Process system for producing exquisite sand by adopting machine-made sand vertical mill

A process system, a technology of machine-made sand, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of poor operation stability of vertical mills, incompatible with green production, high frequency of downtime and maintenance, reduce the energy consumption of auxiliary machines, facilitate the The effect of large-scale production and high energy efficiency and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

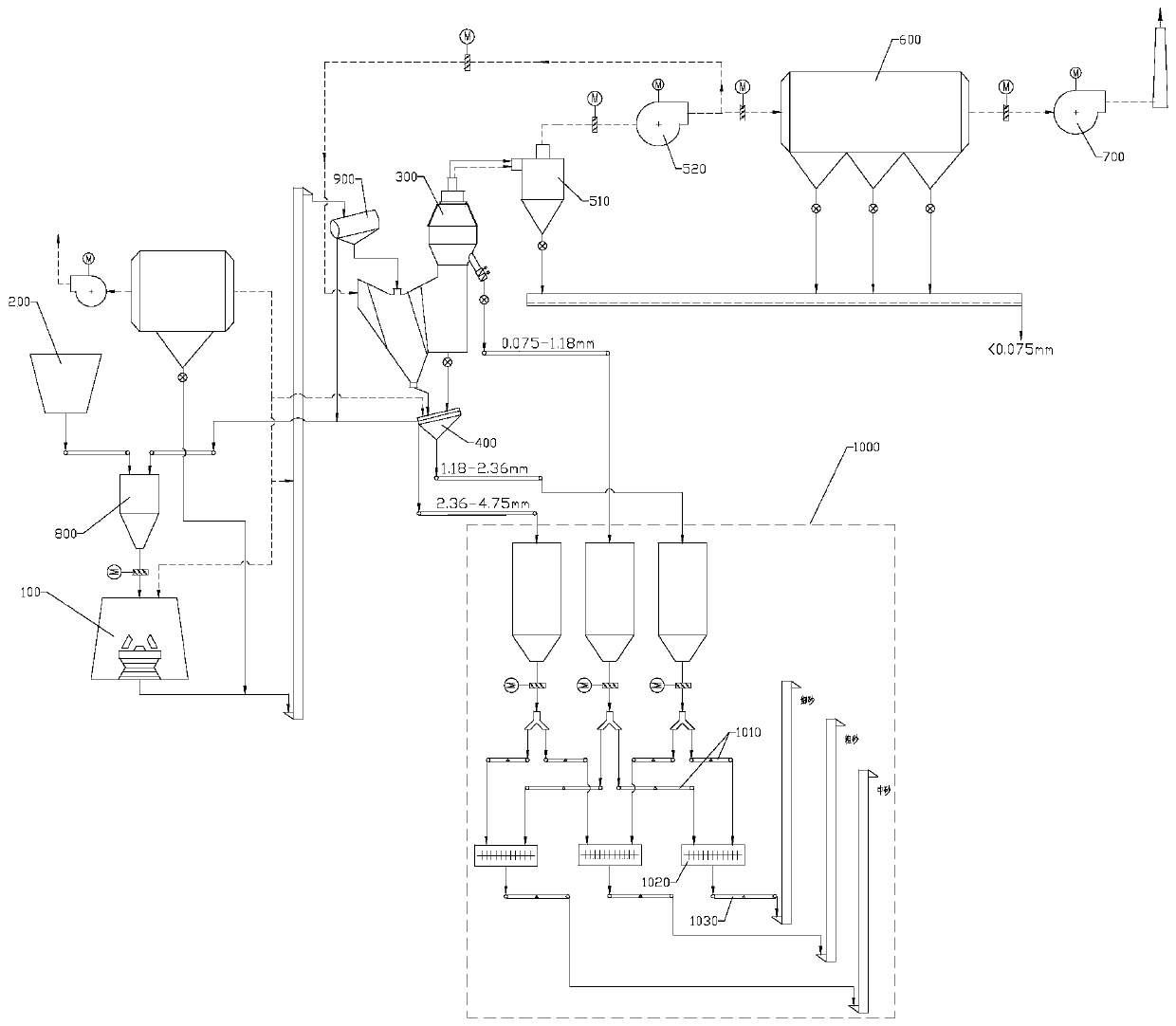

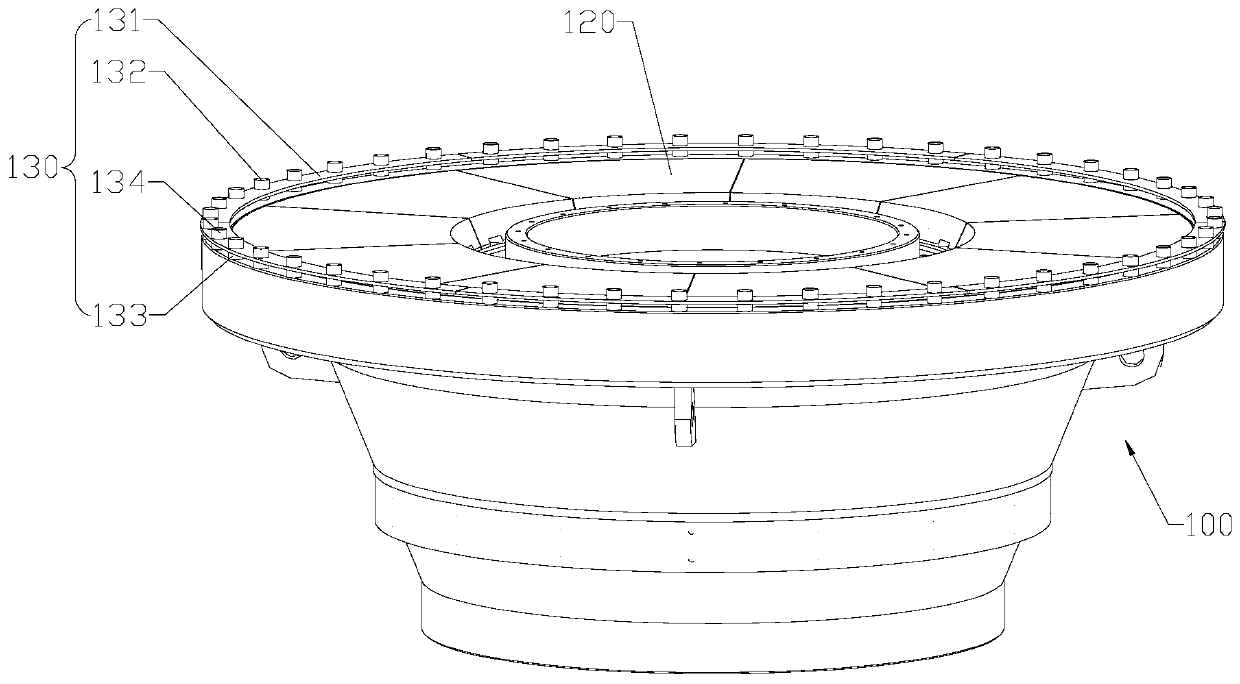

[0049] see figure 1 , the present embodiment provides a process system for producing high-quality sand with a machine-made sand vertical mill, including a raw material bin 200, a machine-made sand vertical mill 100, a combined powder separator 300, a vibrating screen 400, and a powder removal mechanism 500. The mechanism 500 includes a cyclone 510 and a circulating fan 520. The outlet of the raw material bin 200 is connected to the material inlet of the machine-made sand vertical mill 100. The material outlet of the machine-made sand vertical mill 100 is connected to the material inlet of the combined powder separator 300 through a hoist. The outlet at the bottom of the powder separator 300 is connected to the vibrating screen 400, and the vibrating screen 400 returns the on-screen material to the machine-made sand vertical mill 100. The air outlet of the combined powder separator 300 is connected to the cyclone 510, and the air outlet of the cyclone 510 Connected with the cir...

Embodiment 2

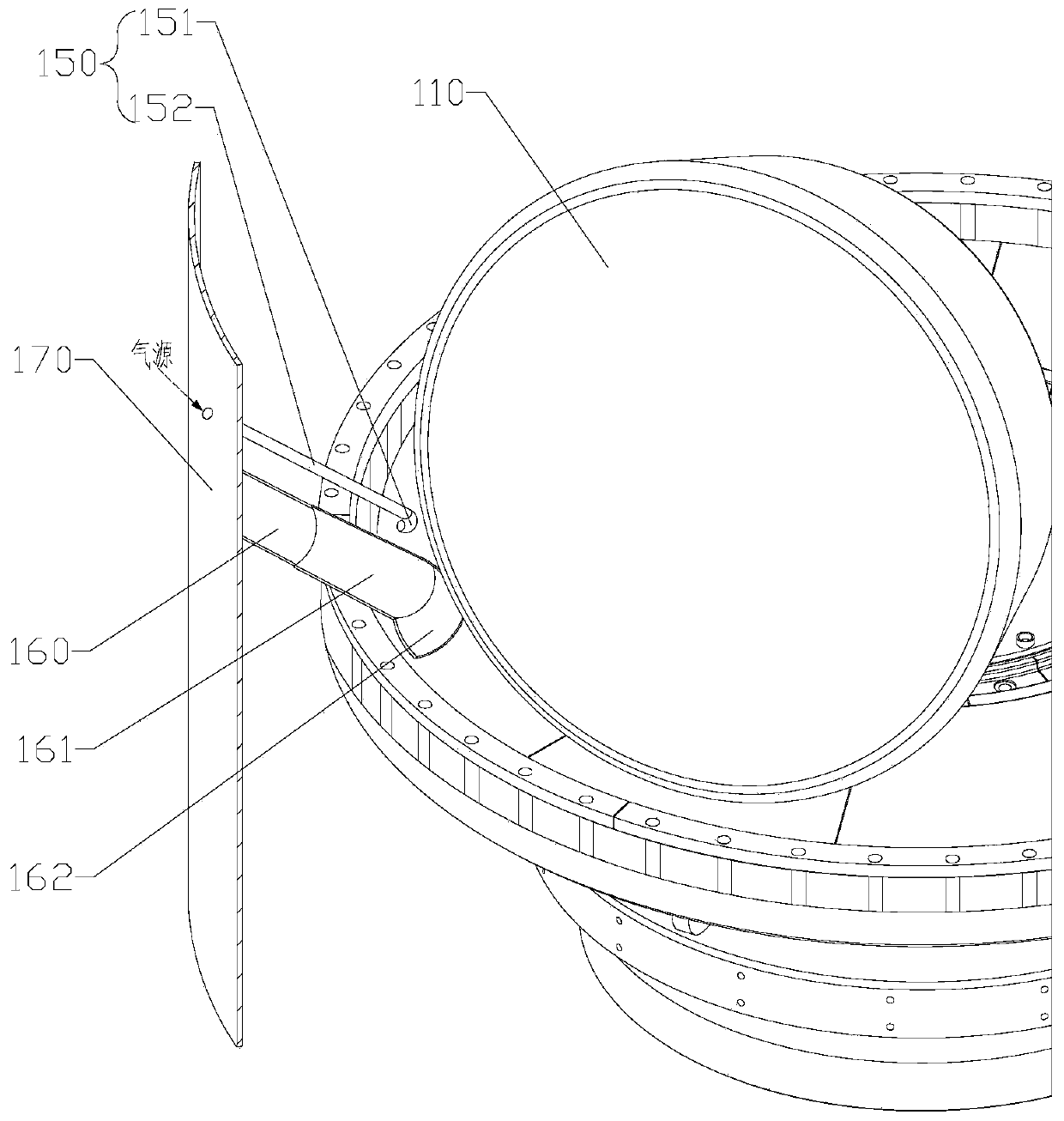

[0100] Unlike Example 1, see Figure 4, the material retaining ring in this embodiment is a leaping material retaining ring 140, and the upper part of the leaping material retaining ring 140 is provided with several discharge openings 141, so that the leaping material retaining ring 140 forms a concave-convex structure, so The total area of the discharge opening 141 is 40-60% of the total area of the spanning retaining ring 140 .

[0101] This straddling structure allows some materials to be discharged and some to be blocked, reducing the escape of unground materials and increasing the content of qualified products in the grinding materials. After the material is ground by the grinding roller 110 for a certain period of time, the fine powder accumulates at the corner of the bottom of the retaining ring, forming a slope, which can be used as a stable material layer. After subsequent grinding, the ground material can pass through the formed Slope out of the mill.

[0102] ...

Embodiment 3

[0105] see Figure 5 and 6 The combined powder separator 300 provided in Embodiment 1 includes a sand selection mechanism 310 and a powder selection mechanism 320, the sand selection mechanism 310 is located below the powder selection mechanism 320 and is connected by an expansion joint 330; the expansion joint 330 The function is to compensate for manufacturing errors and deformation of the upper and lower parts of the mechanism caused by temperature changes.

[0106] The sand selection mechanism 310 includes an air intake housing 311, a sand selection housing 312 and a sand collection housing 313, the air intake housing 311, the sand selection housing 312 and the sand collection housing 313 are sequentially connected by flanges; The air inlet housing 311 is provided with a plurality of air distribution plates 317 from top to bottom on the side close to the sand selection housing 312, and the air inlet flange is on the side away from the sand selection housing 312; the sand ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com