NaY molecular sieve preparation method and NaY molecular sieve prepared by NaY molecular sieve preparation method

A molecular sieve and solution technology, which is applied in the directions of fajhedral crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of environmental pollution, complicated NaY molecular sieve process, increase NaY molecular sieve preparation time, etc., and achieve environmental friendliness. , shorten the production cycle, the effect of broad prospects for industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] According to one aspect of the present invention, it relates to a preparation method of NaY molecular sieve. The method comprises the steps of:

[0037] a) contacting the aluminum source with a sodium hydroxide solution to obtain a sodium aluminum solution;

[0038] b) contacting the silicon source with a sodium hydroxide solution to obtain a sodium-silicon solution;

[0039] c) contacting the sodium-aluminum solution with the sodium-silicon solution to obtain mixture I;

[0040] d) contacting the mixture I with an acidic aluminum source solution to obtain a gel;

[0041] e) crystallizing the gel to obtain the NaY molecular sieve.

[0042] According to one aspect of the present invention, in the sodium aluminum solution, the content of sodium oxide is not less than 20% by weight, preferably 20-30% by weight; the content of aluminum oxide is 4-8% by weight.

[0043] According to one aspect of the present invention, in step a), the contact conditions of the aluminum sou...

Embodiment 1

[0067] Feed molar ratio is Na 2 O: Al 2 o 3 :SiO2 2 :H 2 O=2.5:1:7.5:173. specific,

[0068] Preparation of sodium aluminum solution: Take 200g of water, add 41.9g of sodium metaaluminate, stir until completely dissolved. Then add 101.3g of sodium hydroxide and stir until completely dissolved to obtain a sodium-aluminum solution. The temperature of the solution was kept at 35°C during the preparation process. In the prepared sodium aluminum solution, the content of sodium oxide is 25%, and the content of aluminum oxide is 5%.

[0069] Take 84g of water, add 23.1g of sodium hydroxide, stir until completely dissolved, then add dropwise 107.1g of 40wt% silica sol, and stir for 0.5 hours to form a uniform solution. Then raise the temperature to 90°C and treat for 10 minutes to obtain a sodium-silicon solution. In the prepared sodium-silicon solution, the content of sodium oxide is 8%, and the content of silicon oxide is 20%.

[0070] Take 94.15g of sodium-silicon solutio...

Embodiment 2

[0076] Same as [Example 1], except that the silicon source is solid silica gel.

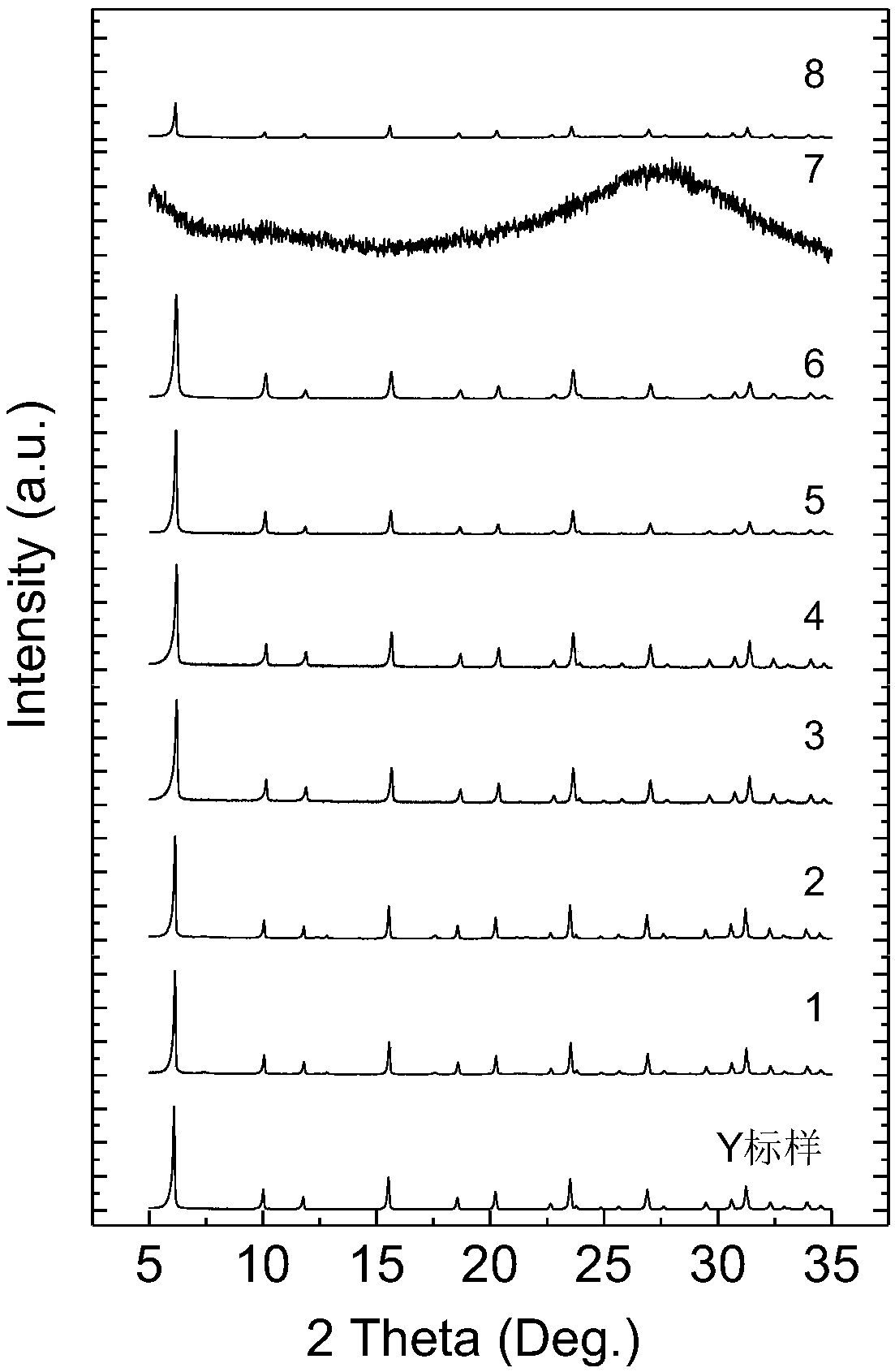

[0077] figure 1 The middle curve 2 is the XRD spectrum of the product. The spectrogram shows that it is a pure-phase NaY molecular sieve with a relative crystallinity of 91%.

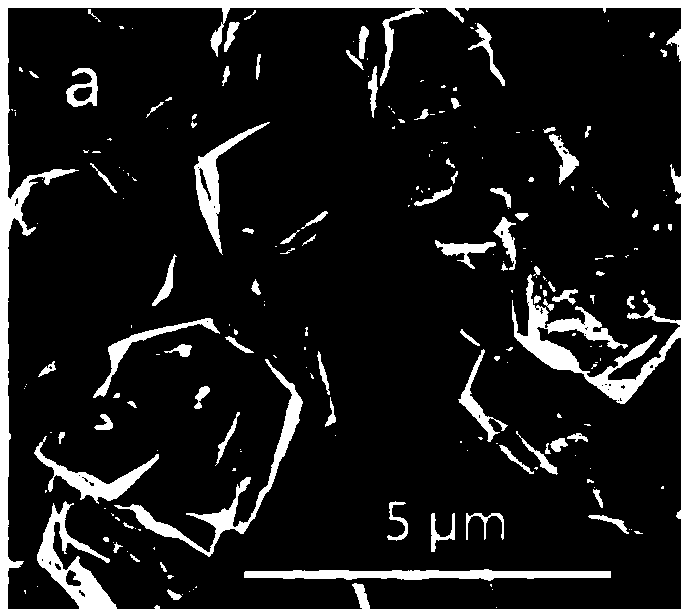

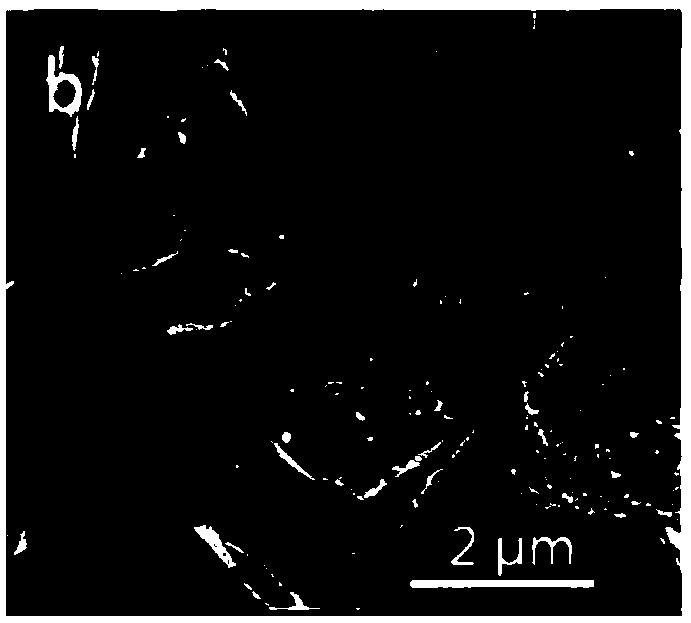

[0078] image 3 A scanning electron microscope (SEM) photo of the product. Its average crystal grain diameter is 2000 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com