Monolithic embedded integrated silicon acceleration and pressure composite sensor

A composite sensor and embedded structure technology, applied in velocity/acceleration/shock measurement, acceleration measurement using inertial force, microstructure technology, etc., can solve problems such as small gauge factor growth thickness, difficulty in improving sensor performance, and reduced device sensitivity , to achieve the effect of simplifying the processing technology, improving the utilization rate of the surface and reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the above objects, features and advantages of the present invention more obvious and comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

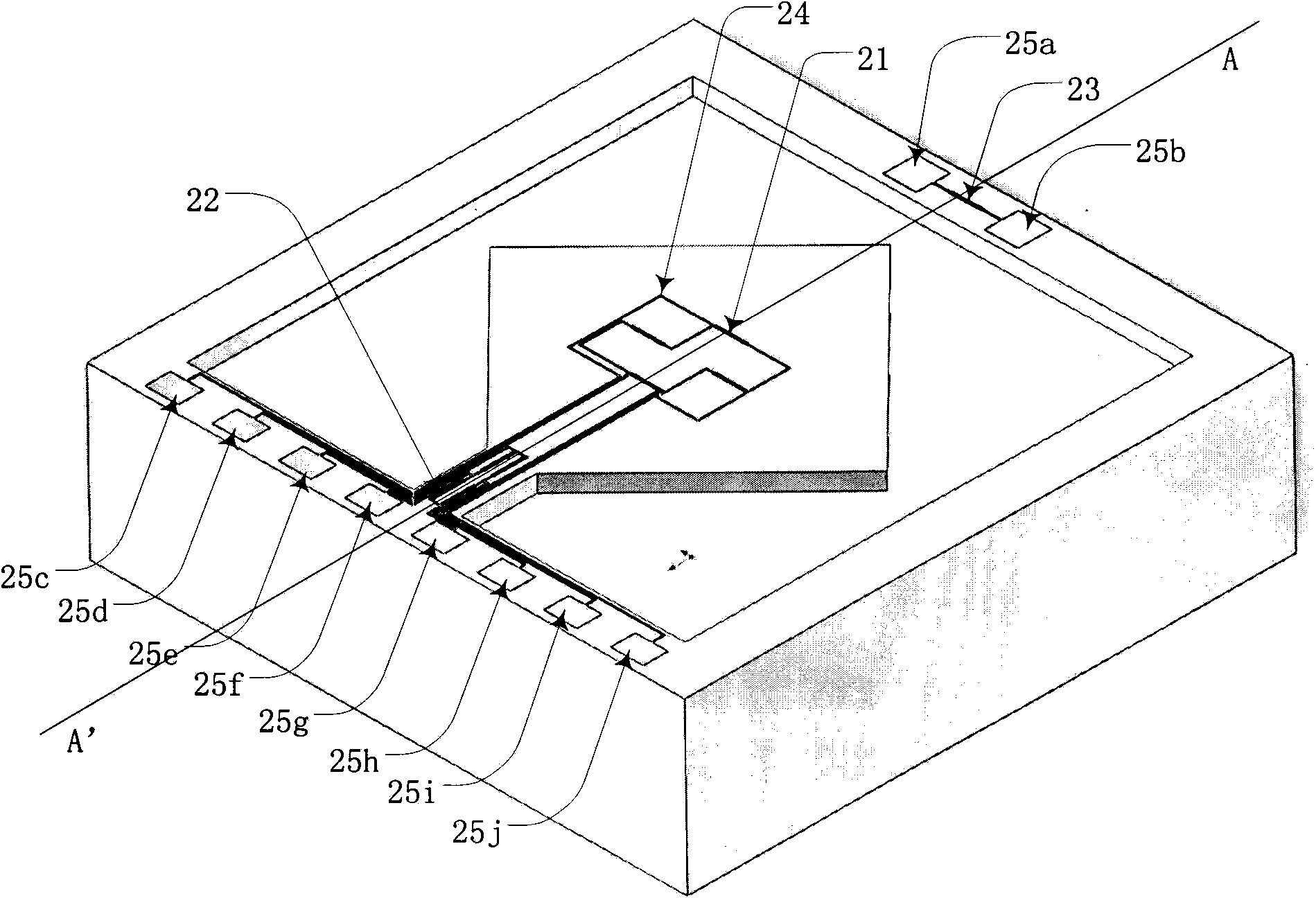

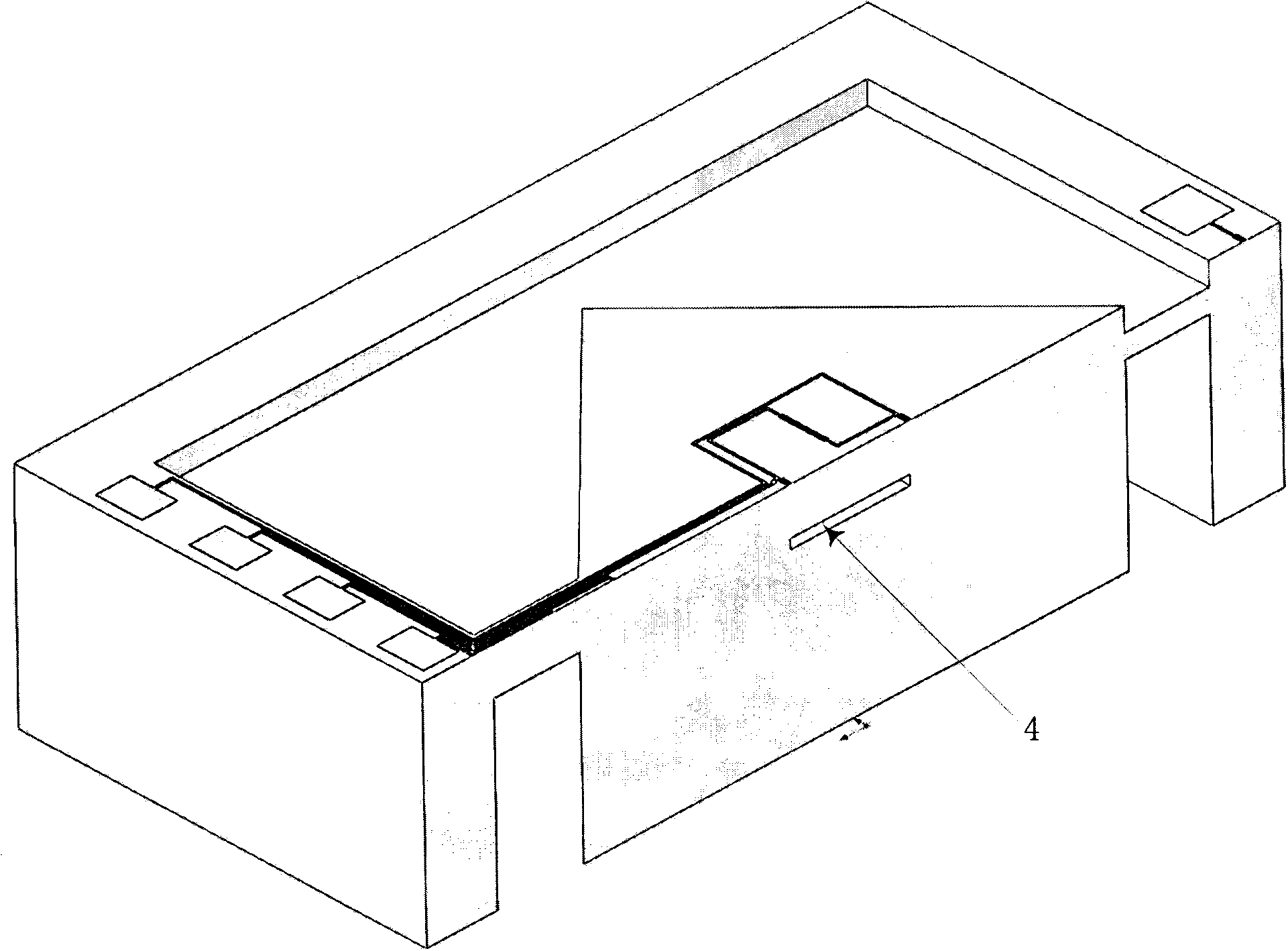

[0035] like Figure 1A ~ Figure 1B As shown, the monolithic embedded structure integrated silicon acceleration and pressure composite sensor includes a pressure sensor force-sensitive resistor 21, an acceleration sensor force-sensitive resistor 22, a temperature-sensitive resistor 23, metal leads 24, and welding electrodes 25a-25j.

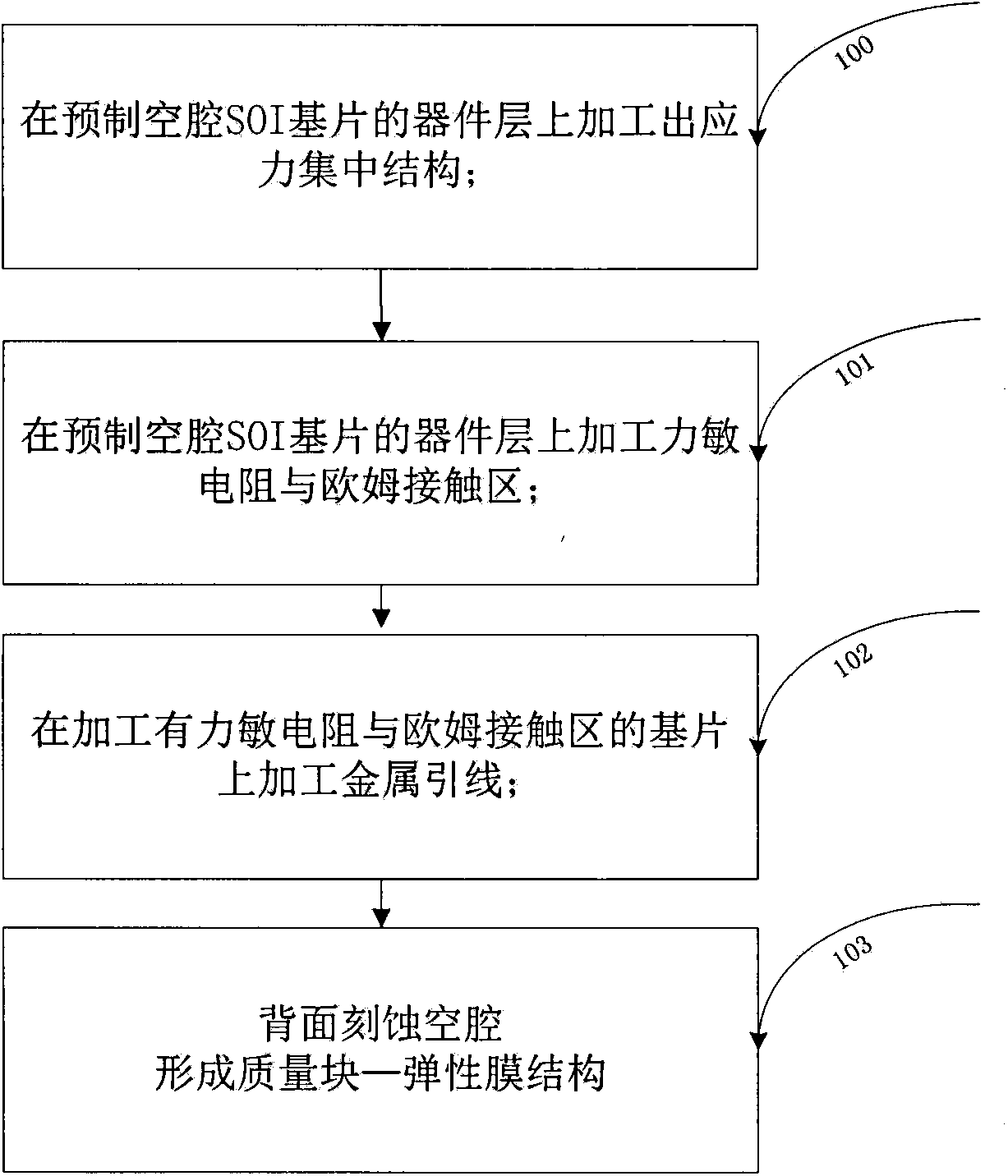

[0036] figure 2 It is a flow chart of the processing steps of the single-chip embedded structure integrated silicon acceleration and pressure composite sensor of the present invention, including the processing step of the stress concentration structure (optional), and the processing step 101 of the force sensitive resistor: the device on the prefabricated cavity SOI substrate A force-sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com