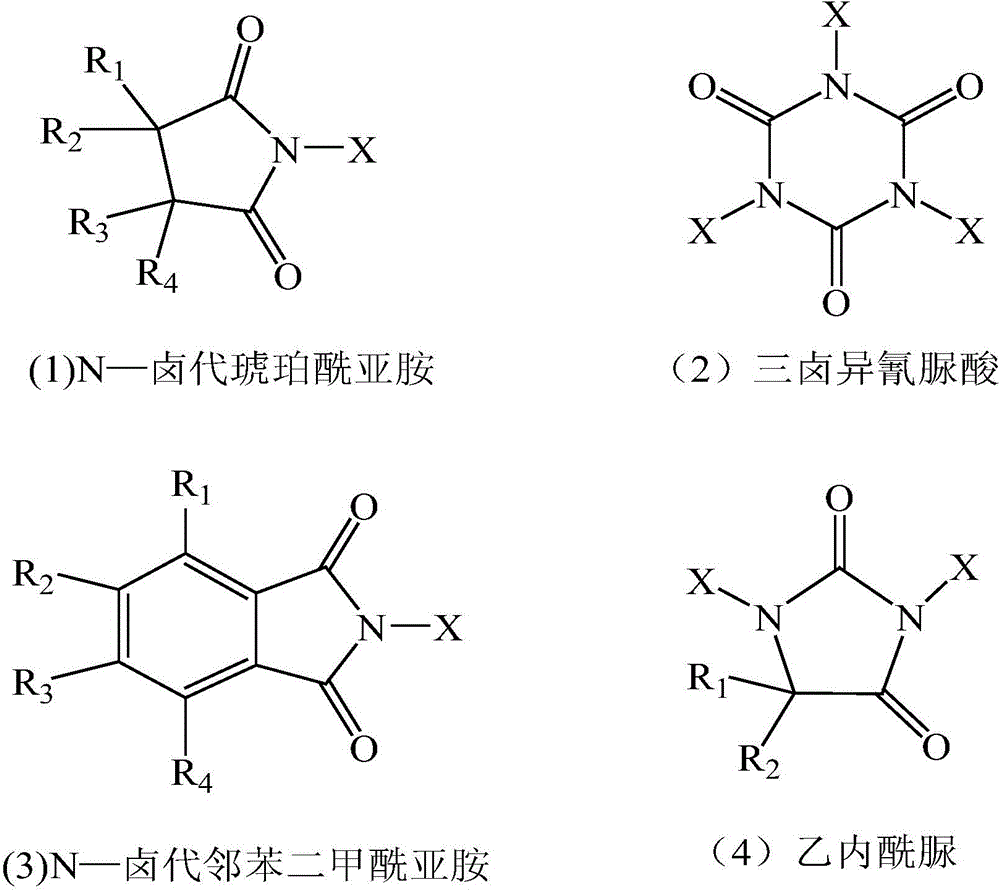

Method used

Image

Examples

Embodiment 1

[0069] In a reactor fully replaced by nitrogen, add 30 mL of ethanol and 0.0532 g of iodine at 25°C, and stir for 20 minutes; add 1.5 g of pentaerythritol, and stir for 20 minutes; add 30 mL of decane, and stir for 20 minutes; add 2 g of kaolin , and stirred for 30 minutes; add 1 gram of magnesium powder, and stir. The reaction temperature was raised to 60°C, stirred, and reacted for 6 hours. Stop the reaction, lower the temperature to 30°C, filter, wash with hexane three times, and dry in vacuo to obtain 6.2 g of carrier with BD=0.38.

Embodiment 2

[0071] In a reactor fully replaced by nitrogen, add 30 mL of ethanol, 10 mL of decyl alcohol, and 0.1 g of iodine at 10°C, and stir for 30 minutes; add 2 g of sorbitol, and stir for 40 minutes; add 25 mL of decane, and stir for 20 minutes; Add 2 grams of silica gel and stir for 40 minutes; add 1.5 grams of magnesium powder and stir. The reaction temperature was raised to 70°C, stirred, and reacted for 8 hours. Stop the reaction, lower the temperature to 20°C, filter, wash with hexane four times, and dry in vacuo to obtain 8.2 g of carrier with BD=0.37.

Embodiment 3

[0073] In a reactor fully replaced by nitrogen, add 50 mL of ethanol and 0.5 g of iodine at 30°C and stir for 30 minutes; add 1 g of citric acid and stir for 40 minutes; add 40 mL of decane and stir for 30 minutes; add 2 grams of magnesium chloride , and stirred for 60 minutes; add 1 gram of magnesium powder, and stir. The reaction temperature was raised to 65°C, stirred, and reacted for 8 hours. Stop the reaction, lower the temperature to 20°C, filter, wash with hexane four times, and dry in vacuo to obtain 6.2 g of carrier with BD=0.38.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com