Earphone earplug and preparation method thereof

A technology for earplugs and earphones, which is used in earphone manufacturing/assembly, earphone/earphone accessories, gaseous chemical plating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

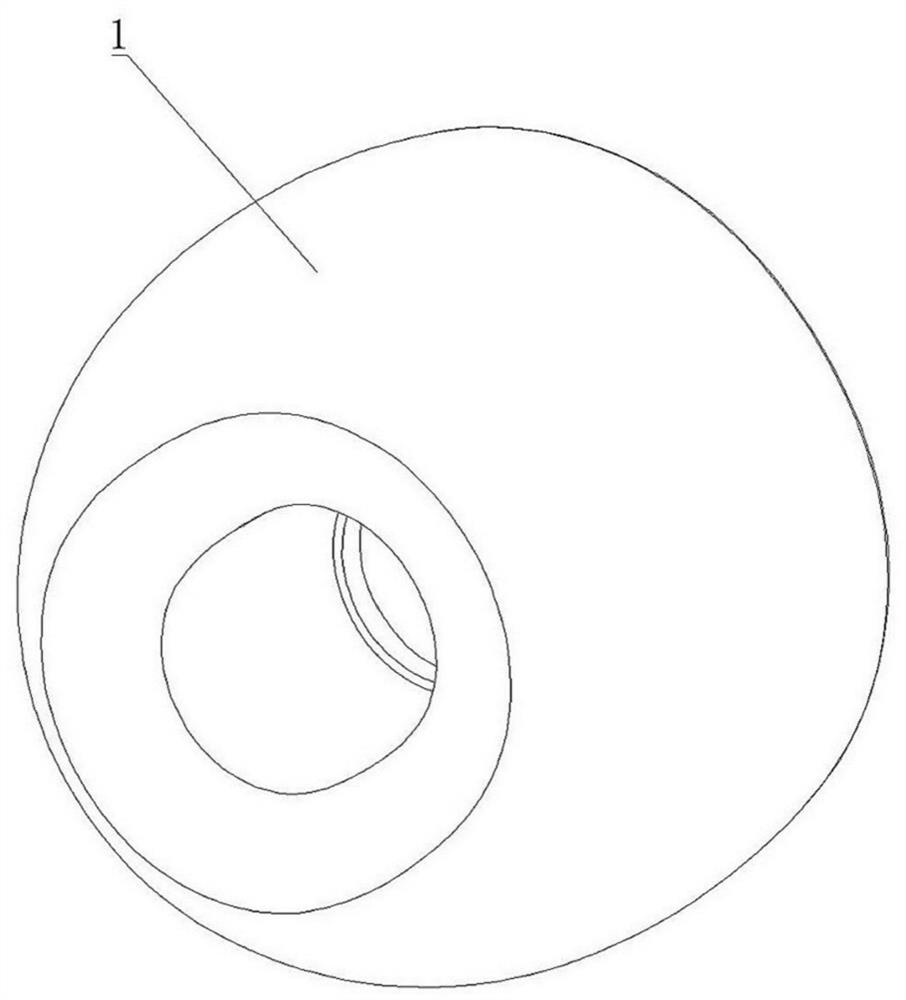

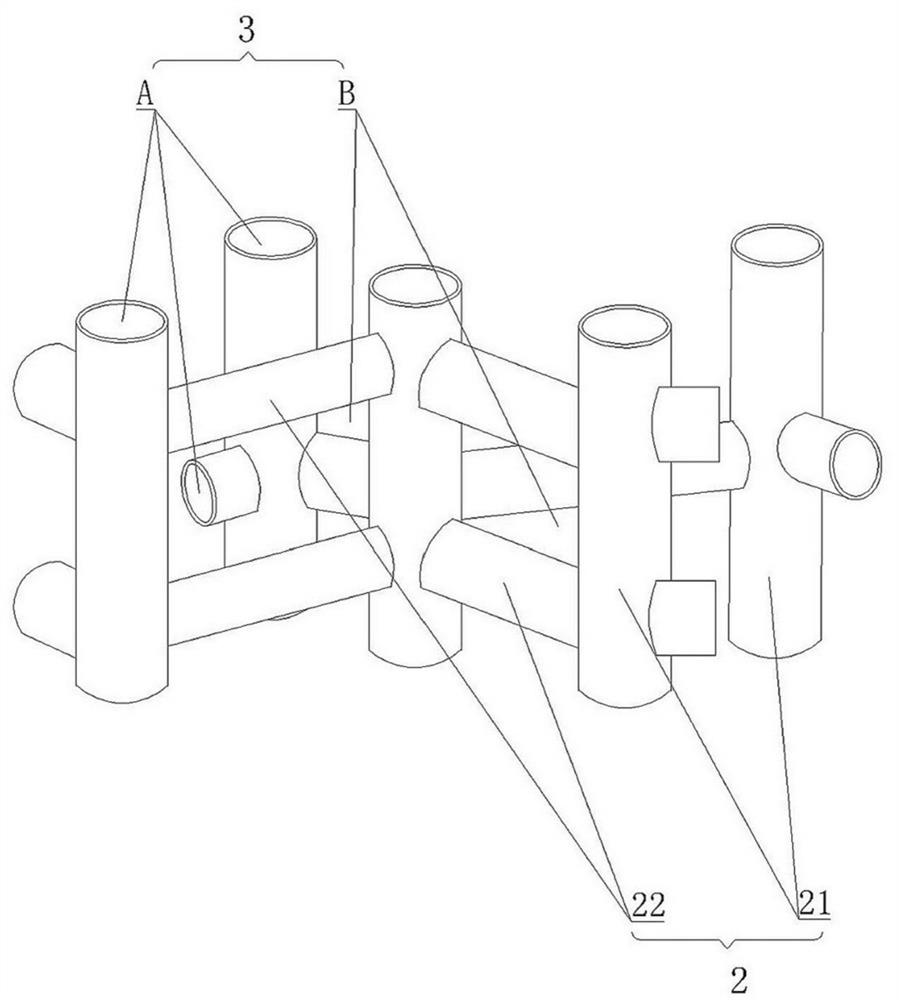

[0033] Embodiment one: if figure 1 As shown, an earphone earplug includes an earplug body 1, the earplug body 1 is an antibacterial silicone earplug, the antibacterial silicone earplug is made of antibacterial silicone, the outer surface of the earplug body 1 is covered with a nano antibacterial protective film, The thickness of the antibacterial protective film is 5-50nm, and its preferred thickness is 22nm; the nano-antibacterial protective film is a PECVD coating, which not only has a good antibacterial effect, is not easy to breed bacteria, and is resistant to salt spray corrosion, sweat corrosion, and abrasion resistance. The treated earplug cover is soft and comfortable to wear, and while bringing beautiful and pleasant music to the user, the ear comfort is also satisfied.

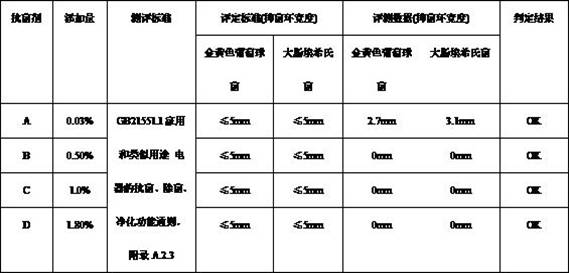

[0034] Described antibacterial silica gel comprises antibacterial agent finished product, and described antibacterial silica gel comprises described antibacterial agent finished product 0.04wt% by we...

Embodiment 2

[0040] Embodiment 2: The difference from Example 1 is that the antibacterial silica gel contains the finished antibacterial agent, and the antibacterial silica gel includes 6wt% of the finished antibacterial agent by weight percentage, and the antibacterial silica gel includes all the antibacterial agent by weight percentage. Said nano antibacterial agent 1.8 wt%. The finished antibacterial agent includes 270wt% of the porous antibacterial agent carrier by weight percentage.

[0041] The nano-antibacterial agent is a combination of two metal-based antibacterial agents, the nano-antibacterial agent is a combination of a silver-based antibacterial agent and a nickel-based antibacterial agent, or the nano-antibacterial agent is a combination of a silver-based antibacterial agent and a titanium-based antibacterial agent. Combination, or the nano antibacterial agent is the combination of the nickel-based antibacterial agent and titanium-based antibacterial agent.

Embodiment 3

[0042] Embodiment 3: The difference from Example 1 is that the antibacterial silica gel includes the finished antibacterial agent, and the antibacterial silica gel includes 0.83wt% of the finished antibacterial agent by weight percentage, and the finished antibacterial agent includes antibacterial agent and Porous antibacterial agent carrier, the antibacterial silica gel includes 0.5 wt% of the antibacterial agent by weight percentage.

[0043] The finished antibacterial agent includes 240wt% of the porous antibacterial agent carrier by weight percentage.

[0044] The nano antibacterial agent is a combination of two metal-based antibacterial agents, and the antibacterial agent is a combination of silver-based antibacterial agents, nickel-based antibacterial agents, and titanium-based antibacterial agents.

[0045] The present invention also relates to a preparation method of earphone earplugs:

[0046] Specifically include the following steps:

[0047] Step 1: After weighing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com