A kind of preparation method of titanium catalyst component and its titanium catalyst component, and a kind of preparation method of titanium catalyst and its titanium catalyst

A technology of titanium catalyst and titanium compound, which is applied in the field of preparation of titanium catalyst components, can solve the problems of unsatisfactory shape of catalytically active polymerization products and lower performance of final products in copolymer resins, and achieve high bulk density and high catalytic performance. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

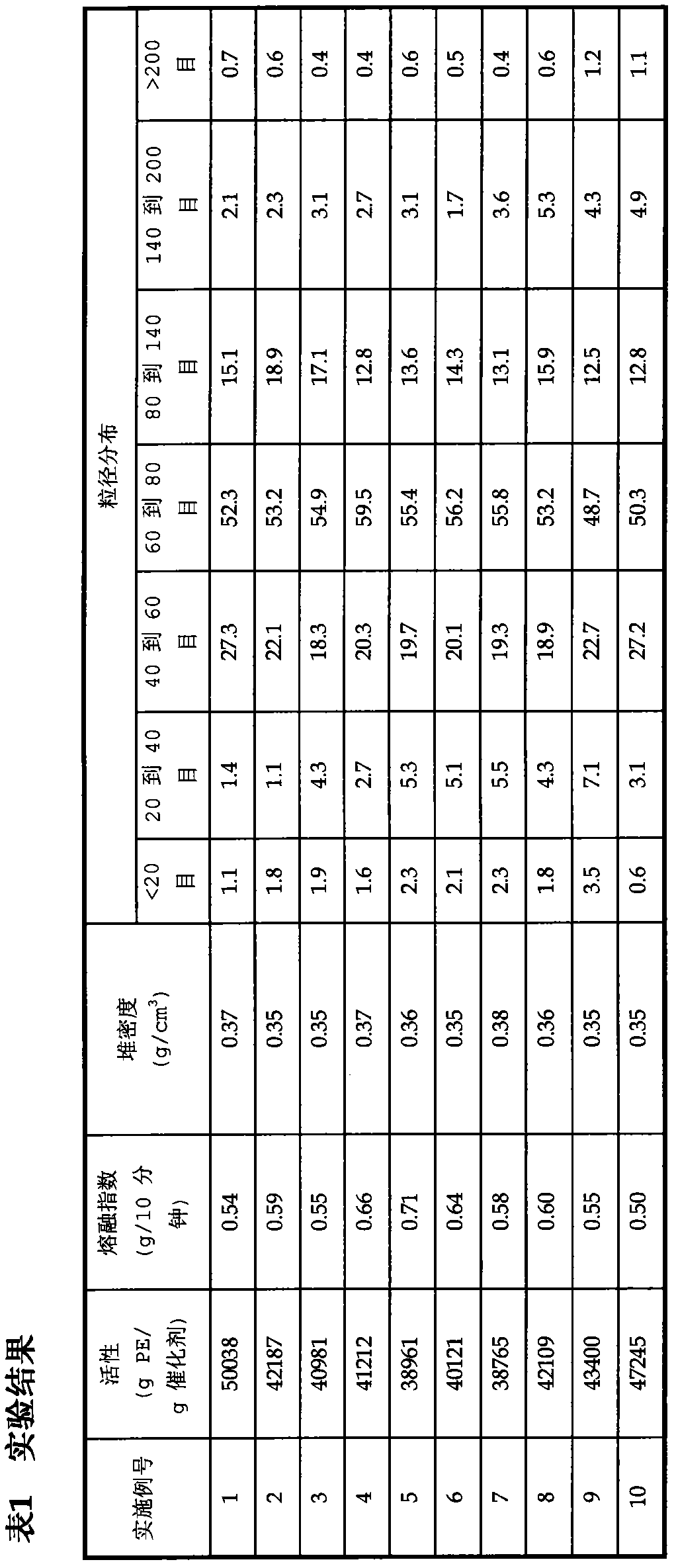

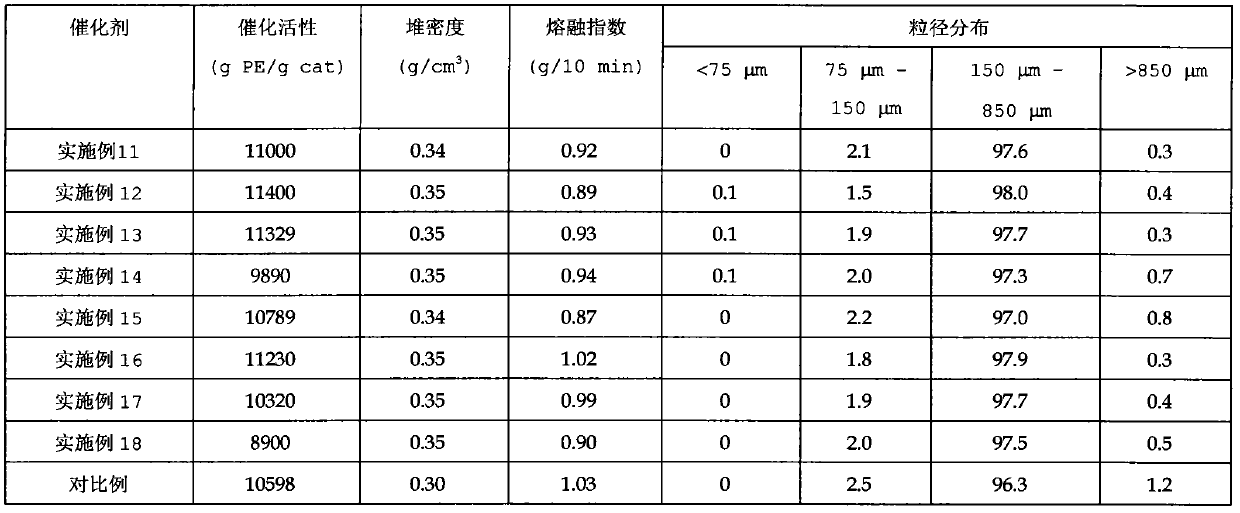

Examples

Embodiment 1

[0088] 4.76 g (50 mmol) of anhydrous magnesium chloride, 75 ml of decane and 16.3 g (125 mmol) of isooctyl alcohol were heated to 130° C. and allowed to react for 3 hours to obtain a homogeneous solution. To this solution was added 15 mmol of tributyl borate and stirred at 50° C. for 2 hours to dissolve tributyl borate in the solution. All the homogeneous solution obtained above was cooled to room temperature, and then added dropwise to 150 ml of titanium tetrachloride maintained at 0°C within 1 hour while stirring. After completion of the dropwise addition, the temperature of the mixture was maintained at 0°C for 1 hour, then raised to 120°C over 2 hours with stirring, and maintained at this temperature for 2 hours. After 2 hours of reaction, the resulting solid was separated by hot filtration. The solid catalyst is fully washed with hexane and decane respectively until no precipitated titanium compound can be detected in the cleaning liquid, and a solid titanium catalyst co...

Embodiment 2

[0092] 4.76 g (50 mmol) of anhydrous magnesium chloride, 75 ml of decane and 16.3 g (125 mmol) of isooctyl alcohol were heated to 130° C. and allowed to react for 3 hours to obtain a homogeneous solution. To the solution, 15 mmol of phenylenediethyl borate was added and stirred at 50° C. for 2 hours to dissolve the phenylenediethyl borate in the solution. All the homogeneous solution obtained above was cooled to room temperature, and then added dropwise to 150 ml of titanium tetrachloride maintained at 0°C within 1 hour while stirring. After completion of the dropwise addition, the temperature of the mixture was maintained at 0°C for 1 hour, then raised to 120°C over 2 hours with stirring, and maintained at this temperature for 2 hours. After 2 hours of reaction, the resulting solid was separated by hot filtration. The solid catalyst is fully washed with hexane and decane respectively until no precipitated titanium compound can be detected in the cleaning liquid, and a solid ...

Embodiment 3

[0096] The method of embodiment 3 is the same as that of embodiment 1, except that: 20 mmol of tributyl borate is added. The aggregation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com