Semiconductor structure and forming method thereof

A technology of semiconductor and channel structure, applied in semiconductor devices, semiconductor/solid-state device manufacturing, transistors, etc., can solve the problems of poor overall performance of semiconductor devices, improve surface utilization, improve carrier mobility, and improve integration degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Currently formed devices still suffer from poor performance. The reasons for the poor performance of the device are analyzed in conjunction with a method of forming a semiconductor structure.

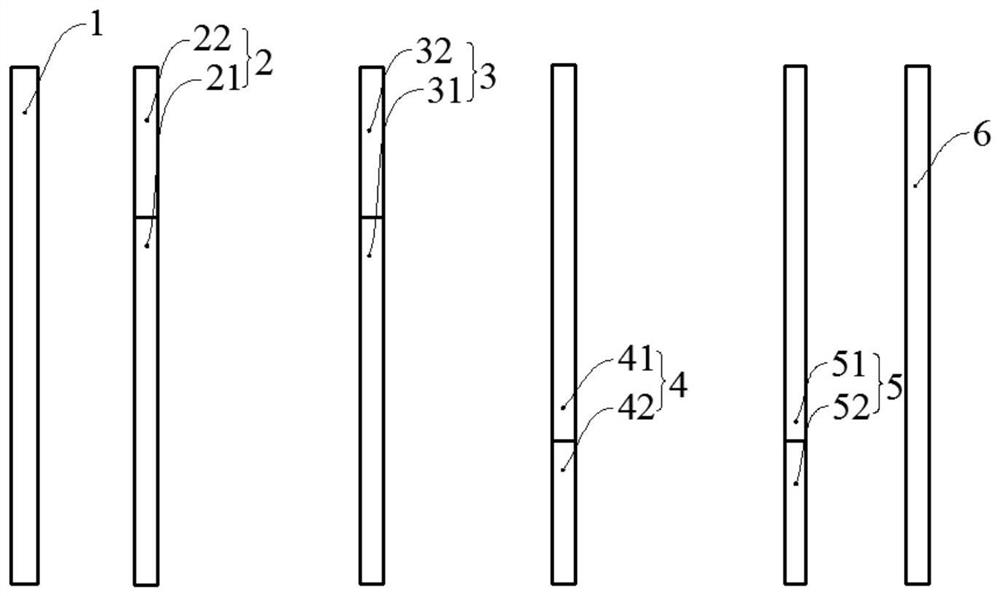

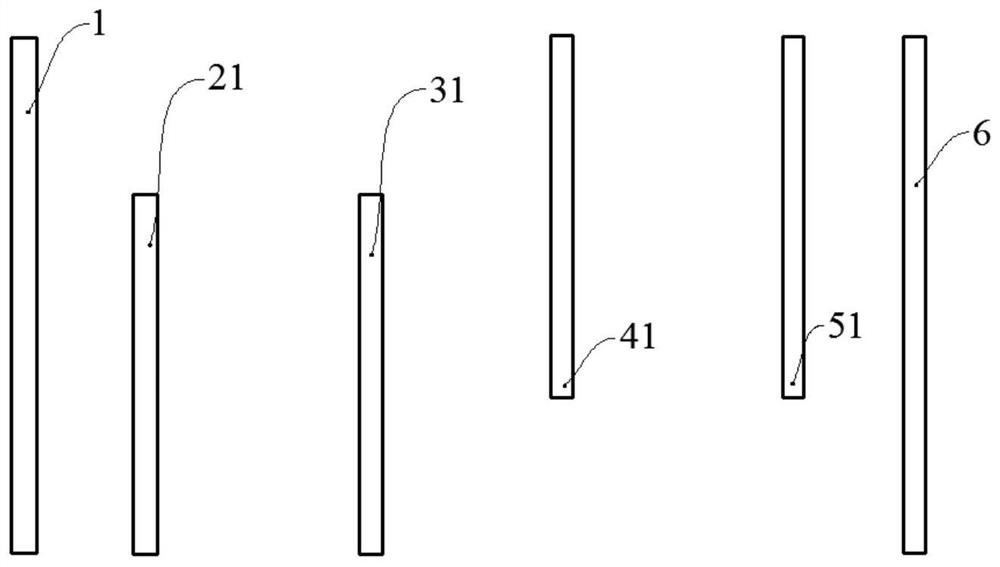

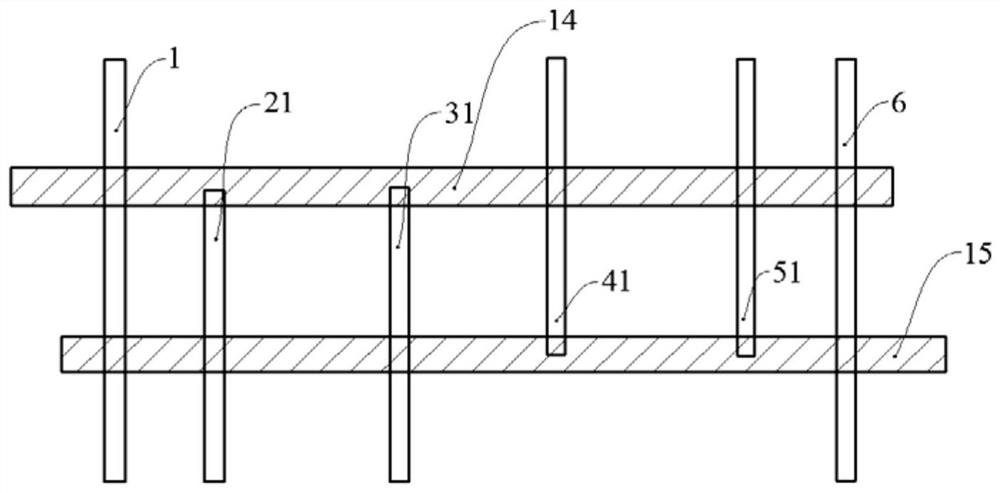

[0014] refer to Figure 1 to Figure 4 It is a structural schematic diagram corresponding to each step in a method for forming a semiconductor structure.

[0015] Such as figure 1 As shown, a base is provided, and the base includes a substrate (not shown in the figure) and six discrete fins located on the substrate, the fins extend in the longitudinal direction, and the first fins in the transverse direction 1. The second fin 2 , the third fin 3 , the fourth fin 4 , the fifth fin 5 and the sixth fin 6 , the second fin 2 is symmetrical to the fifth fin 5 , The third fin 3 is centrally symmetrical to the fourth fin 4, the first fin 1 includes a first device fin, and the second fin 2 includes a second device fin 21 and a second dummy fin 22. The third fin 3 includes the third dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com