Method for preparing solid catalyst component for olefin polymerization and catalyst for olefin polymerization

A solid catalyst, a technology for olefin polymerization, which is applied in the field of solid catalyst components of regular olefin polymers, and can solve the problems of unsatisfactory hydrogen modulation sensitivity and stereospecificity, and insufficient isotactic index of polymers.

Active Publication Date: 2014-12-03

CHINA PETROLEUM & CHEM CORP +1

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

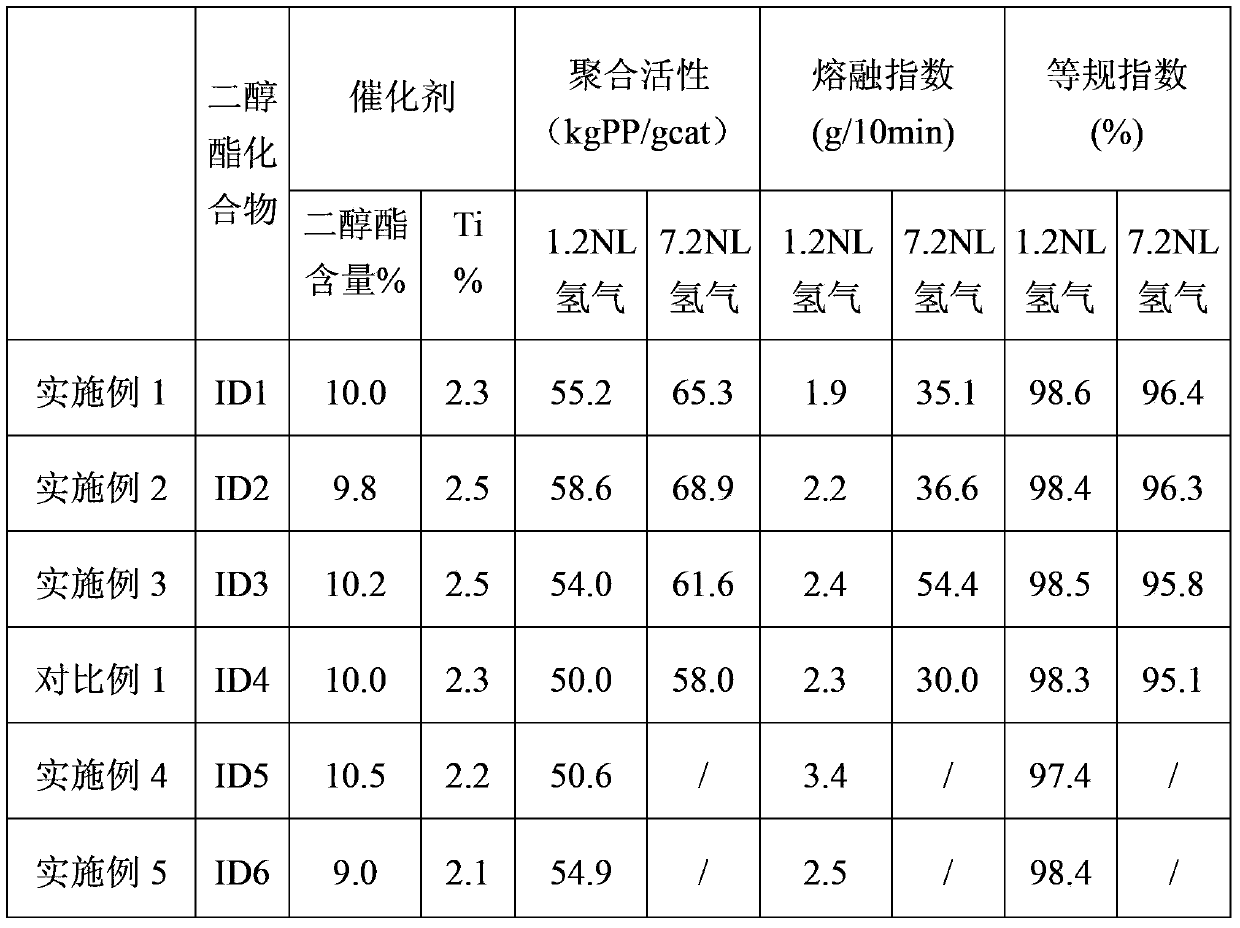

[0003] At present, there is a document disclosing a glycol ester compound. By using this glycol ester compound as an electron donor in an olefin polymerization catalyst, a catalyst with excellent comprehensive performance can be obtained. When used for propylene polymerization, it has a higher Polymerization activity and stereospecificity, the molecular weight distribution of the obtained polymer is also broad, but the catalyst activity, hydrogen sensitivity and stereospecificity are not satisfactory, especially when producing high melt index polymers under high hydrogen concentration , the isotactic index of the obtained polymer is not high enough and needs to be further improved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0041] The examples given below are only used to explain and describe the present invention, and do not constitute any limitation to the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

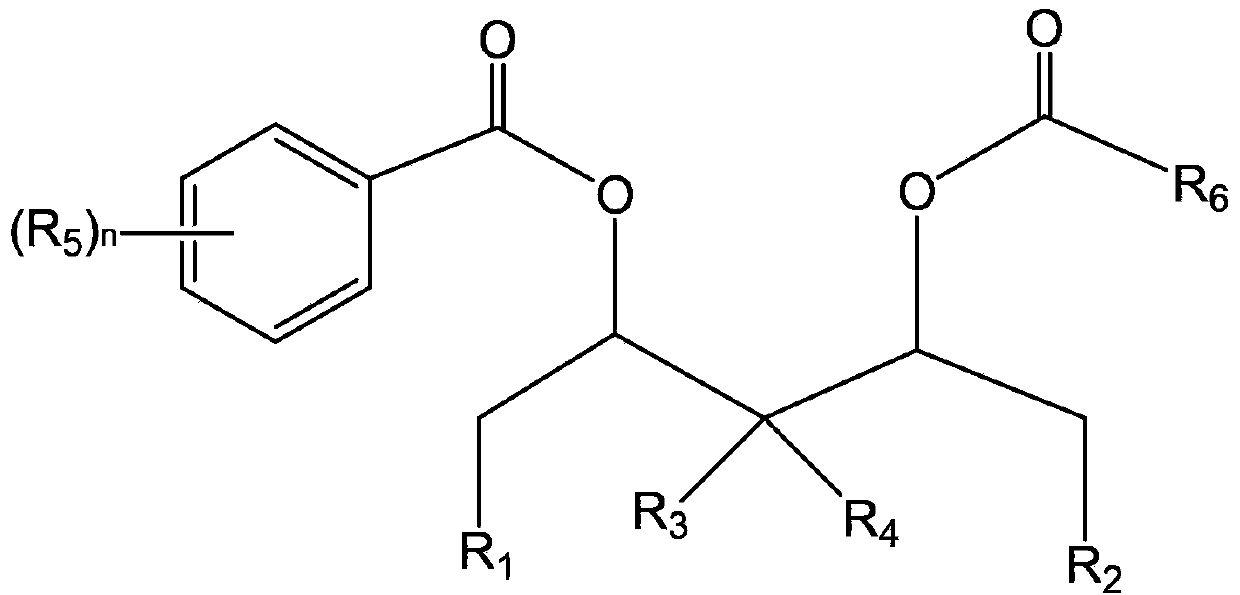

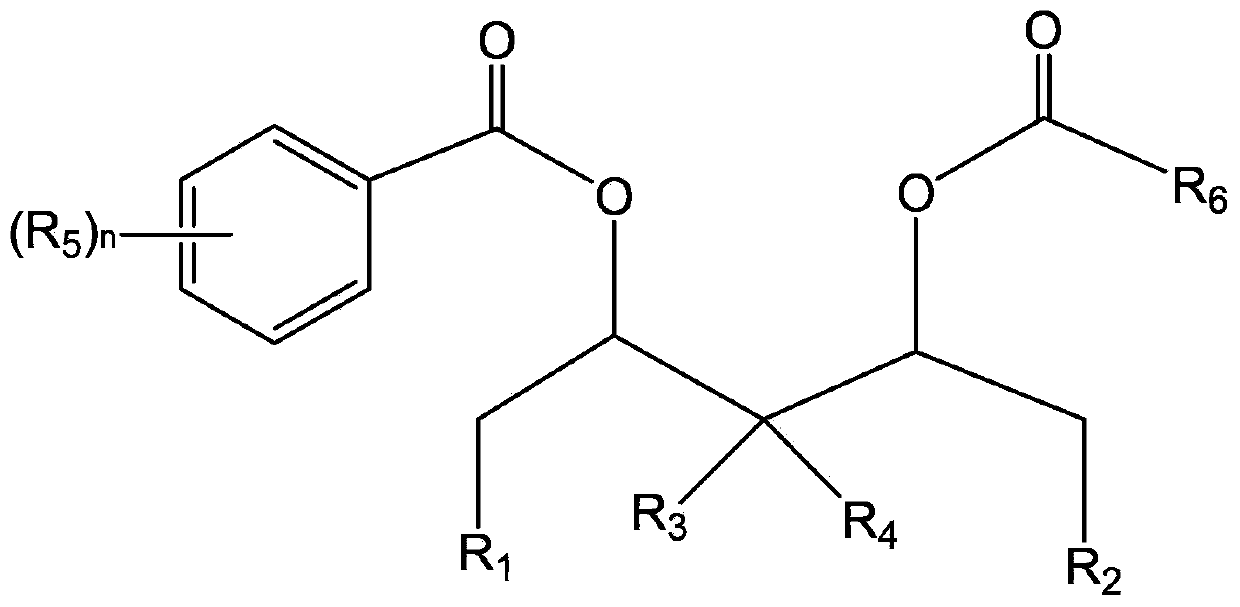

The invention discloses a method for preparing a solid catalyst component for an olefin polymerization reaction. The method comprises the following steps of dissolving a magnesium compound in a solvent system containing a hydrocarbon compound and an alcohol compound, mixing a titanium compound and the above solution at a temperature of -40 to 0 DEG C, adding an electron donor compound into the mixture at a temperature of 50-150 DEG C, and carrying out washing by an inert diluent to obtain the solid catalyst component. The used electron donor is at least one of diol ester compounds shown in the general formula (I). The catalyst system provided by the invention has greatly improved polymerization activity, hydrogen response and stereospecificity. Through the solid catalyst component and the catalyst, a polymer having a high fusion index and high isotacticity is obtained. Compared with the prior art, the solid catalyst component has the advantages that if polymer melt indexes are the same, in other words, hydrogen response is the same, isotactic indexes are improved, and if polymer isotactic indexes are the same, the polymer melt indexes are improved, in other words, the hydrogen response is improved.

Description

technical field [0001] The invention relates to a solid catalyst component, in particular to a solid catalyst component for preparing high-melting index high isotactic olefin polymers. The invention also relates to a catalyst system containing the solid catalyst component and the application of the catalyst system in olefin polymerization. Background technique [0002] It is well known that solid titanium catalyst components based on magnesium, titanium, halogen and electron donors can be used in olefin polymerization, especially in the polymerization of α-olefins with 3 or more carbon atoms. Polymers with higher yield and higher stereoregularity, in which the electron donor compound is one of the essential components in the catalyst component, and with the development of the internal electron donor compound, the polyolefin catalyst is constantly updated. Currently , A variety of electron donor compounds have been disclosed in large quantities, such as polycarboxylic acids,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08F10/00C08F10/06C08F10/02C08F4/649C08F4/658C08F4/651

Inventor 李昌秀高明智刘海涛陈建华马晶蔡晓霞马吉星王军张晓帆胡建军

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com