Grinding device for hydraulic valve element

A technology of hydraulic valves and grinding discs, which is applied in the direction of grinding drive devices, grinding/polishing safety devices, grinding machines, etc., to achieve the effect of improving surface utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

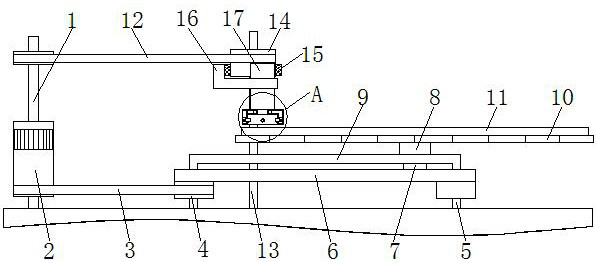

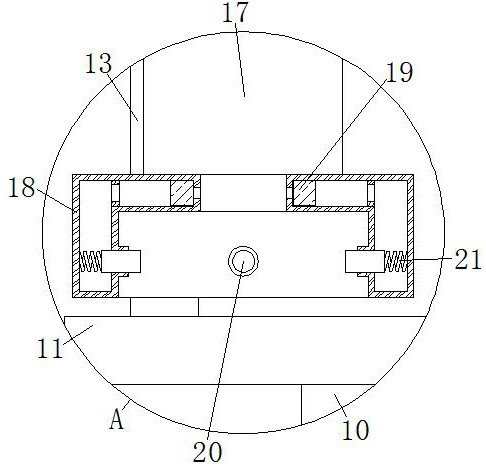

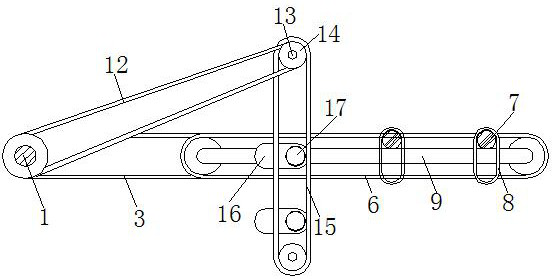

[0019] see image 3 , Figure 4 , the straight line where the rack belt II6 is located is perpendicular to the straight line where the rack belt IV15 is located, and when the rack belt IV15 is parallel to the rack belt II6, the two ends of the rack belt II6 protrude from the two ends of the rack belt IV15, and pass The strip II6 controls the lateral movement of the fixed block 7 and the slider 8, and then drives the fixed slider 16 and the movable rod 17 to move through the rotation of the rack belt IV15, and the straight line where the rack belt IV15 is located and the straight line where the rack belt II6 is located are perpendicular to each other, that is, the rack belt IV15 and the rack belt II6 move at the same time, so that the movement of the movable rod 17 and the slider 8 is carried out simultaneously, so that when the tray 10 follows the movement of the slider 8, the bottom of the fixed box 18 The movement trajectory of the fixed hydraulic spool on the surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com