Propylene polymer production method

A technology for a propylene polymer and a production method, which is applied in the field of in-situ regulation of the properties of propylene polymers, can solve the problems of lowering the dew point of the circulating gas, easily generating bubbles, and worsening the heat transfer effect of the system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] 1) Raw materials

[0081] The main catalyst obtained in the preparation example; triethylaluminum is used as a cocatalyst; diisopropyldimethoxysilane (DIPDMS) is used as an external electron donor; propylene, ethylene and hydrogen are polymerization grades, after removing water, Oxygen was used, and hexane was used after dehydration.

[0082] 2) Test device

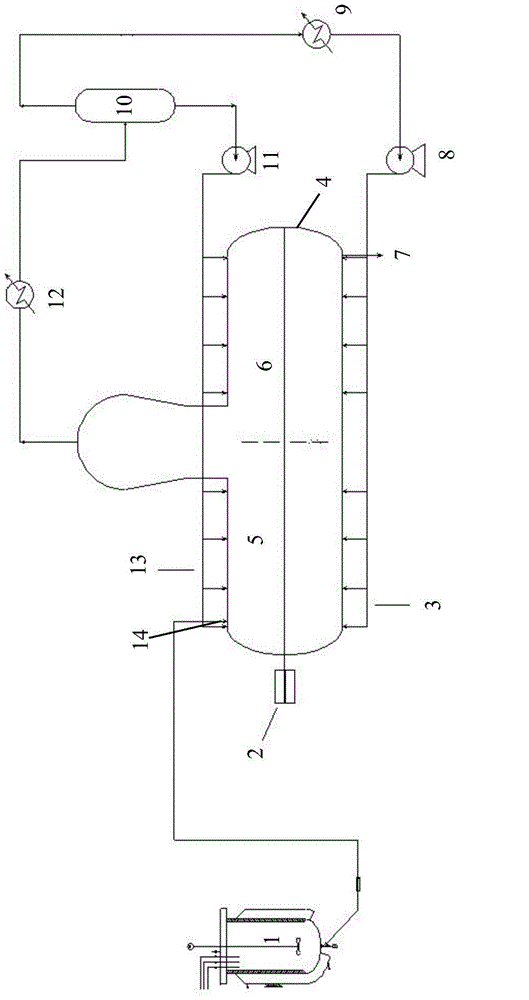

[0083] Such as figure 1 The shown device adopts the serial process of continuous tank type prepolymerization reactor 1 + horizontal tank gas phase reactor 4 . Prepolymerization reactor 1 has a volume of 5 liters, is a vertical stirring tank with jacket cooling, and the stirring blade is a turbine-type oblique paddle, and the stirring speed is 500 rpm; the volume of horizontal gas phase reactor 4 is 0.2 cubic meters, and the stirring The paddle is a T-shaped inclined blade with an inclination angle of 10 degrees, and the stirring speed is 100 rpm driven by the stirring shaft 2 . 3) Test conditions

[0084]Step ...

Embodiment 2

[0090] 1) raw material, with embodiment 1.

[0091] 2) The test device is the same as in Example 1.

[0092] 3) Test conditions

[0093] The reaction temperature in the second reaction zone is 85° C., and the others are the same as in Example 1. The specific process conditions are shown in the attached table.

[0094] 4) Test results

[0095] The continuous test was carried out for 48 hours according to the above conditions, and the operation of the device was stable. The polymer obtained by the reaction was analyzed and tested, and the results are listed in Table 1.

Embodiment 3

[0097] 1) raw material, with embodiment 1.

[0098] 2) The test device is the same as in Example 1.

[0099] 3) Test conditions

[0100] The reaction temperature in the second reaction zone is 95° C., and the others are the same as in Example 1. The specific process conditions are shown in the attached table.

[0101] 4) Test results

[0102] The continuous test was carried out for 48 hours according to the above conditions, and the operation of the device was stable. The polymer obtained by the reaction was analyzed and tested, and the results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com