Preparation method of catalyst component for polymerization of vinyl and catalyst for polymerization of vinyl

A technology for ethylene polymerization and catalysts, which is applied in the preparation of catalyst components for ethylene polymerization and the field of catalysts, which can solve the problems of low polymer melt index, impact on production environment, cumbersome preparation process, etc., and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

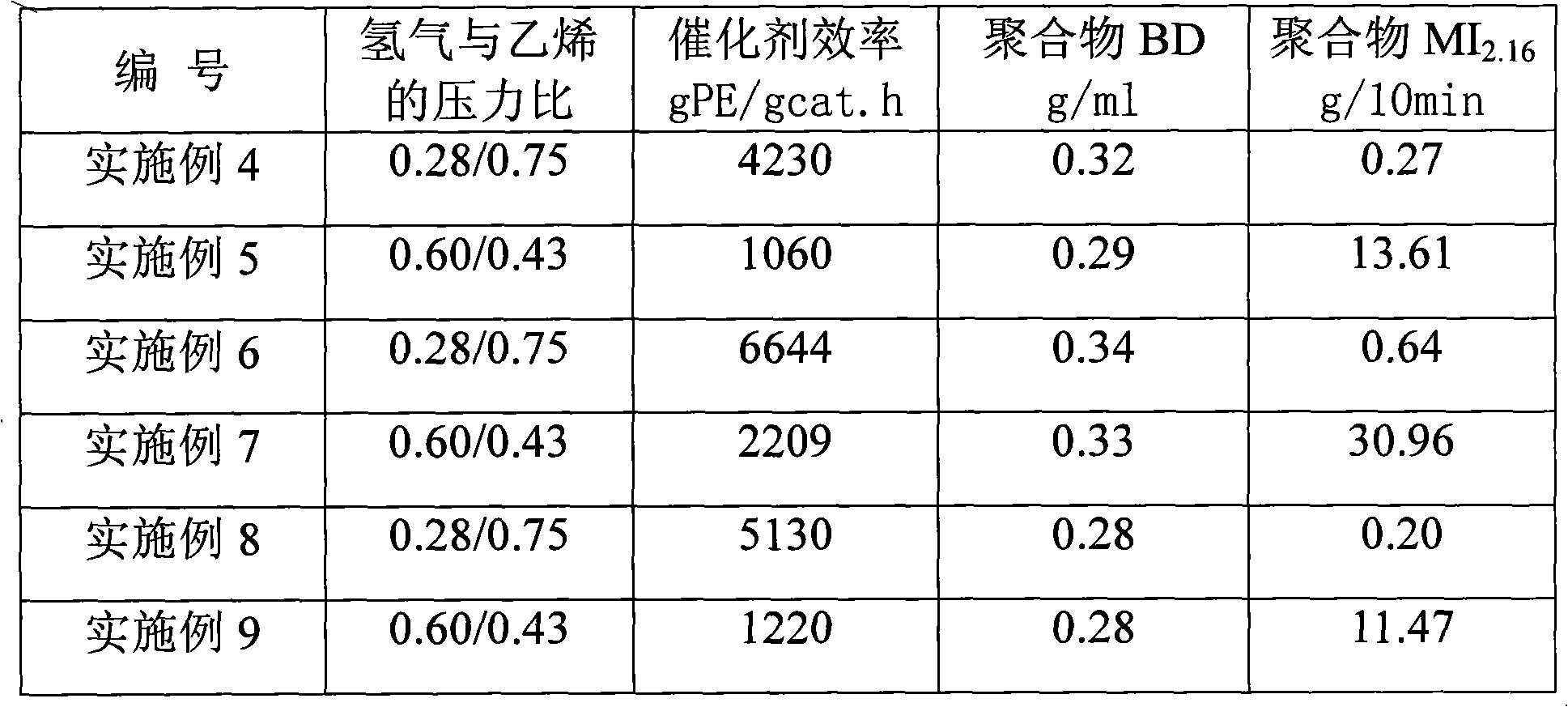

Examples

Embodiment 1

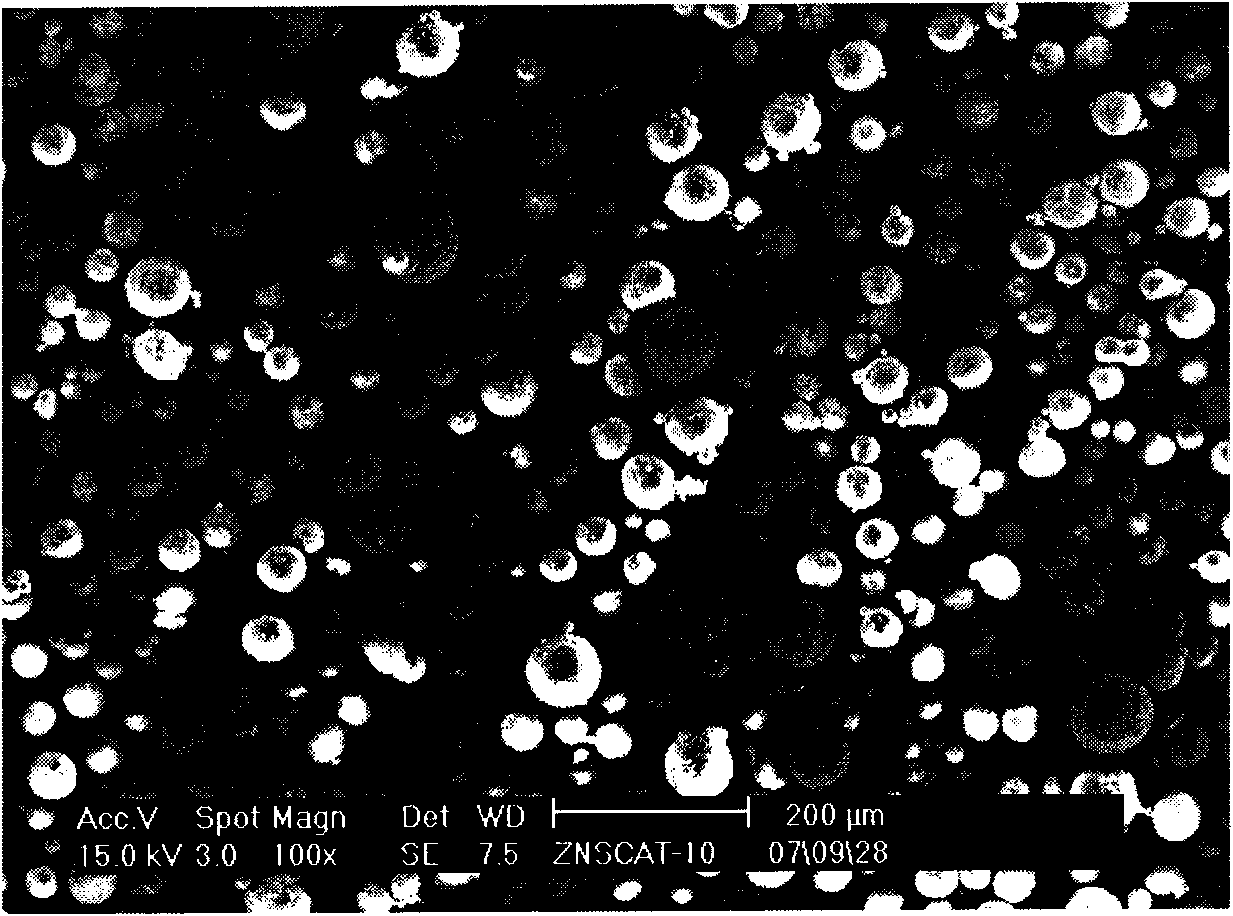

[0037] Preparation method of spherical catalyst component

[0038] (1) Modified pretreatment of magnesium chloride alcoholate

[0039] Under the protection of nitrogen, 40.15 grams of spherical magnesium chloride alcoholate was added to a 250 ml glass reactor, heated to 110 ° C, and maintained for 4 hours to obtain 23.54 grams of white spherical particles, with an average particle size of 52.6 microns and an alcohol content of 25.3%. (weight).

[0040] (2) Loading of active components

[0041] Under the protection of nitrogen, add 5.80 g of the spherical particles obtained in step (1) into a 250 ml glass reactor, add 40 ml of n-hexane, stir to form a slurry, cool down to -30°C with a low-temperature bath, and slowly add 20.0 ml of The hexane solution of titanium tetrachloride (containing 0.5 ml of titanium tetrachloride) was stirred and reacted for 1 hour, and then the temperature was slowly raised to 50° C. and kept stirring for 2 hours. After the reaction was finished, it...

Embodiment 2

[0045] Preparation method of spherical catalyst component

[0046] (1) Modified pretreatment of magnesium chloride alcoholate

[0047] Under the protection of nitrogen, 40.15 grams of spherical magnesium chloride alcoholate was added to a 250 ml glass reactor, heated to 150 ° C, and maintained for 4 hours to obtain 19.69 grams of white spherical particles, with an average particle size of 56.3 microns and an alcohol content of 18.1%. (weight).

[0048] (2) Loading of active components

[0049] Under nitrogen protection, add 4.24 grams of spherical particles obtained in step (1) into a 250 ml glass reactor, add 40 ml of n-hexane, stir to form a slurry, cool to -30°C with a low-temperature bath, and slowly add 20.0 ml of The hexane solution of titanium tetrachloride (containing 0.5 ml of titanium tetrachloride) was stirred and reacted for 1 hour, and then the temperature was slowly raised to 50° C. and kept stirring for 2 hours. After the reaction was finished, it was allowed...

Embodiment 3

[0053] Preparation method of spherical catalyst component

[0054] (1) Modified pretreatment of magnesium chloride alcoholate

[0055] Under the protection of nitrogen, 37.75 grams of spherical magnesium chloride alcoholate was added to a 250 ml glass reactor, heated to 170 ° C, and maintained for 4 hours to obtain 18.90 grams of white spherical particles with an average particle size of 65.6 microns and an alcohol content of 3.4%. (weight).

[0056] (2) Loading of active components

[0057] Under the protection of nitrogen, add 4.20 grams of spherical particles obtained in step (1) into a 250 ml glass reactor, add 40 ml of n-hexane, stir to form a slurry, cool to 30 °C with a low-temperature bath, and slowly add 20.0 ml of four The hexane solution of titanium chloride (containing 0.5 ml of titanium tetrachloride) was stirred and reacted for 1 hour, and then the temperature was slowly raised to 50° C. and kept stirring for 2 hours. After the reaction was finished, it was al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com