Finish and closure for plastic pasteurizable container

a technology of plastic container and finish, applied in the field of plastic container finish and closure system, can solve the problems of uncontrolled deformation, significant increase in the cost involved in crystallizing the finish, and the plastic container to undergo permanent, so as to prevent any significant loss of pressure and/or product leakage, and minimize the finish distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]Disclosed herein are plastic container packages for products that require pasteurization.

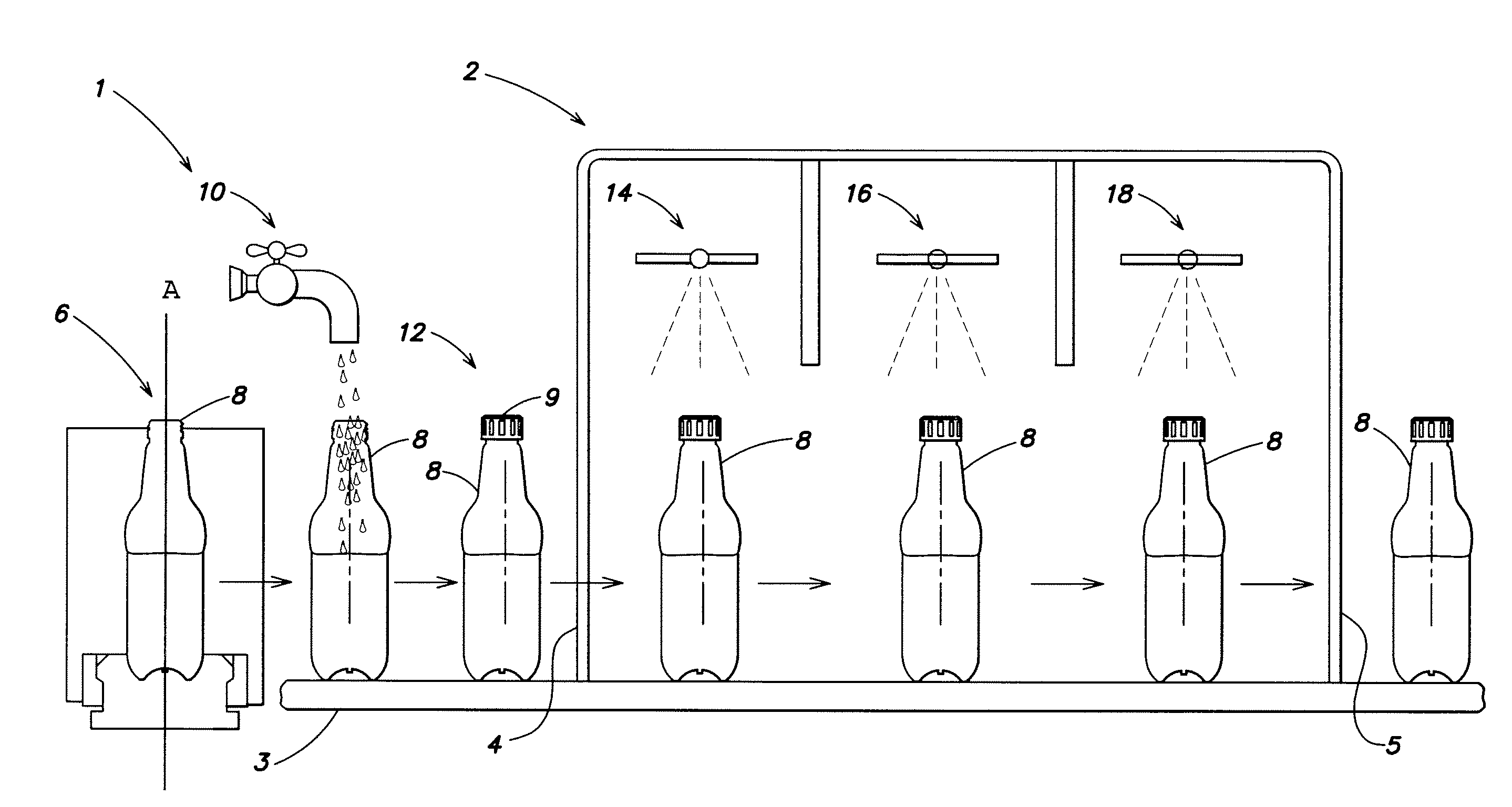

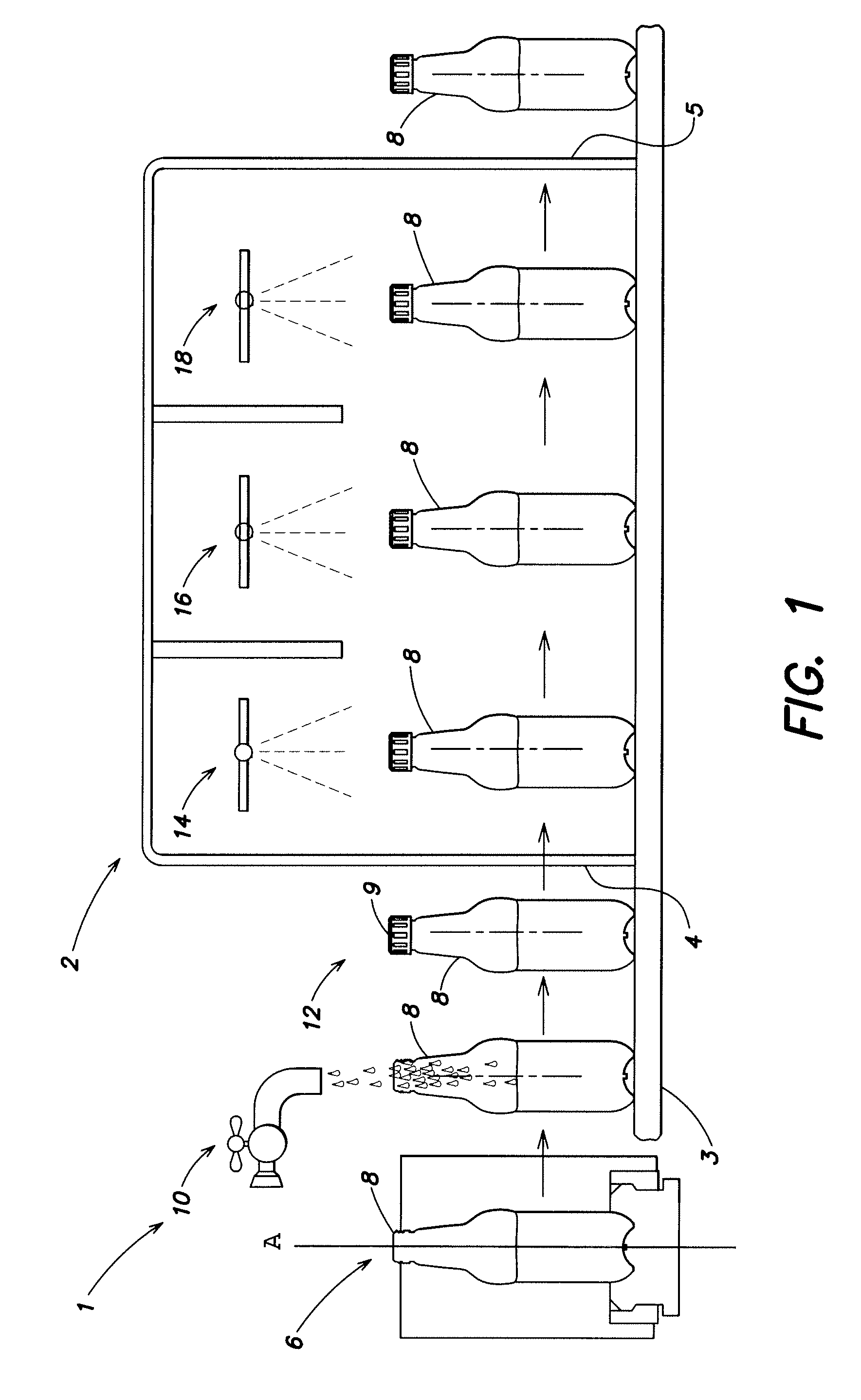

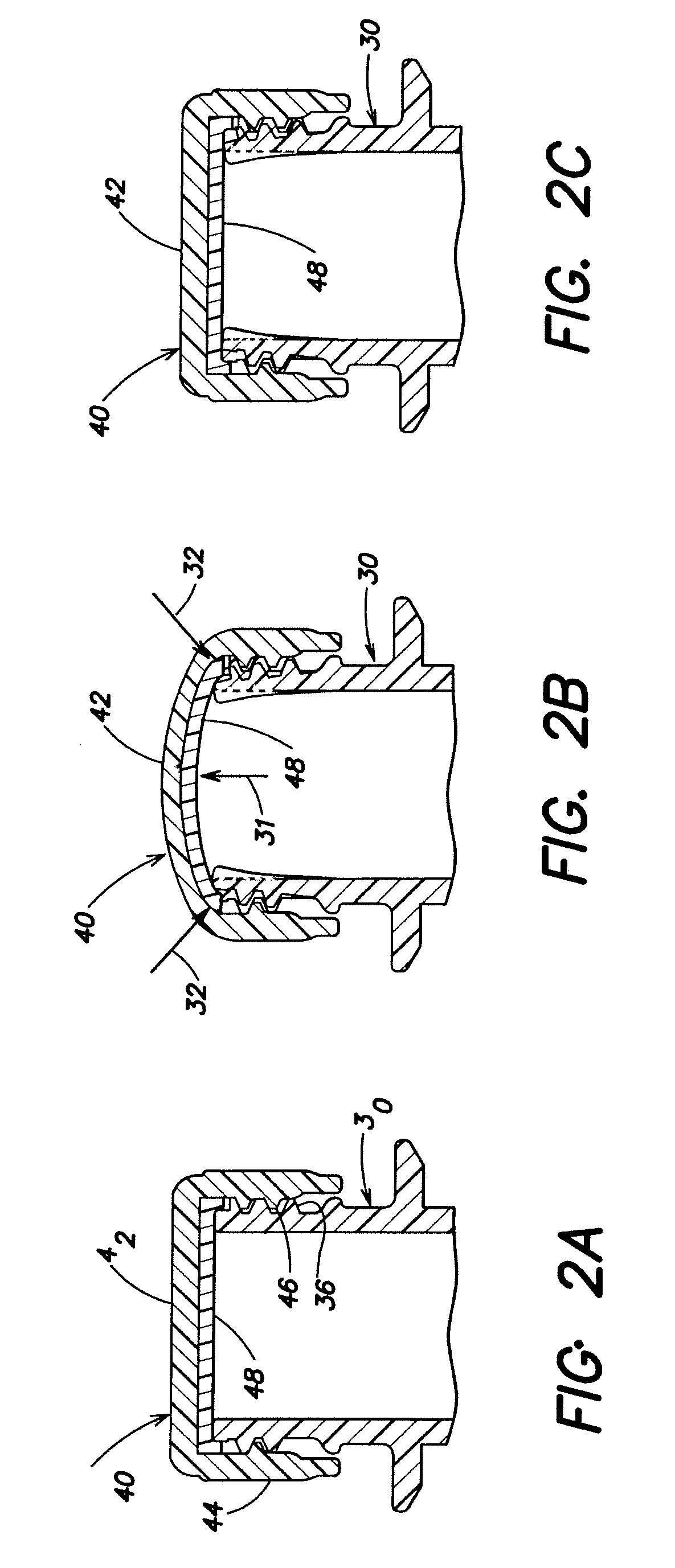

[0044]The pasteurization process has been mechanized and automated for mass packaging. A typical pasteurization apparatus is a tunnel pasteurizer, such as those described in U.S. Pat. Nos. 2,282,187, 4,441,406, and 4,693,902, the disclosures of which are incorporated herein by reference. FIG. 1 schematically shows a system 1 that includes apparatus and processes for the manufacture, filling and pasteurization of a filled plastic container 8 in a pasteurization tunnel 2. System 1 includes a conveyer belt 3 for conveying the containers through stations for filling, capping, and pasteurization processes. A central longitudinal axis A of the container 8 is shown in FIG. 1 and serves throughout this specification as a reference point of orientation (e.g., radially outward from axis A).

[0045]In FIG. 1, container 8 is manufactured in blow mold 6 and downstream from blow mold 6 (in the direction i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com